04-30-2025, 04:32 PM

04-30-2025, 04:32 PM

|

#541

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

After I obtained the metal washer for the compression tool I managed to get the VarioCam out — not without some difficulty, but any victory's a good victory.

The bottom pad indeed had considerable wear, no doubt enough to cause some cam deviation:

I snapped the new pads into place (after carefully inserting the o-ring under the bottom pad). Note the new material's lighter color.

After an hour of trying to reinstall the VarioCam between the camshafts without success, I tightened the compression tool's nut a few more turns (using my little box-end wrench) to get a bit more clearance. However, the nut didn't seem to be moving on the rod. So I removed the tool, and then I saw the reason why — the threads had stripped. The compression tool seems to have been made of soft metal. You can see the spot about 3/4" from the end where the threads are flattened. The nut just spins at that point.

Addendum: I was using a small 8mm box-end wrench, not a ratchet, and it didn't take all that much force to tighten the nut. I've stripped threads before and it usually requires considerable force, unless the metal's soft. I'm going to contact the aftermarket parts company's customer service department and see what they have to say about it.

Surprise! Yet another oddball work stoppage! And the $36 I paid for the compression tool is down the drain. That's bad enough, but I'm dead in the water until I get another compression tool. Time lost.

I was crossing my fingers that things would go smoothly from here on in, because I'm working under a time crunch: I need to have the car on the road by the end of May, because the owners of the house I'm renting are putting it on the market. I bought another house, but I hoped to finish the car here and drive it to my new place. The logistics of moving a half-finished car and another engine would be a nightmare.

I will overcome this latest wacko problem somehow, but in the meantime I say, damn, damn, double-damn hell!

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 04-30-2025 at 09:26 PM.

|

|

|

04-30-2025, 08:46 PM

04-30-2025, 08:46 PM

|

#542

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Post mortem: The most likely way thread damage could occur in the middle of the rod is by tightening it to the limit of compression and then continuing to tighten it. But I was aware of the warnings not to overtighten it or risk breaking something on the VarioCam. I estimated the unit was compressed no more than 90 percent, judging by the tautness of my chain compared with the laxity of chains in videos I've seen. If I had reached the compression limit, I'd think I would have felt some resistance, more than when just tightening the nut. Perhaps the progressively increasing force required to tighten it was just too much for soft threads to handle and they gave out. That said, I have to acknowledge the possibility that I overtightened it, despite being very careful not to. Regardless of the cause, I'm going to need another compression tool. First, I'll see what the company that sold me this one has to say.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 04-30-2025 at 09:22 PM.

|

|

|

05-01-2025, 08:29 AM

05-01-2025, 08:29 AM

|

#543

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

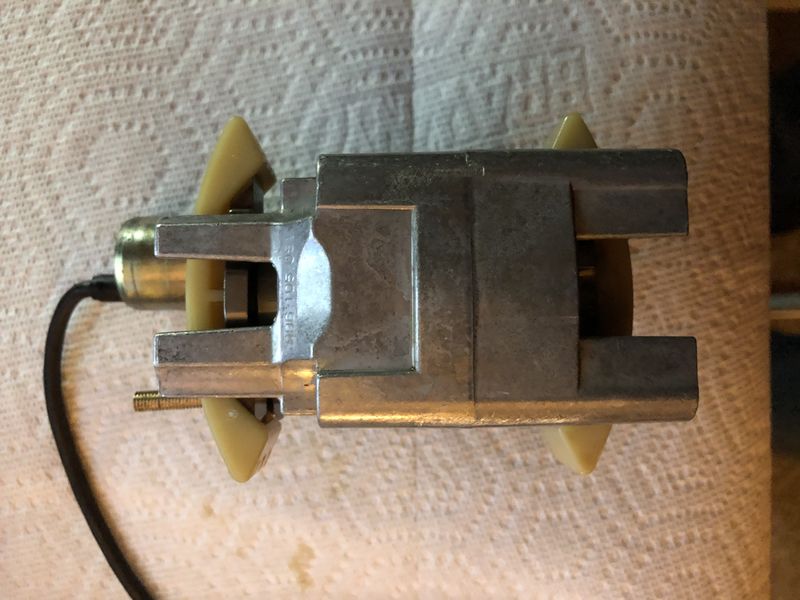

More proof the compression tool was made of soft metal and therefore the defendant is not just a careless idiot who overtightens things. If it please the Court, I present the following photograph as Exhibit 1:

Note the 6mm wide, 1mm deep channel in the shaft near the threads. The nut was full of metal bits from the damaged threads and therefore difficult to turn, so the defendant used a pair of small vice grips to hold the shaft. Apparently, the vice grips weren't cinched down enough, so they carved the channel during a single rotation of the shaft. A channel of this depth could not be created so quickly unless the metal was soft.

And so, ladies and gentlemen of the jury, I submit to you that this entire fiasco resulted from too-soft metal and therefore LoneWolfGal is innocent of boneheaded workmanship.

The defense rests.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 05-01-2025 at 01:25 PM.

|

|

|

05-01-2025, 03:08 PM

05-01-2025, 03:08 PM

|

#545

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,647

|

For future reference, it is always a good idea to lubricate the threads on devices like this to reduce galling and stripping of the threads. When this tool is cranked down, there is a considerable load on the threaded areas as the tool is by design necessity smaller than it should be for the load on it. Any decent lube will do; penetrating oil, engine oil, whatever you have. I personally favor ARP's Ultra Torque Fastener Assembly Lubricant, which we use extensively, but you could even get away using anti seize compound to both protect the treads and make torquing easier and more accurate.

__________________

Anything really new is invented only in ones youth. Later, one becomes more experienced, more famous and more stupid. - Albert Einstein

Last edited by JFP in PA; 05-01-2025 at 03:11 PM.

|

|

|

05-01-2025, 04:13 PM

05-01-2025, 04:13 PM

|

#546

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by JFP in PA

For future reference, it is always a good idea to lubricate the threads on devices like this to reduce galling and stripping of the threads.

|

I did use a dab of engine oil that was clinging to the outside of the VarioCam to lubricate the threads, but I wish I'd had some of that ARP Ultra-Torque product. I'll pick some up. I used to have some anti-seize compound but it got lost in the shuffle.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 05-01-2025 at 05:35 PM.

|

|

|

05-01-2025, 04:43 PM

05-01-2025, 04:43 PM

|

#547

|

|

Registered User

Join Date: Jan 2019

Location: PA

Posts: 1,726

|

Quote:

Originally Posted by LoneWolfGal

|

I was wondering if you were going back to the place you originally got the tool or get the Grainger allthread I told you about. It looks like Grainger's may be a harder metal. At least it's steel. Get a new left-handed nut. Grainger sells a bag of 50 for $1.61.

https://www.grainger.com/product/Hex-Nut-M5-0-80-Thread-22YK31

I imagine they are not high demand parts, so I'd make sure they have them in stock before driving all that way. You may have to order them in advance.

Still, it makes me wonder how the guy whose video I posted got away with using a modified aluminum rod.

Regardless, good luck. I hope you get past this without any more troubles and you have smooth sailing the rest of the build.

__________________

2002 Boxster Base - Arctic Silver - Tiptronic

2010 Subaru Forester

1980 Ford C-8000 Custom Cab Emergency-One Fire Truck

__________________

"I never lose. I either win or I learn." -Nelson Mandela

Last edited by piper6909; 05-01-2025 at 04:51 PM.

|

|

|

05-01-2025, 07:04 PM

05-01-2025, 07:04 PM

|

#548

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by piper6909

I was wondering if you were going back to the place you originally got the tool or get the Grainger allthread I told you about. It looks like Grainger's may be a harder metal. At least it's steel. Get a new left-handed nut. Grainger sells a bag of 50 for $1.61.

https://www.grainger.com/product/Hex-Nut-M5-0-80-Thread-22YK31

I imagine they are not high demand parts, so I'd make sure they have them in stock before driving all that way. You may have to order them in advance.

Still, it makes me wonder how the guy whose video I posted got away with using a modified aluminum rod.

Regardless, good luck. I hope you get past this without any more troubles and you have smooth sailing the rest of the build. |

I'm definitely going to contact the company that sold me the tool and express my dissatisfaction. But before that, I'll let my friend the metal fabricator have a look at it, get his take.

Thanks for pointing me to Grainger; that was a good call. Their threaded rod has a tensile strength of 55,000. Wish I knew the tensile strength of the one I bought. Grainger's rod is one meter in length, so I could make ten 10cm-long compression tools out of it! Then I can dole them out to folks who are attempting the same procedure, along with a prayer book.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 05-01-2025 at 07:14 PM.

|

|

|

05-01-2025, 09:10 PM

05-01-2025, 09:10 PM

|

#549

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Update from Grainger:

Web Price

$6.66/ each

Ships from supplier. Expected to arrive on or before Tue. May 13.

May 13 wouldn't work for me. Unless...while waiting for it to be delivered I could drop the original engine. And if the rod still hasn't been delivered I could unbolt the transmission and bolt it on the new engine with a new clutchplate and throwout bearing. Which reminds me, are M96 flywheel bolts single use only? Haven't seen any references.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

|

|

|

05-02-2025, 02:16 AM

05-02-2025, 02:16 AM

|

#550

|

|

Registered User

Join Date: Jan 2019

Location: PA

Posts: 1,726

|

Quote:

Originally Posted by LoneWolfGal

Update from Grainger:

Web Price

$6.66/ each

Ships from supplier. Expected to arrive on or before Tue. May 13.

May 13 wouldn't work for me. Unless...while waiting for it to be delivered I could drop the original engine. And if the rod still hasn't been delivered I could unbolt the transmission and bolt it on the new engine with a new clutchplate and throwout bearing. Which reminds me, are M96 flywheel bolts single use only? Haven't seen any references. |

Maybe this place can get them to you faster?

https://accu-components.com/us/left-hand-thread-threaded-bars/409371-HTBL-M5-1000-A4?google_shopping=1&c=2&gad_source=1&gbraid=0AAAAADI7_w57vz2S-a5EuY8ShHnKa0XBa&gclid=CjwKCAjwn6LABhBSEiwAsNJrjqzn0v3UBW_rck_eByir Phj6HkeKNTvzkQTYQLJGmKplfkA7lzsy6xoCM6AQAvD_BwE

They are pricier, and 10cm long instead of 1 meter, but if they get to you in a better time...

They also sell new nuts, which I strongly recommend.

I just checked their site and standard shipping is 5 days, expeess is 3 days.

But then you only get one shot and if it strips out, you're back to square 1. I think going with Grainger and pulling the engine out while you're waiting may be your best bet

Last edited by piper6909; 05-02-2025 at 02:37 AM.

Reason: Shipping update.

|

|

|

05-02-2025, 06:34 AM

05-02-2025, 06:34 AM

|

#551

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,647

|

We never reuse either pressure plate or flywheel bolts, they are not that expensive and typically under high loads in use, plus the flywheel bolts are torque to yeild (torque spec + additonal angle) which automaitcally precludes reuse.

Amazon list the threaded rod with one day delivery: https://www.amazon.com/dp/B078H6J4D3/?coliid=ISRITT0IKCK3V&colid=2HC5QQFJX9KXZ&psc=1&ref_=list_c_wl_lv_ov_lig_dp_it

uxcell M5 Fully Threaded Rod, 304 Stainless Steel, 250mm Length, 0.8mm Thread Pitch, Left Hand Threads

__________________

Anything really new is invented only in ones youth. Later, one becomes more experienced, more famous and more stupid. - Albert Einstein

Last edited by JFP in PA; 05-02-2025 at 06:37 AM.

|

|

|

05-02-2025, 11:17 AM

05-02-2025, 11:17 AM

|

#552

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by piper6909

|

Great sleuthing, Al. I like Accu's product better than Grainger's. For one thing, they're stainless steel. For another, left-hand nuts, according to the customer service representative I talked with, are not available from Grainger, which is odd. I ordered a stainless rod and hex nut from Accu, shipping via FedEx. Delivery date is also 5/13, so I'm no worse off.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 05-02-2025 at 01:48 PM.

|

|

|

05-02-2025, 11:32 AM

05-02-2025, 11:32 AM

|

#553

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by JFP in PA

|

Appreciate the info. I ordered new bolts for the pressure plate and flywheel. I went with Accu instead of Amazon for the rod and nut, chiefly because Accu's hex nuts are stainless steel, whereas Amazon's are carbon steel.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 05-02-2025 at 06:07 PM.

|

|

|

05-02-2025, 06:04 PM

05-02-2025, 06:04 PM

|

#554

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

JFP, I'll take a wild stab you install only Genuine Porsche clutch plates and throwout bearings? Myself, I'll have to go with aftermarket, due to budget constraints. Are there any aftermarket clutch parts you recommend? I'm guessing in your shop you go the whole nine yards new flywheel and pressure plate. Wish I could, but again, I don't want to have to move to the poorhouse.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

|

|

|

05-03-2025, 06:02 AM

05-03-2025, 06:02 AM

|

#555

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,647

|

We have had excellent results with the factory parts and generally only use them unless the customer request something special, only then if we think their choice is not going to lead to problems.

We replace the disc, pressure plate, all bolts, throw out bearing, and pilot bearing in a standard replacement. The flywheel only gets replaced if it is either severely heat checked or fails the factory "twist test" for the dual mass assembly.

__________________

Anything really new is invented only in ones youth. Later, one becomes more experienced, more famous and more stupid. - Albert Einstein

|

|

|

05-03-2025, 07:35 AM

05-03-2025, 07:35 AM

|

#556

|

|

Registered User

Join Date: Feb 2024

Location: British Columbia

Posts: 12

|

Quote:

Originally Posted by JFP in PA

We have had excellent results with the factory parts and generally only use them unless the customer request something special, only then if we think their choice is not going to lead to problems.

We replace the disc, pressure plate, all bolts, throw out bearing, and pilot bearing in a standard replacement. The flywheel only gets replaced if it is either severely heat checked or fails the factory "twist test" for the dual mass assembly.

|

Hello, I am really hoping someone could measure the distance from the engine/bellhousing flange to the flywheel friction surface on the M96 (I believe this measurement is the same on all variants) Should be about 50mm. be accurate to the mm.

|

|

|

05-03-2025, 06:34 PM

05-03-2025, 06:34 PM

|

#557

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

I suspect a number of folks who hang out here have bought aftermarket clutch parts. Those who have, do you have any recommendations?

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 05-03-2025 at 09:02 PM.

|

|

|

05-04-2025, 03:15 AM

05-04-2025, 03:15 AM

|

#558

|

|

Registered User

Join Date: Sep 2018

Location: Laval QC

Posts: 845

|

Quote:

Originally Posted by LoneWolfGal

I suspect a number of folks who hang out here have bought aftermarket clutch parts. Those who have, do you have any recommendations?

|

I have used the EPS disk on two cars, good price, no complaints.

https://www.europeanpartssolution.com/power-friction-clutch-disc

... with the new bolts, used flywheel and pressure plate.

__________________

Grant

Arctic Silver 2000 Boxster S - bought with a broken engine, back on the road with the engine replaced

Green 2000 Boxster 5-speed and 1978 928 auto

1987 924S 5-speed (Sold) - Blue 2000 Boxster 5 spd (Sold)

|

|

|

05-04-2025, 08:36 PM

05-04-2025, 08:36 PM

|

#559

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

I couldn't stop fiddling with the cams while waiting for the replacement compression tool to arrive, and I was struck by a Grant Hargraveish idea. First, I used a carpenter's clamp positioned on the new pads to fully compress the VarioCam. (And a C-clamp would have worked just as well, but I didn't have one large enough on hand.) Next, I threaded a heavy-duty pull tie through the holes for the compression tool and pulled it tight to keep the device compressed. Then I removed the clamp. The chain fit over the pads with hardly any trouble. Last, I snipped the pull tie and removed it.

Only one hitch, and I'm not sure it's a problem. I carefully kept the lighter-color chain links mated to the divots in the sprockets so that the cams would be in time with each other. I wanted to keep them both at 12 o'clock (while they were on the table). However, during the manipulation necessary to get the chain in place over the pads the cams rotated a teeny bit, to 1 o'clock, enough so the intake cam's link and divot are slightly apart, even though they're still lined up (see photo 2). I should have checked that before I snipped the pull-tie, because the cams can't be rotated without compressing the pads again. My question is, is it necessary to correct the problem so that both cams' links and divots are at 12 o'clock before they're installed in the head? Or can the cams be rotated slightly by hand after they're installed, with the cam tool inserted into the ends of the cams, the cam retainer loosely bolted in place, and before the double chain's sprocket is bolted to the exhaust cam?

The clamp/pull-tie method certainly works, but I'm going to wait until I have the compression tool to do bank 2's cams, so I can get my money's worth out of it.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 05-04-2025 at 08:49 PM.

|

|

|

05-05-2025, 04:42 AM

05-05-2025, 04:42 AM

|

#560

|

|

Registered User

Join Date: Sep 2018

Location: Laval QC

Posts: 845

|

Quote:

Originally Posted by LoneWolfGal

I couldn't stop fiddling with the cams while waiting for the replacement compression tool to arrive, and I was struck by a Grant Hargraveish idea...

|

LOL

Not original though, I think this is suggested in the Pelican instructions.

Quote:

Originally Posted by LoneWolfGal

Only one hitch, and I'm not sure it's a problem. I carefully kept the lighter-color chain links mated to the divots in the sprockets so that the cams would be in time with each other. I wanted to keep them both at 12 o'clock (while they were on the table). However, during the manipulation necessary to get the chain in place over the pads the cams rotated a teeny bit, to 1 o'clock, enough so the intake cam's link and divot are slightly apart, even though they're still lined up (see photo 2). I should have checked that before I snipped the pull-tie, because the cams can't be rotated without compressing the pads again. My question is, is it necessary to correct the problem so that both cams' links and divots are at 12 o'clock before they're installed in the head? Or can the cams be rotated slightly by hand after they're installed, with the cam tool inserted into the ends of the cams, the cam retainer loosely bolted in place, and before the double chain's sprocket is bolted to the exhaust cam?

|

I don't have a spare engine at the moment (just sold it) so I am trying to visualise this. My understanding is the following...

WIth the crank at TDC for the cylinder bank in question and the slot in the end of the exhaust cam parallel with the valve cover mating surface (and/or - the cam tool installed in the ends of the cams) that cam is properly positioned. Positioning the second cam is a product of the number of chain links between the divots as you call them. You can simply count the links... or use the coloured links... or both. If I remember correctly with the compression bolt in place you can even reposition the cam sprockets vis-a-vis one another. You can move the cams once they are installed in the head before installing the cam tool and attaching the sprocket for the timing chain. With the cam tool installed in the ends of the cams nothing will move, but the divot for the exhaust cam is by definition in the right place. With the divots properly placed the slot in the end of the intake cam should be properly aligned also.

Hope this is clearer for the reader than it is for the writer.

__________________

Grant

Arctic Silver 2000 Boxster S - bought with a broken engine, back on the road with the engine replaced

Green 2000 Boxster 5-speed and 1978 928 auto

1987 924S 5-speed (Sold) - Blue 2000 Boxster 5 spd (Sold)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 04:27 PM.

| |