01-29-2018, 01:25 PM

01-29-2018, 01:25 PM

|

#1

|

|

Registered User

Join Date: Mar 2013

Location: Scotland

Posts: 82

|

Seal removal on Dual Row IMSB

After much time I have finally decided not to replace my IMS bearing even though I am replacing clutch/flywheel and RMS.

Mine has the dual row bearing with very low failure rates and I don't want to replace what I think might be a perfectly good bearing. I just don't like the idea of messing about with something and potentially creating more problems.

I will however remove the flange and have a look at it (and replace the bearing if it appears to be about to fail) and I would like to remove the outer seal to allow better oil flow. Flange seal to be replaced too.

Baz from Hartech posted a good essay on his thoughts and I agree with what he says but he goes into some detail about removing the seal here and I am not totally sure what this means...

Removing the outer seal of an existing bearing is a good option (if the existing bearing seems OK) and the only danger then is to make sure the spindle is not strained when aligning the out spider carrier back into the location hole. This spindle has a weak spot where an "O" ring is fitted and is it unfortunate that at precisely the point that the spider fits on to the spindle the outer diameter of the spider fits into its location hole and both need the IMS to be pulled sideways to pull against the chain tension (even with the tensioners relaxed) to locate both in their respective holes.

Has anyone done this?

This is the whole thread on Pistonheads. https://www.pistonheads.com/gassing/topic.asp?t=1564383

Last edited by Troutman; 01-29-2018 at 01:29 PM.

|

|

|

01-29-2018, 02:12 PM

01-29-2018, 02:12 PM

|

#2

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,657

|

Quote:

Originally Posted by Troutman

After much time I have finally decided not to replace my IMS bearing even though I am replacing clutch/flywheel and RMS.

Mine has the dual row bearing with very low failure rates and I don't want to replace what I think might be a perfectly good bearing. I just don't like the idea of messing about with something and potentially creating more problems.

I will however remove the flange and have a look at it (and replace the bearing if it appears to be about to fail) and I would like to remove the outer seal to allow better oil flow. Flange seal to be replaced too.

Baz from Hartech posted a good essay on his thoughts and I agree with what he says but he goes into some detail about removing the seal here and I am not totally sure what this means...

Removing the outer seal of an existing bearing is a good option (if the existing bearing seems OK) and the only danger then is to make sure the spindle is not strained when aligning the out spider carrier back into the location hole. This spindle has a weak spot where an "O" ring is fitted and is it unfortunate that at precisely the point that the spider fits on to the spindle the outer diameter of the spider fits into its location hole and both need the IMS to be pulled sideways to pull against the chain tension (even with the tensioners relaxed) to locate both in their respective holes.

Has anyone done this?

This is the whole thread on Pistonheads. https://www.pistonheads.com/gassing/topic.asp?t=1564383 |

Many times.

He is refering the the center bolt which he calls the "spindle", and he calls the flange cover a "spider carrier". The factory center bolt has a rather severe undercut which is where the bolt oring sits. It is also the most likely point where the factory center bolt fails, so he is telling you to be careful with it. The LN bearings come with a completely different center bolt specifically to address this weakness.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

01-29-2018, 04:20 PM

01-29-2018, 04:20 PM

|

#3

|

|

Registered User

Join Date: Dec 2017

Location: Cambria, CA

Posts: 121

|

If you have a flange bolt that is of suspect design for my money you replace the bearing, put in the latest technology in flange bolts and as long as you have gone that far incorporate direct oil feed. I just replaced my double row IMS on my 2000 S. The bearing I took out was, as it turns out, in good shape. Nevertheless, I put in a new double row bearing, new flange bolt and direct oil feed. It seems you either go that direction or just leave the whole thing alone and hope for the best.

|

|

|

01-29-2018, 10:34 PM

01-29-2018, 10:34 PM

|

#4

|

|

Registered User

Join Date: Mar 2013

Location: Scotland

Posts: 82

|

So pulling the flange off to replace the seal is not as easy as it sounds?

I would leave the whole thing alone but because my RMS has sprayed oil everywhere I don't know if the IMS flange is leaking too...I suspect it is, but not nearly as much as the RMS.

For me the whole IMS thing is blown way out of proportion, there are lots more ways an engine can fail other than that bearing..a broken cam chain would do the same..but for me I have snapped off 8 of the 12 header bolts removing the exhaust system to change the RMS.

I had to take the headers off because the 3 bolts at the next join were non existent and no way of drilling out what was left of them. I nearly scrapped the car because of these and they are not something mentioned regularly.

In the UK, my car a 99 2.7 70k miles full PSH 1 owner, perfect condition is worth about £5k. A dealer offered me £3k p/ex because of the oil leak from the RMS.

Here she is..£5k!

|

|

|

01-30-2018, 02:37 AM

01-30-2018, 02:37 AM

|

#5

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,657

|

In order to pull the flange and get at the seal, the engine has to be prepped as though you were going to pull and replace the IMS bearing( locked at TDC, cams locked, tensioners pulled, etc.).

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

01-30-2018, 09:43 AM

01-30-2018, 09:43 AM

|

#6

|

|

Registered User

Join Date: Mar 2013

Location: Scotland

Posts: 82

|

I went ahead and ordered a complete tool kit from a company that make them in Sheffield for £100. Stainless steel too.

https://www.i6automotive.co.uk/workshop-tools/porsche-ims-bearing-removal-puller-tool.html

I figure I can sell it afterwards and get most of the money back.

Cover will be off soon so I can have a look at the bearing and make a decision. If it's firm and solid I'll pul the outer seal off, if it's wobbly at all I'll replace it, LN or EPS , I haven't decided yet.

|

|

|

01-30-2018, 10:02 AM

01-30-2018, 10:02 AM

|

#7

|

|

Registered User

Join Date: Jun 2016

Location: Arizona

Posts: 379

|

I'm no expert in this matter, but a visual, although better than nothing, will only tell you so much. And I think you'll be only able to tell only if there is extreme wobble/wear. Inspecting the oil filter for magnetic metallic flakes is probably going to tell you more too...

I have a factory reman 2006 3.2 with the big bearing and can not replace it easily, so I pulled the outer seal for better lubrication. Then again, I drive that car hard, and I don't worry too much about it.

__________________

2002 Boxster S - NHP 200 Cell Headers,test pipes,Borla CatBack,Competition Plenum,74 mm TB, EVOMS Tune,Tarett UDP,Eibach Swaybars,BIlstein PSS9s,TuneRS rear toe links,wheel studs,15 mm wheel spacers on all 4,EBC yellow stuff pads,Sebro rotors, EBS oil baffles,160 deg Thermostat,2 quart Accusump,full filtration remote oil filter,rad fan switch,custom gauge/switch plate, Race Capture data logging, 90K miles

|

|

|

01-31-2018, 05:35 AM

01-31-2018, 05:35 AM

|

#8

|

|

Registered User

Join Date: Mar 2013

Location: Scotland

Posts: 82

|

My IMS removal kit arrived today, it looks good but I don't think the cam lock is going in the slot in the cam properly. Does anyone know the actual width of the slot in the cam and whether it's a square slot or tapered.? Mine is a 5 chain engine so only 1 slot.

Same for the bank on the right... the steel plate they are made from is 6mm thick.

Do I need to lock both side?

|

|

|

01-31-2018, 11:16 AM

01-31-2018, 11:16 AM

|

#9

|

|

Registered User

Join Date: Mar 2013

Location: Scotland

Posts: 82

|

So I removed the flywheel and there was some oil spread about the rear of the engine, some had gone out the gaps in the bell housing and covered the right rear of the engine.

Not really obvious if the IMSB flange seal was leaking but I reckon it might have been weeping. The RMS oil must fling out when the engine is running and spread everywhere.

Cleaned it all up.

So I locked up the cams after modifying the tools I got. Pulled the tensioners and pulled the flange.

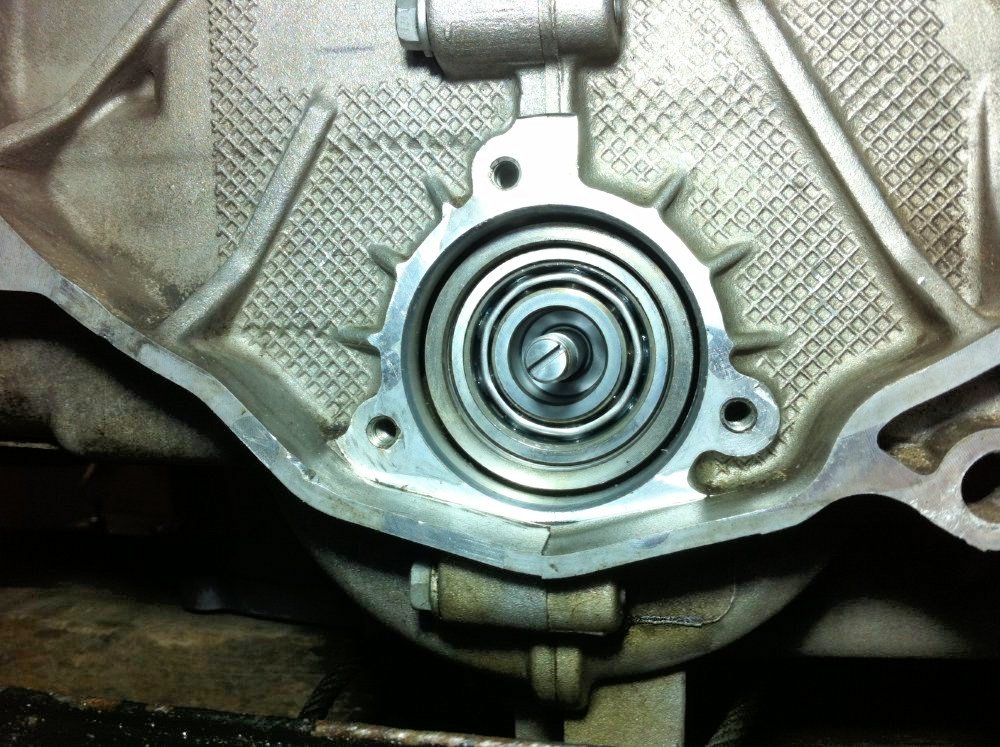

As I thought the bearing looks perfect with no movement on it whatsoever...It looks like it was just fitted. Dual row.

So now I'm thinking leave it in, get a new type flange from Porsche and fit new clutch/flywheel, RMS ..job done....right?

Well I just don't know what the races/balls are like.probably like new no doubt.

Need to make a decision.

|

|

|

02-01-2018, 08:53 AM

02-01-2018, 08:53 AM

|

#10

|

|

Registered User

Join Date: Jul 2016

Location: Maryland

Posts: 54

|

If you're looking for a budget-friendly solution you could pull that bearing (since you already bought the tool) and replace it with a good quality 3204 2RS C3 (SKF or FAG, $70). You will need to source a 47mm ring clip and 3.13mm center bolt spacer to account for the new bearing being narrower without a retaining wire groove. In my opinion you can reuse the center bolt if you don't use it to pull the old bearing out (obviously it was not designed for that). You can buy an updated triple seal flange or reuse your old flange and fit a viton x-type seal for a little leak insurance.

I did all this on my car 5k miles ago and it hasn't blown up or leaked yet (Yay! One data point...). My factory dual row bearing was tight after 18 years and 65k miles, so I plan to replace it every clutch service. My opinion is that if you have a dual row, you have a maintenance item (sealed ball bearings are service items in any application). If you have a single row car, you have a design deficiency and need to upgrade your bearing to an after market dual row or plain bearing. PM me it you want to take this route and I can give you specific links to what I bought.

|

|

|

02-01-2018, 01:39 PM

02-01-2018, 01:39 PM

|

#11

|

|

Registered User

Join Date: Mar 2013

Location: Scotland

Posts: 82

|

Well thanks for the tip but I caved in and went ahead and bought an LN dual row as well as clutch, DMF, RMS etc etc...

Ironically if I was keeping the car, and I might after all this expense, i would have left it, it was more if I was going to trade it in for a 997, much easier to sell a car that's had the IMS/RMS done together.

The tools I bought were junk, they are going back, the puller has an ID of 47 mm, the same as the OD of the bearing..impossible.

I'll do another post when I get the bearing changed.

|

|

|

02-01-2018, 04:20 PM

02-01-2018, 04:20 PM

|

#12

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,657

|

Quote:

Originally Posted by Troutman

Well thanks for the tip but I caved in and went ahead and bought an LN dual row as well as clutch, DMF, RMS etc etc...

|

Good move............

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

02-03-2018, 04:33 AM

02-03-2018, 04:33 AM

|

#13

|

|

Registered User

Join Date: Apr 2016

Location: SE Michigan

Posts: 496

|

Quote:

Originally Posted by Troutman

Well thanks for the tip but I caved in and went ahead and bought an LN dual row as well as clutch, DMF, RMS etc etc...

Ironically if I was keeping the car, and I might after all this expense, i would have left it, it was more if I was going to trade it in for a 997, much easier to sell a car that's had the IMS/RMS done together.

The tools I bought were junk, they are going back, the puller has an ID of 47 mm, the same as the OD of the bearing..impossible.

I'll do another post when I get the bearing changed.

|

Please post when you replace the original dual row bearing, curious to see its condition.

__________________

1997 Boxster arctic silver/ red, XNE riveted mahogany/ leather steering wheel & 917-style wood shift knob, Ben’s short shifter, PSE, 996 TB, UDP, stereo/ center console delete, hardtop and speedster humps, daily driver rain or shine or snow!

|

|

|

02-10-2018, 08:35 AM

02-10-2018, 08:35 AM

|

#14

|

|

Registered User

Join Date: Apr 2016

Location: SE Michigan

Posts: 496

|

Looks like your original bearing is still in great shape.

So the new bearing you got feels not that tight and rolls???

__________________

1997 Boxster arctic silver/ red, XNE riveted mahogany/ leather steering wheel & 917-style wood shift knob, Ben’s short shifter, PSE, 996 TB, UDP, stereo/ center console delete, hardtop and speedster humps, daily driver rain or shine or snow!

|

|

|

02-10-2018, 01:29 PM

02-10-2018, 01:29 PM

|

#15

|

|

Registered User

Join Date: Mar 2013

Location: Scotland

Posts: 82

|

New LN Retrofit is very similar although it has been in the freezer all day ready for fitting tomorrow, so the grease will be firmer, but I don't remember it spinning easily before it went in.

|

|

|

02-13-2018, 08:32 AM

02-13-2018, 08:32 AM

|

#16

|

|

Registered User

Join Date: Mar 2013

Location: Scotland

Posts: 82

|

Today I fitted the new IMS Bearing ...yes it's done, it's in there.

I had to use a block of nylon so I could use a metal mallet to tap it in. My rubber mallet just wasn't heavy enough. That's me hitting the fitting tool , not the bearing.

Then you fit the Spiro-Loc ..had to get in touch with LN as I've never seen one of these before let alone fit one. Wanted to get it right.

Apparently I was the first person in 10 years to ask how to insert a Spiro-Loc.

Then i put a small smear of silicone grease on the gasket and carefully pulled on the new flange using the 3 old bolts. Waiting for Loctite to finish that.

Also my RMS tool arrived today, I had my machine man make it out of nylon. It's brilliant and made fitting the RMS so easy.

Btw, I removed the outer seal from my old bearing and it's perfect inside, no play or noise or anything, it's like a brand new bearing would be.

I would say dual row failures are most likely from poor alignment , in fact I bet the single is too but it fails quicker.

Why did I change it? Because I was there and I was spending a load of money anyway and it can be forgotten about for a while..if I was strapped for cash, after I saw it and felt it, I would have tried to replace the O ring and left it alone.

Clutch and DMF to go in next.

|

|

|

02-13-2018, 11:07 AM

02-13-2018, 11:07 AM

|

#17

|

|

Registered User

Join Date: Dec 2017

Location: Cambria, CA

Posts: 121

|

I love that nylon RMS tool. I made one out of pvc parts and wasn't all that thrilled with how it came out.

|

|

|

02-13-2018, 11:33 AM

02-13-2018, 11:33 AM

|

#18

|

|

Registered User

Join Date: Mar 2013

Location: Scotland

Posts: 82

|

Yeah it's superb, t just takes all the guess work out of it.

Measuring 13mm inside he crank etc is just about impossible. This does it for you.

|

|

|

04-06-2018, 12:36 AM

04-06-2018, 12:36 AM

|

#19

|

|

Registered User

Join Date: Nov 2017

Location: UK

Posts: 5

|

Hello Troutman, great thread, read with interest, which side of Scotland are you in? I must visit the place some time, (Londoner - eww), and fish for some wild trout..

I have a few contributions to your dilemmas:

1, was the thermostat shiny clean when you refitted and it still leaked? that is a worry, was it OEM?

2, You queried how the IMSb bolt could support the side loading of the cam chains - This is now how it works - The inner face of the IMS bearing rides on the 'spider flange', that through bolt merely keeps the assembly true - i.e. stops the bearing meandering fore and aft.

3, You noted your original IMB bearing was as new once the seals were removed, but also must note it was completely devoid of the gearing grease such a bearing requires to survive when sealed by the plastic sides.. I am a fan of the seal removal & splash oil feed lubrication strategy - as you have adopted for the replacement, I would like to copy this idea on my build.

4, exhaust stud jig - what does it look like and are you willing to rent it out? You say you'll be renting out the IMSB tools also, I think I'll be a customer when the time comes also.

Looking forward to updates,

Beers!

Harry

|

|

|

04-06-2018, 06:03 AM

04-06-2018, 06:03 AM

|

#20

|

|

Registered User

Join Date: Jul 2011

Location: Richmond, VA (The Fan)

Posts: 978

|

Quote:

Originally Posted by Bullet-Proof_Biscuit

Hello Troutman, great thread, read with interest, which side of Scotland are you in? I must visit the place some time, (Londoner - eww), and fish for some wild trout..

3, You noted your original IMB bearing was as new once the seals were removed, but also must note it was completely devoid of the gearing grease such a bearing requires to survive when sealed by the plastic sides.. I am a fan of the seal removal & splash oil feed lubrication strategy - as you have adopted for the replacement, I would like to copy this idea on my build.

Beers!

Harry

|

I’ve removed three IMS bearings from my car over the last 7 years (two upgraded units) all had seals. The seals on every bearing I’ve pulled had failed and the bearings were full of oil. Removing the seal seems like a good idea. (And no there isn’t a reason to replace them this much, it’s always been a “while you’re in there” thing).

Cheers,

__________________

1997 Boxster 4.2L Audi V8 Bi-Turbo

2003 911 C2

NASA HPDE Instructor

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 03:01 PM.

| |