02-11-2013, 11:21 AM

02-11-2013, 11:21 AM

|

#1

|

|

Theoretical propagandist

Join Date: Dec 2011

Location: Pacific Northwest

Posts: 793

|

Interesting morning today...

Well, it was a strange morning today. Decided it was going to be sunny and the Boxster needed to go for a spin. Two miles from home, going between first and second gear on a slow acceleration I feel a thud in my seat and all of a sudden I have no power!

Clutch still works, engine is running fine, gears shift like they are suppose to but nothing will make the car go forward.  I am stuck. Thankfully it happened right at a construction zone and the guys quickly came over and got me out of the road and to a really nice parking spot on the side.

Well, called the wife, she brought the truck and we got the car back home into the garage and on the lift. I am guessing at this point it might be a broken shifter cable or linkage. No dice either of those as they are looking just fine. But then my keen eye (I am able to spot things amiss quite well...not in this case) I notice my drivers side axle sitting on my suspension. It doesn't belong there???

Long and the short of it, the screws had backed out of the transmission and it went clunk! Nothing bent or broken just all of the screws had worked there way out. When I reinstalled my transmission last year, I had used blue lock tight with new bolts when I put the car back and checked the torque...but somehow I must have just missed it. My thought on blue verses red was if I had to pull the axles off, I didn't want to run the chance of snapping off a bolt. I have seen this happen to a few folks, but those may have been due to corrosion from years of being in one spot?

Also, I have read many threads on here about how axles have popped off due to not torquing the bolts down and I thought I was good on this one...in the end I wasn't. Oh well, today was a big lesson learned and I will be checking out both axles and all screws later today. I will post some pictures of before and after just as a reference point.

__________________

When life throws you curves, aim for the apex...

|

|

|

02-11-2013, 11:42 AM

02-11-2013, 11:42 AM

|

#2

|

|

Registered User

Join Date: Oct 2008

Location: O.C. CA

Posts: 3,709

|

I think this is the 3rd time this year someone has posted this on a forum. I use blue loctite for the same reason. You have to minimize the amount of grease that gets on the bolt threads when you install the bolts. If enough grease is in the threads of the bolt &/or half shafts the locktite is in-effective.

|

|

|

02-11-2013, 11:59 AM

02-11-2013, 11:59 AM

|

#3

|

|

1999 base

Join Date: Dec 2011

Location: Coral Springs FL

Posts: 1,617

|

Quote:

Originally Posted by BYprodriver

I think this is the 3rd time this year someone has posted this on a forum. I use blue loctite for the same reason. You have to minimize the amount of grease that gets on the bolt threads when you install the bolts. If enough grease is in the threads of the bolt &/or half shafts the locktite is in-effective.

|

+1 on that.

most of the time you hear about that, it happens after an axle rebuilt.

when you install back the shaft and tighten the bolts, some grease squeezed out, and contaminate the tread.

last time i installed the shafts, i spent a lot of time cleaning the bolts and the treads with wire brush and alcohol.

used blue loctite, and re-torque after 500 miles.

worked for me so far.

it is also not a bad idea to re-torque the bolts with every oil change.

|

|

|

02-11-2013, 11:51 AM

02-11-2013, 11:51 AM

|

#4

|

|

Moderator

Join Date: Feb 2012

Location: DFW

Posts: 782

|

Hi Eric,

The same exact thing happened to me last week. Apparently the grease can work its ways into the threads, negating even loctite. Interestingly enough, I spoke to some Porsche specialists and they don't recommend the use of loctite. Rather, the use of upgraded grade 12.9 bolts and lock washers will solve the problems of loosening from vibration. Clean the grease thoroughly with q tips and brake cleaner, and check torque after 1,000 miles.

Last edited by Kenny Boxster; 02-11-2013 at 08:46 PM.

|

|

|

02-11-2013, 04:48 PM

02-11-2013, 04:48 PM

|

#5

|

|

Theoretical propagandist

Join Date: Dec 2011

Location: Pacific Northwest

Posts: 793

|

Quote:

Originally Posted by Kenny Boxster

Hi Eric,

The same exact thing happened to me last week. Apparently the grease can work its ways into the threads, negating even loctite. Interestingly enough, I spoke to some Porsche specialists and they don't recommend the use of loctite. Rather, the use of upgraded grade 12 bolts and lock washers will solve the problems of loosening from vibration. Clean the grease thoroughly with q tips and brake cleaner, and check torque after 1,000 miles.

|

Kenny, this is really funny you would post up about a longer bolt and lock washer. (I will get to that at the end)

In looking back at my installation of the axles and the bolts on the right side axle I I believe there are two things at play here: Grease as others have said may have infiltrated during initial installation; and the length of the bolts.

In looking at still attached passenger side, I noticed that the new bolts I had ordered for the axles DID NOT go through to the other side of the axle mounting plate on the transmission. At best that was only giving it 5 or so threads to hold itself in and was not taking advantage of the entire mounting surface. Also I did find two bolts on the passenger side that were loose!

So with that in mind (Kenny here is where your input comes in) I headed off to Tacoma Screw and Fastener with my bolts and decided that I was going to go with a longer bolt and a high collar lock washer for added security.

For those that would ask, the bolts I used the first time were new OEM Porsche bolts (I never reuse bolts in this type of application). Also the question was asked about what was damaged? Two bolts got their ends smashed over and that made for a bit of effort to get them out. I had to drop the splash pan and use a drift punch and stout hammer to punch them out...ugh!

In the end, the whole cash out of pocket was $19.97 for a dozen new bolts and lock washers.

Here are a couple of shots of the scene of the crime:

I have lifted this up to the transmission as the whole axle was laying on the cat.

A view of the area

All fixed up...

Here is a close up of how much I now have sticking through...

Upgraded right side

Here is the difference between the two bolts

All I can say is this was not how I planned on spending the day, but very glad that the only real damage was two bolts and a lesson learned on checking bolts. While I had the car up on the lift, I ran through all the other bolts within reach and made sure everything was snug...gratefully they were snug.

__________________

When life throws you curves, aim for the apex...

Last edited by Eric G; 02-12-2013 at 02:07 AM.

|

|

|

02-11-2013, 07:38 PM

02-11-2013, 07:38 PM

|

#6

|

|

Registered User

Join Date: Oct 2008

Location: O.C. CA

Posts: 3,709

|

There are 3 or 4 different 10.9 grade axle bolts for Boxsters depending on year & trans application.

|

|

|

02-11-2013, 08:39 PM

02-11-2013, 08:39 PM

|

#7

|

|

Moderator

Join Date: Feb 2012

Location: DFW

Posts: 782

|

Quote:

Originally Posted by BYprodriver

There are 3 or 4 different 10.9 grade axle bolts for Boxsters depending on year & trans application.

|

Yes! Also the S model and the base model use different bolts as well. Quite a plethora.

The 12.9 grade is terrific, I'd recommend it- I found my stock bolts starting to strip, even though I was not over tightening them!

Last edited by Kenny Boxster; 02-11-2013 at 08:46 PM.

|

|

|

02-11-2013, 09:48 PM

02-11-2013, 09:48 PM

|

#8

|

|

Registered User

Join Date: Dec 2012

Location: Colorado

Posts: 159

|

Good to know. I torqued these bolts a month ago but don't recall if they were totally cleaned/degreased.

__________________

2000 Boxster S

|

|

|

02-11-2013, 12:31 PM

02-11-2013, 12:31 PM

|

#9

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

Use spray brake cleaner to degrease the bolts and holes and alllow to dry before using LocTite; they will stay put.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

02-11-2013, 12:44 PM

02-11-2013, 12:44 PM

|

#10

|

|

Registered User

Join Date: Apr 2012

Location: Riverside, CA

Posts: 1,666

|

Does anything typically get damaged when that happens?

At highway speed it could get ugly really fast unless the shaft stays reasonably inline with its original position.

__________________

"It broke because it wants to be Upgraded  "

2012 Porsche Performance Driving School - SanDiego region

2001 Boxster S, Top Speed muffler, (Fred's) Mini Morimotto Projectors, Tarret UDP,

Short Shifter, Touch Screen Dual Din Radio, 03 4 Bow glass Top (DD & Auto-X since May 17,2012)

|

|

|

02-11-2013, 12:59 PM

02-11-2013, 12:59 PM

|

#11

|

|

Registered User

Join Date: Apr 2008

Location: Southern New jersey

Posts: 1,054

|

Grease will not work it's way into a loctited bolt if it was clean during assembly. That means NO grease in the threads, or on the bolt.

|

|

|

02-12-2013, 01:39 AM

02-12-2013, 01:39 AM

|

#12

|

|

Registered User

Join Date: Nov 2010

Location: Australia- Brisbane

Posts: 47

|

10.9 bolts and spring washers is a no no--- your torque values will not be accurrate.

|

|

|

02-12-2013, 09:07 AM

02-12-2013, 09:07 AM

|

#13

|

|

Moderator

Join Date: Feb 2012

Location: DFW

Posts: 782

|

Quote:

Originally Posted by howe

10.9 bolts and spring washers is a no no--- your torque values will not be accurrate.

|

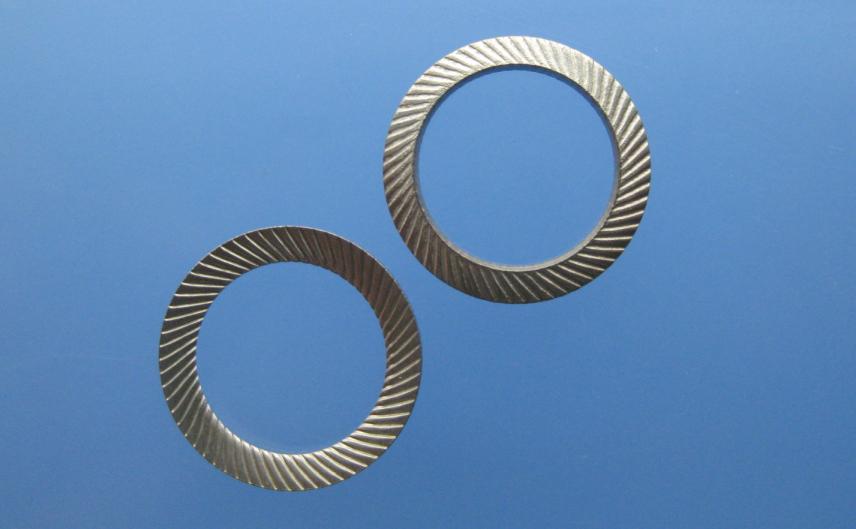

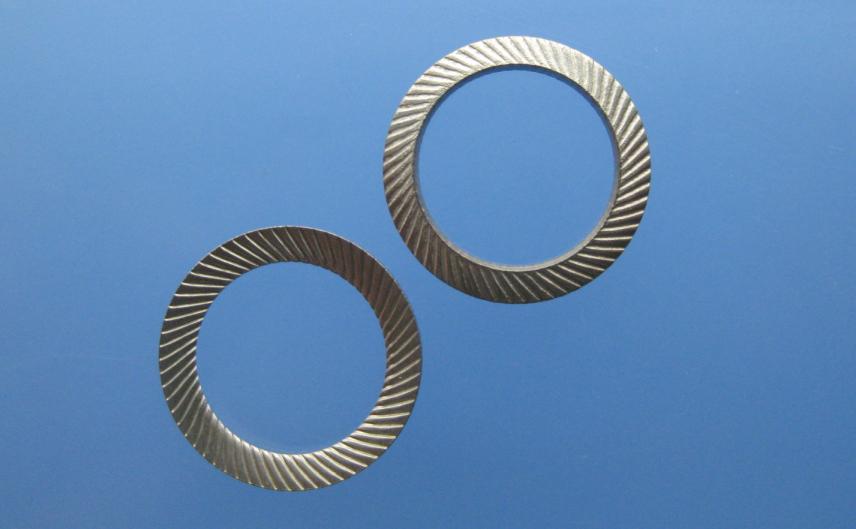

Eric, these locking washers is what is specifically used:

My apologies for not being clear enough. I didn't notice spring washers were used until howe pointed that out in the pictures. I don't know if spring washers would be the best application, but the schnorr washer was what Zim's sold me.

|

|

|

02-12-2013, 09:40 AM

02-12-2013, 09:40 AM

|

#14

|

|

Theoretical propagandist

Join Date: Dec 2011

Location: Pacific Northwest

Posts: 793

|

Quote:

Originally Posted by Kenny Boxster

Eric, these locking washers is what is specifically used:

My apologies for not being clear enough. I didn't notice spring washers were used until howe pointed that out in the pictures. I don't know if spring washers would be the best application, but the schnorr washer was what Zim's sold me. |

I will give these guys a month on the car and see how they are doing. If I find even one loose, I will order these up and try them out. I can easily see the difference from my high collar lock washers and these.

I will say, it felt good to drive her today with NO issues!

__________________

When life throws you curves, aim for the apex...

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 05:27 PM.

| |