11-10-2024, 01:18 PM

11-10-2024, 01:18 PM

|

#181

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by 78F350

Someone else can comment on that bolt, but I always have the engine mount bolted to the engine. If I need to attach to it, I run a nylon strap (scrap seat belt) around the frame of the mount and chain onto that.

|

I think I'll follow your lead and bolt the engine-mounting bracket to the engine before installing it. Thanks for the idea. In any case, there's a good chance I'll end up at least replacing the motor mount's bushing, since rubber deteriorates over time. While I'm at it, I might as well also replace the manual transmission's mounts, for the same reason. I want my 986 to be as vibration-free as possible. I once rode in one that almost vibrated the fillings out of my teeth.

7 pm addition: After reading about the travails of pressing a new rubber bushing into an existing engine mount, I think I'll just save time and grief by buying a whole new mount with bushing already installed, seeing as how they're fairly reasonably priced.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 11-16-2024 at 07:56 PM.

|

|

|

11-16-2024, 04:07 AM

11-16-2024, 04:07 AM

|

#182

|

|

Registered User

Join Date: Sep 2022

Location: Noblesville, IN

Posts: 12

|

Engine swaps

These guys have a great reputation for rebuilt engines.

https://www.amsporsche.com/

Looking at a 3.4 fully rebuilt. $13,300 shipped to the US

|

|

|

11-16-2024, 10:43 AM

11-16-2024, 10:43 AM

|

#183

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by 986RennWagen

These guys have a great reputation for rebuilt engines.

https://www.amsporsche.com/

Looking at a 3.4 fully rebuilt. $13,300 shipped to the US |

When price is no object...

Nevertheless, it'll be pretty great to have a zero-time engine behind you, so more power to you. Literally.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 11-16-2024 at 07:59 PM.

|

|

|

11-17-2024, 06:23 AM

11-17-2024, 06:23 AM

|

#184

|

|

Registered Member

Join Date: Oct 2022

Location: NJ

Posts: 221

|

Quote:

Originally Posted by LoneWolfGal

I think I'll follow your lead and bolt the engine-mounting bracket to the engine before installing it. Thanks for the idea. In any case, there's a good chance I'll end up at least replacing the motor mount's bushing, since rubber deteriorates over time. While I'm at it, I might as well also replace the manual transmission's mounts, for the same reason. I want my 986 to be as vibration-free as possible. I once rode in one that almost vibrated the fillings out of my teeth.

7 pm addition: After reading about the travails of pressing a new rubber bushing into an existing engine mount, I think I'll just save time and grief by buying a whole new mount with bushing already installed, seeing as how they're fairly reasonably priced.

|

Yup. Been there, done that. Except I had to learn the hard way…

__________________

Tom Coradeschi

03 Boxster

|

|

|

12-03-2024, 07:05 PM

12-03-2024, 07:05 PM

|

#185

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

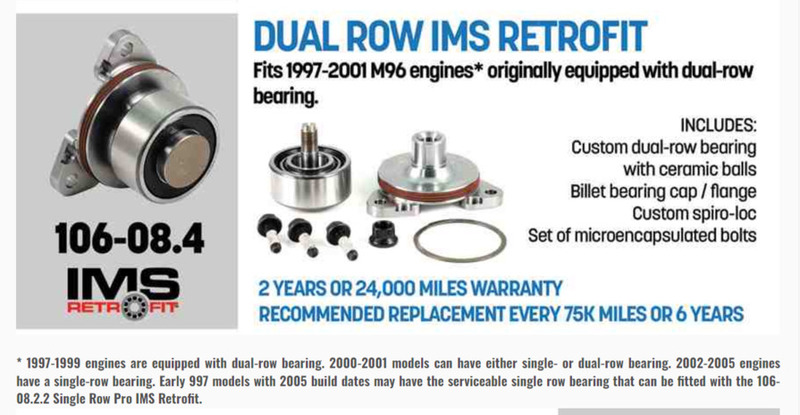

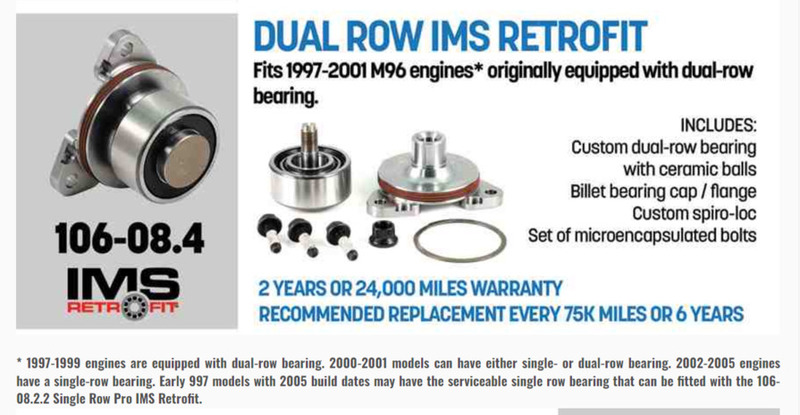

Still haven't made a decision about which IMS bearing to install in the new engine, but I noted that LN's prices for their ceramic-bearing Retrofits have been reduced from $999 to $799. And apparently they supply new flanges with the bearings. Anyone know why this is? I had assumed the existing flange would be usable. At any rate, LN's pricing is headed in the right direction.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 12-03-2024 at 07:08 PM.

|

|

|

12-04-2024, 03:17 AM

12-04-2024, 03:17 AM

|

#186

|

|

Registered Member

Join Date: Oct 2022

Location: NJ

Posts: 221

|

Quote:

Originally Posted by LoneWolfGal

Still haven't made a decision about which IMS bearing to install in the new engine, but I noted that LN's prices for their ceramic-bearing Retrofits have been reduced from $999 to $799. And apparently they supply new flanges with the bearings. Anyone know why this is? I had assumed the existing flange would be usable. At any rate, LN's pricing is headed in the right direction.

|

Currently at $495 for either single or double row on their sale page

https://lnengineering.com/sale.html

EDIT (can’t delete) - not the same items you are look8ng at.

__________________

Tom Coradeschi

03 Boxster

Last edited by tcoradeschi; 12-04-2024 at 03:20 AM.

|

|

|

12-04-2024, 08:33 AM

12-04-2024, 08:33 AM

|

#187

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,657

|

Quote:

Originally Posted by LoneWolfGal

Still haven't made a decision about which IMS bearing to install in the new engine, but I noted that LN's prices for their ceramic-bearing Retrofits have been reduced from $999 to $799. And apparently they supply new flanges with the bearings. Anyone know why this is? I had assumed the existing flange would be usable. At any rate, LN's pricing is headed in the right direction.

|

LN has always replaced the flange because they use a larger and stronger center bolt than the factory did. And LN always has a sale around Thanksgiving every year.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

12-09-2024, 02:17 PM

12-09-2024, 02:17 PM

|

#188

|

|

Registered User

Join Date: Jan 2007

Location: BC

Posts: 1,354

|

Quote:

Originally Posted by JFP in PA

So, after belittling and denying the R&D development of a former helicopter mechanic working out of a converted chicken coop in the woods of GA, and a very creative machinist with a small machine shop in IL, the almighty elves in the Black Forest came to realize that they both had the optimum IMS bearing fix procedures and parts, now making the elves customers of these two guys. Pure automotive karma............

|

Priceless. 😂

A little late to the party on this thread, but this JFP gem made my week.

__________________

2001 Boxster, 5 spd, Seal Grey

|

|

|

12-10-2024, 07:06 AM

12-10-2024, 07:06 AM

|

#189

|

|

Registered User

Join Date: Sep 2018

Location: Illinois

Posts: 320

|

Well, JFP is a treasure!

Now if he could work his magic on my Cayenne Turbo...

__________________

A cynic is a man who, when he smells flowers, looks around for a coffin.

-H. L. Mencken

|

|

|

12-10-2024, 07:33 PM

12-10-2024, 07:33 PM

|

#190

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Had a chance to ride shotgun to Safeway and back in a 718, a 2021* model. No denying it, it was a lovely machine. As well it should be, considering it had an $90K+ price tag in '21. The interior made my humble 986 look positively spartan. One thing I noticed right off the bat was the exhaust note. There's something about the sound of the 986's naturally aspirated flat six. It's music to the ears. The 718's turbo-charged four sounded refined and almost polite. And truth be told, I really don't think the stylings of the later-model Boxsters were an improvement over Grant Larson's exterior design for the 986. The 718's jutting, angular front-end treatment and trick taillights are wrong notes in a symphony. I did not share these opinions with the guy who owned the 718.

Back to the question of which IMS bearing will replace the one in the new engine. After thoroughly exploring alternatives, I've made a decision, and here's how it came about. First, I considered a stock bearing with steel balls, either an OEM bearing or one such as this from 123Bearing ( https://www.123bearing.com/bearing-housing/deep-groove-bearing/double-row/bd20-17-a-ddua17nx01-nsk#container-tech-schema). In either case, I would have removed the outer seal so that oil from the sump could lubricate it, and hoped for the best. The price is certainly right, especially 123Bearing's. But I kept coming back to LN Engineering's hybrid-ceramic IMS Retrofit. Here's what LN has to say about their product:

"The IMS Retrofit uses an open bearing (no grease seal), [to] allow engine oil to freely enter and exit the bearing. The ceramic hybrid bearing used in all IMS Retrofit kits require minimal oiling, far exceeded by oil in the engine’s 'integrated dry sump.'" [Emphasis mine]

LN also stated:

" Forced oiling of a ball or roller IMS bearing does not provide any benefit as the bearing does not require or benefit from additional oil. Lubrication alone is not the problem." [Emphasis mine]

LN sold me on the Retrofit, although in so doing they eliminated from my consideration their expensive, forced-oiling IMS Solution. (That, and the fact that they priced it out of my reach. Even the Retrofit is pushing the boundary of my financial reach. In fact, it will have to wait until after Christmas.) Anyway, the hand wringing is at an end. I choose the Retrofit.

Only one thing can make me reconsider: an email reply from 123Bearing that says, "We have decided your suggestion that we offer a reasonably priced ceramic-hybrid IMS bearing for the Porsche 986 has merit. We agree the product will sell like hotcakes, and therefore we are putting it into production without delay."

*EDIT: I apparently misunderstood when 718 Guy told me the year of his car. He meant the 718 line was introduced in 2016, but his was a 2021.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 12-12-2024 at 09:48 AM.

|

|

|

12-13-2024, 02:12 PM

12-13-2024, 02:12 PM

|

#191

|

|

Registered User

Join Date: Sep 2018

Location: Illinois

Posts: 320

|

LoneWolfGal, I think you misunderstand the Solution.

It is a plain bearing as those on your crankshaft, so it certainly needs an oil feed!

Any other replacement is still on the clock, and will need to be replaced periodically. I think LN even says this in the description.

The "Solution" is supposed to be a permanent fix, which is obviously cheaper if you keep the car for a long time.

I have purchased one, but my plan is to use the ball bearing version on the one I'm rebuilding now, and using the Solution for the next one which gets the Nickies treatment.

__________________

A cynic is a man who, when he smells flowers, looks around for a coffin.

-H. L. Mencken

|

|

|

12-14-2024, 10:52 PM

12-14-2024, 10:52 PM

|

#192

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by Newsguy

LoneWolfGal, I think you misunderstand the Solution.

It is a plain bearing as those on your crankshaft, so it certainly needs an oil feed!

Any other replacement is still on the clock, and will need to be replaced periodically. I think LN even says this in the description.

The "Solution" is supposed to be a permanent fix, which is obviously cheaper if you keep the car for a long time.

I have purchased one, but my plan is to use the ball bearing version on the one I'm rebuilding now, and using the Solution for the next one which gets the Nickies treatment.

|

After researching them in depth, I believe I understand the options, including the Solution. If cost were no object, I would choose the Solution, based on respect for JFP's full-throated endorsement and for Jake Raby's technical prowess. But Raby also designed the ceramic-hybrid Retrofit, my second choice. At the very least, did you not find the excerpts I quoted from LN Engineering's website cause for thoughtful reflection? One would assume LN knows what they're talking about, don't you agree?

-30-

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 12-14-2024 at 11:16 PM.

|

|

|

12-15-2024, 07:10 AM

12-15-2024, 07:10 AM

|

#193

|

|

Registered User

Join Date: Sep 2018

Location: Illinois

Posts: 320

|

That is exactly the point.

They say the replacement is only good for a specific interval.

From LN:

Roller bearings, like ball bearings, will have service intervals, requiring future replacement, even if manufacturers claim otherwise. The only IMS replacement that is permanent and does not require future servicing is the IMS Solution which is based on the oil pressure fed plain bearing design used by Porsche for the Mezger engine's intermediate shaft.

And:

It is best practice to replace the IMS bearing as part of regular preventative maintenance. Depending on what bearing technology is used, service intervals can vary greatly, with the IMS Solution's oil fed plain IMS bearing is considered the best solution to prevent IMS bearing failures.

Personally, I prefer one and done.

I'm deep enough in this engine that I do not wish to be doing this work again on a regular basis.

__________________

A cynic is a man who, when he smells flowers, looks around for a coffin.

-H. L. Mencken

|

|

|

12-15-2024, 08:17 AM

12-15-2024, 08:17 AM

|

#194

|

|

Registered User

Join Date: Jan 2019

Location: PA

Posts: 1,726

|

Quote:

Originally Posted by Newsguy

That is exactly the point.

They say the replacement is only good for a specific interval.

From LN:

Roller bearings, like ball bearings, will have service intervals, requiring future replacement, even if manufacturers claim otherwise. The only IMS replacement that is permanent and does not require future servicing is the IMS Solution which is based on the oil pressure fed plain bearing design used by Porsche for the Mezger engine's intermediate shaft.

And:

It is best practice to replace the IMS bearing as part of regular preventative maintenance. Depending on what bearing technology is used, service intervals can vary greatly, with the IMS Solution's oil fed plain IMS bearing is considered the best solution to prevent IMS bearing failures.

Personally, I prefer one and done.

I'm deep enough in this engine that I do not wish to be doing this work again on a regular basis.

|

LN guarantees the "solution" for 5 years, and that's only if you have it installed by one of their certified shops. You can find replacement engines for less than what that would cost. There are DIYers who will have no problem with replacing the bearing while they replace the clutch.

You say you put nickies and you have a lot invested in your engine so the solution is the perfect choice for you. But that doesn't mean it's the perfect choice for everybody.

I think LoneWolfGal did her research, she fully understands the options, and made the best choice for her. I will look forward to reading her updates on the project.

|

|

|

12-15-2024, 10:48 AM

12-15-2024, 10:48 AM

|

#195

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by Newsguy

That is exactly the point.

They say the replacement is only good for a specific interval.

From LN:

Roller bearings, like ball bearings, will have service intervals, requiring future replacement, even if manufacturers claim otherwise. The only IMS replacement that is permanent and does not require future servicing is the IMS Solution which is based on the oil pressure fed plain bearing design used by Porsche for the Mezger engine's intermediate shaft.

And:

It is best practice to replace the IMS bearing as part of regular preventative maintenance. Depending on what bearing technology is used, service intervals can vary greatly, with the IMS Solution's oil fed plain IMS bearing is considered the best solution to prevent IMS bearing failures.

Personally, I prefer one and done.

I'm deep enough in this engine that I do not wish to be doing this work again on a regular basis.

|

The dueling excerpts. At the very least, LN's website contains contradictory information. A person who does her own wrenching is in a different position than folks who have it done for them. PIper6909 made a telling point about LN's requirement that the Solution be installed by a certified Porsche shop to qualify for their limited, five-year warranty. That would cost probably three to four grand, parts and labor. An individual's financial means factors heavily into the equation. I shelled out $4200 (including shipping), for a low-miles engine. Am I going to blow almost another two grand on the Solution when I can't install it myself without voiding the warranty?! Not bloody likely! I've heard nothing but good things about ceramic-hybrid bearings. Even Porsche guru JFP, whose credibility is beyond reproach, has gone on record in this forum with his approval of LN's Retrofit. That's good enough for me.

-30-

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 12-17-2024 at 01:00 PM.

|

|

|

12-17-2024, 11:53 AM

12-17-2024, 11:53 AM

|

#196

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

I've been studying a series of videos featuring Jake Raby, particularly one in which he demonstrates how to replace the IMS bearing and rear main seal. Raby is a fount of knowledge when it comes to Porsche engines, much of it esoteric. He mentioned in passing other parts that were candidates for replacement while the engine was out of the car:

oil pressure sending unit

oil pressure sensor (same as previous?)

fuel pressure regulator

rollers for belt

hose clamps

release bearing

air-oil separator (AOS)

crankshaft position sensor

positive crankcase ventilation conduits

grounding strap

VarioCam ramps

timing chain

cam chain guide ramps

slave cylinder on transmission

exhaust clamps

His recommendations were for the 99,000-mile demo engine in the video. Given that my new engine has only 39,000 miles on it, I wasn't planning to replace many parts beyond the IMS bearing and probably the rear main seal. However, replacing some of the parts in Raby's list makes sense to me. I would greatly appreciate additional advice about this, with my engine's relatively low miles in mind.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 12-26-2024 at 09:00 AM.

|

|

|

12-17-2024, 12:50 PM

12-17-2024, 12:50 PM

|

#197

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,657

|

Quote:

Originally Posted by LoneWolfGal

I've been studying a series of videos featuring Jake Raby that demonstrate how to replace the iMS bearing and rear main seal. Raby is a fount of knowledge when it comes to Porsche engines, much of it esoteric. He mentioned in passing other parts that were candidates for replacement while the engine was out of the car:

oil pressure sending unit

oil pressure sensor (same as previous?)

fuel pressure regulator

rollers for belt

hose clamps

release bearing

air-oil separator (AOS)

crankshaft position sensor

positive crankcase ventilation conduits

grounding strap

VarioCam ramps

timing chain

cam chain guide ramps

slave cylinder on transmission

exhaust clamps

His recommendations applied to the 88,000-mile demo engine in the video. Given that my new engine has only 39,000 miles on it, I wasn't planning to replace many parts beyond the IMS bearing and probably the rear main seal. However, replacing some of the parts in Raby's list makes sense to me. I would greatly appreciate additional advice about this, with my engine's relatively low miles in mind.

|

What year and size is your new engine?

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

12-17-2024, 01:06 PM

12-17-2024, 01:06 PM

|

#198

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by JFP in PA

What year and size is your new engine?

|

It's a 2.7L M96 out of a 2000 986, not sure what series — M96.1, M96.2, etc.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

|

|

|

12-17-2024, 02:05 PM

12-17-2024, 02:05 PM

|

#199

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,657

|

Quote:

Originally Posted by LoneWolfGal

It's a 2.7L M96 out of a 2000 986, not sure what series — M96.1, M96.2, etc.

|

OK, it is a five-chain engine; I would replace the IMS, RMS, AoS, pilot bearing, throw out bearing, clutch, flywheel (if it is in poor condition), and definitely the chain wear pads between the cams. WIth the engine on a stand, all of these are simple replacements, in the car some are not so much easy to get at. I would also pull the oil pump cassette, look at the pump gears for signs of wear, and replace the pump drive shaft which is investment cast garbage and replace it with LN's chrome moly steel replacement. I would also consider replacing the PCV valve and line to the AoS while they are accessible, and also the oil level gauge sender for the same reason. A new water pump (factory only), low temp thermostat, and upgrade the engine to the "S" oil cooler, one of the cheapest longevity items you can put on a base engine.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

12-17-2024, 03:00 PM

12-17-2024, 03:00 PM

|

#200

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by JFP in PA

OK, it is a five-chain engine; I would replace the IMS, RMS, AoS, pilot bearing, throw out bearing, clutch, flywheel (if it is in poor condition), and definitely the chain wear pads between the cams. WIth the engine on a stand, all of these are simple replacements, in the car some are not so much easy to get at. I would also pull the oil pump cassette, look at the pump gears for signs of wear, and replace the pump drive shaft which is investment cast garbage and replace it with LN's chrome moly steel replacement. I would also consider replacing the PCV valve and line to the AoS while they are accessible, and also the oil level gauge sender for the same reason. A new water pump (factory only), low temp thermostat, and upgrade the engine to the "S" oil cooler, one of the cheapest longevity items you can put on a base engine.

|

Many thanks, JFP. I'm on it.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 07:23 PM.

| |