07-16-2016, 02:25 PM

07-16-2016, 02:25 PM

|

#21

|

|

Registered User

Join Date: Sep 2013

Location: Montreal, QC. (currently expat to Shanghai)

Posts: 3,249

|

Quote:

Originally Posted by FauxDiablo

We could build our own IMS retrofit and patent everything.

I would use a (thick) GM-style cam bearing that just gets press-fit into the end of the IMS, and then redesign the flange with a big surface for it to rotate around...and have the oil pressure-fed onto that surface via a tap by the oil filter. Or has that been done already? Unfortunately, that is too simple and wouldn't even need the microprocessor.

|

The system we debate on has not much in common with the durability of the bearing itself. You will still need to change your bearing shall you want something better than stock. It won't make any bearings live longer.

Be clear, the system is designed for real-time tracking of the condition of your bearing. Eyes on your bearing tune at all time & speeds + emergency kill switch features. Nice? We can design it so it will make engines live longer; you'll be able to spot your Clinks & Clunks trends and possibly even catch when that 'stray' ferrous metal passes a valve

anything out of the curve can be registered as fault codes. Limitless really

Those 'modern' sensors runs pretty fast band ranges these days lolll. High temp, metal shielded leads, life warranty stuff man

__________________

______________________________

'97 Boxster base model 2.5L, Guards Red/Tan leather, with a new but old Alpine am/fm radio.

|

|

|

07-16-2016, 02:43 PM

07-16-2016, 02:43 PM

|

#22

|

|

Registered User

Join Date: Sep 2013

Location: Montreal, QC. (currently expat to Shanghai)

Posts: 3,249

|

Quote:

Originally Posted by imon_2nd

Hello, Nine8Six.

Good idea and it will work. I say that having worked as a senior development engineer for hardware and software in various digital products, including a lot of audio. I'm a 25-year+ member of IEEE and AES.

You may be underestimating the amount of code that has to be written, not to mention the extensive debugging required to make it reliable. In this case, the amount of code will be driven by the large number of digital filters needed and the interaction among them. This is because motors are noisy places. Picking out the relevant signal from the noise could only be achieved by "self learning" algorithms "hearing" more than a few failures. Lacking any database of failure sounds, the software will have to determine the onset of failure based on changes from "normal." Of course "normal" will vary from motor to motor and across a large operating range.

In short, this is a hard problem that does not lend itself to generalization. Some strategies may be transferable to other motors in other models of cars, but most of the code will not be reusable.

If you were the Director of Engineering at Porsche and asked me as a consultant to bid for this software work, I would estimate 2 man-years. At my rates, that is over $300K.

Good luck with it.

Cheers,

Dave

|

Hi Dave

Wow, thanks so much for jumping in and taking the time to write here. Exactly what I meant, we need minds like yourself to set the rules and standards also! Welcome to the speak (it is just a speak still).

Would you join us if;

1. I base the backend on the Cortex and open SSH root access to the libraries. I can get dns to serve that to all interested developers and yourself. I can also look into setting up a lab with both analog and digital interfaces for the sensor signals. Should be fairly easy (cheap!) to provide.

2. I machine a mid sized replica of the steel base shaft assembly and chains and get it to rotate 24/7 here at the shop (using electric). Providing developers with real-time data to prototype onto. That’s right, live, on the Internet.

Something you'd still consider 300K? In all honesty I had estimated about 25~50k max but that only if using other's SDK (commercial or contracted, same really).

Your advice is priceless so (please!) stick around mate. That bearing needs a serious fix lollll

__________________

______________________________

'97 Boxster base model 2.5L, Guards Red/Tan leather, with a new but old Alpine am/fm radio.

|

|

|

07-16-2016, 04:30 PM

07-16-2016, 04:30 PM

|

#23

|

|

Registered User

Join Date: Jul 2016

Location: Minnesnowta

Posts: 90

|

All the vibration and harmonics aside, I need to run this by you smart people...

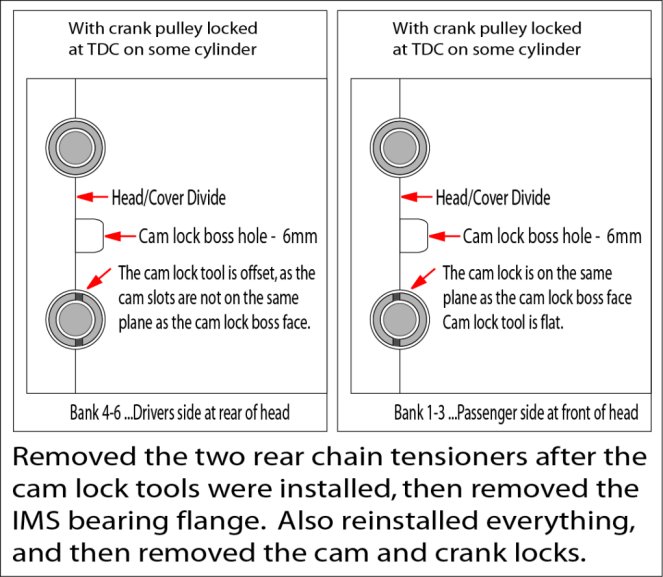

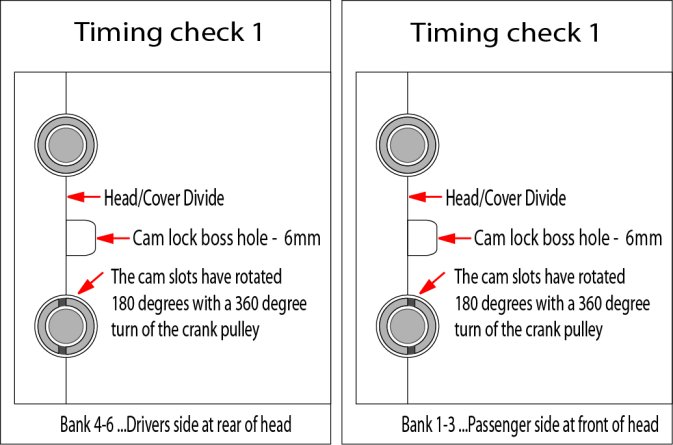

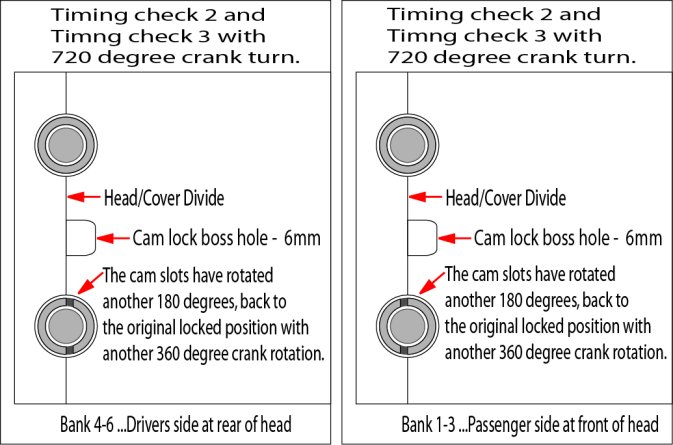

I just reinstalled the IMS flange, reinstalled the chain tensioners, and removed the cam and crank locks. Do the following diagrams look as they should? I think they do, but just a little nod of approval would make it a great night!

Basically I am checking the timing on what appears to be a five chain system.

|

|

|

07-16-2016, 05:06 PM

07-16-2016, 05:06 PM

|

#24

|

|

Registered User

Join Date: Sep 2013

Location: Montreal, QC. (currently expat to Shanghai)

Posts: 3,249

|

Faux - I swear to god my intention wasn't to hijack your thread lolllll Although I've done that twice now in less than one week (I think)

Was under the impression you were making a statement about "its fine" and intended to leave that thread without a particular update.

Should have checked with you before. Sorry bud.

No idea on visuals above, can;t help. Those all look terribly complicated if you ask me (geez man). Hope someone here can give you a hand soon

__________________

______________________________

'97 Boxster base model 2.5L, Guards Red/Tan leather, with a new but old Alpine am/fm radio.

|

|

|

07-16-2016, 07:44 PM

07-16-2016, 07:44 PM

|

#25

|

|

Registered User

Join Date: May 2014

Location: S.California

Posts: 2,029

|

FauxD

I suggest you consider removing the seal before you replace the flange.

But first ask the Forum.

The theory is that the grease has gone so if you remove the seal, the IMSB will bet a little oil bath for lubrication.Better than no lubricant.

Some replacement IMSB kits have that seal already removed so it is a reasonable proposition to consider.

|

|

|

07-16-2016, 07:52 PM

07-16-2016, 07:52 PM

|

#26

|

|

Registered User

Join Date: May 2016

Location: Maui

Posts: 57

|

So you guys will have this all in place by... *checks watch* end of next week?

|

|

|

07-17-2016, 12:21 AM

07-17-2016, 12:21 AM

|

#27

|

|

Registered User

Join Date: Jun 2014

Location: LB, Germany

Posts: 1,520

|

Hello imon_2nd,

i think there must be existing programming libraries for that problem. First music industry has developed a large range of digital filters. Such systems are in cars for a longer period - for example knock sensors. And shure there are other industries where this kind of diagnosis is used.

I agree when it comes to the point when you say the engines are different and additionally the engines are not new. But the idea of the nine8six was detect change. So if i got it right, this unit can learn the state of the engine. And if anything significant changes it alarms. Problem i agree is that to detect what are the parameters for an IMSB alarm. So an idea is to bulld a database where everyone who has that unit will be connected to an internet data base and the units sends her data everytime the car was moved. So the data can be analyzed and can be a learning system. Additionally it is important that the owner gives information about his car according to the data. And also it would be useful to get an info from the owner if the car was phyically diagnosed for an intermediate shaft bearing problem or if was replaced and when and what type. If we could do software updates from the web to the unit, we could inform the unit about these parameters and also of parameters to the specific engines. So this would be more like a self learning system.

And that would be an interesting part, because if the owner has for example a failed water pump and he will tell us when the water pump was replaced, we would know OK - this data came from a failed water pump and so on.

So it would be a more collaborative system than an endless reserarch system.

Regards, Markus

PS: do we need another thread?

|

|

|

07-17-2016, 09:18 AM

07-17-2016, 09:18 AM

|

#28

|

|

Registered User

Join Date: Sep 2013

Location: Montreal, QC. (currently expat to Shanghai)

Posts: 3,249

|

Quote:

Originally Posted by Mauiguy

So you guys will have this all in place by... *checks watch* end of next week?

|

In a sense, yes, pretty much. Like I said, the applied technology is already existing so we are not reinventing anything or reformulating this world’s equation in any ways.

SDK (solvers if you prefer) are available through untested free libraries (github), by buying commercial solvers (Siemens) or by contracting someone who already has it done e.g. roughly 20+ companies listed who specialize in vibration here in China, some manufacturing testing equipment already. Or contract friend Dave and he’ll write this all up for you from scratch (at a price of course).

The other option of course is getting some talents from the community itself, the leaders in bearing trends, to join up and DIY. I think we have pretty much all we need here lollll

Surely Porsche Co Inc Phd and the community would appreciate the effort. Would make 986forum famous also.

Anyway, the concept/prototype is written black on white, for those who didn't follow, see post #6. Won’t get any better than that as for a solution to permanently cancel this mighty bearing worry/obsession problem. Sadly!

I’m stopping here Faux, we’ll throw in another thread soon. Which I hope you’ll join to offer help (HQ in Germany!). We still need that website with the paid avert setup thingy

__________________

______________________________

'97 Boxster base model 2.5L, Guards Red/Tan leather, with a new but old Alpine am/fm radio.

|

|

|

07-17-2016, 11:51 AM

07-17-2016, 11:51 AM

|

#29

|

|

Registered User

Join Date: Sep 2013

Location: Montreal, QC. (currently expat to Shanghai)

Posts: 3,249

|

Quote:

Originally Posted by Mauiguy

So you guys will have this all in place by... *checks watch* end of next week?

|

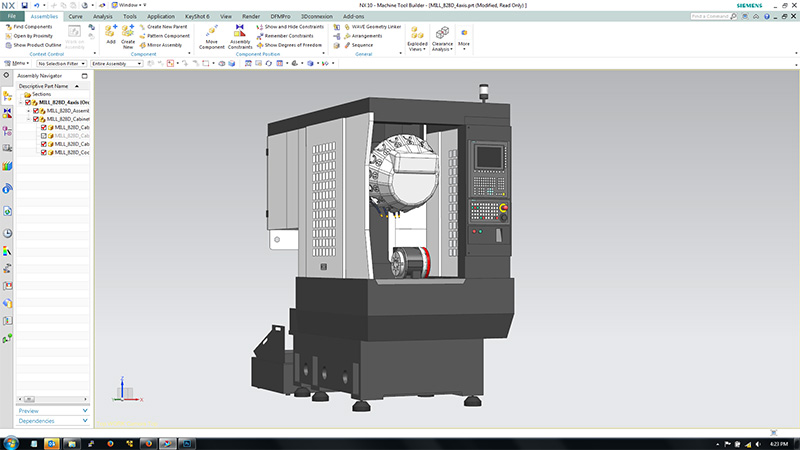

There; the shaft that will be machined out of steel and chained X6 (we just want noise for now, lots of it!). We’ll also place a nice little NSK bearing with a replica flange on it and spin it @3k all day long. Place two micro (super-super fast mhz) accelerometer sensors on each sides of the flange and that will provide enough real-time data (aka bearing time wavelength) to a dev team to (at least) develop the core backend code.

All BS propaganda atm but regardless, gives you an idea of how fast these things move in a real world. Not next week, but may well be the week after

(sorry, Faux, Sunday eve here; wife reading downstairs, nothing to do mate lolll)

Oh geez, already sent to CAM and being machined lolll

__________________

______________________________

'97 Boxster base model 2.5L, Guards Red/Tan leather, with a new but old Alpine am/fm radio.

|

|

|

07-17-2016, 12:54 PM

07-17-2016, 12:54 PM

|

#30

|

|

Registered User

Join Date: Jun 2014

Location: LB, Germany

Posts: 1,520

|

Hi nine8six,

i'm not that fast with building up a european hq.  But i think we need a little business plan and a kickstarter project to gain money for a prototype.

Maybe this could change the car diagnostic business. And also could bring car diagnostic to cars that never where designed to have any.

"You can tame a wild horse but never put life in a dead one." David Ogilvy.

Think we have a wild horse.

Maybe some now know what my profession is.

Regards, Markus

|

|

|

07-17-2016, 01:23 PM

07-17-2016, 01:23 PM

|

#31

|

|

Registered User

Join Date: Aug 2009

Posts: 1,466

|

Quote:

Originally Posted by FauxDiablo

I love your posts.

Also...Could someone just isolate the OBD2 equivalent of something that constantly monitors camshaft deviation? All it would have to do is start screaming when it realizes that the pattern is that of one chain side slacking and the other chain side tightening really fast and forming a "wave" readout of some sort, which would indicate that the rear of the IMS shaft is is moving in an eccentric or orbital path around the bearing (axially disturbed). |

One of my regular routines on returning from the track is connecting the Durametrics and doing a sample of the cam timing actual and the cam timing specified. It been good so far +-.5 once the oil temp is leveled off.

__________________

2003 Black 986. modified for Advanced level HPDE and open track days.

* 3.6L LN block, 06 heads, Carrillo H rods, IDP with 987 intake, Oil mods, LN IMS. * Spec II Clutch, 3.2L S Spec P-P FW. * D2 shocks, GT3 arms & and links, Spacers front and rear * Weight reduced, No carpet, AC deleted, Remote PS pump, PS pump deleted. Recaro Pole position seats, Brey crouse ext. 5 point harness, NHP sport exhaust

|

|

|

07-17-2016, 07:46 PM

07-17-2016, 07:46 PM

|

#32

|

|

Registered User

Join Date: Jul 2016

Location: Minnesnowta

Posts: 90

|

Quote:

Originally Posted by Nine8Six

There; the shaft that will be machined out of steel and chained X6 (we just want noise for now, lots of it!). We’ll also place a nice little NSK bearing with a replica flange on it and spin it @3k all day long. Place two micro (super-super fast mhz) accelerometer sensors on each sides of the flange and that will provide enough real-time data (aka bearing time wavelength) to a dev team to (at least) develop the core backend code.

All BS propaganda atm but regardless, gives you an idea of how fast these things move in a real world. Not next week, but may well be the week after

(sorry, Faux, Sunday eve here; wife reading downstairs, nothing to do mate lolll)

Oh geez, already sent to CAM and being machined lolll

|

That's an awesome virtual mill you have there! If I had one I would just use it as a video game. Oops, crashed the spindle, no problem, reset.

|

|

|

07-18-2016, 01:27 AM

07-18-2016, 01:27 AM

|

#33

|

|

Registered User

Join Date: Sep 2013

Location: Montreal, QC. (currently expat to Shanghai)

Posts: 3,249

|

Markus - let this boil for 2~3 days and we'll talk, happy for you to take the lead on this. We need a team man... let's see if we can get the finest of the finest off this forum and RL combined. Let's talk over another thread soon!

Quote:

Originally Posted by FauxDiablo

That's an awesome virtual mill you have there! If I had one I would just use it as a video game. Oops, crashed the spindle, no problem, reset.

|

Haha, that’s the lathe bud, the mill is below. Oil cooled 20,000RPM spindle, 60meter/min travel speed, servo 16x tool changer (tool change in 1.2sec). All powered by a (Nano-bit precision) Siemens Sinumerik controller and Sinamics drives & servos. German engineering at its finest.

Does a pair of adjustable GT3 control arms in <6min. The mill alone worth twice more than the latest GT4 also

Feel ya, but sadly you can’t crash them, the SIM are linked and in sync with the actual physical machines' limit switches. Extremely event-less and boring!

__________________

______________________________

'97 Boxster base model 2.5L, Guards Red/Tan leather, with a new but old Alpine am/fm radio.

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 11:06 AM.

| |