Hey guys,

I've been lurking around for 12 months or so gaining lots of info on my purchase last year, a '99 model 2.5 silver Boxster.

I shopped in my 4.0L V8 TVR Wedge to join the 986 brigade as I'd always fancied one, even after owning a 320bhp BMW Z3m. (which my son redesigned quite badly)

Although the IMS bearing is a potential issue, it is not at the front of my thoughts all the time. But I follow all the threads related to it on hear. I do and always have done all my own maintenance, from oil changes to engine rebuilds. (because I am too tight in the wallet department :ah:.)

I have a clutch waiting to go in at some point, although it isn't slipping but my RMS is leaking so it is to be taken apart sometime soon. So I will fit an IMSB of some kind while in there.

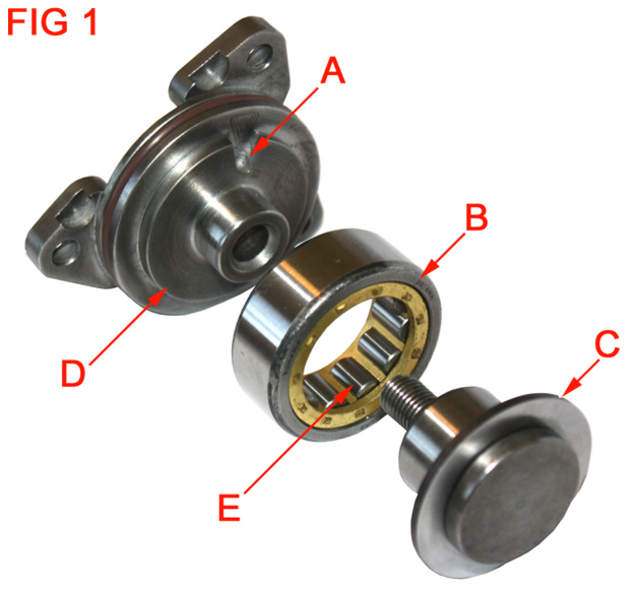

So to my point, I don't recall seeing the below item mentioned on here>>

Porsche IMS Intermediate Shaft Bearing Repair ETERNAL FIX (ebay no. 181254668411)

As you can see, (hopefully picture uploaded) it is a roller bearing as apposed to ball bearing.

Has this slipped by people or is it an unproven source? Or even worse, has it slipped by me and all you guys already know about it

And just because I can, a photo