11-01-2013, 03:49 AM

11-01-2013, 03:49 AM

|

#141

|

|

Registered User

Join Date: Nov 2010

Location: Australia- Brisbane

Posts: 47

|

Something interesting as a comparison w.r.t. lubrication of deep groove ball bearings.

ROTAX 582, water cooled 2 stoke engine run 6207 and 6206 DGBB's on their crankshaft @6500 RPM,

Lubrication? 50:1 pre mix, that not a lot of oil.

|

|

|

11-01-2013, 08:42 AM

11-01-2013, 08:42 AM

|

#142

|

|

Registered User

Join Date: Apr 2012

Location: Ontario, Canada

Posts: 598

|

thom, if you read my posts you would see that we are largely in agreement: for example, in post 84 I suggest that for owners of the double-row bearings, the LN retrofit is the most cost-effective answer; for those with the single-row bearing, I opine that is likely also the case, although WITH BETTER EVIDENCE, I suggest that the DOF may also prove to be an important augmentation to a bearing upgrade/replacement.

We know that the dual-row bearing is more durable than the single row. We also believe that a properly engineered ceramic bearing should be more durable than a steel one. Finally, we know that inadequate lubrication is a causal factor in IMS bearing failure, regardless of the type of bearing. What we do not know is whether, especially for the single-row bearing, splash lubrication will be sufficient to ensure trouble-free, long term use. It would seem that LN are also unsure, in that they recommend replacement of their upgraded bearing every 3 years, or 50,000 miles. I wonder how many of the original sealed single-row bearings would have failed if replaced on that schedule!

Brad

|

|

|

11-01-2013, 09:03 AM

11-01-2013, 09:03 AM

|

#143

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,650

|

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

11-01-2013, 11:16 AM

11-01-2013, 11:16 AM

|

#144

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

|

It would seem that LN are also unsure, in that they recommend replacement of their upgraded bearing every 3 years, or 50,000 miles.

|

We are quite sure.. Absolutely positive, that the issue is not lubrication.

The single row retrofit bearing is recommended as a 50K component due to it's size and load carrying capacity- nothing more.

The single row bearing simply is not robust enough, even when superior ceramic balls and hardened races are utilized. Two rows are certainly better than one.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

11-01-2013, 12:26 PM

11-01-2013, 12:26 PM

|

#145

|

|

Registered User

Join Date: Apr 2012

Location: Ontario, Canada

Posts: 598

|

JFP, to you it may be a dead horse, but to others it has been worthwhile discussing the various bearings and the lubrication of the same. Jake, we all now know that dual-row are better than single-row and Porsche's own numbers verify the same. Indeed, it seems that your own opinion on the same has also evolved over the years for, as I recall, a couple of years ago your opinions in that regard were much more circumspect.

Nevertheless, if lubrication is a contributing factor to IMS bearing failure (and I thought we were all in agreement on that as well), then does it not also stand to reason that a better lubricated bearing should outlast one with poorer lubrication?

You believe that splash lubrication with seals removed is not only adequate, but better than DOF for various reasons (aeration of the oil, etc.) and you may be right. Only time and further testing will tell.

Regardless, my understanding of the issues has been enhanced by this thread and I strongly suspect that the same is true for others. JFP, if it has been tiresome for you, so be it. Anyway, barring some new and unexpected news/information, I'm certainly out of here.

Cheers!

Brad

|

|

|

11-01-2013, 01:25 PM

11-01-2013, 01:25 PM

|

#146

|

|

Registered User

Join Date: Sep 2013

Location: Montreal, QC. (currently expat to Shanghai)

Posts: 3,249

|

Quote:

Originally Posted by Jake Raby

The single row bearing simply is not robust enough, even when superior ceramic balls and hardened races are utilized. Two rows are certainly better than one.

|

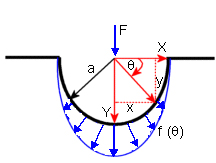

You guys need to look into modern simulation software. They are capable of answering many (members') questions without anyone having to break anything

e,g with a nonuniform distribution

f(θ) = Fo*Sin(q) = (Fo)*(y/a) = 1.333*Fo*y

where:

f(θ) is the intensity of the force

a is the radius of the hole

and Fo is a scale factor calculated such that the sum of all forces acting on the nodes in the vertical direction (ΣFo*Sin2(θ)) is set equal to the specified force value, F.

Intensity of the force is assumed uniform in the z-direction.

__________________

______________________________

'97 Boxster base model 2.5L, Guards Red/Tan leather, with a new but old Alpine am/fm radio.

|

|

|

11-01-2013, 01:28 PM

11-01-2013, 01:28 PM

|

#147

|

|

Registered User

Join Date: Sep 2013

Location: Montreal, QC. (currently expat to Shanghai)

Posts: 3,249

|

Wish I'd have this crazy shaft diameter, alloy types, and bearing dimensions. I could run your simulation real quick but I don't! I just have a Boxster

__________________

______________________________

'97 Boxster base model 2.5L, Guards Red/Tan leather, with a new but old Alpine am/fm radio.

|

|

|

11-01-2013, 01:43 PM

11-01-2013, 01:43 PM

|

#148

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,650

|

Quote:

Originally Posted by southernstar

JFP, to you it may be a dead horse, but to others it has been worthwhile discussing the various bearings and the lubrication of the same. Jake, we all now know that dual-row are better than single-row and Porsche's own numbers verify the same. Indeed, it seems that your own opinion on the same has also evolved over the years for, as I recall, a couple of years ago your opinions in that regard were much more circumspect.

Nevertheless, if lubrication is a contributing factor to IMS bearing failure (and I thought we were all in agreement on that as well), then does it not also stand to reason that a better lubricated bearing should outlast one with poorer lubrication?

You believe that splash lubrication with seals removed is not only adequate, but better than DOF for various reasons (aeration of the oil, etc.) and you may be right. Only time and further testing will tell.

Regardless, my understanding of the issues has been enhanced by this thread and I strongly suspect that the same is true for others. JFP, if it has been tiresome for you, so be it. Anyway, barring some new and unexpected news/information, I'm certainly out of here.

Cheers!

Brad

|

Let's see, Group A has an opinion based upon years of experience and thousands of successful installations, Group B has a different, and somewhat opposing opinion, based upon a handful of installations and a track record that can probably be measured in weeks. This is not even close to a fair comparison. Through most of this tedious debate, I have read a lot of speculation, supposition, hyperbole, and in some cases wishful thinking packaged as "a logical conclusion". Basically, those that support one view can not or will not accept the potential of the other, and visa versa.

If spraying unfiltered oil on the back of an OEM style steel bearing assembly truly is the future for the M96/97 design engines, in a year or two it may become more obvious, but right now it looks more like trying to develop a trend line from too few data points and a whole lot of arguing. Those of us that stake our business's reputation on how well an aftermarket part will perform will take a wait and see position until there is enough data to confirm its viability. And arguing and posturing is not going to change that.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

Last edited by JFP in PA; 11-01-2013 at 01:51 PM.

|

|

|

11-01-2013, 03:11 PM

11-01-2013, 03:11 PM

|

#149

|

|

Registered User

Join Date: Jun 2007

Location: NW Indiana

Posts: 156

|

Just throwing this out there:

I work with very expensive rotating equipment everyday. A few years ago, we started converting most of our bearings from oil bath (either oil flung up by an oil ring or having a level of oil just slightly above the outer race at the bottom of the bearing) to an oil mist system. The oil mist provides the bearing with a very small mist of oil to be pulled through the bearing. Most people thought that there would be bearing failure because of lack of lubrication, but the data shows that this is not the case. This misting amount is so miniscule, hardly any oil at all.

Bearings do not need much oil to work properly and of course, too much is not better. They do need "good" oil though.

I am sure that Jake could test (maybe he already has) how much oil is splashed up to this bearing. It would show whether that was enough lubrication.

The only scenario where there might not be enough oil momentarily would be immediately upon start-up and under hard cornering.

My Boxster has a 3.4L from an 06 Cayman. So I have that huge, single row bearing. I talked to Charles when I bought the engine and since I didn't want to open an engine with 20K on it, he suggested that I remove the outer race. I did and have ran it that way for the last few summers.

__________________

2002 Boxster S with 3.4L Variocam-Plus Engine Swap

|

|

|

11-01-2013, 05:06 PM

11-01-2013, 05:06 PM

|

#150

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

Originally Posted by Nine8Six

You guys need to look into modern simulation software. They are capable of answering many (members') questions without anyone having to break anything

e,g with a nonuniform distribution

f(θ) = Fo*Sin(q) = (Fo)*(y/a) = 1.333*Fo*y

where:

f(θ) is the intensity of the force

a is the radius of the hole

and Fo is a scale factor calculated such that the sum of all forces acting on the nodes in the vertical direction (ΣFo*Sin2(θ)) is set equal to the specified force value, F.

Intensity of the force is assumed uniform in the z-direction. |

Breaking things and gaining first hand experience is required.

Too many simulations were utilized when designing the M96 engine, IMHO.

The sweet spot between simulations and real world practical application is where I try to operate.

Plus, I REALLY enjoy breaking things. I am damn good at it, too.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

11-02-2013, 01:21 AM

11-02-2013, 01:21 AM

|

#151

|

|

Registered User

Join Date: Sep 2013

Location: Montreal, QC. (currently expat to Shanghai)

Posts: 3,249

|

Quote:

Originally Posted by Jake Raby

Breaking things and gaining first hand experience is required.

Too many simulations were utilized when designing the M96 engine, IMHO.

The sweet spot between simulations and real world practical application is where I try to operate.

Plus, I REALLY enjoy breaking things. I am damn good at it, too.

|

Couldn't agree more with you that breaking things is the proper way to get things tested, but not necessarily designed - modern software have helped a lot since the last decade. We had a "vault" filled with blown up everything when I was a wage-slave in Milton Keynes back in the days. The most expansive rubbish-pile I saw in my life! I've mopped the floors around it many times

Simulation software are excellent at pre-evaluating stresses vs material-types and sizes selections. Some even comes with unique features under Menu > Dumb > Very Dumb > where you can select: Driver has failed O2 sensors, bad MAF, clogged FIs, Wal-Mart cheap oil, and it simulate the rapid effects of contamination and oil balls has on engines, steels and seals

Priceless. Look up for ANSYS Co. ( ANSYS - Simulation Driven Product Development)

__________________

______________________________

'97 Boxster base model 2.5L, Guards Red/Tan leather, with a new but old Alpine am/fm radio.

Last edited by Nine8Six; 11-02-2013 at 06:58 AM.

|

|

|

11-02-2013, 07:42 AM

11-02-2013, 07:42 AM

|

#152

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Everything has a place.. We use simulations when they make sense, for all other things we use practical application. I use simulation software primarily for designing my camshafts and engine combinations.

The ability to put a cylinder head on a flow bench, gather port flow data, then throw a camshaft in the profiler and gather those numbers, then throw all of that into the matching engine simulation software and start building a new combination without having to assemble it is a great thing. That said, there are few times that things in the real world go the same when building that magical combination, and of course the second generation of it is always better than the first.

Its engine evolution.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

11-05-2013, 07:21 AM

11-05-2013, 07:21 AM

|

#153

|

|

Registered User

Join Date: Jul 2007

Location: Texarkana, Texas

Posts: 959

|

Quote:

Originally Posted by JFP in PA

Let's see, Group A has an opinion based upon years of experience and thousands of successful installations, Group B has a different, and somewhat opposing opinion, based upon a handful of installations and a track record that can probably be measured in weeks.

|

I'm still at a loss as to why people question the benefit of properly lubricating a ball bearing... Yes, the DOF system is a new product and doesn't have thousands of installs, but the SCIENCE that it is based on is old and well proven. So why question it so much? Sorry for being so blunt, but I think it's time to call it like it is... I personally discount most of what LN Engineering and Jake Raby have said regarding lubrication not being the issue because Jake has made it very clear that he is out for blood in a fierce competition here. He's looking to crush alternative products. If there is real science that he wants to share to add to the discussion of lubrication, then add it. Instead we get vague responses about our AOS maybe failing...

I think the whole story on the importance of proper lubrication has changed. The IMS Retrofit website has been updated to sternly warn against direct oil lubrication now. Their UK distributor website hasn't been updated/changed yet though and it is very, very clear throughout - poor lubrication is the key contributor to the IMS failures.

PORSCHE Intermediate shaft upgrade kit for PORSCHE BOXSTER ENGINE 986 AND PORSCHE 911 996 ENGINE

The failure differences between single row 6204, double row, and single row 6305 bearings seem obvious to me. Without the proper lubrication what kind of problem are you going to have? Accelerated wear. Now if you have more balls or a bigger bearing will you be able to tolerate more wear before failure? Absolutely. So you would expect higher failure rates with the smaller 6204 bearing, but not because the bearing is so weak that it is failing due to low tensile strength. No, when we see IMS bearing failures we don't see shattered, broken bearing balls. What we see are worn races, worn balls, worn cages.

I don't need 12,000 installs and years of experience to tell me that proper lubrication is the best answer to wear. No, there are millions and millions of installs and decades and decades of experience that tell us that proper lubrication is the BEST way to minimize wear in a ball bearing. That's why I see the IMS Retrofit with a stronger bearing as just a band aid solution while the direct oil feed is a real fix, root cause solution.

Kirk Bristol

__________________

2000 Boxster S - Gemballa body kit, GT3 front bumper, JRZ coilovers, lower stress bars

2003 911 Carrera 4S - TechArt body kit, TechArt coilovers, HRE wheels

1986 911 Carrera Targa - 3.2L, Euro pistons, 964 cams, steel slant nose widebody

1975 911S Targa - undergoing a full restoration and engine rebuild

Also In The Garage - '66 912, '69 912, '72 914 Chalon wide body, '73 914

|

|

|

11-05-2013, 09:23 AM

11-05-2013, 09:23 AM

|

#154

|

|

Registered User

Join Date: Sep 2010

Location: Foster City CA

Posts: 1,099

|

I question DOF for one simple reason. Nobody that I've seen has provided one single hard fact that shows

lubrication is a problem for unsealed replacement bearings. Just because someone says something doesn't mean it's so.

|

|

|

11-05-2013, 09:54 AM

11-05-2013, 09:54 AM

|

#155

|

|

Registered User

Join Date: Jul 2007

Location: Texarkana, Texas

Posts: 959

|

Quote:

Originally Posted by thom4782

I question DOF for one simple reason. Nobody that I've seen has provided one single hard fact that shows

lubrication is a problem for unsealed replacement bearings. Just because someone says something doesn't mean it's so.

|

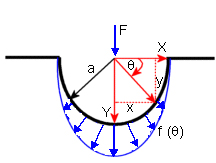

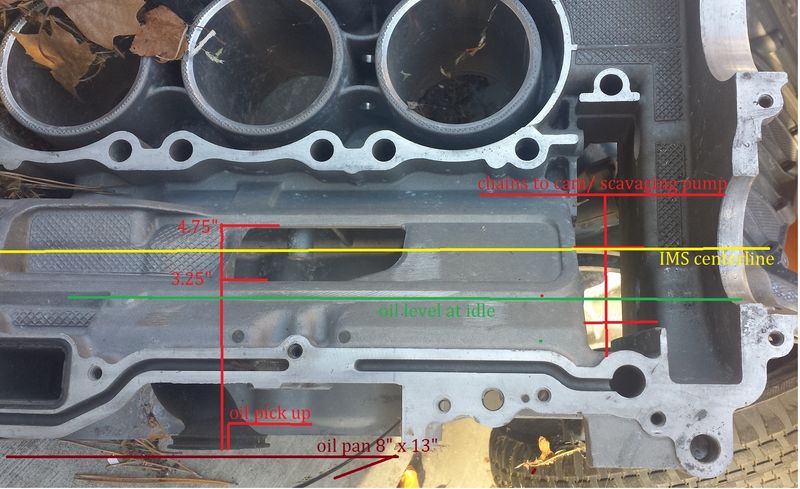

Exactly, no one has proven exactly how much oil an unsealed replacement bearing gets, even LN Engineering has not shown us how much oil actually gets to their ceramic bearing if it is just left unsealed. What we do have though are pictures like this from Feelyx

This shows that the sump level is clearly below the IMS bearing (the green line). Then we also have pictures that show the small slit that the oil has to "splash" through to lubricate the bearing.

Then on top of that we have a dozen or more IMS Retrofit failures and a new video on the TuneRS website showing a badly worn Retrofit bearing after just 40K or so miles...

So you are right, there is no direct evidence to support the LN Engineering claim that there is sufficient splash lubrication for an unsealed bearing, but the indirect evidence would make me very uneasy about trusting such an important bearing to marginal, at best, oil splash. I think the indirect evidence is enough for me to want a more reliable and consistent supply of oil to this bearing = DOF. Now I have asked LNE in another post for any testing that they've done to show the oil level during dynamic running conditions, but they have not produced anything. On the other hand I just installed a DOF system on my 2003 Carrera 4S this last weekend and I have the peace of mind now that I know exactly what the state of lubrication will be for that bearing under all running conditions like hard cornering, hard braking, and acceleration - it will be exactly the same!!!

Kirk Bristol

__________________

2000 Boxster S - Gemballa body kit, GT3 front bumper, JRZ coilovers, lower stress bars

2003 911 Carrera 4S - TechArt body kit, TechArt coilovers, HRE wheels

1986 911 Carrera Targa - 3.2L, Euro pistons, 964 cams, steel slant nose widebody

1975 911S Targa - undergoing a full restoration and engine rebuild

Also In The Garage - '66 912, '69 912, '72 914 Chalon wide body, '73 914

|

|

|

11-05-2013, 09:56 AM

11-05-2013, 09:56 AM

|

#156

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

|

Jake has made it very clear that he is out for blood in a fierce competition here

|

I am a Marine. I know nothing else :-)

Nothing personal against anyone, of course.

Time will tell it all, just like it already has with our products over the past 5 years of application. One thing is for sure, the pros won't ever be bragged upon, but you can guarantee that each and every "con" and "issue" will find its way into the public. It always does. This holds true for the handful of issues that we have had and with enough units sold, it will hold true for every single other product out there.

Charles will be here later this week and we have an M96 on the engine dyno :-)

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

Last edited by Jake Raby; 11-05-2013 at 09:58 AM.

|

|

|

11-05-2013, 10:03 AM

11-05-2013, 10:03 AM

|

#157

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,650

|

Quote:

Originally Posted by Kirk

I'm still at a loss as to why people question the benefit of properly lubricating a ball bearing... Yes, the DOF system is a new product and doesn't have thousands of installs, but the SCIENCE that it is based on is old and well proven. So why question it so much? Sorry for being so blunt, but I think it's time to call it like it is... I personally discount most of what LN Engineering and Jake Raby have said regarding lubrication not being the issue because Jake has made it very clear that he is out for blood in a fierce competition here. He's looking to crush alternative products. If there is real science that he wants to share to add to the discussion of lubrication, then add it. Instead we get vague responses about our AOS maybe failing...

I think the whole story on the importance of proper lubrication has changed. The IMS Retrofit website has been updated to sternly warn against direct oil lubrication now. Their UK distributor website hasn't been updated/changed yet though and it is very, very clear throughout - poor lubrication is the key contributor to the IMS failures.

PORSCHE Intermediate shaft upgrade kit for PORSCHE BOXSTER ENGINE 986 AND PORSCHE 911 996 ENGINE

The failure differences between single row 6204, double row, and single row 6305 bearings seem obvious to me. Without the proper lubrication what kind of problem are you going to have? Accelerated wear. Now if you have more balls or a bigger bearing will you be able to tolerate more wear before failure? Absolutely. So you would expect higher failure rates with the smaller 6204 bearing, but not because the bearing is so weak that it is failing due to low tensile strength. No, when we see IMS bearing failures we don't see shattered, broken bearing balls. What we see are worn races, worn balls, worn cages.

I don't need 12,000 installs and years of experience to tell me that proper lubrication is the best answer to wear. No, there are millions and millions of installs and decades and decades of experience that tell us that proper lubrication is the BEST way to minimize wear in a ball bearing. That's why I see the IMS Retrofit with a stronger bearing as just a band aid solution while the direct oil feed is a real fix, root cause solution.

Kirk Bristol |

Science? What science? If you are willing to accept the statement that "Lubrication is a good thing" as science, you are much easier to convince than those of us that maintain these cars for other people. Until I see published, valid, and statistically meaningful long term performance by these oil feed systems, I will choose to withhold judgment on them; not that they are wrong, but that they are unproven.

As for your supposition that LN used to say lubrication was a problem and now has reversed that stance, that is not correct. LN has always stated that the breakdown of the OEM grease in the sealed bearing and its washing away when the seals begin to fail precipitate bearing failures. It is that lack of lubrication by the now displaced grease, and the break down of the oil that often gets trapped in its place that eats these bearings. But they have correctly expressed concern both about running unfiltered oil into ceramic bearings, and about the thickness of the oil feed flange significantly reducing the center bolt engagement and support. LN has stated for years that they were adamantly opposed to installing their bearings into engines that showed signs of significant metallic debris in the oil or filter because it can lead to premature bearing wear and failure, which is one of several reasons they developed the spin on oil filter system that uses filters without by-pass mechanisms. A recent article in the technical section of "Excellence" discussed the importance of oil filtration in these engines and why it is important to consider replacing the OEM system with a "full flow" (read no bypass) style filter, even if it is the only modification you make to the car.

Unfortunately, your perspective does not align with mine, as having more than 10,000 ceramic bearings happily running around for several years without unfiltered oil being squirted into them tells me an entirely different story.....................

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

11-05-2013, 11:54 AM

11-05-2013, 11:54 AM

|

#158

|

|

Registered User

Join Date: Jul 2007

Location: Texarkana, Texas

Posts: 959

|

Quote:

Originally Posted by JFP in PA

Science? What science?

|

I can step outside the door of my office, walk out into the factory where I work and see THOUSANDS of examples where the science behind the direct oil feed system is working today, right now, and has been working here since 1973, 24 hrs/day, 350 days/year. This is nothing new and there are thousands of factories around the world the same as mine. The APPLICATION of this lubrication technology is new to the IMS problem, but this is not, by any stretch, a new idea or new technology or new science. Direct oil lubrication of a ball bearing is very old and very well proven. It is not going to ruin your bearing. It is not going to make your AOS explode. It's just going to lubricate the bearing, reduce wear, and make it run cooler.

Kirk Bristol

__________________

2000 Boxster S - Gemballa body kit, GT3 front bumper, JRZ coilovers, lower stress bars

2003 911 Carrera 4S - TechArt body kit, TechArt coilovers, HRE wheels

1986 911 Carrera Targa - 3.2L, Euro pistons, 964 cams, steel slant nose widebody

1975 911S Targa - undergoing a full restoration and engine rebuild

Also In The Garage - '66 912, '69 912, '72 914 Chalon wide body, '73 914

|

|

|

11-05-2013, 12:03 PM

11-05-2013, 12:03 PM

|

#159

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

Originally Posted by Kirk

I can step outside the door of my office, walk out into the factory where I work and see THOUSANDS of examples where the science behind the direct oil feed system is working today, right now, and has been working here since 1973, 24 hrs/day, 350 days/year. This is nothing new and there are thousands of factories around the world the same as mine. The APPLICATION of this lubrication technology is new to the IMS problem, but this is not, by any stretch, a new idea or new technology or new science. Direct oil lubrication of a ball bearing is very old and very well proven. It is not going to ruin your bearing. It is not going to make your AOS explode. It's just going to lubricate the bearing, reduce wear, and make it run cooler.

Kirk Bristol

|

Are those machines powered by M96 engines?

The biggest mistake that can be made is treating this engine like any other machine. Thats the opening line in both my WTI Engine Mechanical Class as well as my M96 102 Engine Rebuild School.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

11-05-2013, 12:31 PM

11-05-2013, 12:31 PM

|

#160

|

|

Registered User

Join Date: Sep 2013

Location: Montreal, QC. (currently expat to Shanghai)

Posts: 3,249

|

Quote:

Originally Posted by Kirk

I can step outside the door of my office, walk out into the factory where I work and see THOUSANDS of examples where the science behind the direct oil feed system is working today, right now, and has been working here since 1973, 24 hrs/day, 350 days/year. This is nothing new and there are thousands of factories around the world the same as mine. The APPLICATION of this lubrication technology is new to the IMS problem, but this is not, by any stretch, a new idea or new technology or new science. Direct oil lubrication of a ball bearing is very old and very well proven. It is not going to ruin your bearing. It is not going to make your AOS explode. It's just going to lubricate the bearing, reduce wear, and make it run cooler.

Kirk Bristol

|

Yes, proven indeed however it requires "SAE" oil and it to be surgically clean. How on earth are you applying this to a IC motor often contaminated with fuel and glycol exactly?!

The seal on your IMS bearing is made of edacrylonitrile butadiene in case one needs to use science to make sense of things. The other questions you may want to ask yourself is why it is sealed per design, and what eats the seal off the bearing, again, before you think about giving it more of what may destroyed it at first place.

Again, change your oil frequently, have your MAF/O2 air and fuel distribution spot-on and your bearing will work perfectly as designed and will live forever like on thousands of other pcars.

So simple

__________________

______________________________

'97 Boxster base model 2.5L, Guards Red/Tan leather, with a new but old Alpine am/fm radio.

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 04:38 PM.

| |