02-26-2015, 05:25 PM

02-26-2015, 05:25 PM

|

#21

|

|

Registered User

Join Date: May 2014

Location: S.California

Posts: 2,029

|

The 72/50 issue has been covered in previous posts years ago ,usually they mention BMW also.The poster was Harn I think on the 'other' P-car Forum.

The unknown is what subsequent running changes to dimensions/tolerances/specs were made .The critical issue imho is - are the latest/interchange parts less likely to jam the tappet hard into the bucket ?Forget the Porsche numbers.Porsche do not make the part.INA do. INA do not need to change part numbers if they make minor(?) running changes to the part.Except for the hammered/jammed issue ,my tappets were mostly perfect after 90k miles.Pity not to use them but if they got jammed soon after reuse ,that would be stupid.At $40== x 24,I might have tried it. At $8x24 ,it was .....

The part I found via INA and bought as a BMW item(now revised to Porsche also) on Rock Auto is totally unproven in terms of long term functionality in the M96. Yes, it is dimensionally perfect but there may be more to this issue than simple physical dimensions. According to Rock Auto I was the first customer to buy this part via them for this unlisted application. Neither Rock Auto nor their vendor in England would commit in writing an assurance the lifter would work correctly in the M96. I guess they have gotten a little bolder recently and added the M96 to that application listing.

Yes, the savings are huge which was why I was so puzzled that my original research got no interest. $8 vs $40++ x 24 = significant to me.

If is requires replacement with the $40++ item soon ,it will be a very expensive failure. Beware!

|

|

|

02-27-2015, 02:49 AM

02-27-2015, 02:49 AM

|

#22

|

|

Registered User

Join Date: Jun 2014

Location: LB, Germany

Posts: 1,526

|

Hi Gelbster,

if you've found a INA part number on your OEM Porsche hydraulic lifters and the lifters are exact the same, i didn't see a problem.

If not. i think it is very risky to use them, because the valves are lenghtend over time. So it is very important to compensate this lengthening. Else the valve won't close perfect. This will cause a less in horsepower on the one hand, but much more important it will prevent that the valve will be cooled. And this will cause damaged valves, valve seats and valve shaft seals. And this will cause much much higher costs to repair.

Here is a video that shows the function of hydraulic lifters:

http://youtu.be/lorANZ1Tptw

If the oil reservoir and diameter of the oil pathways in the hydraulic lifter are not exactly the same, the lifter can not work as designated.

Regards from germany

Markus

|

|

|

02-27-2015, 09:18 AM

02-27-2015, 09:18 AM

|

#23

|

|

Registered User

Join Date: May 2014

Location: S.California

Posts: 2,029

|

Markus,

You are correct

I relied on the Interchange information and physical dimensions.The INA part is very common & has many applications if you go through all the Interchange sources.

Here is the Rock Auto info:

2001 PORSCHE BOXSTER 3.2L H6 : Engine : Valve Lifter

BGA Part # HL6330 {#11321748884} Hydraulic Type; Height: 24mm; Outer Diameter: 33mm; Single Lifter

$8.53 each minus 10% discount but shipping from U.K. s $28+

Here is the interchange info from YoYo:

HL6330,BGA HL6330; Valve Tappet

HL6330,BGA HL6330; Valve Tappet

To date, nobody has chimed in here or on other Forums to say :"Yes, I used that part and it has worked correctly for xx,xxx miles".There may be a reason for that..........?

|

|

|

02-27-2015, 10:07 AM

02-27-2015, 10:07 AM

|

#24

|

|

Registered User

Join Date: Jun 2014

Location: LB, Germany

Posts: 1,526

|

Hi Gelbster,

did a little online research. FEBI Bilstein which is a well known after market supplier for OEM parts (not a dealer) lists the hydraulic lifters for Porsche.

Measures

lenght: 24 mm

outer-diameter: 33 mm

Part numbers:

BMW 11 32 1 748 884

Porsche 996 105 041 50 <- make 100% shure these are the right ones for your car.

Febi Bilstein 07589

Link: Herzlich Willkommen in unserem Internetkatalog

Info: http://cars.febi-parts.com/download/Ventilspiel_D.PDF

Also searched the INA online parts catalogue: medias® professional – Product catalogue

But no results for the given part number on the ebay website: 420004910.

INA in general doesn't produce hydraulic lifters. Their business is bearings.

Please check Porsche part number, because the 3.2 is not listed in the FEBI catalogue. Only 2.5 and 2.7 engines are listed! So make 100% shure that it is the right Porsche OEM part number for your car.

Because the FEBI part number is correct i would say go for it in general - if the Porsche part number is correct for the 3.2 engine. And make shure you get original FEBI Bilstein parts, which are high quality parts.

Regards from germany

Markus

Last edited by Smallblock454; 02-27-2015 at 10:49 AM.

|

|

|

02-27-2015, 12:20 PM

02-27-2015, 12:20 PM

|

#25

|

|

Registered User

Join Date: May 2014

Location: S.California

Posts: 2,029

|

Markus ,

Thank you for your research . I wish you had been involved when I was stumbling through this subject solo last summer.

The YoYo link in my previous post shows the Febi-Bilstein numbers also.

|

|

|

02-27-2015, 05:01 PM

02-27-2015, 05:01 PM

|

#26

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

I urge anyone doing these hybrid lifter installations to closely measure the dimensions of the lifter crown. The part numbers won't tell you much of anything when it comes to precision differences between units.

The lifter crown is very important to lifter rotation, and therefore, life.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

02-27-2015, 05:48 PM

02-27-2015, 05:48 PM

|

#27

|

|

Registered User

Join Date: Dec 2009

Location: Orange County, CA

Posts: 2,015

|

Quote:

Originally Posted by Jake Raby

I urge anyone doing these hybrid lifter installations to closely measure the dimensions of the lifter crown. The part numbers won't tell you much of anything when it comes to precision differences between units.

The lifter crown is very important to lifter rotation, and therefore, life.

|

Very interesting comment!

Is this because when the lifter does not rotate, it will wear prematurely on a single spot?

Thank you!

|

|

|

02-28-2015, 12:48 AM

02-28-2015, 12:48 AM

|

#28

|

|

Registered User

Join Date: Sep 2013

Location: uk, notts

Posts: 141

|

PET lists the same number, all 24 so both exhaust and inlet, across all 986 engines.

|

|

|

03-02-2015, 10:42 AM

03-02-2015, 10:42 AM

|

#29

|

|

Registered User

Join Date: Sep 2013

Location: uk, notts

Posts: 141

|

Today I had a look at the lifters I have here out of a 99/2000 3.4.

Marked up INA 577.16. When I google the 577.9 mentioned in a previous post, I find nothing, but the 577.16 does come up.

I watched those you tube videos, very interesting to the point today I dismantled a few, and they would all seem serviceable.

One word of warning I would heed if rebuiling lifters, in one video the guy uses a magnet to keep holdof all the small parts....DONT DO THIS....the spring and ball for the check valve are SO small that if they become magnetized, I would imagine would effect their operation.

The other video, the guy says not to open up the relief valve element, but to me this step is very necessary to successfully renovate a stuck lifter, as you need to clean this out if it's gunged up with old oil.

I also purchased a BGA lifter today so I will have a good compare tomorrow against the INA.

Also got my shop to speak to Febi Bilstein about the ones they list, hoping they would be INA, but the technical line said that they had them made for themselves....?

|

|

|

03-02-2015, 11:26 AM

03-02-2015, 11:26 AM

|

#30

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Now for the funny part.. When approaching INA at the International Motorsport Show a few months ago, they denied ever building this lifter, or even having a part number for it.

Be less concerned with the hydraulic properties, and more concerned with the physical properties of the lifter crown. The surface finish also matters, especially during break in/ work hardening. I have seen some of the replacement lifters that literally had a surface that was achieved with a scotchbrite wheel. Thats what you'll get when you pay for a cheap lifter, and its no way to achieve a proper roughness average.

I get calls about this all the time. The quickest way to cost yourself thousands of dollars is by trying to save a couple hundred. We call it "Stupidity tax" around here, and it gets paid a lot.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

03-02-2015, 11:44 AM

03-02-2015, 11:44 AM

|

#31

|

|

Registered User

Join Date: May 2012

Location: Dover,Kent,England

Posts: 78

|

Quote:

Originally Posted by jimk04

Today I had a look at the lifters I have here out of a 99/2000 3.4.

Marked up INA 577.16. When I google the 577.9 mentioned in a previous post, I find nothing, but the 577.16 does come up.

I watched those you tube videos, very interesting to the point today I dismantled a few, and they would all seem serviceable.

One word of warning I would heed if rebuiling lifters, in one video the guy uses a magnet to keep holdof all the small parts....DONT DO THIS....the spring and ball for the check valve are SO small that if they become magnetized, I would imagine would effect their operation.

The other video, the guy says not to open up the relief valve element, but to me this step is very necessary to successfully renovate a stuck lifter, as you need to clean this out if it's gunged up with old oil.

I also purchased a BGA lifter today so I will have a good compare tomorrow against the INA.

Also got my shop to speak to Febi Bilstein about the ones they list, hoping they would be INA, but the technical line said that they had them made for themselves....?

|

Hi Jim, its steve from boxa aka Marseille, did the same as you over the weekend with some of the spare lifters i have after seeing that video, took a hell of a pull to get one of them apart both looked ok but wouldn't fancy reusing them after the force needed to pull them apart, i'm sticking with my old set which were running quiet before i removed them

|

|

|

03-02-2015, 02:16 PM

03-02-2015, 02:16 PM

|

#32

|

|

Registered User

Join Date: Sep 2013

Location: uk, notts

Posts: 141

|

Hey Steve, yes I thought this was your thread. It has dug up some interesting info.

I would be happy to reuse them after taking them to bits, but I understand the call you make, like Jake says, costly if it all goes wrong

Must get on with my 3.4 build!

|

|

|

03-03-2015, 11:42 AM

03-03-2015, 11:42 AM

|

#33

|

|

Registered User

Join Date: Sep 2013

Location: uk, notts

Posts: 141

|

tappet crown observations, no objective measurements, I wouldnt have the means, but you can SEE a slight difference.

BGA

INA (admittedly with 50k miles on) definitely 'flatter'. I dont think there is any discernable wear on here, as the mark from the valve is very central, doesnt contact wide enough to have flattened out a crown.

|

|

|

03-03-2015, 12:30 PM

03-03-2015, 12:30 PM

|

#34

|

|

Registered User

Join Date: May 2014

Location: S.California

Posts: 2,029

|

Tappet crown- thank you for sharing the observations.

What significance does this have for the jammed-up-in-the-bucket tappet problem?

Does the crown(offset slightly?) cause the tappet to rotate rotate ? And does a little rotation prevent jamming?

Or does jamming occur if there is almost total leak-down of oil from the tappet when the car sits for a long time ? Then when you eventually restart ,the tappet has no hydraulic 'cushion' ,so it gets hammered up into the bucket ?

All WAG but it would be good to understand this issue.

|

|

|

03-03-2015, 01:51 PM

03-03-2015, 01:51 PM

|

#35

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

Quote:

Originally Posted by Gelbster

Tappet crown- thank you for sharing the observations.

What significance does this have for the jammed-up-in-the-bucket tappet problem?

Does the crown(offset slightly?) cause the tappet to rotate rotate ? And does a little rotation prevent jamming?

Or does jamming occur if there is almost total leak-down of oil from the tappet when the car sits for a long time ? Then when you eventually restart ,the tappet has no hydraulic 'cushion' ,so it gets hammered up into the bucket ?

All WAG but it would be good to understand this issue.

|

Go back and reread Jake's comments about the crown finish and hardness. If the face against the cam is not hardened, and with a crown to promote rotation, the crown will wear into a mushroom shape, making it impossible to remove, while also tearing up the cams.

Anyone that has ever wiped out a flat tappet cam will know exactly what he is referring to.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

03-03-2015, 11:05 PM

03-03-2015, 11:05 PM

|

#36

|

|

Registered User

Join Date: Sep 2013

Location: uk, notts

Posts: 141

|

I cant comment on the crown's 'job', I can only see that the BGA tappet has a more pronounced crown. It isnt offset Gelbster, just me struggling to capture the image in a phone!

The tappet would only leak down and then get hammered in if the relief valve element was gunged up. I have had these to pieces and when you put them back together they spring about all over, but you fill this tappet in these pictures up with oil by depressing the tiny ball/spring and then it allows oil in, and it becomes pretty solid....how you need it.

I assume the ball depressing happens with engine oil pressure in situ, but like I say if the tiny relief mechanism is blocked with old oil, it wont work effectively.

This is all my take on the whole thing, nothing certain here.

|

|

|

03-03-2015, 11:40 PM

03-03-2015, 11:40 PM

|

#37

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

Originally Posted by JFP in PA

Go back and reread Jake's comments about the crown finish and hardness. If the face against the cam is not hardened, and with a crown to promote rotation, the crown will wear into a mushroom shape, making it impossible to remove, while also tearing up the cams.

Anyone that has ever wiped out a flat tappet cam will know exactly what he is referring to.

|

Exactly.. I don't give a damn about the contact surface to the valve stem, as long as its the proper hardness.

The crown that follows the cam lobe is whats absolutely unforgiving and effects lifter surface speed and reset as the cam lobe wipes across it. This is a critical dimension and one thousandth of an inch may as well be a mile.

FYI- I have seen brand new lifters come with improper crown radius, and we have to check every single lifter that we install because of this. It sucks, but we save our asses every time that we do it.

Assume nothing, quantify everything.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

03-04-2015, 12:28 AM

03-04-2015, 12:28 AM

|

#38

|

|

Registered User

Join Date: Jun 2014

Location: LB, Germany

Posts: 1,526

|

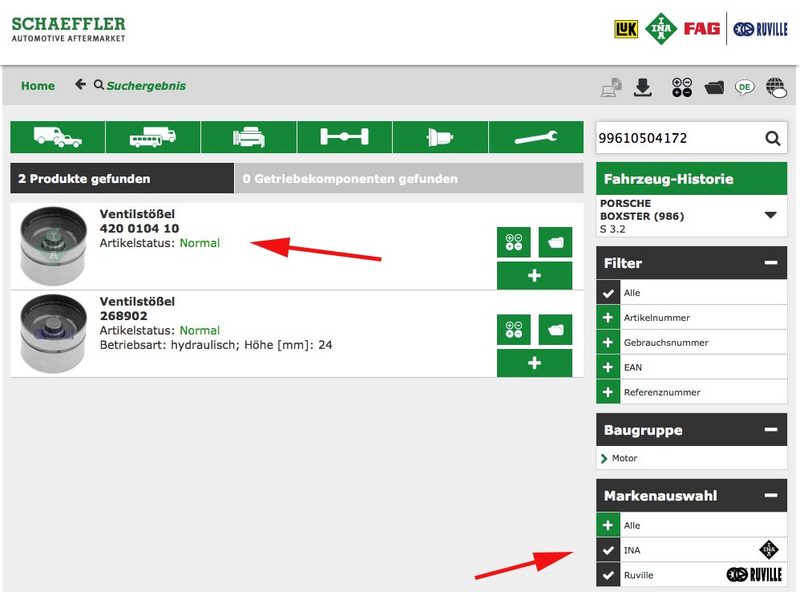

Hi,

did some more research. INA produces hydraulic barrel tappets.

INA Deutschland | Branchen & Anwendungen | Standard Ventiltrieb

Porsche part number: 996 105 041 50.

There are 2 different parts available.

INA part number 265010 Ventilstößel (8 per package, 24 needed)

INA part number 420 0049 10 Ventilstößel (8 per package, 24 needed)

Please take a look in the INA parts online catalogue. Use navigation to switch between different engine types.

Example link: 986, 3.2, 252 HP

Schaeffler Automotive Aftermarket

Schaeffler Automotive Aftermarket

And i have to correct myself. INA produces the parts. Febi Bilstein distributes the INA hydraulic barrel tappets. See: Hydraulic cam followers

I recommend to buy from a local parts dealer, not from ebay.

Last edited by Smallblock454; 03-04-2015 at 12:45 AM.

|

|

|

03-04-2015, 08:50 AM

03-04-2015, 08:50 AM

|

#39

|

|

Registered User

Join Date: May 2014

Location: S.California

Posts: 2,029

|

Markus,

Great research as usual.

According to Auto Atlanta Porsche the Porsche part number was updated to

99610504172.

Using the 99610504172 in your excellent INA reference you provide this updated Porsche # is INA 268902 Ventilstößel or 420 0104 10 Ventilstößel

This crosses over to BGLA #HL6330 on Rock auto. So many 'translations' bothers me......

Here is a previous attempt to understand this opaque issue:

Lifter replacement/upgrade/fix - Rennlist Discussion Forums

|

|

|

03-04-2015, 10:03 AM

03-04-2015, 10:03 AM

|

#40

|

|

Registered User

Join Date: Jun 2014

Location: LB, Germany

Posts: 1,526

|

Hi Gelbster,

thanks for the 99610504172 hint.

Did a little more research. The 420 0049 10 is the INA part number, whereas the 265010 the Ruville part number is. Ruville is a after market sub brand of the Schäffler Group / INA. Ruville: Your System Specialist für Engine & Chassis.

Porsche somtines changes part numbers without changing, or improving the part itself. This is caused by the ERP system.

So in short 420 0049 10 is the INA OEM part for all 986 engines.

About price difference. It is quite normal that Porsche charges enormous spreads. In general it's hard to get OEM parts, because Porsche has contracts with suppliers. For example you'll never get after market SHW brake rotors.

Regards

Markus

Last edited by Smallblock454; 03-04-2015 at 10:14 AM.

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 04:20 AM.

| |