03-25-2025, 12:32 PM

03-25-2025, 12:32 PM

|

#401

|

|

Registered User

Join Date: Jul 2024

Location: Cambridge Ontario

Posts: 144

|

okay i have read the thread over and i think i understand your issue .. as a mechanical guy i think i can help... if LN cant.

now that you can get a socket on and hold the middle with the screwdriver... .. you need to grind 2 flats on the socket..

this will allow you to put a crowfoot on the socket, then put your torque wrench on the crows foot and tighten to spec. Remember that the torque value will need to be recalculated due to the length of the crow's-foot but that value is easy ...

just remember your torque wrench has to fit on the crows foot and clear the socket.. I have a small head beam torque wrench which is perfect, but they might be hard to find now.

something like this if the head of your torque wrench is too big.

https://www.summitracing.com/parts/ttn-23140?srsltid=AfmBOopI5wdDN9cYew5rCafy3rX_JrlLD1np 3yvxx_Jx2pEQD6JddE2zKtQ

Last edited by theiceman; 03-25-2025 at 12:38 PM.

|

|

|

03-25-2025, 12:39 PM

03-25-2025, 12:39 PM

|

#402

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,649

|

Use the crows foot at a right angle to the torque wrench head and no correction is required.

The problem you are encountering is why we use the pass thru sockets I mentioned earlier; they have a hex built into them:

__________________

Anything really new is invented only in ones youth. Later, one becomes more experienced, more famous and more stupid. - Albert Einstein

Last edited by JFP in PA; 03-25-2025 at 12:41 PM.

|

|

|

03-25-2025, 02:41 PM

03-25-2025, 02:41 PM

|

#403

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Thanks, guys. I see how a crowfoot would work in this application. With a crowfoot on the socket the nut could be torqued while the screwdriver holds the stud. Sort of a Rube Goldberg solution, but whatever works is a good solution. In the service of this approach, I just bought a $15 set of metric crowfoot wrenches and a $53 bench grinder with a 6" wheel for grinding the flats on the socket. I wanted one anyway. Even if Jake comes up with a different solution, I can always use the tools.

Honestly, I could've completely rebuilt a 350 cu in Chevy engine in less time than I've spent fiddling with these wackadoodle problems.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 03-25-2025 at 03:11 PM.

|

|

|

03-25-2025, 03:22 PM

03-25-2025, 03:22 PM

|

#404

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,649

|

Quote:

Originally Posted by LoneWolfGal

Honestly, I could've completely rebuilt a 350 cu in Chevy engine in less time than I've spent fiddling with these wackadoodle problems.

|

Welcome to the world of Porsche ownership and maintenace.................

And believe it or not, Porsche actually makes and sells an obscure and very expensive tool that does exactly what is being described..........

__________________

Anything really new is invented only in ones youth. Later, one becomes more experienced, more famous and more stupid. - Albert Einstein

|

|

|

03-25-2025, 04:48 PM

03-25-2025, 04:48 PM

|

#405

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by JFP in PA

Welcome to the world of Porsche ownership and maintenace...

|

It's humbling, as I said. On the plus side, it does supply plenty of you-gotta-be-kidding stories to tell.

Quote:

|

And believe it or not, Porsche actually makes and sells an obscure and very expensive tool that does exactly what is being described..........

|

I don't doubt it. Have you seen one in the flesh?

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

|

|

|

03-26-2025, 04:51 AM

03-26-2025, 04:51 AM

|

#406

|

|

Registered User

Join Date: Jan 2019

Location: PA

Posts: 1,726

|

Sorry I didn't read this before you went out and bought more tools, but probably the reason they suggested a 'zip' driver is because it makes sudden impact bursts which could jar the nut into turning without the stud, same way using an impact gun on a wheel lug will not cause the entire wheel to turn like it would when using lug wrench. You could make your own "impact" by simply putting a ratchet on it and lightly tapping the handle with a hammer. Then once you're comfortable that it's properly seated and turns you could troque down to spec.

Last edited by piper6909; 03-26-2025 at 04:58 AM.

|

|

|

03-26-2025, 06:35 AM

03-26-2025, 06:35 AM

|

#407

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,649

|

Quote:

Originally Posted by LoneWolfGal

It's humbling, as I said. On the plus side, it does supply plenty of you-gotta-be-kidding stories to tell.

I don't doubt it. Have you seen one in the flesh?

|

I've only seen photos of it, basically it is exactly what just about everyone cobbles together to get the job done, only it cost $400 nearly 15 years ago. Funny bit is I was picking up parts at my local Porsche dealer and a tech was replacing a leaking IMS flange (common on early models, Porshe released a second design with better lip seals), and I looked at what he was using: a cheap deep socket with the business end turned down slightly on a lathe, center drilled out, and a nut welded on the back of it. A $10 functional replacement for the $400 factory tool...................

__________________

Anything really new is invented only in ones youth. Later, one becomes more experienced, more famous and more stupid. - Albert Einstein

|

|

|

03-26-2025, 09:23 AM

03-26-2025, 09:23 AM

|

#408

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by JFP in PA

Funny bit is I was picking up parts at my local Porsche dealer and a tech was replacing a leaking IMS flange (common on early models, Porshe released a second design with better lip seals), and I looked at what he was using: a cheap deep socket with the business end turned down slightly on a lathe, center drilled out, and a nut welded on the back of it. A $10 functional replacement for the $400 factory tool...................

|

I love stuff like that. Forum member Grant fabricated an IMS bearing extractor and installer out of exhaust pipe! Adapt, improvise, overcome... oorah! A friend of mine who's a metal fabricator eyeballed LN's Pro kit and said, "Yeah, it wouldn't be too tough to make this stuff." Of course, he has lathes and all sorts of sophisticated tools. Too bad he's in Canada or I would've called on him to help me modify the socket.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

|

|

|

03-26-2025, 09:38 AM

03-26-2025, 09:38 AM

|

#409

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by piper6909

Sorry I didn't read this before you went out and bought more tools, but probably the reason they suggested a 'zip' driver is because it makes sudden impact bursts which could jar the nut into turning without the stud, same way using an impact gun on a wheel lug will not cause the entire wheel to turn like it would when using lug wrench. You could make your own "impact" by simply putting a ratchet on it and lightly tapping the handle with a hammer. Then once you're comfortable that it's properly seated and turns you could troque down to spec.

|

Jake Raby replied to my trouble ticket:

"Piper6909 in the thread is offering some good information. Usually when this scenario occurs the threads of the stud, or the nut have debris or burrs creating this instance. Heavy lubricants can also lead to this when applied to threads. With all the assistance on the thread you have what you need to move forward. The trick that LN advised may seem unorthodox, but it works and does so without any detrimental impacts."

Al, since I don't have a pneumatic zip gun, I'm going to try my powered ratchet and maybe the old-school impact hammer method you suggested. The crowfoot set and bench grinder won't be here until tomorrow anyway. I'm not sorry I bought them. You can't have too many tools. I plan to pick up the set of pass-thru sockets JFP recommended.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 03-26-2025 at 10:21 AM.

|

|

|

03-26-2025, 11:17 AM

03-26-2025, 11:17 AM

|

#410

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by theiceman

i cant get a clear pic of the stud.. is it slotted in the middle ,, is that a small hole with a thread inside ??

|

The stud has a slot with a hole in the center, which makes it necessary to use a fairly large flat-blade screwdriver, large enough to span the hole. Not sure about the purpose of the hole, but it's not threaded inside.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

|

|

|

03-26-2025, 10:15 PM

03-26-2025, 10:15 PM

|

#412

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by piper6909

|

I have an impact driver, a Ryobi. I got tied up with something today, but I'm planning to try it out tomorrow. If it doesn't work, I'll try the old-school hammer method. If that doesn't work, my new bench grinder and crowfoot wrenches are supposed to be here tomorrow and the Rube Goldberg method will almost certainly work. That is, after I grind a couple of flat sides on the socket for the crowfoot. I'll bet the bench grinder wouldn't break a sweat.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

Last edited by LoneWolfGal; 03-27-2025 at 08:56 AM.

|

|

|

03-27-2025, 02:21 PM

03-27-2025, 02:21 PM

|

#413

|

|

Registered User

Join Date: Jan 2019

Location: PA

Posts: 1,726

|

Quote:

Originally Posted by LoneWolfGal

I have an impact driver, a Ryobi. I got tied up with something today, but I'm planning to try it out tomorrow. If it doesn't work, I'll try the old-school hammer method. If that doesn't work, my new bench grinder and crowfoot wrenches are supposed to be here tomorrow and the Rube Goldberg method will almost certainly work. That is, after I grind a couple of flat sides on the socket for the crowfoot. I'll bet the bench grinder wouldn't break a sweat.

|

The Ryobi should do it.

|

|

|

03-27-2025, 11:29 PM

03-27-2025, 11:29 PM

|

#414

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by piper6909

The Ryobi should do it.

|

I'm looking forward to trying it, but I couldn't find my set of impact socket adapters. I turned this place upside down looking for them. So I ordered a $5 set with Prime overnight delivery. In the meantime I've been having fun with my Wen bench grinder, grinding the upper part of the socket to receive a 14mm crowfoot wrench, in case the Ryobi can't seat the nut on the stud. The Wen is a marvelous tool. Don't know how I got along without it.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

|

|

|

03-29-2025, 03:16 PM

03-29-2025, 03:16 PM

|

#415

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by piper6909

The Ryobi should do it.

|

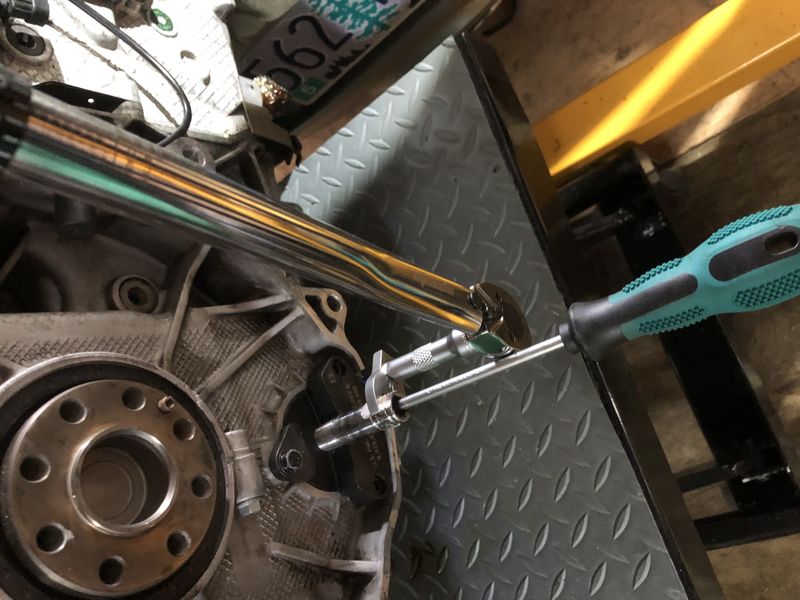

You called it, Al. The Ryobi did the trick. And now the nut is torqued to 18 ft lbs, a hair short of the max of 20. Still, I'm a little sorry I didn't give this contraption a chance to do its stuff. It probably would have set the nut just as surely as the impact driver.

I didn't spend a lot of time grinding facets on the socket, more proof I'm getting a handle on my compulsive perfectionism. Not that I didn't think about it. But this part of the installation procedure has dragged on so long that I modified the socket to the point where the 14mm crowfoot wrench would fit on it and called it good. It ain't pretty but it works. Or would, if given a chance.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

|

|

|

03-29-2025, 03:32 PM

03-29-2025, 03:32 PM

|

#416

|

|

Registered User

Join Date: Jan 2019

Location: PA

Posts: 1,726

|

Quote:

Originally Posted by LoneWolfGal

You called it, Al. The Ryobi did the trick. And now the nut is torqued to 18 ft lbs, a hair short of the max of 20. Still, I'm a little sorry I didn't give this contraption a chance to do its stuff. It probably would have set the nut just as surely as the impact driver.

I didn't spend a lot of time grinding facets on the socket, more proof I'm getting a handle on my compulsive perfectionism. Not that I didn't think about it. But this part of the installation procedure has dragged on so long that I modified the socket to the point where the 14mm crowfoot wrench would fit on it and called it good. It ain't pretty but it works. Or would, if given a chance.

|

Great!

And that's a beautiful contraption you made!

__________________

2002 Boxster Base - Arctic Silver - Tiptronic

2010 Subaru Forester

1980 Ford C-8000 Custom Cab Emergency-One Fire Truck

__________________

"I never lose. I either win or I learn." -Nelson Mandela

|

|

|

03-29-2025, 03:49 PM

03-29-2025, 03:49 PM

|

#417

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by piper6909

Great!

And that's a beautiful contraption you made!  |

Thanks, Al. I think I'll try this one next:

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

|

|

|

03-30-2025, 03:37 PM

03-30-2025, 03:37 PM

|

#418

|

|

Registered User

Join Date: Dec 2009

Location: Orange County, CA

Posts: 1,996

|

Did you replaced the tensioner pads already? Then you should be ready to swap the engines right? :-)

Last edited by Gilles; 03-30-2025 at 03:41 PM.

|

|

|

03-30-2025, 06:17 PM

03-30-2025, 06:17 PM

|

#419

|

|

Registered User

Join Date: Apr 2023

Location: Oregon

Posts: 545

|

Quote:

Originally Posted by Gilles

Did you replaced the tensioner pads already? Then you should be ready to swap the engines right? :-)

|

I was planning to put in the rear main seal next, but I've been psyching myself up to do the cam chain wear pads reading, watching videos, making sure I've got everything I'll need, wondering if I should replace the chains** at the same time. Before I put a ratchet on the cam covers I want to be absolutely certain I understand each step. I'm getting close.

**On a 39K-miles engine I would expect the cam chains to have minimal wear, but then, chains are relatively inexpensive. Still, where do you stop throwing new parts at it? Everything I'm doing to this engine I regard as critical stuff, including replacing the motor and transmission mounts. Sure, it would be nice to replace the AOS; water pump, coils and plugs, oil pressure sending unit and sensor, fuel pressure regulator, crankshaft position sensor, positive crankcase ventilation conduits, etc., etc. Then I could drive to the poorhouse in style! After I make a decision on the cam chains I think I'm going to draw the line there. It's getting close to a year since I've driven my baby. I'm jonesing to get it back on the road.

__________________

2000 986 base

Arctic Silver/black

2.7 liter

5-speed manual

|

|

|

03-30-2025, 07:21 PM

03-30-2025, 07:21 PM

|

#420

|

|

Registered User

Join Date: Sep 2018

Location: Laval QC

Posts: 854

|

Quote:

Originally Posted by LoneWolfGal

... **On a 39K-miles engine I would expect the cam chains to have minimal wear, but then, chains are relatively inexpensive. Still, where do you stop throwing new parts at it? Everything I'm doing to this engine I regard as critical stuff, including replacing the motor and transmission mounts. Sure, it would be nice to replace the AOS; water pump, coils and plugs, oil pressure sending unit and sensor, fuel pressure regulator, crankshaft position sensor, positive crankcase ventilation conduits, etc., etc. Then I could drive to the poorhouse in style! After I make a decision on the cam chains I think I'm going to draw the line there. It's getting close to a year since I've driven my baby. I'm jonesing to get it back on the road.

|

Of all the stuff you mention I would only consider changing the AOS simply because it is a lot easier to do with the engine out. Water pump, coils, plugs, CPS etc can be changed when and if necessary with the engine in the car. Chains should be fine.

__________________

Grant

Arctic Silver 2000 Boxster S - bought with a broken engine, back on the road with the engine replaced

Green 2000 Boxster 5-speed and 1978 928 auto

1987 924S 5-speed (Sold) - Blue 2000 Boxster 5 spd (Sold)

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 08:45 AM.

| |