02-03-2018, 04:53 AM

02-03-2018, 04:53 AM

|

#21

|

|

Registered User

Join Date: Apr 2016

Location: SE Michigan

Posts: 496

|

Quote:

Originally Posted by Mig

Replacing the bearing with just another bearing doesn't fix the underlying issue of the grease in the bearing being washed away by the engine oil.

Yes, I will be replacing,mine on a regular basis. Plan is to replace it next summer. I do my own work and won't be bashing in the new bearing. (I've seen some of those videos on YouTube).

Yes, these engines weren't designed to have the bearing replaced, but that doesn't mean that it can't be done safely.

If you don't want to replace the bearing regularly, then I believe you need to invest in a solution whereby the bearing is fed by oil (DOF, EPS, or LN Solution).

|

When oil can wash away grease in the bearing, it can also lube the bearing. I know that oil can get inside the IMS hollow shaft. With fresh oil and 'thoughtful' driving (keep rev higher, avoid condensation/ fuel contaminants in oil from short distance driving without engine fully warmed up, etc.), bearing can still be reasonably lubed without grease. My thought anyway...

It's more of a design issue of the single row bearing, which may be replaced regularly... but I would not do so with the dual row bearing. Rather than spending money on bearings, my contingency would rather be a whole replacement engine.

__________________

1997 Boxster arctic silver/ red, XNE riveted mahogany/ leather steering wheel & 917-style wood shift knob, Ben’s short shifter, PSE, 996 TB, UDP, stereo/ center console delete, hardtop and speedster humps, daily driver rain or shine or snow!

|

|

|

02-05-2018, 01:06 PM

02-05-2018, 01:06 PM

|

#22

|

|

Registered User

Join Date: Mar 2013

Location: Scotland

Posts: 82

|

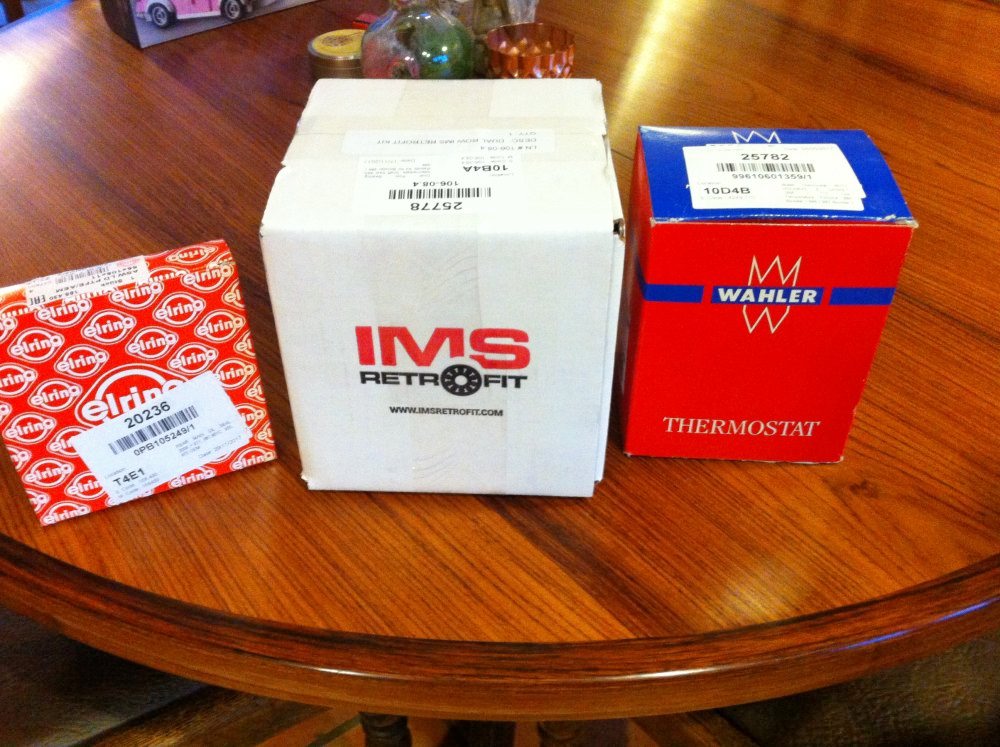

Lots of new parts arrived today including the clutch, DMF and these...

and unboxed...

Thought I would fit a new thermostat while it was off and the coolant drained, went for the low temp one.

I put the new RMS in but it went from 10mm to 15mm its one slight tap so it's got to come out and a new one put in a bit more carefully this time.

Trying to find some pipe with a 56mm OD to pull the old (but perfect) IMS bearing out.

As I said before the kit I bought was rubbish, nothing worked..found out it was all from the Far East.

|

|

|

02-10-2018, 04:45 AM

02-10-2018, 04:45 AM

|

#23

|

|

Registered User

Join Date: Mar 2013

Location: Scotland

Posts: 82

|

I ordered a new IMS tool kit from Design 911 in Essex. 2 days later it arrived, they had sent the wrong one but quickly dispatched another correct one which was the only one they stock, the EPS tool kit not LN( which the bearing is ...from them!)

They stock all the tool kits from LN but not the Retrofit one.

Anyway it appeared to me the kit had been used already which I am discussing with them now..nothing wrong with that..it just shouldn't be full price (£200).

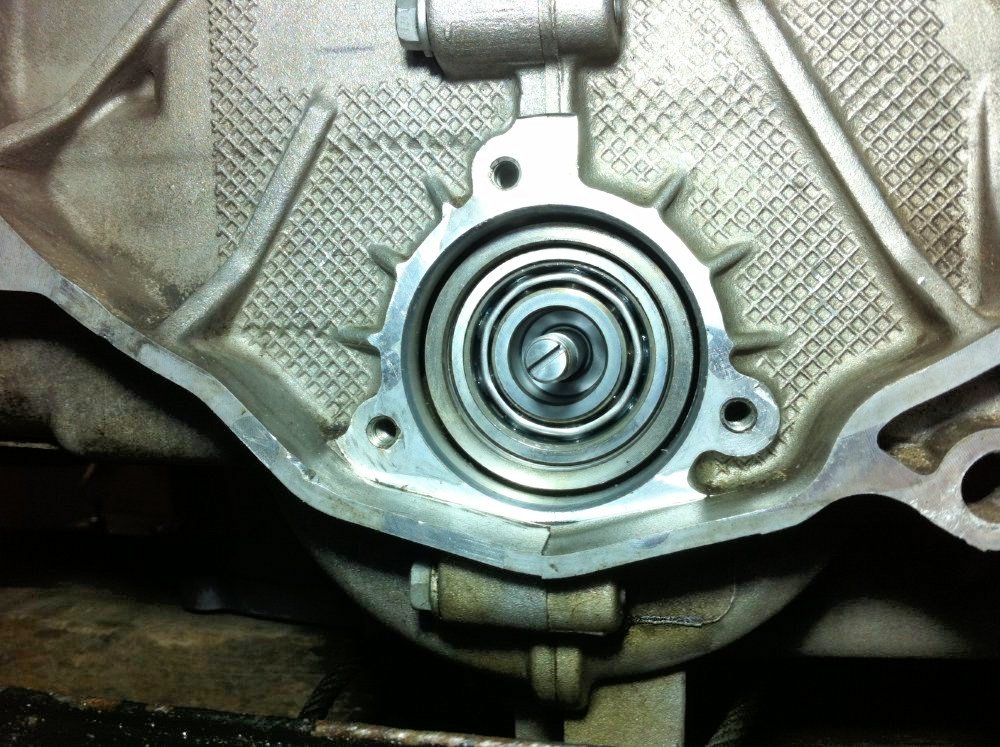

Bearing came out easily enough, there was lots of black oil behind it but it appears to be very solid , no play at all, and quite stiff to turn. By this I mean if you hold it by the centre bolt and try to spin it, it won't. It does turn but you have to do it, it doesn't roll at all but it's smooth. The outer seal is very hard to remove, it's in very good condition.

Here it is

You can see old grease still coming out at 11)clock position.

I am getting a RMS tool made up from plastic by the same chap who made my exhaust stud drill guides, this will ensure it's 13mm and dead square.

All these tools will be available for hire (in the UK) when I've finished this.

It's quite amazing to think that the whole IMS, chains etc are all supported at the flywheel end by that tiny centre bolt. There must be some force from the cams that the bolt has to deal with.

Last edited by Troutman; 02-10-2018 at 05:45 AM.

|

|

|

02-10-2018, 08:35 AM

02-10-2018, 08:35 AM

|

#24

|

|

Registered User

Join Date: Apr 2016

Location: SE Michigan

Posts: 496

|

Looks like your original bearing is still in great shape.

So the new bearing you got feels not that tight and rolls???

__________________

1997 Boxster arctic silver/ red, XNE riveted mahogany/ leather steering wheel & 917-style wood shift knob, Ben’s short shifter, PSE, 996 TB, UDP, stereo/ center console delete, hardtop and speedster humps, daily driver rain or shine or snow!

|

|

|

02-10-2018, 01:29 PM

02-10-2018, 01:29 PM

|

#25

|

|

Registered User

Join Date: Mar 2013

Location: Scotland

Posts: 82

|

New LN Retrofit is very similar although it has been in the freezer all day ready for fitting tomorrow, so the grease will be firmer, but I don't remember it spinning easily before it went in.

|

|

|

02-13-2018, 08:32 AM

02-13-2018, 08:32 AM

|

#26

|

|

Registered User

Join Date: Mar 2013

Location: Scotland

Posts: 82

|

Today I fitted the new IMS Bearing ...yes it's done, it's in there.

I had to use a block of nylon so I could use a metal mallet to tap it in. My rubber mallet just wasn't heavy enough. That's me hitting the fitting tool , not the bearing.

Then you fit the Spiro-Loc ..had to get in touch with LN as I've never seen one of these before let alone fit one. Wanted to get it right.

Apparently I was the first person in 10 years to ask how to insert a Spiro-Loc.

Then i put a small smear of silicone grease on the gasket and carefully pulled on the new flange using the 3 old bolts. Waiting for Loctite to finish that.

Also my RMS tool arrived today, I had my machine man make it out of nylon. It's brilliant and made fitting the RMS so easy.

Btw, I removed the outer seal from my old bearing and it's perfect inside, no play or noise or anything, it's like a brand new bearing would be.

I would say dual row failures are most likely from poor alignment , in fact I bet the single is too but it fails quicker.

Why did I change it? Because I was there and I was spending a load of money anyway and it can be forgotten about for a while..if I was strapped for cash, after I saw it and felt it, I would have tried to replace the O ring and left it alone.

Clutch and DMF to go in next.

|

|

|

02-13-2018, 11:07 AM

02-13-2018, 11:07 AM

|

#27

|

|

Registered User

Join Date: Dec 2017

Location: Cambria, CA

Posts: 121

|

I love that nylon RMS tool. I made one out of pvc parts and wasn't all that thrilled with how it came out.

|

|

|

02-13-2018, 11:33 AM

02-13-2018, 11:33 AM

|

#28

|

|

Registered User

Join Date: Mar 2013

Location: Scotland

Posts: 82

|

Yeah it's superb, t just takes all the guess work out of it.

Measuring 13mm inside he crank etc is just about impossible. This does it for you.

|

|

|

02-14-2018, 04:49 AM

02-14-2018, 04:49 AM

|

#29

|

|

Registered User

Join Date: Mar 2013

Location: Scotland

Posts: 82

|

One thing that I found quite strange about the IMSB is the centre stud.

I'm sure you have all figured this out many years ago and it's weakness has been mentioned on this thread already but I find it hard to believe that that stud (M8) is all that is supporting the rear end of the IMS which is driving the cams.

Well I know the bearing is but that is being supported by that stud/bush and the flange is fixing the stud to the engine ( which is very secure).

I suppose by increasing the diameter of the stud you have to decrease the thickness of the flange internal busing part as there is only the same amount of space inside the bearing.

|

|

|

02-14-2018, 08:42 AM

02-14-2018, 08:42 AM

|

#30

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,657

|

Quote:

Originally Posted by Troutman

One thing that I found quite strange about the IMSB is the centre stud.

I'm sure you have all figured this out many years ago and it's weakness has been mentioned on this thread already but I find it hard to believe that that stud (M8) is all that is supporting the rear end of the IMS which is driving the cams.

Well I know the bearing is but that is being supported by that stud/bush and the flange is fixing the stud to the engine ( which is very secure).

I suppose by increasing the diameter of the stud you have to decrease the thickness of the flange internal busing part as there is only the same amount of space inside the bearing.

|

There are three major flaws in the factory center bolt:

1. There is a rather severe under cut in it to accommodate an O-ring seal; when they break, they tend to break at this undercut.

2.The material of construction, it is mild steel.

3.It needed to be larger in diameter.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

Last edited by JFP in PA; 02-18-2018 at 02:46 PM.

|

|

|

02-18-2018, 11:11 AM

02-18-2018, 11:11 AM

|

#31

|

|

Registered User

Join Date: Apr 2016

Location: SE Michigan

Posts: 496

|

Quote:

Originally Posted by JFP in PA

There are three major flaws in the factory center bolt:

1. There is a rather severe under cut in it to accommodate an O-ring seal; when they break, they tend to break at this undercut.

2.The material of construction, it is mild steel.

3.It need to be larger in diameter.

|

Does this poorly designed factory bolt take any part of the bearing failure?

__________________

1997 Boxster arctic silver/ red, XNE riveted mahogany/ leather steering wheel & 917-style wood shift knob, Ben’s short shifter, PSE, 996 TB, UDP, stereo/ center console delete, hardtop and speedster humps, daily driver rain or shine or snow!

|

|

|

02-18-2018, 02:44 PM

02-18-2018, 02:44 PM

|

#32

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,657

|

Quote:

Originally Posted by Boxstard

Does this poorly designed factory bolt take any part of the bearing failure?

|

Yes. Sometimes when the bolt fails, the IMS bearing can move off axis, timing chain(s) jump, and you get piston to valve contact related failure. The IMS bearing itself is still relatively OK except for the bolt failure. Other times, the bearing itself is tearing up, possibly causing the bolt failure; so it can go either way.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

02-18-2018, 04:07 PM

02-18-2018, 04:07 PM

|

#33

|

|

Registered User

Join Date: Apr 2016

Location: SE Michigan

Posts: 496

|

Quote:

Originally Posted by JFP in PA

Yes. Sometimes when the bolt fails, the IMS bearing can move off axis, timing chain(s) jump, and you get piston to valve contact related failure. The IMS bearing itself is still relatively OK except for the bolt failure. Other times, the bearing itself is tearing up, possibly causing the bolt failure; so it can go either way.

|

Interesting... sorry one more question, this tapered bolt is common for factory dual- and single-row bearings? If so, obviously bearing design itself accounts for the failure more I guess.

__________________

1997 Boxster arctic silver/ red, XNE riveted mahogany/ leather steering wheel & 917-style wood shift knob, Ben’s short shifter, PSE, 996 TB, UDP, stereo/ center console delete, hardtop and speedster humps, daily driver rain or shine or snow!

|

|

|

02-19-2018, 02:22 PM

02-19-2018, 02:22 PM

|

#34

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,657

|

Quote:

Originally Posted by Boxstard

Interesting... sorry one more question, this tapered bolt is common for factory dual- and single-row bearings? If so, obviously bearing design itself accounts for the failure more I guess.

|

Both the OEM single and dual rows use similar center bolts, but they are not exactly the same due to the bearing depth differences.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

02-20-2018, 09:11 AM

02-20-2018, 09:11 AM

|

#35

|

|

Registered User

Join Date: Mar 2013

Location: Scotland

Posts: 82

|

Here's a photo of the stud.

You can see that the O-ring groove is the weak spot, the threaded part at the end is there to put that nut on which stops the stud coming loose from the bearing and falling into the IMS, causing all sorts of problems of which a match and a gallon of fuel word sort out nicely.

Been drilling out broken manifold studs today and re-tapping them. Dreadful job.

|

|

|

02-20-2018, 09:24 AM

02-20-2018, 09:24 AM

|

#36

|

|

Registered User

Join Date: Mar 2013

Location: Scotland

Posts: 82

|

With the O ring removed it's about 8mm in the groove, 10mm either side.

|

|

|

03-25-2018, 07:12 AM

03-25-2018, 07:12 AM

|

#37

|

|

Registered User

Join Date: Mar 2013

Location: Scotland

Posts: 82

|

Thought I would post an update on my wee project.

Everything is back in, I bought some new exhaust clamps as the old ones were bad.

Very straightforward apart from a persistent leak from the new thermostat, in the end i smeared some sealant on both sides of the new gasket and that fixed it.

The main difference I noticed was how light the new clutch is, I thought i hadn't bled it correctly but it's all good , just very light to press.

Engine goes really well, revs up so easily. Since changing the new front engine mount the whole car feels much more planted, one of the easiest things to do with the best gains is to change a worn out front mount.

Really pleased and now considering keeping it (i've had it 7yrs) as I wanted a 997 but after going for a quick blast in this yesterday I reckon I'll hold on to it, there is no way a 997 is £20k more fun than this.

Just started on the front brakes, I was getting some shudder at high speeds in Germany last year, so I'm going to replace discs and pads on the front. Then it should be good for a long road trip.

|

|

|

04-06-2018, 12:36 AM

04-06-2018, 12:36 AM

|

#38

|

|

Registered User

Join Date: Nov 2017

Location: UK

Posts: 5

|

Hello Troutman, great thread, read with interest, which side of Scotland are you in? I must visit the place some time, (Londoner - eww), and fish for some wild trout..

I have a few contributions to your dilemmas:

1, was the thermostat shiny clean when you refitted and it still leaked? that is a worry, was it OEM?

2, You queried how the IMSb bolt could support the side loading of the cam chains - This is now how it works - The inner face of the IMS bearing rides on the 'spider flange', that through bolt merely keeps the assembly true - i.e. stops the bearing meandering fore and aft.

3, You noted your original IMB bearing was as new once the seals were removed, but also must note it was completely devoid of the gearing grease such a bearing requires to survive when sealed by the plastic sides.. I am a fan of the seal removal & splash oil feed lubrication strategy - as you have adopted for the replacement, I would like to copy this idea on my build.

4, exhaust stud jig - what does it look like and are you willing to rent it out? You say you'll be renting out the IMSB tools also, I think I'll be a customer when the time comes also.

Looking forward to updates,

Beers!

Harry

|

|

|

04-06-2018, 06:03 AM

04-06-2018, 06:03 AM

|

#39

|

|

Registered User

Join Date: Jul 2011

Location: Richmond, VA (The Fan)

Posts: 978

|

Quote:

Originally Posted by Bullet-Proof_Biscuit

Hello Troutman, great thread, read with interest, which side of Scotland are you in? I must visit the place some time, (Londoner - eww), and fish for some wild trout..

3, You noted your original IMB bearing was as new once the seals were removed, but also must note it was completely devoid of the gearing grease such a bearing requires to survive when sealed by the plastic sides.. I am a fan of the seal removal & splash oil feed lubrication strategy - as you have adopted for the replacement, I would like to copy this idea on my build.

Beers!

Harry

|

I’ve removed three IMS bearings from my car over the last 7 years (two upgraded units) all had seals. The seals on every bearing I’ve pulled had failed and the bearings were full of oil. Removing the seal seems like a good idea. (And no there isn’t a reason to replace them this much, it’s always been a “while you’re in there” thing).

Cheers,

__________________

1997 Boxster 4.2L Audi V8 Bi-Turbo

2003 911 C2

NASA HPDE Instructor

|

|

|

04-07-2018, 12:54 AM

04-07-2018, 12:54 AM

|

#40

|

|

Registered User

Join Date: Mar 2013

Location: Scotland

Posts: 82

|

Quote:

Originally Posted by Bullet-Proof_Biscuit

Hello Troutman, great thread, read with interest, which side of Scotland are you in? I must visit the place some time, (Londoner - eww), and fish for some wild trout..

I have a few contributions to your dilemmas:

1, was the thermostat shiny clean when you refitted and it still leaked? that is a worry, was it OEM?

2, You queried how the IMSb bolt could support the side loading of the cam chains - This is now how it works - The inner face of the IMS bearing rides on the 'spider flange', that through bolt merely keeps the assembly true - i.e. stops the bearing meandering fore and aft.

3, You noted your original IMB bearing was as new once the seals were removed, but also must note it was completely devoid of the gearing grease such a bearing requires to survive when sealed by the plastic sides.. I am a fan of the seal removal & splash oil feed lubrication strategy - as you have adopted for the replacement, I would like to copy this idea on my build.

4, exhaust stud jig - what does it look like and are you willing to rent it out? You say you'll be renting out the IMSB tools also, I think I'll be a customer when the time comes also.

Looking forward to updates,

Beers!

Harry

|

Harry, thanks for your comments, i'll answer as best I can.

The thermostat was from Design911 (Wahler) as are most of the bits I have bought. My engine face was very clean, the old gasket came off in one piece. Not sure why it kept leaking.

With regards to the spindle, you're absolutely right. If the bolt snapped, and it has no reason to, the spindle could in theory fall out the back into the IMS. The bearing would be still have 75% support from the flange, that's what really supports it.

I got that wrong earlier.

I was in two minds as to whether should bother with the cost of replacing the bearing, with tools it was £500 I think. I could have just pulled the grease seal off and I am very confident it would have been fine for another 100k miles especially as it was a dual row but like others have said, when you've gone to that much effort with Clutch / Flywheel / RMS etc, etc you may as well fit a new bearing. In for a penny etc...

There's no question if it was a single row.

If you go to the link below it shows the exhaust stud tools and all that with the manifold studs. They were a challenge I can tell you but all back together now and running really well, with a very light clutch.

The tools are now on ebay and I have advertised them on here too. they are £50/week for everything. £350 deposit and I return £300 when I get them back in a good state.

The RMS tool is brilliant. I can put a stud tool in as well. They do get worn if you have to do lots but they are easy to make. I can give you the email of the guy that made mine.

Anything else you want to know please ask.

BTW I have a trout farm here in Scotland...watching the Ospreys this morning going for them, amazing to see.

http://986forum.com/forums/performance-technical-chat/70662-anyone-got-cam-locking-tools.html

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 11:43 PM.

| |