Today I fitted the new

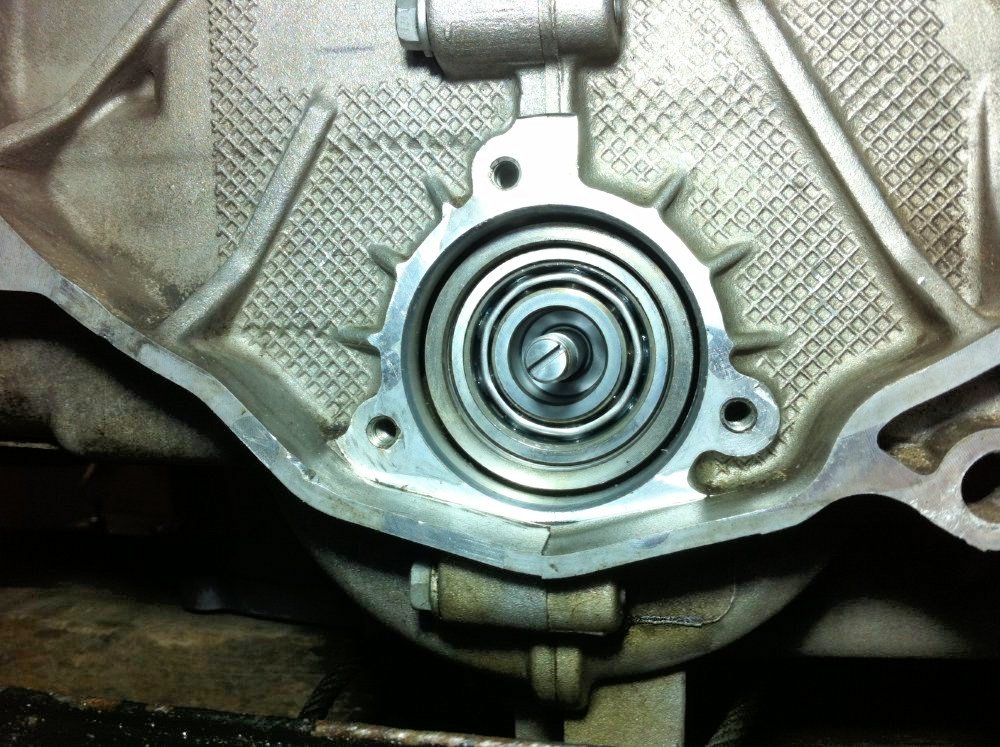

IMS Bearing ...yes it's done, it's in there.

I had to use a block of nylon so I could use a metal mallet to tap it in. My rubber mallet just wasn't heavy enough. That's me hitting the fitting tool , not the bearing.

Then you fit the Spiro-Loc ..had to get in touch with LN as I've never seen one of these before let alone fit one. Wanted to get it right.

Apparently I was the first person in 10 years to ask how to insert a Spiro-Loc.

Then i put a small smear of silicone grease on the gasket and carefully pulled on the new flange using the 3 old bolts. Waiting for Loctite to finish that.

Also my RMS tool arrived today, I had my machine man make it out of nylon. It's brilliant and made fitting the RMS so easy.

Btw, I removed the outer seal from my old bearing and it's perfect inside, no play or noise or anything, it's like a brand new bearing would be.

I would say dual row failures are most likely from poor alignment , in fact I bet the single is too but it fails quicker.

Why did I change it? Because I was there and I was spending a load of money anyway and it can be forgotten about for a while..if I was strapped for cash, after I saw it and felt it, I would have tried to replace the O ring and left it alone.

Clutch and DMF to go in next.