05-07-2025, 10:13 AM

05-07-2025, 10:13 AM

|

#581

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Okay, I'm confused now. I understand that Loctite on flywheels and pressure plate bolts is advisable, but what about using ARP lubricant and/or blue Loctite on cam caps and camshaft cover bolts, which I will be dealing with right away, and on sump cover bolts later?

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

|

|

|

05-07-2025, 10:19 AM

05-07-2025, 10:19 AM

|

#582

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

And if you kids don't settle down, I'm going to send your father in.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

|

|

|

05-07-2025, 10:40 AM

05-07-2025, 10:40 AM

|

#583

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

Quote:

Originally Posted by LoneWolfGal

Okay, I'm confused now. I understand that Loctite on flywheels and pressure plate bolts is advisable, but what about using ARP lubricant and/or blue Loctite on cam caps and camshaft cover bolts, which I will be dealing with right away, and on sump cover bolts later?

|

As I noted previously, a dab of blue Loctite on the treads of both the flywheel and pressure plate bolts is advised, plus an application of the ARP lubricant on just the underside of the flywheel bolt heads. I would also use a dab (don't go nuts here) of the ARP on the cam shaft cap bolts. As for both the cam cover and sump cover, a small dab of the ARP is fine, again don't over apply it; I would not use any thread locker on either of these because the bolts are rather small and the use of a thread locker could lead to bolt breakage if furhter maintence is required down the road. This is exactly how we reassemble customer's engines, and we have not had any issues as the result of these practices.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

05-07-2025, 10:49 AM

05-07-2025, 10:49 AM

|

#584

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

Quote:

Originally Posted by LoneWolfGal

And if you kids don't settle down, I'm going to send your father in.

|

No problems here, I just take exception to anyone misquoting or misinterpeting any advice we post, or extrapolating failures from well known problems to every and all applications. Just because one engine design is known to have significant and well known issues, the same thing does not necessarily apply everywhere else.

To again use a legal maxim, "non sequitur"..........

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

05-07-2025, 10:57 AM

05-07-2025, 10:57 AM

|

#585

|

|

Registered User

Join Date: Jan 2019

Location: PA

Posts: 1,726

|

Quote:

Originally Posted by JFP in PA

ALLDATA says "suitable lubricating oil", which is EXACTLY what ARP assembly lube is.

From my post, which you here totally misrepresent, "You definitely want a dot of blue Loctite on the threads of both the pressure plate and flywheel bolts, but a coating of this product underneath the heads of the flywheel bolts makes cranking them to their final +90 degrees after torquing one heck of a lot easier....." Nowhere in this post do I even remotely suggest using mixing or using both on the same surfaces.

"Nam ipsa loquitur" to use a long standing legal maxim...............

|

To.which I replied, "True, but it seems she was talking about lubing the bolts the same way she would lube the compression tool, given she said she bought the product you suggested to lube the threads of the tool, as you suggested.

Now, putting a dab of assembly lube on the inside head of the bolt where it contacts the flywheel and the pressure plate,is definitely a good idea for proper torqueing. But you certainly do not want that on the threads.

And later you replied "This one of many reasons why we always "chase" every threaded opening in an engine case before assembly, and use a small dab of ARP thread lubricant when assembling. Consistency matters."

I'd imagine at least SOME of those "thread openings" require loctite.

So if you never specifically said you use loctite and lube on the same threads, one can surelt get that impression. Consistency matters, and so does clarity.

And going back to ALLDATA, they need to change their manuals, because Subaru specifically says "Engine oil" on the head bolt heads and threads, so the ONLY "suitable lubricating oil" is engine oil, not assembly lube.

Last edited by piper6909; 05-07-2025 at 11:00 AM.

|

|

|

05-07-2025, 11:21 AM

05-07-2025, 11:21 AM

|

#586

|

|

Registered User

Join Date: Jan 2019

Location: PA

Posts: 1,726

|

Quote:

Originally Posted by JFP in PA

... or extrapolating failures from well known problems to every and all applications. Just because one engine design is known to have significant and well known issues, the same thing does not necessarily apply everywhere else.

To again use a legal maxim, "non sequitur"..........

|

Speaking of misquoting, I never said or implied anything of the sort.

|

|

|

05-07-2025, 11:38 AM

05-07-2025, 11:38 AM

|

#587

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Girls! Girls! You're BOTH pretty!

Seriously, seeing two of the most knowledgeable and respected people on the forum at odds is like watching King Kong versus Godzilla. And I'm out of popcorn!

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

|

|

|

05-07-2025, 12:27 PM

05-07-2025, 12:27 PM

|

#588

|

|

Registered User

Join Date: Jan 2019

Location: PA

Posts: 1,726

|

Quote:

Originally Posted by LoneWolfGal

Girls! Girls! You're BOTH pretty!

Seriously, seeing two of the most knowledgeable and respected people on the forum at odds is like watching King Kong versus Godzilla. And I'm out of popcorn!

|

Thanks for the vote of confidence but Jeff is hands down one of, if not the most knowledgeable person on here, and 100 times more knowledgeable than I, especially when it comes to porsches and have a great deal of respect for him. There are, however, times when dealing with laymn like myself and others a little more clarification would help. Not just "get the right part" or "your updated replacement engine is exactly the same as your original engine" and, in this particular case, saying I was wrong for telling you not to use assembly Lube on the flywheel and pressure plate bolt threads.

In the end, we both agreed that you shouldn't use assembly lube on threads where loctite is required, and that's the important takeaway.

Last edited by piper6909; 05-07-2025 at 12:30 PM.

|

|

|

05-07-2025, 02:17 PM

05-07-2025, 02:17 PM

|

#589

|

|

Registered User

Join Date: Dec 2009

Location: Orange County, CA

Posts: 2,016

|

Quote:

Originally Posted by LoneWolfGal

Girls! Girls! You're BOTH pretty!

|

Hahaha..

|

|

|

05-16-2025, 08:11 PM

05-16-2025, 08:11 PM

|

#590

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Another change in plans. Bank 1's cam chain pads are installed, the cams are back in place, and the cam cover has been bolted on. The engine's ready for transport. I had intended to finish the engine — install bank 2's pads and replace some miscellaneous stuff — before I made the move to my new place. However, the house I've been renting is on the market and the sellers are leaning on me to move out ASAP. This project is difficult enough without people breathing down my neck. I could play hardball and tell them to pound sand until July 9, the move-out date in the notice they sent me a month ago. That would be pointless. I'm going to rent an auto-hauler trailer from U-Haul for the 986 and a large covered trailer for the new engine (plus my tools and other possessions). The engine will travel strapped to a 4x4 pallet with 4" wheels (which make it relatively easy to move around on level surfaces). Once I get settled at my new digs I shall resume this project, free of pressure from external forces. In the meantime I'll be checking in here.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 07-27-2025 at 07:15 PM.

|

|

|

05-18-2025, 10:39 AM

05-18-2025, 10:39 AM

|

#591

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

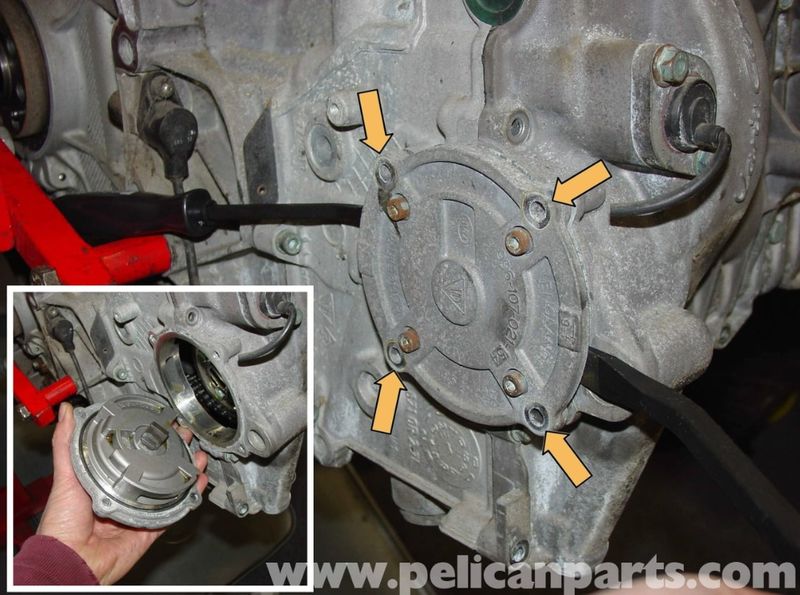

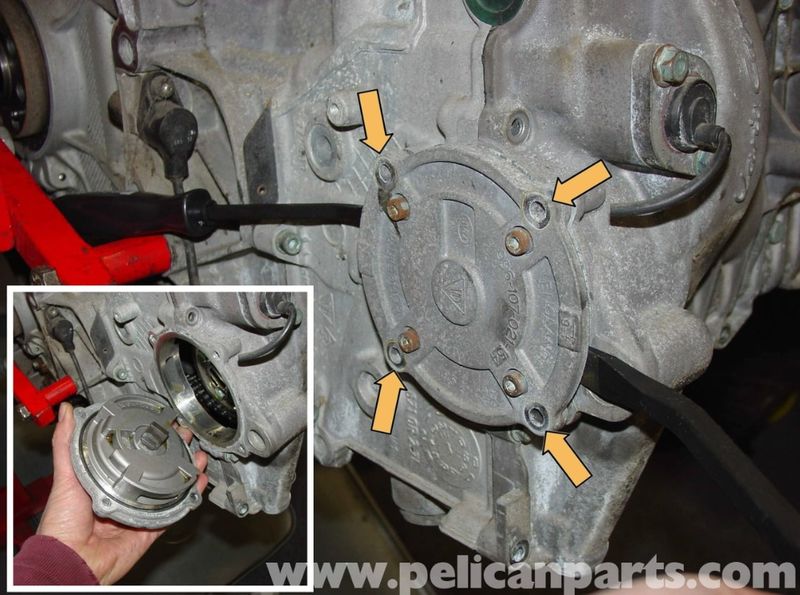

Just a note about the oil scavenge pump... I don't understand why so many how-to articles and videos insist that preserving the pump's orientation using a marker is a must, when the pump's orientation is cast into the face — 1-3 for bank 1, 4-6 for bank 2. As long as the cast numbers on the left side (inside) correspond to that bank's cylinder numbers, it's impossible to make a mistake and mount it upside down. Here's a photo from Pelican's technical article, although the article makes no mention of the cast numbers (which are hard to see in the photo):

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 05-18-2025 at 11:24 AM.

|

|

|

05-18-2025, 01:47 PM

05-18-2025, 01:47 PM

|

#592

|

|

Registered User

Join Date: Jan 2019

Location: PA

Posts: 1,726

|

Quote:

Originally Posted by LoneWolfGal

Just a note about the oil scavenge pump... I don't understand why so many how-to articles and videos insist that preserving the pump's orientation using a marker is a must, when the pump's orientation is cast into the face — 1-3 for bank 1, 4-6 for bank 2. As long as the cast numbers on the left side (inside) correspond to that bank's cylinder numbers, it's impossible to make a mistake and mount it upside down. Here's a photo from Pelican's technical article, although the article makes no mention of the cast numbers (which are hard to see in the photo):

|

Good observation, except on bank 2 the 4-6 stamp would still be on the right, but inside, correct? If that's the case, then both sides are mounted in the same orientation? Yes, the numbers would make a good reference.

But the instructions should be better than "install the same way you took it out" in the event someone was in there before you and reinstalled it upside-down. For example, does the indented rectangle in the inner circle of the outside cover point up on both? If so, that could be another reference. Or, perhaps more importantly given they evidently come apart, the notch on the INSIDE part that meets the cam (shown in smaller picture facing the installer's thumb) would be the best reference.

There's a thread on this:

https://986forum.com/forums/boxster-general-discussions/65231-scavenging-pump-orientation.html

Post #4 by RodJ shows a diagram with 1-3 stamp on the inside (towards crank) and the arrows pointing down for bank 1, and the next post says 4-6 towards the crankshaft for bank 2. (so they are actually both oriented the same way)

Not sure why the Pelican article didn't mention the stamp numbers or arrows. Seems to me it would be simplest to say "the arrows are supposed to point down on both banks"

__________________

2002 Boxster Base - Arctic Silver - Tiptronic

2010 Subaru Forester

1980 Ford C-8000 Custom Cab Emergency-One Fire Truck

__________________

"I never lose. I either win or I learn." -Nelson Mandela

Last edited by piper6909; 05-18-2025 at 02:02 PM.

|

|

|

05-18-2025, 02:33 PM

05-18-2025, 02:33 PM

|

#593

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by piper6909

Good observation, except on bank 2 the 4-6 stamp would still be on the right, but inside, correct? If that's the case, then both sides are mounted in the same orientation? Yes, the numbers would make a good reference.

But the instructions should be better than "install the same way you took it out" in the event someone was in there before you and reinstalled it upside-down. For example, does the indented rectangle in the inner circle of the outside cover point up on both? If so, that could be another reference. Or, perhaps more importantly given they evidently come apart, the notch on the INSIDE part that meets the cam (shown in smaller picture facing the installer's thumb) would be the best reference.

There's a thread on this:

https://986forum.com/forums/boxster-general-discussions/65231-scavenging-pump-orientation.html

Post #4 by RodJ shows a diagram with 1-3 stamp on the inside (towards crank) and the arrows pointing down for bank 1, and the next post says 4-6 towards the crankshaft for bank 2. (so they are actually both oriented the same way)

Not sure why the Pelican article didn't mention the stamp numbers or arrows. Seems to me it would be simplest to say "the arrows are supposed to point down on both banks" |

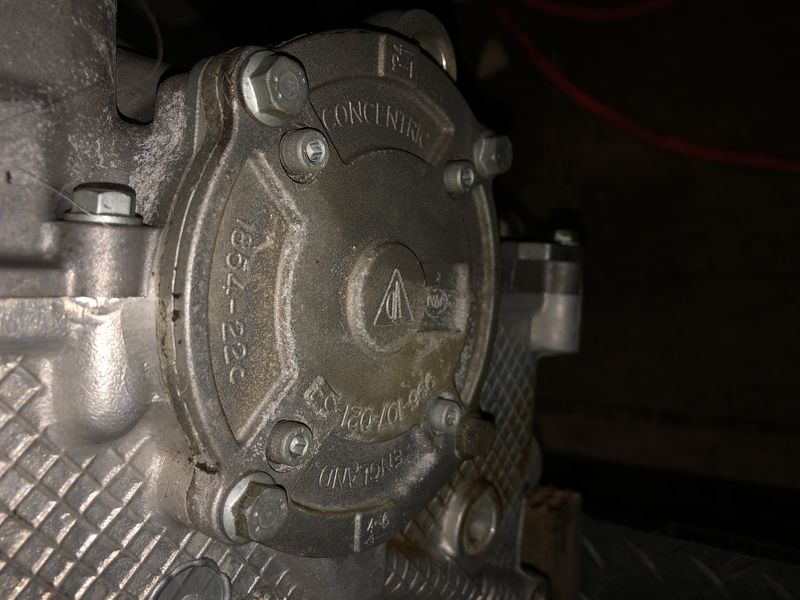

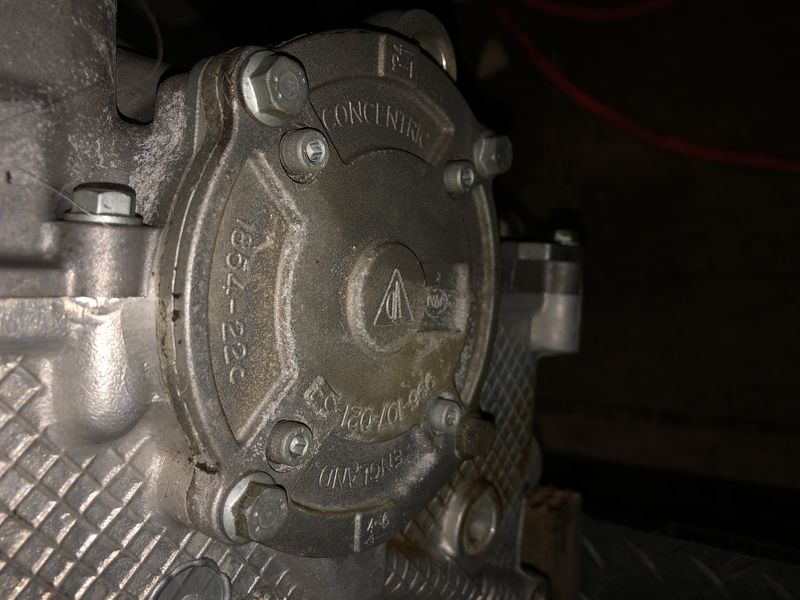

Bank 2's pump is installed upside down in relation to bank 1's, so the number placement is reversed, 4-6 on the left, toward the crankshaft. Note that the rectangular indentation next to the center of the casting is on the top for bank 1, the bottom for bank 2:

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

|

|

|

05-18-2025, 02:49 PM

05-18-2025, 02:49 PM

|

#594

|

|

Registered User

Join Date: Jan 2019

Location: PA

Posts: 1,726

|

Quote:

Originally Posted by LoneWolfGal

Bank 2's pump is installed upside down in relation to bank 1's, so the number placement is reversed, 4-6 on the left, toward the crankshaft. Note that the rectangular indentation next to the center of the casting is on the top for bank 1, the bottom for bank 2:

|

Du'h! I forgot that they're on opposite ends of the engine! Yes, that makes sense. Arrows point DOWN for bank 2. I guess it's easiest to remember what Gelbster in post #5 from the same link says:

"AS I said, forget the ports.You'll get muddled. Use the markings on the face- per the FSM. If Bank 1 the 1-3 marking faces/closest to the c/s

If Bank 2 4-6 faces the c/s."

__________________

2002 Boxster Base - Arctic Silver - Tiptronic

2010 Subaru Forester

1980 Ford C-8000 Custom Cab Emergency-One Fire Truck

__________________

"I never lose. I either win or I learn." -Nelson Mandela

Last edited by piper6909; 05-18-2025 at 02:56 PM.

|

|

|

05-20-2025, 06:10 AM

05-20-2025, 06:10 AM

|

#595

|

|

Registered User

Join Date: Sep 2006

Location: Omaha

Posts: 2,959

|

Quote:

Originally Posted by LoneWolfGal

but I'll listen to a convincing argument why I should.

|

Assuming the engine isn't in yet, you'll never have easier access to those ancillary items. Would suck to put the engine in, then 2 mo from now the water pump goes out. It becomes a balancing act of how much you can budget for those extras, the odds of an old part failing, and the ease of being able to get to it if the engine is in the car. These projects rarely come in under budget, so the 'while you're in there's' always hurt the wallet but might be worth it if you have easy access to them with the engine out.

I had just replaced the front engine mount and my clutch had plenty of meat left on it, so I didn't replace those items. Was glad I replaced the injectors as those were much easier with the engine out and this was on my Cayman - would be more difficult on a Box. I didn't need to change the WP as it was new on my rebuilt engine. Bottom line, I didn't need to spend a lot of aux items, but swapping in a used engine into a more confined area of a Box brings more of them into the equation.

__________________

GPRPCA Chief Driving Instructor

2008 Boxster S Limited Edition #005

2008 Cayman S Sport - Signal Green

1989 928 S4 5 spd - black

|

|

|

05-20-2025, 10:32 AM

05-20-2025, 10:32 AM

|

#596

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by husker boxster

Assuming the engine isn't in yet, you'll never have easier access to those ancillary items. Would suck to put the engine in, then 2 mo from now the water pump goes out. It becomes a balancing act of how much you can budget for those extras, the odds of an old part failing, and the ease of being able to get to it if the engine is in the car. These projects rarely come in under budget, so the 'while you're in there's' always hurt the wallet but might be worth it if you have easy access to them with the engine out.

I had just replaced the front engine mount and my clutch had plenty of meat left on it, so I didn't replace those items. Was glad I replaced the injectors as those were much easier with the engine out and this was on my Cayman - would be more difficult on a Box. I didn't need to change the WP as it was new on my rebuilt engine. Bottom line, I didn't need to spend a lot of aux items, but swapping in a used engine into a more confined area of a Box brings more of them into the equation.

|

Good points, H.B. Besides the parts I've already replaced, including the IMS bearing, rear main seal, and cam chain tensioner pads (almost finished), I plan to replace a number of other items, including motor and transmission mounts and clutch disc, pressure plate, and throwout bearing, as well as various and sundry other things forum members have recommended.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 05-22-2025 at 08:37 PM.

|

|

|

05-25-2025, 06:46 PM

05-25-2025, 06:46 PM

|

#597

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

The almost-finished engine's ready to be covered with a 6x6 tarp and strapped onto the pallet with heavy-duty rachet straps for transport. The pallet's beefy 4" wheels each have a brake, which in addition to securing with ropes to the wall hooks will keep it immobile inside the trailer. I hope. It was a challenge wrestling that 500 lb. engine onto the pallet by myself using the cherry picker. My helpers were otherwise engaged. Hope they're around when I pull the pallet up the trailer's ramp with my come-along, but if not I'm perfectly capable of handling it solo. I hope.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 05-25-2025 at 07:41 PM.

|

|

|

05-26-2025, 01:31 PM

05-26-2025, 01:31 PM

|

#598

|

|

Registered User

Join Date: Jan 2019

Location: PA

Posts: 1,726

|

Quote:

Originally Posted by LoneWolfGal

The almost-finished engine's ready to be covered with a 6x6 tarp and strapped onto the pallet with heavy-duty rachet straps for transport. The pallet's beefy 4" wheels each have a brake, which in addition to securing with ropes to the wall hooks will keep it immobile inside the trailer. I hope. It was a challenge wrestling that 500 lb. engine onto the pallet by myself using the cherry picker. My helpers were otherwise engaged. Hope they're around when I pull the pallet up the trailer's ramp with my come-along, but if not I'm perfectly capable of handling it solo. I hope.

|

I'm surprised you didn't go out and buy a forklift.

__________________

2002 Boxster Base - Arctic Silver - Tiptronic

2010 Subaru Forester

1980 Ford C-8000 Custom Cab Emergency-One Fire Truck

__________________

"I never lose. I either win or I learn." -Nelson Mandela

|

|

|

05-26-2025, 07:41 PM

05-26-2025, 07:41 PM

|

#599

|

|

Registered User

Join Date: Dec 2009

Location: Orange County, CA

Posts: 2,016

|

Quote:

Originally Posted by LoneWolfGal

The almost-finished engine's ready to be covered with a 6x6 tarp and strapped onto the pallet with heavy-duty rachet straps for transport. The pallet's beefy 4" wheels each have a brake, which in addition to securing with ropes to the wall hooks will keep it immobile inside the trailer. I hope. It was a challenge wrestling that 500 lb. engine onto the pallet by myself using the cherry picker. My helpers were otherwise engaged. Hope they're around when I pull the pallet up the trailer's ramp with my come-along, but if not I'm perfectly capable of handling it solo. I hope.

|

Can you get near the truck gate's required height with the cherry picker?

|

|

|

05-26-2025, 11:44 PM

05-26-2025, 11:44 PM

|

#600

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by Gilles

Can you get near the truck gate's required height with the cherry picker?

|

It will be a covered trailer, not a truck. The cherry picker would be my choice if the engine wasn't already covered by a 6x6 tarp and then strapped securely to the pallet. The chain with which I was lifting the engine is under the tarp. I suppose I could rig up another strap setup around the pallet for the cherry picker, but pulling it up the ramp on its wheels seems easier.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 05-27-2025 at 12:23 PM.

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 06:53 AM.

| |