12-30-2013, 07:35 PM

12-30-2013, 07:35 PM

|

#1

|

|

Registered User

Join Date: Apr 2011

Location: DFW

Posts: 713

|

Quote:

Originally Posted by boxster

This issue is driving me crazy. Today I started the car and stayed trying to listed for any noises. I couldnt hear anything from inside the car. then I went near the rear wheels and also couldnt hear anything. then I crawled under the car, and could hear some light ticking sounds, (tick tick tick tick.....) but I have no idea where its coming from exactly, or if it has anything to do with the IMS bearing. the noise is hardly noticeable. but if you crawl under the car and try to block out the exhaust sound, you can hear it. Any ideas what it could be? does it have to be the bearing? or is it normal for a boxer engine perhaps?

|

I had a ticking noise at one point also. Had my bearing done not too long ago and my bearing was fine. That of course is without cracking it open. Turned good though. Usually thats a lifter if I'm not mistaken. Take with a grain of salt.

|

|

|

12-26-2013, 09:11 AM

12-26-2013, 09:11 AM

|

#2

|

|

Registered User

Join Date: May 2011

Location: Miami florida

Posts: 1,591

|

My motor has a bit of a tick, which I think is probably an injector, they can be fairly loud, or possibly something in the valve train, but it goes away, or at least I can't hear it, as soon as I accelerate past idle. I'm not worried.

If you want trace the sound, you need a stethoscope. Put the probe right against the IMSB housing and on both tensioners and listen for anything abnormal.

__________________

Current car

2000 Boxster 2.7l red/black

Previous cars

1973 Opel Manta

1969(?) Fiat 850 Convertible

1979 Lancia Beta Coupe

1981 Alfa Romeo GTV 6

1985 Alfa Romeo Graduate

1985 Porsche 944

1989 Porsche 944

1981 Triumph TR7

1989 (?) Alfa Romeo Milano

1993 Saab 9000

|

|

|

12-26-2013, 09:24 AM

12-26-2013, 09:24 AM

|

#3

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

|

As my attempts to provide a better seal for the IMS bearing seem to be harder than I was hoping at this point,

|

You thought any of this would be easy?

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

12-26-2013, 10:17 AM

12-26-2013, 10:17 AM

|

#4

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

I have the ticking too. I am not too worried about it. I think it could be injectors, lifters, maybe exhaust leaks or loose spark plugs. Comes and goes. Sometimes left side, sometimes right. Sometime when cold, sometimes when hot.

__________________

It's all bad

Last edited by Walter White; 12-26-2013 at 10:25 AM.

|

|

|

12-26-2013, 09:25 PM

12-26-2013, 09:25 PM

|

#5

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

I hit the "Submit" button before I could post pictures.

|

|

|

12-26-2013, 09:27 PM

12-26-2013, 09:27 PM

|

#6

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

Dag nabbit! I did it again. If there is a way to delete these post please let me know.

__________________

It's all bad

|

|

|

12-30-2013, 10:22 PM

12-30-2013, 10:22 PM

|

#7

|

|

Registered User

Join Date: Sep 2013

Location: Montreal, QC. (currently expat to Shanghai)

Posts: 3,249

|

Lathes are for cutting  and don't forget to change your oil often. And your bearing will be just fine!

__________________

______________________________

'97 Boxster base model 2.5L, Guards Red/Tan leather, with a new but old Alpine am/fm radio.

|

|

|

01-01-2014, 12:30 PM

01-01-2014, 12:30 PM

|

#8

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

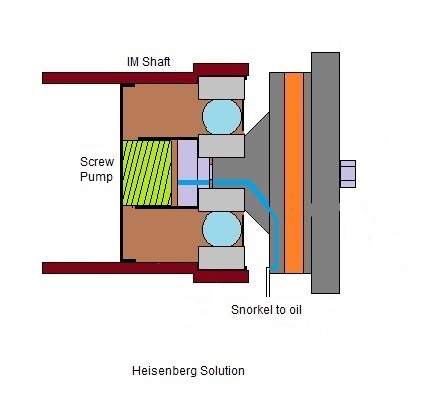

Even more bad ideas

__________________

It's all bad

Last edited by Walter White; 01-01-2014 at 12:47 PM.

|

|

|

01-01-2014, 06:47 PM

01-01-2014, 06:47 PM

|

#9

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

And just how are you going to machine or EDM that pathway through the flange?

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

01-01-2014, 07:22 PM

01-01-2014, 07:22 PM

|

#10

|

|

Registered User

Join Date: Sep 2013

Location: Montreal, QC. (currently expat to Shanghai)

Posts: 3,249

|

It's easy, you vise the part 45degree and you pour 2 drops of 98% H2SO4 in the cavity (sulfuric acid) and wait overnight

Joking aside, that flange will be need to become a quite advanced assembly on it's own if you go this path. I see a 3 pcs (min) flange assembly

__________________

______________________________

'97 Boxster base model 2.5L, Guards Red/Tan leather, with a new but old Alpine am/fm radio.

Last edited by Nine8Six; 01-01-2014 at 07:29 PM.

|

|

|

01-02-2014, 04:25 AM

01-02-2014, 04:25 AM

|

#11

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

From a machining perspective, eliminate the 45 leg and drill 2 holes, or if you're heart is set on the 45, drill it from the surface and plug the surface hole. In any event, it appears the path of this hole could be simplified.

|

|

|

01-03-2014, 10:53 AM

01-03-2014, 10:53 AM

|

#12

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

|

just a supplement to the oil feed the engineers already provide.

|

What oil feed is that?? You lost me.

One issue that leads to wear is longitudinal thrust loads and the ball bearing trying to control them while providing radial support as well. With bank #1 dragging the IMSB sideways and the IMS Tensioner paddle doing the same all these forces challenge both axis of the assembly.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

01-04-2014, 08:56 AM

01-04-2014, 08:56 AM

|

#13

|

|

Registered User

Join Date: Sep 2013

Location: Montreal, QC. (currently expat to Shanghai)

Posts: 3,249

|

Having now seen all kind of tricks RE "the remedy of the IMSB", I take it that nobody really understand the "real" cause of failure of the IMSB? Would that be correct?

Lack of lubrification, high pressure, oil contaminations, driving style, luck/bad luck, karma, or all of these combined maybe?

I respect all those who have brilliant ideas like Walter but man, no prototyping, no testing, no data acquisitions methods, not even a simulation..... you guys have a lot of courage drilling these things

__________________

______________________________

'97 Boxster base model 2.5L, Guards Red/Tan leather, with a new but old Alpine am/fm radio.

Last edited by Nine8Six; 01-04-2014 at 09:00 AM.

|

|

|

01-11-2014, 10:44 AM

01-11-2014, 10:44 AM

|

#14

|

|

Registered User

Join Date: Sep 2013

Location: Montreal, QC. (currently expat to Shanghai)

Posts: 3,249

|

irrelevant. .delete

__________________

______________________________

'97 Boxster base model 2.5L, Guards Red/Tan leather, with a new but old Alpine am/fm radio.

Last edited by Nine8Six; 01-11-2014 at 10:48 AM.

|

|

|

01-12-2014, 08:59 AM

01-12-2014, 08:59 AM

|

#15

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

So the oil pump is driven by the IMS shaft. How about a small oil passage through the hex key from the oil pump to the interier of the IMS shaft and an open bearing at the other end? Plenty of oil, and might be an easy mod. plus your stealing oil from the best place possible.

A small hole in the oil pump driven gear connecting with a passage through the center of the hex drive key, and another small hole through the IMS end fitting at the bottom of the hex drive hole would do the trick.

Couple that with a creamic bearing for overkill. Voila!

__________________

2003 S manual

Last edited by Jamesp; 01-18-2014 at 06:12 PM.

|

|

|

01-12-2014, 10:42 AM

01-12-2014, 10:42 AM

|

#16

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

Now that is something even I would be afraid to try. I am more comfortable with things that can be easily set back to original if things don't work out.

But I am certainly interested in the idea.

Could the oil from the pump be done without removing the IM shaft?

I have been intending to experiment to see if oil in the shaft would affect balance. I would think not, it would just distribute itself evenly inside the shaft I would assume.

__________________

It's all bad

Last edited by Walter White; 01-12-2014 at 10:52 AM.

|

|

|

01-12-2014, 11:09 AM

01-12-2014, 11:09 AM

|

#17

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

Quote:

Originally Posted by Walter White

Now that is something even I would be afraid to try.

|

I think you could warm up to it. Your posts on bearings shows you are comfortable with new ideas.

__________________

2003 S manual

|

|

|

01-12-2014, 12:30 PM

01-12-2014, 12:30 PM

|

#18

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

Quote:

Originally Posted by Jamesp

I think you could warm up to it. Your posts on bearings shows you are comfortable with new ideas.

|

Absolutely. I am anxious to hear more. I am not familiar with the shaft and pump arraignment so it is a little hard for me to understand the details.

I may be a hard sell because right now grease is my first choice. Grease is good. If hope I can make grease a viable lubricant for the IMSB.

When I saw how superior the Nachi seal is to any others, I realized that keeping grease in and oil out may not be impossible.

__________________

It's all bad

Last edited by Walter White; 01-12-2014 at 12:38 PM.

|

|

|

01-12-2014, 04:16 PM

01-12-2014, 04:16 PM

|

#19

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

The patent is part of another claim.

Hell, we have even been patenting the bad ideas, because if we don't someone will "invent them" 5 years later and claiming they are the best thing since sliced bread.

There are times when security means going absolutely over the top, which wastes money and drives the price of the final products up.

When going through these processes we have to think like the enemy and consider any possible other way to reach a similar goal. We have three more patents filed at the present and two more ready to file.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

01-13-2014, 03:58 PM

01-13-2014, 03:58 PM

|

#20

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

I think we all hijacked it!

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 05:45 PM.

| |