02-10-2014, 11:55 AM

02-10-2014, 11:55 AM

|

#221

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

Having an oil flow from the pump would be nice. If I were to use engine oil for lubrication, I figure 10cc/min would be enough to keep the bearing in oil, under certain conditions.

I am looking at vacuum powered pumps now.

__________________

It's all bad

|

|

|

02-10-2014, 04:14 PM

02-10-2014, 04:14 PM

|

#222

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

Walter,

What are you doing to that poor engine? It looks a little... experimental.

__________________

2003 S manual

|

|

|

02-10-2014, 05:01 PM

02-10-2014, 05:01 PM

|

#223

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

That was a minute ago, now I am back on grease. After playing with bearings over-packed with grease, I found out that they will just poop out the excess grease through the seals within a minute or two and remain perfectly happy. And heat just isn't a problem at the RPMs they will be turning.

__________________

It's all bad

|

|

|

02-14-2014, 08:52 AM

02-14-2014, 08:52 AM

|

#224

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

Quote:

Originally Posted by Jamesp

Walter,

What are you doing to that poor engine? It looks a little... experimental.

|

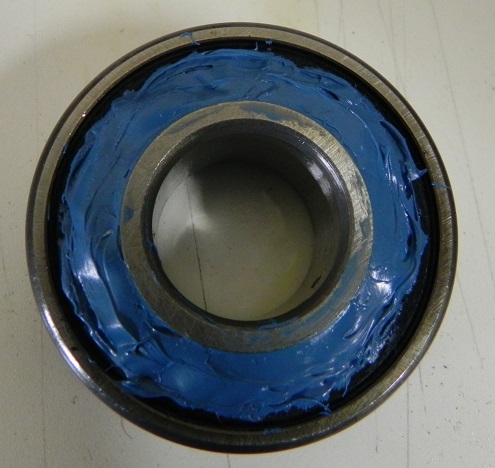

Here's the latest experiment

Molded seal. I will try it out this weekend, after it fully cures.

__________________

It's all bad

|

|

|

02-14-2014, 09:02 AM

02-14-2014, 09:02 AM

|

#225

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

I decided to spend my time omitting the ball bearing, rather than applying a band aid :-)

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

02-14-2014, 05:01 PM

02-14-2014, 05:01 PM

|

#226

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

What I like about you Walter, is that you work in that kingdom where great ideas come from. I think many may look at your ideas and think , "what the heck?". I know I do, some are downright scary to me, but that's the land where really inventive and great ideas come from. Keep it up!

__________________

2003 S manual

|

|

|

02-15-2014, 10:05 AM

02-15-2014, 10:05 AM

|

#227

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

Thanks James. This IMS bearing thing has been fun.

Quote:

Originally Posted by rp17

James, if I'm not mistaken, there is a fixt that sells a oil feed using something similar to what you describe.

|

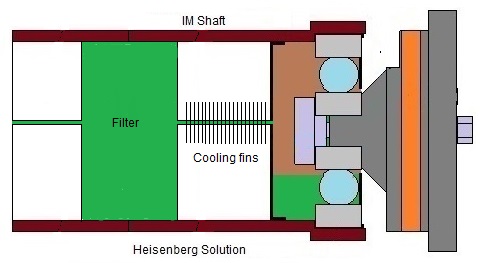

If I were to go this route, this is the way I would want to do it

As I have mentioned, I think 10 cc/min would keep oil flowing out the bearing.

__________________

It's all bad

Last edited by Walter White; 02-15-2014 at 11:08 AM.

|

|

|

11-13-2014, 10:00 AM

11-13-2014, 10:00 AM

|

#228

|

|

Registered User

Join Date: May 2010

Location: uk

Posts: 4

|

Can a blanking plate be fitted before inserting the new IMS bearing. this would stop oil getting into IMS shaft and stop air pressure into bearing from inside shaft, just a thought.

|

|

|

11-13-2014, 10:04 AM

11-13-2014, 10:04 AM

|

#229

|

|

Registered User

Join Date: May 2010

Location: uk

Posts: 4

|

Jamesp,

Can you fit a blanking plate into end of IMS before fitting bearing.

|

|

|

11-14-2014, 03:21 PM

11-14-2014, 03:21 PM

|

#230

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

Wow - a blast from the past! A couple of thoughts on the blanking plate:

The IMS shaft is a pressed assembly and a sealed blanking plate would turn it into a pressure vessel. one that gets temperature and pressure cycled every time the engine runs. That would likely disassemble the IMS tube over time with disastrous results.

The plate would be hard to seal, and would take up real estate on the IMS bearing bore the bearing needs, so the bearing would not fit without additional machining of the IMS shaft which would be complicated.

The IMS threads sure have legs!

I sprung for a Durametric (BUY ONE OF THESE!) and my valve timing is still rock solid after a couple thousand miles with my unique IMS bearing fix which is at least a start. Now I have cam sensor problem I'm chasing and it looks like something electronic crapped out. The engine harness buzzes out clean so I'm looking at the driver for the sensor. My thought is the sensor is not getting energized, just like my thought was the engine harness had a broken wire. Oh well, time will tell and it's a hobby. With luck I wont smoke my ECU searching for voltage. I'm thinking about documenting troubleshooting the camshaft sensor and posting it here as there is almost no information on it on this forum or the rest of the internet. Anybody interested?

__________________

2003 S manual

|

|

|

12-27-2014, 05:40 PM

12-27-2014, 05:40 PM

|

#231

|

|

Registered User

Join Date: Dec 2014

Location: Silver Springs, FL

Posts: 78

|

Indy IMS fix.

My local indy mechanic has been working on these cars for years. His fix is the EPS fix shown in this video:

He charges $1400 to do this on cars with Tiptronic, which includes all parts and includes changing out the AOS, belt, and plugs.

Last edited by BobRickel; 01-12-2015 at 05:25 PM.

Reason: content correction

|

|

|

12-27-2014, 07:31 PM

12-27-2014, 07:31 PM

|

#232

|

|

Registered User

Join Date: Dec 2013

Location: Muncie, In

Posts: 1

|

IMS replacement - Indianapolis

Sorry guys but I'm really needing some help on this one. My 2002 986-S is about to send me to the poorer farm  Anyone know of a good non-Dealer in Indianapolis or close who could handle my IMS replacement. 35,000 miles but I'm paranoid, it had been garaged for most of its life prior to my purchase at 29,000. I guess I should also take this opportunity to replace the clutch?

thanks in advance for any advice..

|

|

|

12-28-2014, 09:32 PM

12-28-2014, 09:32 PM

|

#234

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

Originally Posted by BobRickel

My local indy mechanic has been working on these cars for years. His fix is to pull the engine, center punch a hole from the front oil pressured side of the IMS and put in a roller bearing with no seals. The oil comes through the IMS shaft from the front pressurized side and flows through the roller bearing and out the rear side thus constantly lubricating the bearing with pressurized oil. He charges $1400 to do this on cars with Tiptronic, which includes all parts

|

The part he is center punching is the only thing holding the oil pump drive key from falling into the IMS shaft during operation. I see these failures occur without the assistance of a center punch.

It helps to understand the anatomy of the patient before performing the surgical procedure.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

12-29-2014, 04:39 PM

12-29-2014, 04:39 PM

|

#235

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

Quote:

Originally Posted by BobRickel

My local indy mechanic has been working on these cars for years. His fix is to pull the engine, center punch a hole from the front oil pressured side of the IMS and put in a roller bearing with no seals. The oil comes through the IMS shaft from the front pressurized side and flows through the roller bearing and out the rear side thus constantly lubricating the bearing with pressurized oil. He charges $1400 to do this on cars with Tiptronic, which includes all parts

|

This looks eerily similar to post 192 in this thread, which seems to have some fatal, if yet undefined flaw. Looks good to me, but I'll punch holes in an IMS shaft with very little provocation. Careful with that oil pressure however!

__________________

2003 S manual

|

|

|

01-10-2015, 12:06 AM

01-10-2015, 12:06 AM

|

#236

|

|

Registered User

Join Date: Jan 2015

Location: Bulgaria

Posts: 6

|

Hello i made a big mess on my Boxster S 987 3.4 L

I remove the flange to change the rubber seal of IMS without locking the Crankshaft

and now the shaft is on a side.

What should i do now !

Please check the attached photos

Thank you in advance

|

|

|

01-10-2015, 09:32 AM

01-10-2015, 09:32 AM

|

#237

|

|

Registered User

Join Date: Jul 2014

Location: Tacoma

Posts: 429

|

The problem isn't that you didn't lock the crankshaft, it's that you didn't undo the chain tensioner.

There are plenty of good detailed write ups on doing this job correctly. If you look at one you'll see you caused yourself a ton of extra work. You are now facing a complete cam timing job.

|

|

|

01-10-2015, 10:49 AM

01-10-2015, 10:49 AM

|

#238

|

|

Motorist & Coffee Drinker

Join Date: Jul 2014

Location: Oklahoma

Posts: 3,955

|

Quote:

Originally Posted by Boxe1

Hello i made a big mess on my Boxster S 987 3.4 L

I remove the flange to change the rubber seal of IMS without locking the Crankshaft

and now the shaft is on a side.

What should i do now !

Please check the attached photos

Thank you in advance.

|

I think that happens to more than a few people.

I don't know if it will help, but read through this thread if you haven't already:

IMS Install help! IMS bearing not centered

Be very cautious how you proceed. As Flaps10 implied, you will probably have to release all the tension from your cam chains, recenter the shaft, then reset your cam timing. Trying to force anything or taking short-cuts will probably damage your engine and lead to more problems.

|

|

|

01-11-2015, 06:52 AM

01-11-2015, 06:52 AM

|

#239

|

|

Registered User

Join Date: Jan 2015

Location: Bulgaria

Posts: 6

|

Quote:

Originally Posted by flaps10

The problem isn't that you didn't lock the crankshaft, it's that you didn't undo the chain tensioner.

There are plenty of good detailed write ups on doing this job correctly. If you look at one you'll see you caused yourself a ton of extra work. You are now facing a complete cam timing job.

|

So i face a big problem now ,

Any other advice ?

|

|

|

01-11-2015, 06:54 AM

01-11-2015, 06:54 AM

|

#240

|

|

Registered User

Join Date: Jan 2015

Location: Bulgaria

Posts: 6

|

Quote:

Originally Posted by 78F350

I think that happens to more than a few people.

I don't know if it will help, but read through this thread if you haven't already:

IMS Install help! IMS bearing not centered

Be very cautious how you proceed. As Flaps10 implied, you will probably have to release all the tension from your cam chains, recenter the shaft, then reset your cam timing. Trying to force anything or taking short-cuts will probably damage your engine and lead to more problems. |

Thank you i will check the link now ,

If you get any more info over forum , Appreciate let me know

Best regards

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 07:03 PM.

| |