10-14-2018, 08:59 PM

10-14-2018, 08:59 PM

|

#1

|

|

Registered User

Join Date: Jun 2016

Location: Arizona

Posts: 379

|

Accusump - some data

First event of the 2018 fall season for me in Arizona at Arizona Motorsports Park (AMP). I tested my new Sparco EVO seats and 6 point harness setup and was able to get my personal best time in the 3rd session. What a difference that setup makes!

I also decided I would attempt to quantify the effectiveness of my 2 qt Accusump setup to see if it makes any difference. I used my Autosportlabs Race Capture Track setup with AnalogX reading oil pressure and Accusump ON solenoid voltage.

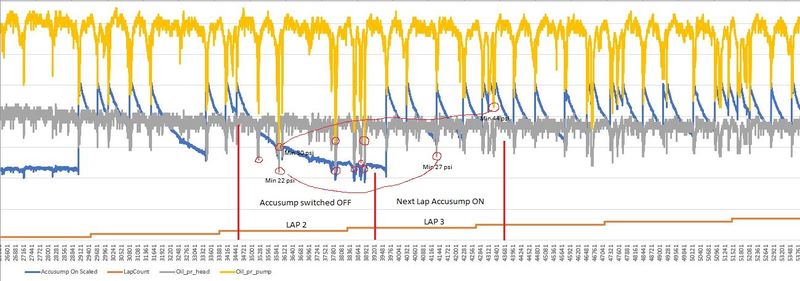

This data was taken from Session 2. In order to minimize any noise (such as the effect of oil temp on oil pressure), I turned the Accusump OFF then back ON on adjacent laps (laps 2 and 3). I'm assuming that my driving is similar for those 2 laps as well. I'll post a rendered video with data for the same laps when I have some time.

The X axis is basically time, with the Lap count showing as a stair step at the bottom. In Blue, I'm showing the voltage of the Accusump solenoid. Spikes indicate it is activated (and dumping oil during that short time). The Orange points show the Oil Pressure as measured at the inlet of the oil filter (so not directly at the oil pump). And lastly, in Grey, is the Oil Pressure as measured at the standard location on the passenger's side cam cover (head). Outside air temp was roughly 75F and oil temperature did not climb beyond 225F. I was running Federal RSR595 tires and lateral Gs were getting up to 1.05-1.15 Gs. I also have an X51 style oil baffle.

Although this is only a single data set at a single track, I think it's pretty clear that the Accusump has a measurable effect. What I can see is that the VC Oil pressure never dips below 27 psi vs 22 psi when Accusump is OFF. Looking at the Pump Oil pressure, it never dips below 44 psi, but dips to 30 psi when turned OFF. This larger effect on Pump oil pressure can be explained by the fact that the Accusump feeds into oiling system much closer to the oil filter than to the pump, and there is a check valve that helps to build up the back pressure.

Is it worth it? Will this prevent oil starvation? I don't know, but just looking at this, it certainly doesn't make it worse.

Let me know what you think

PS... I don't have any relationship with Canton Racing  so I'm not biased on way or the other. I just believe in the power of data

__________________

2002 Boxster S - NHP 200 Cell Headers,test pipes,Borla CatBack,Competition Plenum,74 mm TB, EVOMS Tune,Tarett UDP,Eibach Swaybars,BIlstein PSS9s,TuneRS rear toe links,wheel studs,15 mm wheel spacers on all 4,EBC yellow stuff pads,Sebro rotors, EBS oil baffles,160 deg Thermostat,2 quart Accusump,full filtration remote oil filter,rad fan switch,custom gauge/switch plate, Race Capture data logging, 90K miles

Last edited by AZ986S; 10-14-2018 at 09:08 PM.

|

|

|

10-15-2018, 05:01 AM

10-15-2018, 05:01 AM

|

#2

|

|

Registered User

Join Date: Dec 2012

Location: FL

Posts: 4,145

|

Thank you for sharing, very interesting!

|

|

|

10-15-2018, 09:35 AM

10-15-2018, 09:35 AM

|

#3

|

|

Registered User

Join Date: Sep 2009

Location: toronto

Posts: 2,668

|

Thanks for this! The graph is pretty small.....but one thing really stands out. The VC pressure doesn't really vary that much and depending on resolution may be all but useless in determining rapid changes in oil pressure due to cornering loads, especially with an accusump installed. It may be okay for a startup and that is it.

According to your data it looks like one has to have your transducer at the filter inlet to get any meaningful feed back in the cockpit, while cornering. The 996 oil pressure tap location in the head is not going to tell you much...

__________________

986 00S

Last edited by jaykay; 10-15-2018 at 09:37 AM.

|

|

|

10-15-2018, 09:28 PM

10-15-2018, 09:28 PM

|

#4

|

|

Registered User

Join Date: Jun 2016

Location: Arizona

Posts: 379

|

Here is the 4 minute video of both laps starting with the Accusump turned OFF then back ON for the following lap.

https://youtu.be/E5757Nq36fw

__________________

2002 Boxster S - NHP 200 Cell Headers,test pipes,Borla CatBack,Competition Plenum,74 mm TB, EVOMS Tune,Tarett UDP,Eibach Swaybars,BIlstein PSS9s,TuneRS rear toe links,wheel studs,15 mm wheel spacers on all 4,EBC yellow stuff pads,Sebro rotors, EBS oil baffles,160 deg Thermostat,2 quart Accusump,full filtration remote oil filter,rad fan switch,custom gauge/switch plate, Race Capture data logging, 90K miles

|

|

|

10-16-2018, 08:10 AM

10-16-2018, 08:10 AM

|

#5

|

|

Registered User

Join Date: Sep 2009

Location: toronto

Posts: 2,668

|

Great video! This is very well done! How did you get the solenoid indication on there......what are you using to knit this all together

It looks there is pretty good indication at the VC....I will take back what I said.

I am surprised that the accusmp does not take more of a bite out of pressure drop loss.

__________________

986 00S

|

|

|

10-16-2018, 09:45 AM

10-16-2018, 09:45 AM

|

#6

|

|

Registered User

Join Date: Dec 2012

Location: FL

Posts: 4,145

|

Nice job catching that other car - did you pass him on the lap after the video ended?

|

|

|

10-16-2018, 12:48 PM

10-16-2018, 12:48 PM

|

#7

|

|

Registered User

Join Date: Jun 2016

Location: Arizona

Posts: 379

|

Quote:

Originally Posted by steved0x

Nice job catching that other car - did you pass him on the lap after the video ended?

|

Thanks

Yes I did. I believe that was the 2009 Cayman owned by a track budy.

I ended up getting my personal best for that track during Session 3 @ 1:56.4. I attribute that to the new Sparco seat setup, but I also have a new tune from EVOMS here in Phoenix. The car feels strong. The only thing I would say is that with my current setup, the car feels super well balanced, but with maybe a touch of understeer. Might have to consider adj. LCAs in the front.

BTW, the Canton filter did well as far as I can tell. I'd like to crunch the oil pressure data some more and compare it to last season with the NAPA 1042 filter to see if there is a difference. Hot idle pressure did seem to be a little higher. I'll report back.

__________________

2002 Boxster S - NHP 200 Cell Headers,test pipes,Borla CatBack,Competition Plenum,74 mm TB, EVOMS Tune,Tarett UDP,Eibach Swaybars,BIlstein PSS9s,TuneRS rear toe links,wheel studs,15 mm wheel spacers on all 4,EBC yellow stuff pads,Sebro rotors, EBS oil baffles,160 deg Thermostat,2 quart Accusump,full filtration remote oil filter,rad fan switch,custom gauge/switch plate, Race Capture data logging, 90K miles

|

|

|

10-16-2018, 12:56 PM

10-16-2018, 12:56 PM

|

#8

|

|

Registered User

Join Date: Dec 2012

Location: FL

Posts: 4,145

|

Quote:

Originally Posted by AZ986S

...but with maybe a touch of understeer. Might have to consider adj. LCAs in the front.

|

Refresh my memory, what are you running now for suspension (lowering springs?) and what is your current front alignment?

I'm still fairly well balanced on the M030 USA sport springs and Koni FSD with 225/45/17 front and 255/40/17 with Tarett GT bars, still some understeer but not terrible, would like to dial it down a little more but don't want to get to a major oversteer situation. If I could get just a touch less understeer I would be happy, and maybe I can get there with driving style changes

|

|

|

10-16-2018, 01:02 PM

10-16-2018, 01:02 PM

|

#9

|

|

Registered User

Join Date: Jun 2016

Location: Arizona

Posts: 379

|

Quote:

Originally Posted by jaykay

Great video! This is very well done! How did you get the solenoid indication on there......what are you using to knit this all together

It looks there is pretty good indication at the VC....I will take back what I said.

I am surprised that the accusmp does not take more of a bite out of pressure drop loss.

|

I use RaceRender Pro to edit and render the videos.

My camera is just an old GoPro, but still works fine.

My data setup is the Race Capture Track device on local CanBus. I also attached an Analog input module onto the CanBus, allowing me 4 Analog I/Os. I use those for Oil pressure and Accusump Air side pressure as well. I'm able to get the Accusump solenoid signal by using one of the 5 VDC Analog I/O channels, but since the coil is 12 VDC, I have to run it through a relay. Then, in the RaceRender software, I added the yellow blinking object to come on when the signal is at 5VDC (meaning the Accusump is ON).

As far as the effectiveness of the Accusump at dampening the pressure drop spikes, it does seem to help. My take on that is that the spikes happen so quickly and that the Accusump solenoid taking perhaps 20-100 milliseconds to open the valve, and another delay for the oil flow/pressure to build up to compensate for that dip, by that time some of the pressure drop has already occurred. Some of that can be improved by increasing the Accusump Pressure on the Air Side. That would allow for a quicker reaction, but at the expense of a lower volume of oil. I think this could be tuned to be track specific. Short track, short turns, high pressure and less oil volume. Long sweeping turns track, low pressure with more volume.

__________________

2002 Boxster S - NHP 200 Cell Headers,test pipes,Borla CatBack,Competition Plenum,74 mm TB, EVOMS Tune,Tarett UDP,Eibach Swaybars,BIlstein PSS9s,TuneRS rear toe links,wheel studs,15 mm wheel spacers on all 4,EBC yellow stuff pads,Sebro rotors, EBS oil baffles,160 deg Thermostat,2 quart Accusump,full filtration remote oil filter,rad fan switch,custom gauge/switch plate, Race Capture data logging, 90K miles

|

|

|

10-16-2018, 01:09 PM

10-16-2018, 01:09 PM

|

#10

|

|

Registered User

Join Date: Jun 2016

Location: Arizona

Posts: 379

|

Quote:

Originally Posted by steved0x

Refresh my memory, what are you running now for suspension (lowering springs?) and what is your current front alignment?

I'm still fairly well balanced on the M030 USA sport springs and Koni FSD with 225/45/17 front and 255/40/17 with Tarett GT bars, still some understeer but not terrible, would like to dial it down a little more but don't want to get to a major oversteer situation. If I could get just a touch less understeer I would be happy, and maybe I can get there with driving style changes  |

Yes, same here, would like just a touch less understeer. I'm running H&R sport lowering springs with stock struts. I have the Eibach swaybars, front is fixed, rear is adjustable (on middle hole). Tires are 225/45R17 in front, 255/40R17 rears. Alignment is neg 1.8-2.0 deg camber in front, and 2.5 rear. Front is maxed out for negative camber. .06 Toe in on rear. 0 toe in front.

__________________

2002 Boxster S - NHP 200 Cell Headers,test pipes,Borla CatBack,Competition Plenum,74 mm TB, EVOMS Tune,Tarett UDP,Eibach Swaybars,BIlstein PSS9s,TuneRS rear toe links,wheel studs,15 mm wheel spacers on all 4,EBC yellow stuff pads,Sebro rotors, EBS oil baffles,160 deg Thermostat,2 quart Accusump,full filtration remote oil filter,rad fan switch,custom gauge/switch plate, Race Capture data logging, 90K miles

|

|

|

10-17-2018, 08:51 PM

10-17-2018, 08:51 PM

|

#11

|

|

Registered User

Join Date: Jun 2016

Location: Arizona

Posts: 379

|

I thought I would share my idea concerning the inherent time lag using the Accusump with pressure switch operated solenoid valve.

Knowing that oil pressure dips occur when lateral Gs spike to approx. > 1G, what if I modified this setup to include an adjustable accelerometer switch circuit in parallel to the pressure switch circuit. The idea would be that one could adjust the switch threshold to 0.8 or 0.9 G to open the solenoid valve just a tad earlier than the pressure switch would. This would in effect open the valve slightly before the pressure drop occurs... and keep it open for a minimum amount of time. The goal would be to smooth out any large pressure dips even further.

__________________

2002 Boxster S - NHP 200 Cell Headers,test pipes,Borla CatBack,Competition Plenum,74 mm TB, EVOMS Tune,Tarett UDP,Eibach Swaybars,BIlstein PSS9s,TuneRS rear toe links,wheel studs,15 mm wheel spacers on all 4,EBC yellow stuff pads,Sebro rotors, EBS oil baffles,160 deg Thermostat,2 quart Accusump,full filtration remote oil filter,rad fan switch,custom gauge/switch plate, Race Capture data logging, 90K miles

|

|

|

10-17-2018, 09:25 PM

10-17-2018, 09:25 PM

|

#12

|

|

Registered User

Join Date: Apr 2010

Location: Canada

Posts: 3,153

|

why not take the pressure switch out of the equation all together? without the pressure switch, the accusump immediately oils whenever there is a drop. the concern as per the canton website is that you might run out of oil if it is supplying a lot without recovery ...

Importance of Accusump Valve Selection & How to Choose.

but perhaps go to a 3 quart instead of a 2 quart unit?

perhaps bypass the pressure switch for a session and see what response is like.

edit to add - my gt6 race car has an accusump with a manual valve, but currently no way to monitor pressures (it's from 1968 and a very analog machine ...)

|

|

|

10-18-2018, 10:14 AM

10-18-2018, 10:14 AM

|

#13

|

|

Registered User

Join Date: Jun 2016

Location: Arizona

Posts: 379

|

Quote:

Originally Posted by The Radium King

perhaps bypass the pressure switch for a session and see what response is like.

|

Yes I think I will do that next week. Re-wire to add switch for Bypass or No Bypass.

I do think that chasing rapidly fluctuating oil pressures with a pressure switch and solenoid valve helps some but ideally maybe a switch with adjustable Discharge/Refill setpoints would work better so that you can fine tune it. I still think that a G force based sensing system could be tuned independently of the inherent oil pressure changes /levels occurring due to different oil types/viscosity, temperatures, engine RPM and track conditions.

__________________

2002 Boxster S - NHP 200 Cell Headers,test pipes,Borla CatBack,Competition Plenum,74 mm TB, EVOMS Tune,Tarett UDP,Eibach Swaybars,BIlstein PSS9s,TuneRS rear toe links,wheel studs,15 mm wheel spacers on all 4,EBC yellow stuff pads,Sebro rotors, EBS oil baffles,160 deg Thermostat,2 quart Accusump,full filtration remote oil filter,rad fan switch,custom gauge/switch plate, Race Capture data logging, 90K miles

|

|

|

10-18-2018, 11:02 AM

10-18-2018, 11:02 AM

|

#14

|

|

Registered User

Join Date: Apr 2010

Location: Canada

Posts: 3,153

|

when we are dealing with drops over fractions of a second, the time for the pressure sender to detect and open a valve is significant. if the only downside to having the valve open all the time is potential depletion of the pressurised oil supply, then using an accelerometer to open the valve in an anticipatory basis is a good compromise. OR, i presume you are using the 40 psi switch; what about the 55 psi switch that might catch dips a little sooner?

|

|

|

10-18-2018, 01:34 PM

10-18-2018, 01:34 PM

|

#15

|

|

Registered User

Join Date: Dec 2012

Location: FL

Posts: 4,145

|

I had toyed at one time with the idea of running an accusump with no valve, and having it open all the time. Since I run my oil a little bit low, at times when I was idle and all the oil was out of the accusump, I would be a tiny bit high but I figured that would be OK at idle. I would lose the ability to pre-oil the engine before startup, but since I don't have that capability now anyway, that wouldn't be a loss. My thoughts were:

2 QT Accusump

Set the air pressure to something high, like 50 PSI

I had a formula in a spreadsheet (that I think I have lost) where I could play with the base air pressure and the running oil pressure and it would show me how much oil was stored at that pressure

Then when driving, there would always be an available quantity of pressurized oil, with a min pressure of 50 (or whatever I set to be the min, and at that pressure all the oil would be out of the accusump) that would be available to stabilize the pressure in the event of dips.

I had forgotten that my fuel filter was in the tunnel so I can't put the Accusump there and so the idea fizzled... And maybe it would have fit anyway since I was going to use a 2 qt unit and no valve?

Looking at the real time data in the video above, the 60 PSI air pressure in the accusump, tells me that the oil pressure on the exit side of the accusump was only getting up to 60. So I would plug 50 into my spreadsheet as the base pressure, and then 60 as the running pressure, and it would tell me how much oil would be in the accusump, pressurized at 50 or above, to be available.

Maybe I decided this was useless and so that is another reason why it fizzled

The plus side of this system is that it is fire and forget, no switches to turn on or off, or manual valves to turn on or off.

The minus side is that it wouldn't hold tons of oil and might not be good for really long sweepers if there were long dips. And there is no pre-oil capability.

Looking at how the accusump works in the video, I might revisit it, if I can find my spreadsheet, I'm not sure if I have the energy to recreate the formulas for volume, pressure, etc.. that I used.

Since I don't think anybody else runs it like this, they may have already done the work of figuring it wasn't a good idea

|

|

|

10-18-2018, 08:19 PM

10-18-2018, 08:19 PM

|

#16

|

|

Registered User

Join Date: Jul 2008

Location: austin

Posts: 825

|

Quote:

Originally Posted by AZ986S

First event of the 2018 fall season for me in Arizona at Arizona Motorsports Park (AMP). I tested my new Sparco EVO seats and 6 point harness setup and was able to get my personal best time in the 3rd session. What a difference that setup makes!

I also decided I would attempt to quantify the effectiveness of my 2 qt Accusump setup to see if it makes any difference. I used my Autosportlabs Race Capture Track setup with AnalogX reading oil pressure and Accusump ON solenoid voltage.

This data was taken from Session 2. In order to minimize any noise (such as the effect of oil temp on oil pressure), I turned the Accusump OFF then back ON on adjacent laps (laps 2 and 3). I'm assuming that my driving is similar for those 2 laps as well. I'll post a rendered video with data for the same laps when I have some time.

The X axis is basically time, with the Lap count showing as a stair step at the bottom. In Blue, I'm showing the voltage of the Accusump solenoid. Spikes indicate it is activated (and dumping oil during that short time). The Orange points show the Oil Pressure as measured at the inlet of the oil filter (so not directly at the oil pump). And lastly, in Grey, is the Oil Pressure as measured at the standard location on the passenger's side cam cover (head). Outside air temp was roughly 75F and oil temperature did not climb beyond 225F. I was running Federal RSR595 tires and lateral Gs were getting up to 1.05-1.15 Gs. I also have an X51 style oil baffle.

Although this is only a single data set at a single track, I think it's pretty clear that the Accusump has a measurable effect. What I can see is that the VC Oil pressure never dips below 27 psi vs 22 psi when Accusump is OFF. Looking at the Pump Oil pressure, it never dips below 44 psi, but dips to 30 psi when turned OFF. This larger effect on Pump oil pressure can be explained by the fact that the Accusump feeds into oiling system much closer to the oil filter than to the pump, and there is a check valve that helps to build up the back pressure.

Is it worth it? Will this prevent oil starvation? I don't know, but just looking at this, it certainly doesn't make it worse.

Let me know what you think

PS... I don't have any relationship with Canton Racing  so I'm not biased on way or the other. I just believe in the power of data  |

Thank you for taking the time to share the data.

Mike

__________________

Drivers: '15 Panamera Hybrid (wife's), ' 01 996 GT2, 00 Boxster S, '96 993 Çab/Tip (wife's)

Race Cars: '75 911 RSR Replica & '99 Spec Boxster

mike@lonestarrpm.com

|

|

|

10-19-2018, 08:40 PM

10-19-2018, 08:40 PM

|

#17

|

|

Registered User

Join Date: Jun 2016

Location: Arizona

Posts: 379

|

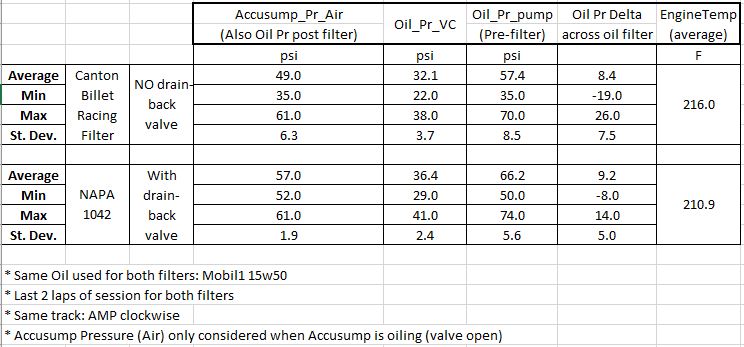

Here is the data comparing the NAPA 1042 filter with the Canton Racing Billet style oil filter, older style with Hex bolt on the bottom. The whole idea behind a racing filter is more flow and less restriction (pressure drop), sometimes at the expense of filter particle size efficiency.

For the NAPA 1042, the data was taken in March 2018 at AMP.

For the Canton Racing, the data was taken just las week October 2018.

Both clockwise. Air temps about the same.

In both cases, I only considered the data for the last 2 laps of the session so as to have engine temp as steady and high as possible, and also only considered the Accusump Air Side Pressure as being the equivalent of the Post Oil Filter pressure when it was oiling (valve open). The NAPA 1042 is rated at 21 microns and 9-11 GPM, and the Canton Racing filter element is rated at 8 microns and 15 GPM.

I was surprised to see that the NAPA 1042 filter did somewhat of a better job, and about the same for the Pressure Delta across the filter. It then dawned on me that the 1042 has an anti-drainback valve whereas the Canton does not. This is important and can affect the effectiveness of the Accusump by eliminating the oil back flow when the Accusump is oiling. This also could explain the higher pressure values and lower standard deviations for the 1042.

What's interesting also is the negative pressure delta across the oil filter. But after giving it some thought, I believe that makes sense since that would happen when the Accusump is oiling initially when the Pump pressure is low from the sudden lateral G load.

This does not mean the Canton Racing filter is no good. It just means that for my set-up, it does not work better than the NAPA 1042 (at least from the limited data).

__________________

2002 Boxster S - NHP 200 Cell Headers,test pipes,Borla CatBack,Competition Plenum,74 mm TB, EVOMS Tune,Tarett UDP,Eibach Swaybars,BIlstein PSS9s,TuneRS rear toe links,wheel studs,15 mm wheel spacers on all 4,EBC yellow stuff pads,Sebro rotors, EBS oil baffles,160 deg Thermostat,2 quart Accusump,full filtration remote oil filter,rad fan switch,custom gauge/switch plate, Race Capture data logging, 90K miles

Last edited by AZ986S; 10-19-2018 at 08:51 PM.

|

|

|

10-19-2018, 10:19 PM

10-19-2018, 10:19 PM

|

#18

|

|

Registered User

Join Date: Jun 2016

Location: Arizona

Posts: 379

|

Quote:

Originally Posted by The Radium King

when we are dealing with drops over fractions of a second, the time for the pressure sender to detect and open a valve is significant. if the only downside to having the valve open all the time is potential depletion of the pressurised oil supply, then using an accelerometer to open the valve in an anticipatory basis is a good compromise. OR, i presume you are using the 40 psi switch; what about the 55 psi switch that might catch dips a little sooner?

|

I thought about using the 55 psi pressure switch. I think the issue is that the oil pressure would be mostly bellow that, so in effect it would be always open. Today I installed a manual pressure switch "bypass" toggle switch so that I can keep the valve always open when needed. I will test that next weekend at AMP again, this time with PCA. I will set the Accusump Air pressure at 15 psi. This should give me 1.5 qts in the Accusump @ 60 psi, then 1 qt @ 30 psi, so about 0.5 qts to play with in real terms. If you start with 30 psi, the starting volume is 1 qt @ 60 psi, and @ 30 psi, it becomes 0 (empty). In theory, the response time is quicker at higher air side pressures, but you also start with less oil.

__________________

2002 Boxster S - NHP 200 Cell Headers,test pipes,Borla CatBack,Competition Plenum,74 mm TB, EVOMS Tune,Tarett UDP,Eibach Swaybars,BIlstein PSS9s,TuneRS rear toe links,wheel studs,15 mm wheel spacers on all 4,EBC yellow stuff pads,Sebro rotors, EBS oil baffles,160 deg Thermostat,2 quart Accusump,full filtration remote oil filter,rad fan switch,custom gauge/switch plate, Race Capture data logging, 90K miles

Last edited by AZ986S; 10-20-2018 at 10:29 AM.

|

|

|

10-28-2018, 08:44 AM

10-28-2018, 08:44 AM

|

#19

|

|

Registered User

Join Date: Jun 2016

Location: Arizona

Posts: 379

|

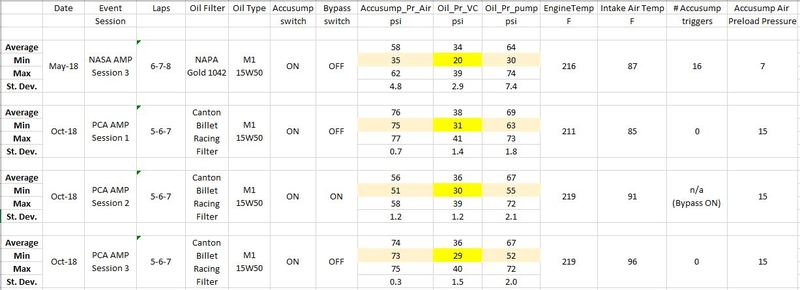

Was at AMP yesterday with the PCA group and logged some more data with and without the Accusump Bypass switch. This is a switch I installed to be able to keep the solenoid valve open, effectively bypassing the pressure switch.

The first session is from a few months ago with NASA at the same track, but with the NAPA Gold 1042 oil filter. The last 3 sessions are from yesterday. I turned on the Bypass switch only for Session 2. I did a fresh oil change with 10 qts of M1 15W50 prior to yesterday's event. I also increased the Accusump air preload to 15 psi from 7 psi previously.

Very similar numbers for all 3 session yesterday, with and without the Bypass switch. BUT, the interesting thing is that the Accusump did not trigger at all during sessions 1 and 3 with the bypass switch OFF. Looking at the pump pressures, it looks like the pressure did not go low enough (35 psi) to trigger the Accusump. The only possible explanation I see for this is that the oil level might be higher with the increased air side pressure. This pushes more of the total oil volume in the sump and less in the Accusump. The electronic oil level gauge was showing 1 bar above full with the Accusump partially empty. Either way, I am happy with the performance of the oiling system yesterday with the lowest VC pressure at 29 psi.

Next event is at Bondurant with NASA and I will collect more data with the bypass ON and OFF. My belief is that keeping the bypass ON with normal oil levels should help reduce the oil pressure drops.

__________________

2002 Boxster S - NHP 200 Cell Headers,test pipes,Borla CatBack,Competition Plenum,74 mm TB, EVOMS Tune,Tarett UDP,Eibach Swaybars,BIlstein PSS9s,TuneRS rear toe links,wheel studs,15 mm wheel spacers on all 4,EBC yellow stuff pads,Sebro rotors, EBS oil baffles,160 deg Thermostat,2 quart Accusump,full filtration remote oil filter,rad fan switch,custom gauge/switch plate, Race Capture data logging, 90K miles

Last edited by AZ986S; 10-28-2018 at 08:49 AM.

|

|

|

10-28-2018, 10:18 AM

10-28-2018, 10:18 AM

|

#20

|

|

Registered User

Join Date: Apr 2010

Location: Canada

Posts: 3,153

|

so, one of the things i am getting is the pressure drop across the filter. it seems high. i note that lne changed the filter they specify. i'd done a bit of research into filter elements - oem is 30 micron but a very large filter element AND has a bypass (not sure what pressure it bypasses at). the napa 1042 is 23 micron AND the element is much smaller in area and no bypass, so strikes me as a bottleneck in the system, and probably why lne went to their latest washable filter with a 60 micron size (they chose less filteration for better flow for a reason i think).

i think the accusump pressure switch is at the accusump, so should track the pre-filter oil pressure closely, yes? so, thinking that the 40 psi switch was spec'd based on a filter that flows better, and with the current config you should consider a higher pressure (55 psi?) switch to be more responsive or, as yu are finding, run without the switch and just let the accusump swing - did you get any indicators that the accusump was depleting itself after a long sweeper or turn complex? otherwise, i think more and more that a remote filter mount with full-size filter is the way to go.

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 10:16 AM.

| |