09-21-2013, 08:30 AM

09-21-2013, 08:30 AM

|

#1

|

|

Registered User

Join Date: Jun 2012

Location: Ontario,Canada

Posts: 84

|

Pedros Techno DOF IMS fix?

I have an 06 Boxster S and seriously considering getting this kit and having my porsche

shop install it,i have about 60k now and no problems yet atleast that i am aware off.

My only concern is with fairly new technology sometimes there are issues that arise down the road that without tons off miles ect may occur.I have a concern that i would like som feed back on.If there is about 60 psi off pressurized oil shooting into the bearings one side(with seal removed) is there any chance that the other inside seal could be forced out or particially out enough by oil pressure,if that was even possible that would be the kiss of death as that oil would burn up in the shaft tube,become acid ect and cause the bearings to pit and blow even faster.Any thoughts on this. Also for those that have done it,what should i expect in terms off cost for the procedure of install.Thx

|

|

|

09-21-2013, 09:22 AM

09-21-2013, 09:22 AM

|

#2

|

|

petrol head

Join Date: Aug 2013

Location: United Kingdom, Stoke on Trent

Posts: 79

|

Can't help you with the cost's etc but yep i've been thinking about the DoF upgrade and exactly the same thoughts have crossed my mind. 60psi hitting the back of a seal that's fitted from the front?? i'll be more than interested in what people have to say.

2001 2.7 57k miles, no trouble as yet and always (up to now anyway) steel free oil filter

|

|

|

09-21-2013, 01:21 PM

09-21-2013, 01:21 PM

|

#3

|

|

Registered User

Join Date: Sep 2010

Location: Foster City CA

Posts: 1,099

|

IIRC, 3rd generation IMS bearings, i.e., the large single row ones that Porsche began installing in 2006, almost never fail. So why do anything?

|

|

|

09-21-2013, 01:43 PM

09-21-2013, 01:43 PM

|

#4

|

|

Registered User

Join Date: Jun 2012

Location: Ontario,Canada

Posts: 84

|

Quote:

Originally Posted by thom4782

IIRC, 3rd generation IMS bearings, i.e., the large single row ones that Porsche began installing in 2006, almost never fail. So why do anything?

|

Almost!!

I am keeping this car for a long time,granted there have not been alot of posts that i can find with problems BUT even Porsche states in its law suit that it is a problem part even the new 06 thru 08 units which have the larger bearing which is great but not the main reason behind why thease bearing are having issues.Listen to Pedros very informative video on the subject and then lets talk turkey.

|

|

|

09-21-2013, 04:31 PM

09-21-2013, 04:31 PM

|

#5

|

|

Registered User

Join Date: Sep 2010

Location: Foster City CA

Posts: 1,099

|

If you want to talk turkey, ask the DOF folks to put an actual number on the table of how many service hours or miles one can expect DOF to add to the lifetime of unsealed IMS bearings, especially new ceramic ones. I'm sure the Boxster community would like to know.

|

|

|

09-22-2013, 06:00 AM

09-22-2013, 06:00 AM

|

#6

|

|

Registered User

Join Date: Aug 2005

Location: Sanford NC

Posts: 2,605

|

The concern with any new part is how it will hold up over time. Porsche tried 2 times to correct IMS issues and each time they only knew they failed and just how badly they failed after several years and many millions of owner driven miles. You figure they had test mules but the problems just didn't show up on their test engines.

Even the LN 3rd generation IMS replacement shaft/bearing for the '05.5-'08s has very few examples in use (less than 20 last time I asked) and it had been available for several years.

Decide if you want to be an early adopter or wait till several hundred have several years of user experience before you say "it is tested enough and I haven't seen any bad reports". And maybe wait till the installer has done a dozen?

You are trying to reduce risk...what approach is the least risky?

|

|

|

09-22-2013, 07:39 AM

09-22-2013, 07:39 AM

|

#7

|

|

Registered User

Join Date: Apr 2009

Location: Perth, Australia

Posts: 165

|

There are people on this forum who are far more mechanically-minded than myself, so I shall reserve all comments on the technical aspect of this dilemma.

I do have considerable experience in assessing risk and reward however. When it comes to insuring an event where the risk is unknown (ie. limited or inaccurate data of failure rates in this case) the only consideration is if it will be a lights-out event or if the cost is manageable. Then one decides if they should self-insure or take out a policy. The trouble in this particular case is none of these "policies" are guaranteed to pay off, sort of like taking home insurance from some guy in the Cayman Islands. Dicey at the best of times and one never knows if it is money well spent or they have been had by a charlatan until it is time to claim on the policy.

In short, if you cannot afford to deal with a blown motor, a few hundred dollars to possibly reduce this risk is PROBABLY money well spent. If you have the attitude of blowing a motor is a blessing in disguise as it will finally give you a reason to go for that 3.6 litre swap then I would be leaving the IMS bearing alone.

|

|

|

09-22-2013, 08:53 AM

09-22-2013, 08:53 AM

|

#8

|

|

Registered User

Join Date: Jun 2012

Location: Ontario,Canada

Posts: 84

|

My concern after looking at this video is if oil that part off the bearing is submersed in(maybe half) is able to penetrate the exterier seal on the bearing and eventually penetrat the inside seal make its way into the IMS shaft,get baked become acidic and eventually make its way back into the bearing again and pit the bearing races and balls causing engine death,then why would even with the DOF kit the inside seal that is permanent not be subject to the same issues as its now sitting in oil which it wasent before PLUS its now subject to up to 60 psi of oil pressure .The pressure may not be an issue as the oil does have somewere else to go so its not air pressure which it has to hold.

Thats why when i pressure test say a coolent system i only use up to 10 lbs because u run the risk of blowing a seal in the motor.So its really comes down to the original problem the seal eventually gives out and lets dirty oil in and eventuallu thru the other side off the bearing regardless if its cool filtered or not.I am still very interested in possibly doing this but need some reassurance,the post below states that its maybe worth doing but after a few more years and a couple thousand cars.I just wish the bearing that porsche installs had a permanent seal of some kind on the inner side that could never be penetrated and therefore this system would be perfect i believe.Just my 2 cents,cdn funds...

|

|

|

09-22-2013, 02:40 PM

09-22-2013, 02:40 PM

|

#9

|

|

Registered User

Join Date: Jun 2012

Location: Ontario,Canada

Posts: 84

|

yes,that seal that is not removed is the big question mark ,what if it fails.probably the reason why the 06 thru 08 bearing have not hadas many issues yet is because the bearing is much larger and therefore the seal is also thicker and stronger lasting longer but eventually the oil will penetrate it and were back to square one as i see it.

|

|

|

09-22-2013, 03:20 PM

09-22-2013, 03:20 PM

|

#10

|

|

Registered User

Join Date: Sep 2010

Location: Foster City CA

Posts: 1,099

|

The large single row bearing can carry the same or greater loads than the dual and early single row bearings respectively. So seal integrity for 2006 engines does play a bigger role. The cheapest strategy and a pretty good one seems to be just keeping the oil fresh and clean, that is change it once a year or every 5000 miles whichever comes first. Removing the outer seal is the next cheapest. And if you want to throw DOF into the mix then, just keep in mind that you'll be introducing another risk factor by changing the geometry and flow paths of the lubrication system. The most expensive route is replacing the bearing with a triple row unsealed ceramic one.

Everyone needs to do their own calculation on how much they want to pay to reduce total risk. Just keep in mind two things. Large single row bearing fail less than 1% of the time. There are many other reasons Boxster engines destroy themselves. Worn chain rails in one of them. Part of figuring what to do is figuring out where you want to spend your money. For me, it's on my worn variocam chain rails in my 100K car.

PS: If the outer seal is removed, then oil will lubricate the bearing and a leaking inner seal won't have a big impact if it has one at all.

Last edited by thom4782; 09-22-2013 at 04:04 PM.

Reason: Added PS

|

|

|

09-23-2013, 06:57 PM

09-23-2013, 06:57 PM

|

#11

|

|

Registered User

Join Date: Apr 2011

Location: DFW

Posts: 713

|

This is a interesting discussion. If the inner seal fails and oil goes pass the seal into the shaft, with more oil being pumped in, wouldn't all of that oil drain out to to crankcase at some point? After all, the oil being pumped in there has to be draining back out at some point. And with a steady flow of clean oil, wouldn't that eventually mix with the oil in the shaft to prevent any oil from catching on fire? Very good questions posted here.

Some have debated that the inner seal was in some case left open or was suppose to be left open so oil could be the source of lubrication. So if new oil is getting pumped in there, does that help flush out old oil? Don't know if it can go out the other side. Someone who has seen the shaft and how it works should be able to answer these very good questions.

By the way is this making a case for the solution which has no bearing our seals? Our does the solution operate in a way that no oil gets in the shaft?

|

|

|

09-23-2013, 07:44 PM

09-23-2013, 07:44 PM

|

#12

|

|

Registered User

Join Date: Jul 2010

Location: California

Posts: 1,859

|

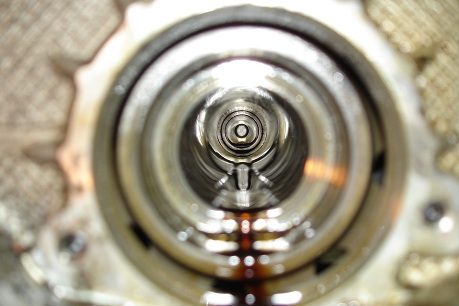

Here is a picture of my IMS when I replaced the single row bearing. There was definitely oil in the shaft and it did not look burnt. I assume the oil gets into the IMS when the motor is not running, when 1/3 of the bearing is submerged in oil (when crankcase is full).

__________________

Jäger

300K Mile Club

|

|

|

09-24-2013, 06:03 AM

09-24-2013, 06:03 AM

|

#13

|

|

Registered User

Join Date: Jun 2012

Location: Ontario,Canada

Posts: 84

|

Watch the video below,the other end off the ims (the shaft) is closed and there fore any oil that manages to penetrate the seal that has not been removed and enters into the shaft will stay there ,it may seep back into the bearing eventually while sitting for extended period off time like over the winter.Note based on this new info i believe it is more important to change your oil prior to putting the car in storage ,that is if u need to do that.That way the oil the bearing is sitting in is atleast clean with little acid which has aqumulated over the miles since your last change.Changing it out in the spring is a wrong move i believe and any moisture that has built up over the winter will be burned off in the first ride.Again i still believe for those with 06 thru 08 cars this may be be the only affordable option and i am still seriously considering it,just want a little more street time on how well it holds up.based on more study it may be that even if a little oil gets by the permenant non removed seal,and it somhow seeps back into the bearing over time it will be washed away by filtered clean cool oil.I would say that if u install the kit and u pull off the outside seal and no oil has penetrated it (still has grease inside) thrn your good to go,but if it appears tht oil has penetrated the first seal than the rear seal may be compramized and u will need to make a judgement call as that time,

|

|

|

09-29-2013, 06:40 AM

09-29-2013, 06:40 AM

|

#14

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

Yesterday I removed my IMS bearing and there was quite a bit of oil in the IMS tube. The shaft is not in the car, and yet no oil was seeping out past the bearing even though the shaft is stored in a manner such that the oil was being sealed in by the bearing end. So the IMS tube is effectively "sealed" by the bearing if the pressure between the inside of the IMS and the outside of the IMS is the same. My thought is that basic physics is at play here. Iincreased temperature in the IMS lowers the air density in the closed volume of the tube forcing air out at the bearing end. When the engine cools, the reverse happens and air, along with entrained oil enters the IMS tube. The IMS shaft is an unintentional pump which cycles once with each engine heating and cooling cycle. The only inlet and outlet to this pump is through, or around the IMS bearing, and there is not much clearance around the bearing. I'm going to drill 2 very small breather holes through the meat of the driven socket into the open shaft area to eliminate the pumping action through the bearing, and allow a small exchange of oil in the shaft. Anyone have thoughts on this?

|

|

|

09-30-2013, 07:39 AM

09-30-2013, 07:39 AM

|

#15

|

|

Registered User

Join Date: Apr 2012

Location: Riverside, CA

Posts: 1,666

|

The IMS tube is not an oven and is the same heat as all the other oil in the engine so all this talk of burnt oil in the IMS tube does not make sense.

However, stale oil that gets into the tube and stays in there for longer periods could potentially be an issue if that oil does not circulate in a reasonable amount of time.

With the DOF installed I seems like there is a greater possibility of more oil getting into the tube and "circulating" so that it hopefully does not reach a degraded acidic stage.

To me this stale oil issue is a product of not driving the car enough, infrequent oil changes or both.

Like anything new, I suppose time will tell if there are any side effects, but intuitively, with a constant supply of filtered oil washing through the bearing with the DOF I would expect much better results than any kind of bearing replacement alone, and if its driven often enough there should never be any stale oil issues with the DOF.

I like this idea better than a bearing replacement as it solves the issue that causes the bearings to fail...lack of adequate lubrication with fresh lubricant and has the added benefit of keeping that bearing at a more consistent and cooler temperature as well, which should also extend its life.

__________________

"It broke because it wants to be Upgraded  "

2012 Porsche Performance Driving School - SanDiego region

2001 Boxster S, Top Speed muffler, (Fred's) Mini Morimotto Projectors, Tarret UDP,

Short Shifter, Touch Screen Dual Din Radio, 03 4 Bow glass Top (DD & Auto-X since May 17,2012)

|

|

|

09-30-2013, 09:35 AM

09-30-2013, 09:35 AM

|

#16

|

|

Registered User

Join Date: Sep 2010

Location: Foster City CA

Posts: 1,099

|

Structural weakness is the primary reason single row bearings

fail more frequently than double row ones. DOF, without bearing replacement, doesn't help this problem.

|

|

|

09-30-2013, 12:18 PM

09-30-2013, 12:18 PM

|

#17

|

|

Registered User

Join Date: Apr 2012

Location: Riverside, CA

Posts: 1,666

|

Thom that is an important distinction which means that the Bearing upgrade AND DOF should be done together for those single row bearings as just the DOF alone in that case would not solve the issue.

Is there any data to confirm the actual cause of failure or are there multiple root causes in various cases?

Its hard to imagine that the Engineers decided to use a bearing that is not structurally sufficient for the loads encountered.

I'd sooner believe that the bearings fail for other root causes such as the acidic pitting, lack of proper lubrication, over heating etc, but I suppose human design error is also a possibility

__________________

"It broke because it wants to be Upgraded  "

2012 Porsche Performance Driving School - SanDiego region

2001 Boxster S, Top Speed muffler, (Fred's) Mini Morimotto Projectors, Tarret UDP,

Short Shifter, Touch Screen Dual Din Radio, 03 4 Bow glass Top (DD & Auto-X since May 17,2012)

|

|

|

09-30-2013, 07:20 PM

09-30-2013, 07:20 PM

|

#18

|

|

Registered User

Join Date: Sep 2010

Location: Foster City CA

Posts: 1,099

|

Data provided in the IMS class action suit indicated single row IMS bearings fail about 8% of the time whereas double row bearings fail 1% or less. Structural weakness is the best explanation for the difference in failure rates with all things being equal except the 1) the relative amount of contact surface areas of the balls and races of the two designs and 2) IIRC the thickness of the bearing support,

Even the dual row bearings, however, do fail so structural weakness cannot explain all failures. I believe compromised lubrication probably explains a lot of the rest and the 1% underlying rate. This phenomena happens when acids and particulates in engine oil causes bearing seal degradation that allows oil to mix with the bearing's grease. The combination lubricates very poorly and after some time the bearing fails.

|

|

|

10-10-2013, 02:36 PM

10-10-2013, 02:36 PM

|

#19

|

|

Registered User

Join Date: Nov 2005

Location: Florida

Posts: 529

|

I don't agree ...

Quote:

Originally Posted by thom4782

Structural weakness is the primary reason single row bearings

fail more frequently than double row ones. DOF, without bearing replacement, doesn't help this problem.

|

... that they fail because of structural weakness.

The reason, IMNSHO why they fail sooner than a double-row or the larger single row is because they have less surface area (between the ball and the race) and when the acid in the burnt oil starts to pit the surface it will fail sooner.

The bearing itself is strong enough to sustain all of the loads the engine will subject it to.

The problem, once more is the lack of proper lubrication.

YMMV.

Happy Boxstering,

Pedro

__________________

Racecar spelled backwards is: Racecar!

|

|

|

10-10-2013, 05:38 PM

10-10-2013, 05:38 PM

|

#20

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

|

fail sooner than a double-row or the larger single row is because they have less surface area (between the ball and the race)

|

This supports our point of view, that the problem IS the bearing.

And of course, there's still one very important fact concerning the 6204 bearing that no one has thought of, and its critical. Those who have attended my class know what it is, and they have held the bearing in their hand and manipulated it in two ways, then observed this critical factor. This is something I only share one on one and will never post anywhere. I am considered putting it into print in my M96 Engine Bible, but haven't made my mind up yet.

That single factor is what makes the difference. Every single Bearing Engineer we have consulted with has brought the point up, but we considered it before they did.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 06:53 AM.

| |