04-19-2012, 07:46 AM

04-19-2012, 07:46 AM

|

#1

|

|

Theoretical propagandist

Join Date: Dec 2011

Location: Pacific Northwest

Posts: 793

|

So the build begins...

So the build begins...

So the project is a 1998 Boxster with a 2.5L engine. Purchased the car for a song with 88K miles on the clock December 2011 ($5000), now just running a little over 90K. Car is in immaculate condition for a car of this age. Body very straight and runs like a champ.

When I first bought Gadget (as I call her), I knew she would need new brakes and rotors and new struts (left rear had leaked out) and having built cars for many years this did not bother me. My Porsche experience was spending the better part of 4 years tearing apart a 928S4 talk about hidden issues. Note: My problem here was the mental passion for the Boxster was high and I assumed that the few mods above were all that was needed and life would be great. Saw Madmod's post and jumped headlong into the fray of getting ready to pull the trigger on a suspension.

But things were going to change.... I joined our local PCA group, started reading everything I could find on the Boxster (after the fact...of course) both here on 986, Mike's site, Pedro's site, Pelican, and Flat6's site and quickly began to uncover lots of little factoids and nuances about the Boxster I had not considered. The dreaded IMS issue, RMS, AOS, bearings, clutch, leaky coolant reservoir...the list kind of grew.

Which brings me today and this post. Realizing I was going to be doing more work then I planned, I have had to take a step back and begin assessing all issues as a system and that if I was going to go through the effort of tearing off the pieces/parts what else could I fix so as not to be repeating the process. Additionally this meant that I needed the car in a more useful position for working on her rather then sitting on jack stands. This in turn meant upgrading the garage as my wife refused to see me spend one more project on my back working on a creeper. So a new heavy duty rubber flooring system along with a mid rise lift from Gregg Smith. Cool beans and a bit of work but I still have yet to get into the car!

So here I am after having spent the better part of two evenings going through Pelican (and referencing Design911 website) for drawings, pictures and part numbers to develop a build list (along with many threads the members here have posted) and my plan as it sits today is as follows:

Suspension ROW M030 replacement (to include all rubber seals, plates and fittings)

Sway bar bushings

Brakes and Rotors

Wheel Bearings (Fronts are catching and since I'm doing the front the backs will go as well)

IMS

RMS

Cam chain tensioners (Cyl 1-3 and Cyl 4-6) harmonic testing showed excess vibration with these

Clutch kit (including flywheel)

Clutch Master Cylinder

Clutch Slave Cylinder

CV joints and boots

AOS

Spark plugs, tubes and O-rings (will test the coil packs to see performance)

Radiator reservoir tank

Left Radiator (may repair over replace as it has a small leak)

Front Engine mount

Sparco Seats with lowered mounting adjustable rails

Gahh top with soft window (modifying to make rear window replaceable without removing top)

System wide fluid flush and replacement.

Before I pull the trigger on the components above I am sending the list to Pelican to have them go through all I have indicated on my build sheet (what a cool option that is for putting a project together) and make sure if I have duplicated anything or have forgotten anything to let me know.

Well this is just the beginning and as I start removing and replacing things I will keep a photo log of the work and if I can I will gladly post pictures of other stuff as requested to help anyone else on their projects. My timeline for finishing this project will be dictated by work as I spend a lot of time traveling and that in itself can knock the wind out of you upon getting home...especially when it is long overseas trips. I hope to be done by this summer...only time will tell.

Please, I am open to helpful hints, suggestions ideas and input from anyone who has more time and experience on the Boxster then me...

__________________

When life throws you curves, aim for the apex...

|

|

|

04-19-2012, 07:55 AM

04-19-2012, 07:55 AM

|

#2

|

|

Track rat

Join Date: Nov 2006

Location: Southern ID

Posts: 3,701

|

While you are in there.... a fresh water pump and LN 160F T-stat. Serpentine belt and idler pulleys if they show any signs of wear.

__________________

2009 Cayman 2.9L PDK (with a few tweaks)

PCA-GPX Chief Driving Instructor-Ret.

Last edited by Topless; 07-31-2012 at 08:32 AM.

|

|

|

07-25-2012, 07:28 PM

07-25-2012, 07:28 PM

|

#3

|

|

Theoretical propagandist

Join Date: Dec 2011

Location: Pacific Northwest

Posts: 793

|

Well, as I begin my project rebuild on my 98' 986. I sent my parts list around to a number of companies looking for bids on supplying all the parts I needed and in the end Pelican came through with shinning numbers. Sure there are a couple of pieces I found elsewhere that I could not pass up the pricing but in the end, I was able to get 98% of all my parts at the best price from Wayne. Additionally, I have the full version of the UK Boxster manual, Bentley manual and Wayne’s 101 Projects book along with about 3 gigs of data from Mike, Pedro, threads from here and across the web. No such thing as having too much information and if I had to ask a question, I wanted to at least be able to discover the answer on my own. With that said, I am sure there will be a few questions somewhere down the line.

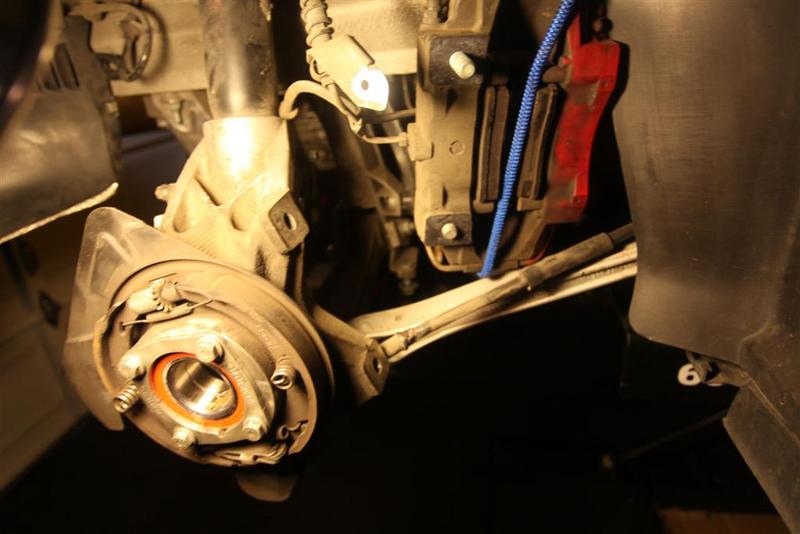

OK, so in deciding where to start I chose the wheel bearings. The wheels came off and I pulled the tires off and got the rims over to the powder coater. The rotors and pads were changed last December so that put me next at the wheel bearings.

Realizing that a number of folks have posted up wheel bearing threads and there are some novel approaches by others to speed the process of replacement, I spent quite a bit of time on the phone and emails with many people and uncovered an aeronautical company specializing in lubrication of aircraft engines and whose owner is a Boxster owner

He has taken his engineering abilities and passion for the Porsche and produced several tools specifically designed for the 986 and some of its issues. Casper Labs casperlabs.com has a new design that allows the replacement of a wheel bearing in ~1 hour/wheel wherein you do not have to remove the suspension the eccentric, nor do you need a hydraulic press for removal nor insertion of the bearings. The tool is fully functional for all four wheels.

I would love to show you how the tool works, but I have been asked not to as he is still building his business market. I will say this is somewhat of a bummer but I will honor my word and not show anything more than what he shows in his marketing pictures. In his defense I bought the first tool off the production line. Hey, I can respect a request…but I can show what it looks like with a bearing out. In the end it did take about 1 hr wheel and in the end I am stoked with how easy the whole process went.

Total cost for this project: Tools, wheel bearings and 5 hours time just under $500.00

Ease of project (using Wayne's format) two wrenches

I was even able to let my wife do one wheel as she is really into this project and at 5'4" and 105lbs she was able to do one complete wheel!

Here are some shots below:

he IMS will be down the road hopefully next week. Next up will be pulling the suspension our and starting on some of the other items. As I take them on I will post up pictures…with that said if there are any pictures someone would like or need of components, let me know and I will take them as I get to those areas.

__________________

When life throws you curves, aim for the apex...

Last edited by Eric G; 08-14-2012 at 02:21 PM.

|

|

|

07-25-2012, 08:00 PM

07-25-2012, 08:00 PM

|

#4

|

|

Registered User

Join Date: Jul 2010

Location: California

Posts: 1,859

|

So how does someone buy the wheel bearing tool? There was nothing obvious on the web site???

__________________

Jäger

300K Mile Club

|

|

|

07-25-2012, 08:08 PM

07-25-2012, 08:08 PM

|

#5

|

|

Theoretical propagandist

Join Date: Dec 2011

Location: Pacific Northwest

Posts: 793

|

Give Bill a call and ask him about the wheel bearing tool:

Bill Ryan

Casper Labs, Inc.

tel. 561-575-3157

__________________

When life throws you curves, aim for the apex...

|

|

|

07-25-2012, 08:11 PM

07-25-2012, 08:11 PM

|

#6

|

|

Registered User

Join Date: Jul 2010

Location: California

Posts: 1,859

|

Thanks, think I will add one to my tool box.

__________________

Jäger

300K Mile Club

|

|

|

07-25-2012, 09:02 PM

07-25-2012, 09:02 PM

|

#7

|

|

Certified Boxster Addict

Join Date: Nov 2010

Location: Los Angeles

Posts: 7,669

|

Be sure to check the dual mass flywheel while you're doing the clutch. It is likely worn out after 90K miles.

And while you have the drive shafts off to replace the CV joints and boots, check the spider gear in the transaxle. If any of the previous owners were doing burnouts, it is likely pitted and worn.

__________________

1999 996 C2 - sold - bought back - sold for more

1997 Spec Boxster BSR #254

1979 911 SC

POC Licensed DE/TT Instructor

|

|

|

07-26-2012, 04:09 AM

07-26-2012, 04:09 AM

|

#8

|

|

Theoretical propagandist

Join Date: Dec 2011

Location: Pacific Northwest

Posts: 793

|

I will be servicing the both axles with new components all around and will definitely look at the trans axle and I need to check the DMFW when I have access to it. I have not had any of the symptoms...but that does not mean anything as parts generally tend to work normally till they are reaching end of life.

My head would like to believe it will be fine, my heart tells me not to listen to my head. Since I have so many upgrades I am doing, I will perform the test...but even if it passes I will likely drop a new one in.

__________________

When life throws you curves, aim for the apex...

Last edited by Eric G; 07-26-2012 at 04:12 AM.

|

|

|

07-29-2012, 07:43 PM

07-29-2012, 07:43 PM

|

#9

|

|

Theoretical propagandist

Join Date: Dec 2011

Location: Pacific Northwest

Posts: 793

|

Well another day and more items knocked out. I have taken the approach that before I just tear things apart and bag and tag parts, I have started a notebook with a detail of each item that is coming off and notes about any issues.

So I decided that the area of the car to start with was at the back end of the car and work my way forward. Pulled the braces and cross brace, pan, sway bar and then dropped the exhaust system as a whole item. As each item came off I spent the time to clean and polish each part back to a nice shine. Many would say why...and I remember advice my dad gave me a long time ago: if you don't clean something when you do work on it, how will you know when something changes and it gets hidden in the existing dirt?

As I dug into the car I was impressed how clean it was considering it is going 14 year old. Not much dirt and little to no leakage on any of the seal. However, like a lot of threads I have read, I spent a fair bit of time cleaning off the cosmoline from parts. A soft wire bristle brush on a drill works wonders to bring that like new look back.

After all that the big item for today was the axles and CV joints. Once the exhaust was out they simply dropped out and were ready to be worked on. If you are planning on doing your CV joints and you order the kit...be aware that your new parts may show up in an unassembled condition. Ball bearing housing and inner spline were rolling around in the box. You would think it would simply be an easy assembly...think again. You need to pay attention to how the inner spline inserts into the body of the CV. After mucking around with it for about 20 minutes, I found that dropping one of the six bearings out, inserting the parts together and then popping the sixth bearing in at the end...the CV joint worked like magic.

After rebuilding the axles, I got my cardboard sheet to put my transmission bolts in when I remove it...and the I found a little surprise. Bolts G and H were MISSING! Not a common thing, but on my 96' Bronco I had the same thing happen where two bolts had backed out over time. Good thing Wayne had the part numbers listed in the project book...so they were ordered today.

Also, thank you Thstone...my DMFW and transmission mounts showed up yesterday. Yeah it was pricey to get the flywheel, but after looking at all the threads and discussions on the forum, I would sooner replace it now then put all these new parts in and have to come back in a year and do the flywheel.

Well, enough gabbing, here are some pics of the work.

__________________

When life throws you curves, aim for the apex...

|

|

|

07-30-2012, 05:13 AM

07-30-2012, 05:13 AM

|

#10

|

|

Registered User

Join Date: May 2011

Location: Maine, USA

Posts: 126

|

Nice thread. Thanks for posting. Keep it coming!

|

|

|

07-30-2012, 07:34 PM

07-30-2012, 07:34 PM

|

#11

|

|

Theoretical propagandist

Join Date: Dec 2011

Location: Pacific Northwest

Posts: 793

|

Today's target was to remove all of the rear suspension components and struts, clean brake housing, wheel hub assembly and suspension cross member of all the cosmoline, grease and oil that has accumulated. This simple task turned out to take the better part of 9 hours today.

In this picture a little surprise jumped out when trying to clean up the gunk on the ebrake cable. Turns out under the rubber guard where the nut on the cable attaches into the main attachment. The rust had built up around this nut and was eroding the nut building oxide up and into the brake cable. I was able to clean all the rust and erosion out then sealed it with a rust proof coating.

The next couple of pictures show the amount of build up of gunk.

All the suspension pieces are out and I have cleaned my components now its time to drop the struts. Since I am doing this a section at a time, I am only working on the rear suspension and struts, the fronts will come later.

With the plug removed I am now able to see all three nuts that are holding the strut in place. For this nut you REALLY WANT TO USE THE TAPE TRICK! If you don't the nut will fall down in to the body of the car and you will kick yourself for not doing this.

Continued in next post...

__________________

When life throws you curves, aim for the apex...

|

|

|

07-30-2012, 07:41 PM

07-30-2012, 07:41 PM

|

#12

|

|

Theoretical propagandist

Join Date: Dec 2011

Location: Pacific Northwest

Posts: 793

|

With all three nuts removed the strut just dropped out. I went into the shop and took all the new components and assembled the new struts and arraigned all the new suspension parts in a layout for both sides of the car. These items will not be installed until I have the tranny dropped, and all the other components in the engine compartment installed.

As you can see with all the parts out, this leaves me a lot of room to work in when I get ready to do the IMS and RMS.

Again, if there are pictures of anything anyone can need...let me know. When stuff is out it is a great time to capture them.

__________________

When life throws you curves, aim for the apex...

|

|

|

07-31-2012, 07:01 PM

07-31-2012, 07:01 PM

|

#13

|

|

Theoretical propagandist

Join Date: Dec 2011

Location: Pacific Northwest

Posts: 793

|

Dug in and finally struck IMS gold...

__________________

When life throws you curves, aim for the apex...

|

|

|

07-31-2012, 07:12 PM

07-31-2012, 07:12 PM

|

#14

|

|

Theoretical propagandist

Join Date: Dec 2011

Location: Pacific Northwest

Posts: 793

|

Uncovered the IMS...

__________________

When life throws you curves, aim for the apex...

|

|

|

07-31-2012, 07:18 PM

07-31-2012, 07:18 PM

|

#15

|

|

Registered User

Join Date: Jul 2010

Location: California

Posts: 1,859

|

Eric,

I recommend replacing the seals on the oil cooler while your at it, inexpensive and easy to do.

__________________

Jäger

300K Mile Club

|

|

|

07-31-2012, 07:28 PM

07-31-2012, 07:28 PM

|

#16

|

|

Theoretical propagandist

Join Date: Dec 2011

Location: Pacific Northwest

Posts: 793

|

Quote:

Originally Posted by Jager

Eric,

I recommend replacing the seals on the oil cooler while your at it, inexpensive and easy to do.

|

Good call, I had not thought of that. I will order them tonight. Thank you sir.

__________________

When life throws you curves, aim for the apex...

|

|

|

08-01-2012, 12:29 PM

08-01-2012, 12:29 PM

|

#17

|

|

Registered User

Join Date: May 2011

Location: Maine, USA

Posts: 126

|

Thanks for the thread. Very interesting.

|

|

|

08-01-2012, 06:19 PM

08-01-2012, 06:19 PM

|

#18

|

|

Theoretical propagandist

Join Date: Dec 2011

Location: Pacific Northwest

Posts: 793

|

A slow day...but a day of learning...

Well to say today was productive would be a good thing and a bad thing. Today started out with the intention of installing the AOS, Clutch Slave and Reservoir. Got the AOS out with not much difficulty as having nothing in the back end made it very simple.

Before I installed the new AOS, I wanted to replace the Reservoir since there was "more" room to access the hoses. Let me say to anyone who has replaced the reservoir without dropping the tranny and exhaust system and suspension...I tip my hat to you as you are gods among men! I could not imagine how you did it. So at this point is where my day goes sideways.

First off, here is how much space you have to work with in removing the hose clamps from the back side of the tank.

While I commend Porsche on building a good car, I would like to smack the back of the head on the engineer who designed this aspect. I have a feeling it was the same one who did the IMS. After fighting the clamps, cramped space and poor angle to see the danged parts, I realized I needed to drain the reservoir before I pulled the last hose. Getting inside the trunk I found that you only need to pull the carpet back right at the corner wherein I exposed the three bolts that hold the reservoir tank. After draining the radiator fluid I was able to pull the tank into the trunk and remove the final clamps. While the tank was not cracked, it was deeply colored, indicating the plastic was hardened and would not have held out much longer.

Couple of notes here: The new tanks do not come with the dipstick hole drilled. This was an easy fix and a little filling and the tube was easily reinserted. Secondly, you need to be extremely careful with the cooling level sensor at the bottom of the tank. It will be a stiff turn to twist it out and you need to be careful when reinserting it in the new tank.

Well, as I finished bolting it back in place I needed to install the second piece of the oil filler tube. That was when I found that the third tube that attaches to the engine was broken. Dang, this is going to be a pain. Before I tear out parts to get to this I decide to pull out one of my unique tools. I have a 25' 4mm borescope that I used to inspect how bad this might be.

The main computer unit:

The working end of the borescope:

I did not buy this for the build, but for a project at work that proves to be useful in inspecting internal parts of engines and other hard to see areas.

The scope found that at the bottom of the third pipe there was a crack that went 3/4 of the way around the pipe and is showed to be an old crack as there as a build up of old oily sludge that seemed to have been plugging the crack.

OK, this means that the AOS is not going to be installed as I will be pulling the throttle body out when the new pipe arrives.

So lets move on to the Clutch Slave...not! Seems I did not read the Pelican part list on the slave as there are two additional parts you need. The adapter and new hose. Seems that the old slave body was metal and had a traditional screw in fitting.

Well the additional parts Porsche is extremely proud of, the adapter is $160.00 and the hose is $140.00. In placing this order I added a few more items and tools so, this aspect of the build will wait till next week.

So tomorrow will be the front suspension and steering tie rods and hopefully a tad bit more productive.

__________________

When life throws you curves, aim for the apex...

|

|

|

08-01-2012, 08:21 PM

08-01-2012, 08:21 PM

|

#19

|

|

Registered User

Join Date: Jun 2012

Location: Bedford, TX

Posts: 2,755

|

Interesting thread! You are a better man than me

__________________

______________________________________________

2001 Boxster S Lapis Blue

TS Cat Bypass Pipes and exhaust

iPad Mini Dash Install

DEPO Tail Lights

|

|

|

08-01-2012, 08:35 PM

08-01-2012, 08:35 PM

|

#20

|

|

Registered User

Join Date: Oct 2011

Location: sac. ca

Posts: 156

|

I love threads like this....

Eric, Could I get your old bearing to inspect?

__________________

98 boxster

82 280sl parts for sale

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 11:33 AM.

| |