11-14-2013, 03:52 AM

11-14-2013, 03:52 AM

|

#1

|

|

petrolinmyveins

Join Date: Apr 2013

Location: cumbria uk

Posts: 5

|

Another IMS bearing thread

Hey guys,

I've been lurking around for 12 months or so gaining lots of info on my purchase last year, a '99 model 2.5 silver Boxster.

I shopped in my 4.0L V8 TVR Wedge to join the 986 brigade as I'd always fancied one, even after owning a 320bhp BMW Z3m. (which my son redesigned quite badly)

Although the IMS bearing is a potential issue, it is not at the front of my thoughts all the time. But I follow all the threads related to it on hear. I do and always have done all my own maintenance, from oil changes to engine rebuilds. (because I am too tight in the wallet department :ah:.)

I have a clutch waiting to go in at some point, although it isn't slipping but my RMS is leaking so it is to be taken apart sometime soon. So I will fit an IMSB of some kind while in there.

So to my point, I don't recall seeing the below item mentioned on here>>

Porsche IMS Intermediate Shaft Bearing Repair ETERNAL FIX (ebay no. 181254668411)

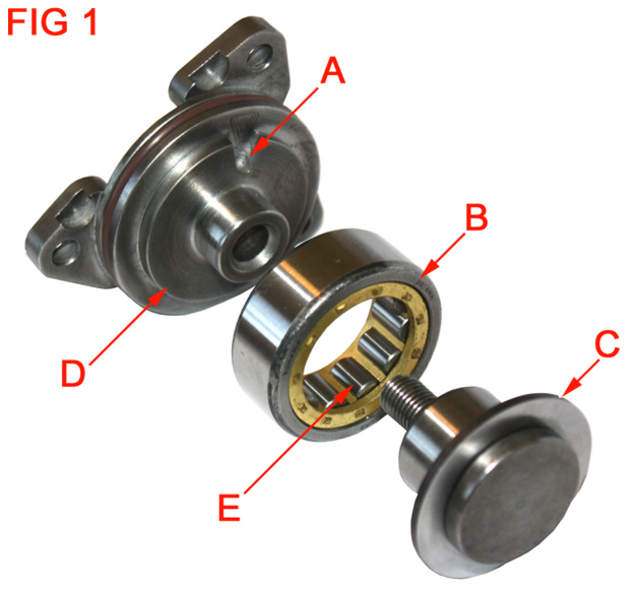

As you can see, (hopefully picture uploaded) it is a roller bearing as apposed to ball bearing.

Has this slipped by people or is it an unproven source? Or even worse, has it slipped by me and all you guys already know about it

And just because I can, a photo

|

|

|

11-14-2013, 04:10 AM

11-14-2013, 04:10 AM

|

#2

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

A man after my own heart with the tight in the wallet department comment. Also I just don't trust anybody but me to work on my cars - too many bad experiences in that department. From what I've seen roller bearings demand that the rotating shaft be aligned axially very, very closely. Ball bearings allow much more misalignment which appears appropriate with the IMS. I put a new IMS bearing in yesterday evening. I used a sealed Nachi greased ball bearing with a vented IMS shaft. I'll tell you I'm way out in the wilderness on this one as I made it up myself, but I'm sure enough that its right to bet my engine on it.

|

|

|

11-14-2013, 04:44 AM

11-14-2013, 04:44 AM

|

#3

|

|

Registered User

Join Date: Nov 2005

Location: Florida

Posts: 529

|

Quote:

Originally Posted by Jamesp

I used a sealed Nachi greased ball bearing with a vented IMS shaft. I'll tell you I'm way out in the wilderness on this one as I made it up myself, but I'm sure enough that its right to bet my engine on it.

|

Do you have any pics of the vented IMS.

That was one of our routes to solve the issue, but was not further developed because it requires engine tear-down.

Good luck

Happy Boxstering

Pedro

__________________

Racecar spelled backwards is: Racecar!

|

|

|

11-14-2013, 05:44 AM

11-14-2013, 05:44 AM

|

#4

|

|

Registered User

Join Date: Apr 2012

Location: Ontario, Canada

Posts: 598

|

Yes Tony, the Vertex roller bearing replacement has been discussed here previously and the consensus seems to be that, in spite of the obviously greater surface area of roller bearings, they are ill-suited to the IMS application: roller bearings are not intended for, nor are they capable of dealing with the thrust loads that the IMS is subjected to.

Brad

|

|

|

11-14-2013, 10:06 AM

11-14-2013, 10:06 AM

|

#5

|

|

Registered User

Join Date: Jul 2007

Location: Texarkana, Texas

Posts: 959

|

Yes, I believe thrust or axial load handling is the big issue with the Eternal Fix roller bearing. However, according to their website that is now updated with more information, they say that they have a patent-pending way of dealing with thrust. But they don't give any technical details. They do refer to their bearing as a "thrust" roller bearing...  I don't know... I'll believe it when I see it. I'd want specific technical details as to how they overcame the poor thrust handling of a roller bearing. I really question it because bearing companies have not be able to overcome this issue for decades! So I'd like to know how an aftermarket, cheap (as in low cost and sometimes low quality) parts manufacturer like Vertex cracked the code that the big bearing makers could not.

Kirk Bristol

__________________

2000 Boxster S - Gemballa body kit, GT3 front bumper, JRZ coilovers, lower stress bars

2003 911 Carrera 4S - TechArt body kit, TechArt coilovers, HRE wheels

1986 911 Carrera Targa - 3.2L, Euro pistons, 964 cams, steel slant nose widebody

1975 911S Targa - undergoing a full restoration and engine rebuild

Also In The Garage - '66 912, '69 912, '72 914 Chalon wide body, '73 914

|

|

|

11-14-2013, 02:32 PM

11-14-2013, 02:32 PM

|

#6

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

Quote:

Originally Posted by ppbon

Do you have any pics of the vented IMS.

That was one of our routes to solve the issue, but was not further developed because it requires engine tear-down.

Good luck

Happy Boxstering

Pedro

|

These videos explain my thoughts on why all IMS bearings run in oil, and not grease, and what to do about it. It's simply PV=nRT, with the pressure venting through the bearing seal. For those who don't speak perfect gas law, as the air temperature inside the shaft goes up when the car runs, air is forced from the inside of the shaft through the bearing grease seal, when the engine cools, air is forced back into the IMS through the bearing grease seal. The videos show that problem and the solution, and it could be done with the shaft in, but would take cleverly designed custom designed tooling to do it.

I used the pelican parts bolt (Thanks Wayne!) but chose a Nachi 6204 NSE s - the seal material is Viton instead of Buna-n - a little better material and it is a sealed bearing.

1 986 IMS Bearing Failure Mode - YouTube

3 Eliminating 986 IMSB Differential Pressure - YouTube

7 My IMS forward plan - YouTube

|

|

|

11-14-2013, 03:04 PM

11-14-2013, 03:04 PM

|

#7

|

|

Registered User

Join Date: Jun 2012

Location: Ontario,Canada

Posts: 84

|

James,i think your on to something and obviously Pedro agrees,but how do u make drill those holes without splitting the motor and if it is possible what about the 06 thru 08 models with there bearing installed from inside the case on assembly.Again great info and well documented

|

|

|

11-14-2013, 03:14 PM

11-14-2013, 03:14 PM

|

#8

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

Quote:

Originally Posted by moresquirt

James,i think your on to something and obviously Pedro agrees,but how do u make drill those holes without splitting the motor and if it is possible what about the 06 thru 08 models with there bearing installed from inside the case on assembly.Again great info and well documented

|

I have not looked at the larger bearing, but from what I've seen in passing there is little problem with them in the base, thought some say their reliability can be improved by removing the grease seal and relying on splash or DOF. If I had one of them I'd be tempted to leave it alone. When replacing my IMS I searched a long time to replace it with a shaft using the 6204 bearing so it could be serviced. I'm not sure that was the best choice.  As far as drilling the hole with the shaft in the engine, for the removable (6204) bearing, with the bearing removed a very small 90 degree drill bit drive with a predetermined set back would need to be built. Not impossible, but not easy either. Milwaukee makes one commercially that is close, but I think it would be custom tooling to drill from the inside of the shaft.

Last edited by Jamesp; 11-14-2013 at 03:21 PM.

Reason: complete the answer

|

|

|

11-15-2013, 05:58 AM

11-15-2013, 05:58 AM

|

#9

|

|

Registered User

Join Date: Dec 2010

Location: Eastern canada

Posts: 262

|

James P, your theory seems to be based on the pressure difference that can occur within the tube, why does the simple solution of removing the IMS bearing grease seals non't address this issue?

|

|

|

11-15-2013, 09:33 AM

11-15-2013, 09:33 AM

|

#10

|

|

petrolinmyveins

Join Date: Apr 2013

Location: cumbria uk

Posts: 5

|

Quote:

Originally Posted by southernstar

Yes Tony, the Vertex roller bearing replacement has been discussed here previously and the consensus seems to be that, in spite of the obviously greater surface area of roller bearings, they are ill-suited to the IMS application: roller bearings are not intended for, nor are they capable of dealing with the thrust loads that the IMS is subjected to.

Brad

|

So I haven't stumbled across an eternal fix then, damn and blast.

This is what I shopped in to join the Pcar club. Had various ones for 12 years or so but this was the best.

As said, 4.0L v8, tubular chassis and fibreglass body and only 1100kg

Last edited by tonysilver986; 11-15-2013 at 02:17 PM.

|

|

|

11-15-2013, 10:03 AM

11-15-2013, 10:03 AM

|

#11

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

Quote:

Originally Posted by pjq

James P, your theory seems to be based on the pressure difference that can occur within the tube, why does the simple solution of removing the IMS bearing grease seals non't address this issue?

|

The lubrication properties of oil and grease are completely different. Splash oil on an open 6204 steel bearing would be dicey at best. The same bearing with grease is fine. The trick is keeping the grease in the bearing.

|

|

|

11-15-2013, 10:55 AM

11-15-2013, 10:55 AM

|

#12

|

|

Registered User

Join Date: Apr 2012

Location: Ontario, Canada

Posts: 598

|

Tony, I remember the cars. The Boxster is, of course, much more refined, has much better handling, creates a much better exhaust note, has a much better top, is better assembled and does not have the inevitable rattles of fiberglass on a steel chassis. Cool car though.

Brad

|

|

|

11-15-2013, 01:23 PM

11-15-2013, 01:23 PM

|

#13

|

|

petrolinmyveins

Join Date: Apr 2013

Location: cumbria uk

Posts: 5

|

All the above reasons is why I changed to a boxster, apart from one important one, the exhaust noise.

Nothing can compare to the noise of an almost straight through exhaust connected to a thundering V8 lump. The pops and bangs on the overrun is awesome. That's the only thing I miss about the TVR.

So far I have fitted a double din touchscreen cd/rad/satnav/dvd player, sports back box with sports headers ready to go on soon. New discs/pads and clear rear lights which I really like

|

|

|

11-15-2013, 02:15 PM

11-15-2013, 02:15 PM

|

#14

|

|

petrolinmyveins

Join Date: Apr 2013

Location: cumbria uk

Posts: 5

|

Help!!!!!

I replied to this thread but it hasn't shown. It is in my post history but other than that it has disappeared

|

|

|

11-16-2013, 05:47 AM

11-16-2013, 05:47 AM

|

#15

|

|

Registered User

Join Date: Aug 2005

Location: Sanford NC

Posts: 2,606

|

Another day, another proposed approach.

Based on theory. Untested in quantity.

|

|

|

11-16-2013, 07:04 AM

11-16-2013, 07:04 AM

|

#16

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

True enough there isn't a track record for this as I made it up myself, but based on "theory" is debatable. Its based on engineering experience with unintentional pressure vessels and the perfect gas law.

|

|

|

11-17-2013, 05:35 AM

11-17-2013, 05:35 AM

|

#17

|

|

Registered User

Join Date: Aug 2005

Location: Sanford NC

Posts: 2,606

|

Based on theory until several have survived for many miles and months in the real innards of our engines. Only way you could have confidence that your customers investment would be protected.

If I have a 8% chance of failure with the OEM single row, am I reducing risk below that figure by installing XYZ fix? Until I can answer that question affirmatively based on data ....

|

|

|

11-17-2013, 06:16 AM

11-17-2013, 06:16 AM

|

#18

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

I didn't realize you were involved in designing an approach to fix this. What redesign approach were you involved in, and what engineering principles and testing and verification requirements did you employ? I'd like your opinion on going forward with the understanding my only customer is me. This is just a toy that may become a DD.

I went with the original bearing design because I could not find actual bearing load data to perform a meaningful L10 calc. Estimating the bearing load data makes the calculation worthless - just a guess. So I trusted the Germans on that one.

For the "test and verification program" (on one car!) I put off installing a new flywheel because I'm going to replace the flywheel and bearing in about 15 - 20K and assess the viability of the grease after a year. I have an identical control bearing I will cut open at the same time to compare lubricant degradation in the installed bearing. I'll let this forum know how that turns out, but it will be awhile.

|

|

|

11-17-2013, 06:20 AM

11-17-2013, 06:20 AM

|

#19

|

|

recycledsixtie

Join Date: Nov 2011

Location: Edmonton Canada

Posts: 824

|

Quote:

Originally Posted by tonysilver986

All the above reasons is why I changed to a boxster, apart from one important one, the exhaust noise.

Nothing can compare to the noise of an almost straight through exhaust connected to a thundering V8 lump. The pops and bangs on the overrun is awesome. That's the only thing I miss about the TVR.

So far I have fitted a double din touchscreen cd/rad/satnav/dvd player, sports back box with sports headers ready to go on soon. New discs/pads and clear rear lights which I really like

|

I have sent you a pm.

|

|

|

11-21-2013, 08:25 AM

11-21-2013, 08:25 AM

|

#20

|

|

Registered User

Join Date: Sep 2013

Location: Bay Area, CA

Posts: 310

|

Another IMS bearing thread

I was just reading through this month's edition of Porsche panorama magazine when I came across this

I think it's the roller bearing IMS 'eternal fix' mentioned here. I guess the creator must believe in it enough to move from eBay listings to porsche magazines.

__________________

If you are interested in a Comfort-Top module, please visit:

https://www.enhancedautomods.com/shop/comfort-top

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 02:52 PM.

| |