12-05-2019, 06:55 PM

12-05-2019, 06:55 PM

|

#41

|

|

On the slippery slope

Join Date: Mar 2014

Location: Austin and Palm Springs

Posts: 3,800

|

Quote:

Originally Posted by 78F350

I remembered that a green Suburban had been parked back to back with my car across the parking lot lane. I drove the same car to work this morning and brought a tape measure. The height of the damage matches the Suburban bumper (parked in the far corner of the lot this morning). I found small paint chips that match my car on the bumper. The problem was that there was a lot more damage to the back of the Suburban. I see the Suburban regularly and it's usually very clean and polished. The damage is new, but not *just* from hitting my car.

I wrote a short polite note, saying what I thought happened and giving my info if they would like to respond. A while later 'Rhonda' came to my office and explained that she had been in an accident a week ago (police report in hand) and that no, she hadn't hit my Porsche. Two kids in college, insurance company wants to total her car, just before Christmas, ....

There's no witness. It's a small community and although we don't know each other, we know all the same people. She is a hard working part-time receptionist driving a 30 year old Suburban and I'm a pilot with 7 or 8 Porsches -who counts those things anyway. Time and trouble to fix it myself vs time and trouble to legally prove she did it and still get it fixed. This is not a battle worth fighting. One more job on my winter projects list.

|

the good karma you get will more than offset the cost

__________________

2004 Boxster S 6 speed - DRL relay hack, Polaris AutoTop DIY

2004 996 Targa Tip

Instructor - San Diego region

2014 Porsche Performance Driving School

2020 BMW X3, 2013 Ram 1500, 2016 Cmax, 2004 F-150 "Big Red"

|

|

|

12-06-2019, 08:38 AM

12-06-2019, 08:38 AM

|

#42

|

|

Registered User

Join Date: Nov 2006

Location: In the garage...

Posts: 1,738

|

We all are passionate about our vehicles and hate to see them blemished particularly due to other's errors. That said, we all can stand from catching a break here and there and you'll never feel bad helping out someone in need. Sounds like "Rhonda" could really use the break you are giving her and hopefully she will pay it forward to someone else.

A hassle for sure but the juice ain't worth the squeeze. In this instance you'll feel better helping her out rather than making her pay.

Good decision and an even better lesson for us all.

__________________

"Cool Prius!" - Nobody

|

|

|

12-06-2019, 01:08 PM

12-06-2019, 01:08 PM

|

#43

|

|

Registered User

Join Date: Apr 2011

Location: Alabama

Posts: 487

|

If Rhonda fessed up, under the circumstances I think I would tell her Merry Christmas, make a joke about it, and just take care of it myself.

But I don't like being lied to or taken advantage of, I certainly don't want to set a precedent of just rolling over when this does happen, and I don't like reinforcing bad or antisocial behavior in others, so if I thought she was lying I might just press the issue even if it would ultimately cost me more in this particular case.

Maybe I am becoming a grumpy old man.

|

|

|

12-06-2019, 08:48 PM

12-06-2019, 08:48 PM

|

#44

|

|

Registered User

Join Date: Apr 2011

Location: florida

Posts: 487

|

Take bumper off heat it with blow dryer and pop it out best you can bring it to get resprayed no more than 400 dollars new or used taillight .....done. I have 2 stock 02 taillights maybe I could pass on. I think yours may be aftermarket. I just put my bumper back on yesterday for the second time only reason I know. Also painted bumperettes while i was there

|

|

|

12-06-2019, 08:49 PM

12-06-2019, 08:49 PM

|

#45

|

|

Registered User

Join Date: Apr 2011

Location: florida

Posts: 487

|

Have yours sanded and painted you will love it i am sure

|

|

|

12-07-2019, 02:57 AM

12-07-2019, 02:57 AM

|

#46

|

|

Registered User

Join Date: Jul 2013

Location: Bastrop, Tx

Posts: 2,644

|

Sorry to hear about your misfortune. To me, that looks like someone backed into your bumper with a trailer hitch. The dent looks too focused and small to be the middle of a bumper.

__________________

Woody

|

|

|

12-07-2019, 06:24 AM

12-07-2019, 06:24 AM

|

#47

|

|

Motorist & Coffee Drinker

Join Date: Jul 2014

Location: Oklahoma

Posts: 3,953

|

Thanks all...

I really don't have any doubt at this point that it was that Suburban. Given the layout of the parking lot and what was parked there that day, it wouldn't make much sense for any of the other vehicles to have done it. I'd park back to back with an early '90s Suburban to prove the point, but I've obsessed enough about this already.

Here's a pic with a slightly downward view of the Suburban bumper and how it lines up including the scuff on the bumperette.

Considering the mass of a Suburban slowly backing into the soft plastic bumper of a 986, I think she may not have felt it happen. ...I hope that she didn't.

I have another matching tail light already. I can do the paint work myself. I plan to get a gallon of Arctic Silver, so that along with the bumper, I'll have enough paint to fix some spots on THAT as well - hood and a rear fender.

__________________

I am not an attorney, mechanic, or member of the clergy. Following any advice given in my posts is done at your own peril.

|

|

|

12-13-2019, 06:43 PM

12-13-2019, 06:43 PM

|

#48

|

|

Motorist & Coffee Drinker

Join Date: Jul 2014

Location: Oklahoma

Posts: 3,953

|

I replaced the tail light and spent a few minutes with a heat gun to pop the dent out without taking the bumper off. Prepping and repainting the bumper is going to take a lot of time. For now, I have a temporary solution to cover the paint damage:

__________________

I am not an attorney, mechanic, or member of the clergy. Following any advice given in my posts is done at your own peril.

|

|

|

06-04-2020, 09:32 PM

06-04-2020, 09:32 PM

|

#49

|

|

Motorist & Coffee Drinker

Join Date: Jul 2014

Location: Oklahoma

Posts: 3,953

|

I have too many projects and too many cars. I plan to sell THIS and THAT. ...but I want to fix up a few things before I sell them so, MORE projects. THIS only has a few issues that I plan to address and one of them was the rear bumper damage. I didn't want to sell it with the stickers covering the bad paint.

I found a spray can of Arctic Silver Metallic 92U paint among my boxes of stuff that came with cars. It came from one of the several vendors... scratch-something or color chip. When tested, it matched color well and sprayed smooth. "Awesome." I thought, "I can just spray the bad corner and blend it in with the rest of the bumper." I did a few hours of prime and fill to get it perfectly smooth and feathered. I sprayed the color, the clearcoat and it looked decent, but was a little dark at one edge when it all dried. No big deal I thought, there was just enough paint left to go back over that edge. I did a light wet-sand then went to wipe it with a cloth that had some industrial grade alcohol. The alcohol turned the paint gummy and the cloth pulled streaks across the paint. Ruined and not much paint left. Time to pull the bumper off and do it right.

THAT needs some paint work too. It had a few rough spots when I bought it and they have gotten worse over time. I decided to get a full gallon of paint, a Nason single stage acrylic, and use it for both cars. About $200 at O'Reilly Auto Parts for the paint and hardener with Military (retired) discount. I already have some basic supplies, a 60 gallon air compressor, and Devilbiss spray gun set. All I need is some skill and more patience.

Re-sanded. Re-primed.

Re-painted. It looks pretty good from about two feet. The paint was still soft and a little tacky last I checked. Hopefully I can just put it on the car and leave it alone, but part of me wants to do a very fine sand and polish on it still - which will probably ruin it again.

__________________

I am not an attorney, mechanic, or member of the clergy. Following any advice given in my posts is done at your own peril.

|

|

|

06-04-2020, 09:53 PM

06-04-2020, 09:53 PM

|

#50

|

|

Registered User

Join Date: Oct 2018

Location: North Cali

Posts: 854

|

Looks spotless to me. You really made that with a spray can? Great job, don`t ruin it!

|

|

|

06-05-2020, 07:39 PM

06-05-2020, 07:39 PM

|

#51

|

|

Registered User

Join Date: Jan 2019

Location: PA

Posts: 1,726

|

I'm with itsnotanova. No way that bumper did that damage. Too sharp of a crease for that bumper to do it. Nonetheless, I commend you for cutting Rhonda a break while you were so certain she did it. I hope you get all you ask when you sell it.

__________________

2002 Boxster Base - Arctic Silver - Tiptronic

2010 Subaru Forester

1980 Ford C-8000 Custom Cab Emergency-One Fire Truck

__________________

"I never lose. I either win or I learn." -Nelson Mandela

|

|

|

06-05-2020, 09:21 PM

06-05-2020, 09:21 PM

|

#52

|

|

Motorist & Coffee Drinker

Join Date: Jul 2014

Location: Oklahoma

Posts: 3,953

|

Quote:

Originally Posted by piper6909

... Too sharp of a crease for that bumper to do it. ...

|

Thanks, my picture doesn't show it well, but in person and with the small chips of Arctic Silver Metallic paint still on her bumper, I have no doubt.

Quote:

|

You really made that with a spray can?

|

I first tried with a spray can, but messed it up. When painting it is Very important to make sure that all the paints and solvents that you use are compatible and mine weren't. The re-paint was done with a spray gun. The paint I used was a single stage acrylic, meaning that there is no need for clear coat over it - it has the gloss as one of it's components.

I set it back on the car today to see how well the color match was. Tomorrow, I'll finish mounting it. I'm really happy with the color and how well the paint laid smooth. I'm going to have to polish the original paint now.

__________________

I am not an attorney, mechanic, or member of the clergy. Following any advice given in my posts is done at your own peril.

|

|

|

06-06-2020, 02:55 PM

06-06-2020, 02:55 PM

|

#53

|

|

Registered User

Join Date: Jan 2019

Location: PA

Posts: 1,726

|

Quote:

Originally Posted by 78F350

Thanks, my picture doesn't show it well, but in person and with the small chips of Arctic Silver Metallic paint still on her bumper, I have no doubt.

|

Yes, I saw that. Could it be that the silver paint came off the other car from the other accident? (A lot of cars have the same shade of silver. You'd be hard pressed to see a difference between Porsche's Arctic Silver Metallic and Dodge's Bright Silver Metallic, for example. I know, I have both.) And it's also obvious to me that the big dent on her chrome bumper and warpage on the plastic bumper tread was caused by the other accident. There's no way those damages could happen at low parking speeds. So, the silver paint could be from the other car, right?

Maybe she did it, but there's no certainty there, IMHO. To me, the dent on your bumper doesn't match up with the shape of her bumper. Also, the horizontal part (under the license plate) of her bumper is the lowest point on her bumper, yet the marks on your bumperette are higher than the bottom of the crease on your bumper cover. More importantly, the bumperettes stick out farther than the crease on the bumper cover, yet the aforementioned horizontal part of her bumper is either on the same plane or sticks out farther than the rest of her bumper. So, if that hit your bumperette, as you indicated in your drawings, the horizontal bend in her bumper could not have hit your bumper cover to cause that vertical crease damage.

Your damage was more likely caused by something like this:

https://realtruck.com/p/ami-swing-step-grille-guard/asm-19285-505-asm-19285k/?kpid=go_cmp-9884836042_adg-100686975739_ad-431585076121_pla-313046400386_dev-c_ext-_prd-ASM-19285-505%26ASM-19285K_sig-EAIaIQobChMIvIjNwJnu6QIVTeG1Ch1tWAj1EAYYCSABEgK_Nf D_BwE&utm_medium=cpc&utm_source=google&utm_campaig n=Grille%20Guards%20%26%20Bull%20Bars%20-%20Smart%20Shopping&utm_term=&gclid=EAIaIQobChMIvI jNwJnu6QIVTeG1Ch1tWAj1EAYYCSABEgK_NfD_BwE

I just wouldn't want you to go on resenting this person if she didn't do it.

Either way, huge respect for letting it go. I hope you get all you ask for it when you sell.

__________________

2002 Boxster Base - Arctic Silver - Tiptronic

2010 Subaru Forester

1980 Ford C-8000 Custom Cab Emergency-One Fire Truck

__________________

"I never lose. I either win or I learn." -Nelson Mandela

Last edited by piper6909; 06-08-2020 at 07:32 PM.

|

|

|

06-12-2020, 09:43 AM

06-12-2020, 09:43 AM

|

#54

|

|

Registered User

Join Date: Oct 2018

Location: North Cali

Posts: 854

|

Quote:

Originally Posted by 78F350

Thanks, my picture doesn't show it well, but in person and with the small chips of Arctic Silver Metallic paint still on her bumper, I have no doubt.

I first tried with a spray can, but messed it up. When painting it is Very important to make sure that all the paints and solvents that you use are compatible and mine weren't. The re-paint was done with a spray gun. The paint I used was a single stage acrylic, meaning that there is no need for clear coat over it - it has the gloss as one of it's components.

I set it back on the car today to see how well the color match was. Tomorrow, I'll finish mounting it. I'm really happy with the color and how well the paint laid smooth. I'm going to have to polish the original paint now.

|

Thanks for sharing this. I`d like to do a very similar paint job on my SAAB convertible, the rear bumper has some deep scratches and looks very ugly. Would you recommend anything special to use to patch them up before sanding and painting?

|

|

|

06-12-2020, 10:45 AM

06-12-2020, 10:45 AM

|

#55

|

|

Motorist & Coffee Drinker

Join Date: Jul 2014

Location: Oklahoma

Posts: 3,953

|

Quote:

Originally Posted by Homeoboxter

... Would you recommend anything special to use to patch them up before sanding and painting?

|

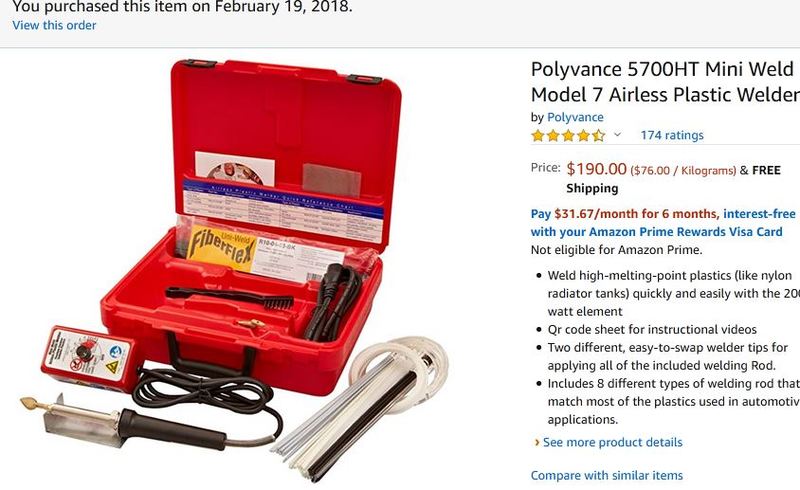

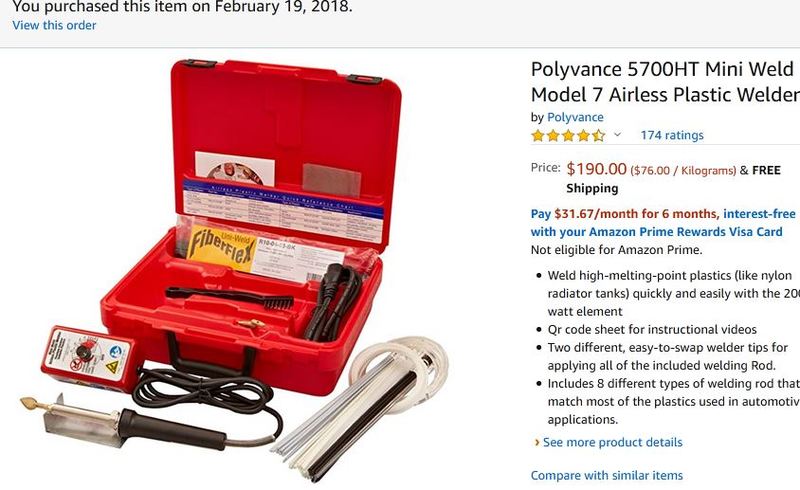

I have a Polyvance Plastic Welding kit that came with some material called FiberFlex welding rods. It's a fiber reinforced plastic. I have also used the kit to repair cracked and broken under-belly panels. This page has information and a video of a bumper repair similar to how I have done it:

https://www.polyvance.com/video/bumper-repair/fiberflex-bumper-repair-3

On a bumper cover, I prefer doing a 'plastic weld' type of fill to using a body filler such as Bondo.

I did some plastic welding with a soldering iron before I bought it, but really like the temperature control and materials included with this kit. Repair a couple plastic panels and it has paid for itself:

__________________

I am not an attorney, mechanic, or member of the clergy. Following any advice given in my posts is done at your own peril.

|

|

|

06-12-2020, 11:07 AM

06-12-2020, 11:07 AM

|

#56

|

|

Motorist & Coffee Drinker

Join Date: Jul 2014

Location: Oklahoma

Posts: 3,953

|

Next up for body work is THAT. The paint on the rear was obviously a re-spray that had been done at some time in the past. About a year ago some of the clear coat started to peel from the repair and there were some fine cracks in the paint. Yesterday, I started sanding off the bad clear and Dremmeling out the cracks. The cracks were almost 1/4" through body filler before I got down to metal. That's not good. I had guessed that it was only a little over a millimeter thick.

I had planned to just use filler after digging out the cracks. Now I think I should try something different. I happen to already have a left rear quarter panel cut from a car that I scrapped a few years ago. I have never done a body panel welding-type repair, but I think that it will be the best way to proceed.

...and to think I started 'cleaning' these two cars up to sell because I have too many other projects that I want to get to.

__________________

I am not an attorney, mechanic, or member of the clergy. Following any advice given in my posts is done at your own peril.

|

|

|

06-12-2020, 12:49 PM

06-12-2020, 12:49 PM

|

#57

|

|

Registered User

Join Date: Oct 2018

Location: North Cali

Posts: 854

|

Quote:

Originally Posted by 78F350

I have a Polyvance Plastic Welding kit that came with some material called FiberFlex welding rods. It's a fiber reinforced plastic. I have also used the kit to repair cracked and broken under-belly panels. This page has information and a video of a bumper repair similar to how I have done it:

https://www.polyvance.com/video/bumper-repair/fiberflex-bumper-repair-3

On a bumper cover, I prefer doing a 'plastic weld' type of fill to using a body filler such as Bondo.

I did some plastic welding with a soldering iron before I bought it, but really like the temperature control and materials included with this kit. Repair a couple plastic panels and it has paid for itself:

|

Thanks, lots of useful information. Looks like the "Bondo" is what I will need for this job.

|

|

|

06-15-2020, 02:52 PM

06-15-2020, 02:52 PM

|

#58

|

|

Motorist & Coffee Drinker

Join Date: Jul 2014

Location: Oklahoma

Posts: 3,953

|

Starting on the quarter panel repair video:

https://youtu.be/m-xhVzEb9tM

__________________

I am not an attorney, mechanic, or member of the clergy. Following any advice given in my posts is done at your own peril.

|

|

|

06-15-2020, 04:49 PM

06-15-2020, 04:49 PM

|

#59

|

|

Motorist & Coffee Drinker

Join Date: Jul 2014

Location: Oklahoma

Posts: 3,953

|

So far it seems to be working. Bonus: No blood lost, I still have all my fingers, used a mask for the cuts and grinding, and I can still see with both eyes.

Prepping the patch panel.

Cutting the old panel off.

Fitting the patch.

It's hot and I'm tired. I'm going to hold of on the final fitting and welding until tomorrow.

__________________

I am not an attorney, mechanic, or member of the clergy. Following any advice given in my posts is done at your own peril.

|

|

|

06-15-2020, 09:11 PM

06-15-2020, 09:11 PM

|

#60

|

|

Registered User

Join Date: Oct 2018

Location: North Cali

Posts: 854

|

Yeah, it`s more labourous, but this is the right way to do this. The patch is fitting nicely!

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is Off

|

|

|

All times are GMT -8. The time now is 10:52 AM.

| |