10-20-2013, 10:08 AM

10-20-2013, 10:08 AM

|

#61

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

Kirk,

I'm not trying to design anything to sell. I'm just looking for an IMS redesign that provides adequate bearing life and addresses the root cause of the bearing lubrication failure. Your 20% discussion points to inadequate design by Porsche. Doing the calc on the existing bearing answers the L10 question.

|

|

|

10-20-2013, 10:17 AM

10-20-2013, 10:17 AM

|

#62

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Those 8 balls inside the single row IMSB sure do become "individual components" when they are expelled into the engine oil and create engine wide collateral damage.

Kirk,

You are not the first to point out the outer race rotation Vs inner race rotation. No gold star yet.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

10-20-2013, 10:40 AM

10-20-2013, 10:40 AM

|

#63

|

|

Registered User

Join Date: Jul 2007

Location: Texarkana, Texas

Posts: 959

|

Quote:

Originally Posted by Jamesp

Kirk,

I'm not trying to design anything to sell. I'm just looking for an IMS redesign that provides adequate bearing life and addresses the root cause of the bearing lubrication failure. Your 20% discussion points to inadequate design by Porsche. Doing the calc on the existing bearing answers the L10 question.

|

I am with you. Okay, I think I will do some calculations this next week too. We know the load ratings for the NSK stock bearing. I posted on Pelican Parts a link to the SKF bearing calculator that makes it easy to get an L10 calc. This assumes that the inner race is moving though. I suspect you can just multiply the results by 0.8 to get an answer for the outer race rotating.

SKF Bearing Calculator

You can use the numbers from the stock bearing to compare to other options. I believe I have seen LN post their ceramic bearing load figures in a forum post. You will have to "assume" a certain level of radial and axial loads. Thus you won't get a definitive answer, but you will get calculations that you can use to compare the options available.

The one variable I don't know is what TuneRS is using for their ceramic bearing. What is the load capacity of that option? Does it use a nylon cage? I plan to call Mike at TuneRS next week to ask these questions and add it to the mix for comparison. I want to include them because, although I am still investigating, my gut feel right now is that the TuneRS DOF with ceramic bearing is the best "bang for buck" option that I can install myself in my own shop. If the radial load rating of their bearing is good and you've got consistent oil feed, then it seems that this solution would address the major failings of the stock bearing.

Kirk Bristol

__________________

2000 Boxster S - Gemballa body kit, GT3 front bumper, JRZ coilovers, lower stress bars

2003 911 Carrera 4S - TechArt body kit, TechArt coilovers, HRE wheels

1986 911 Carrera Targa - 3.2L, Euro pistons, 964 cams, steel slant nose widebody

1975 911S Targa - undergoing a full restoration and engine rebuild

Also In The Garage - '66 912, '69 912, '72 914 Chalon wide body, '73 914

|

|

|

10-20-2013, 11:42 AM

10-20-2013, 11:42 AM

|

#64

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

|

the best "bang for buck" option that I can install myself in my own shop.

|

The things that motivate the DIY installer are quite different than those who are looking for an installation program and a Certified Installer to carry out the process. The majority of those reading these threads do not have the proper resources to carry out a DIY IMS intervention process, no matter which of the technologies will be employed.

We made the decision long ago not to support DIY installations and to do whatever possible to have Certified Installers apply our technology. Its no fun having to travel across North America as a WTI Instructor, and its much less fun to host my "M96 102" classes here at the Flat 6 Innovations 2-3 times per year to train the installers and evaluate them. It puts such a hiatus on R&D and engine assembly that I am having to build yet another training center off site to support these classes.

While there are other technologies on the market now, none of the others offer a true program for the installers.

Kirk, you are a fairly sharp individual. You are one of the few who I believe could carry out a successful DIY of most any IMSR intervention. I don't hand out compliments, they have to be earned.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

10-20-2013, 05:25 PM

10-20-2013, 05:25 PM

|

#65

|

|

Registered User

Join Date: Sep 2010

Location: Foster City CA

Posts: 1,099

|

To me, this whole DOF debate is really simple. If one sets aside all the theorizing about why IMSBs fail and starts from the point where one has installed an unsealed ceramic replacement bearing, the DOF question boils down to these two questions:

- Does DOF substantially extend the operating lifetimes of unsealed ceramic replacement IMSBs compared to ones lubricated by being submerged in sump oil and splash oil?

- Does DOF create additional risks to engine and IMSB longevity and reliability?

No one that I know of has put a number on the table (or even an estimate for that matter) that answers the first question. If the answer to the first question is "no" or "not by much", then one doesn't need to know the answer to the second question because it wouldn't make sense to take the risk.

|

|

|

10-21-2013, 05:42 AM

10-21-2013, 05:42 AM

|

#66

|

|

Registered User

Join Date: Apr 2012

Location: Ontario, Canada

Posts: 598

|

thom, what numbers do we have for the longevity of unsealed ceramic bearings using splash oil ( I mean, apart from the recommended replacement at 4 years/50,000 miles)?

Brad

|

|

|

10-21-2013, 07:25 AM

10-21-2013, 07:25 AM

|

#67

|

|

Registered User

Join Date: Jun 2008

Location: Illinois

Posts: 147

|

Quote:

Originally Posted by thom4782

To me, this whole DOF debate is really simple. If one sets aside all the theorizing about why IMSBs fail and starts from the point where one has installed an unsealed ceramic replacement bearing, the DOF question boils down to these two questions:

- Does DOF substantially extend the operating lifetimes of unsealed ceramic replacement IMSBs compared to ones lubricated by being submerged in sump oil and splash oil?

- Does DOF create additional risks to engine and IMSB longevity and reliability?

No one that I know of has put a number on the table (or even an estimate for that matter) that answers the first question. If the answer to the first question is "no" or "not by much", then one doesn't need to know the answer to the second question because it wouldn't make sense to take the risk. |

Spot on. How does spraying oil at a bearing extend it's life when it is already submerged or at the worst case scenario, partially submerged in oil in a crankcase filled with oil being whipped around by the chains?

Jake and I researched all our options as far where to supply oil for the IMS Solution and the only location we found suitable that didn't adversely affect operation of the engine was from the spin on oil filter adapter, which thankfully we had already developed and gone through the whole patent process years ago knowing we would be using it for such a purpose later on.

__________________

Charles Navarro

President, LN Engineering and Bilt Racing Service

http://www.LNengineering.com

Home of Nickies, IMS Retrofit, and IMS Solution

|

|

|

10-21-2013, 08:05 AM

10-21-2013, 08:05 AM

|

#68

|

|

Registered User

Join Date: Jun 2008

Location: Illinois

Posts: 147

|

Quote:

Originally Posted by southernstar

thom, what numbers do we have for the longevity of unsealed ceramic bearings using splash oil ( I mean, apart from the recommended replacement at 4 years/50,000 miles)?

Brad

|

Whatever data we have is empirical evidence gained through the many years and thousands of bearings we have installed and serviced. Without any precedence for bearing life, we had to give our best guess for what would be a conservative service interval for these bearings. We now know that the dual row, triple row, and later 06-08 bearing, when upgraded with one of our IMS Retrofit or IMS Upgrades, is likely a permanent fix to last the life of the engine (or until something else fails in the engine).

As far as the single row IMS Retrofit, we've seen many easily clear this 4 year, 50,000 mile interval with zero issues. We use the same single row bearing as part of the bearing stack for the triple row IMS Upgrade and with over a 1000 of those in service with zero issues- the bearing itself isn't an issue. However, there have been some limited failures of the single row bearing.

We know that of the failures we've seen, most of them can be attributed to installation error, but that aside, I know that there have probably been an equal number of improperly carried out dual row IMS retrofits and those haven't had problems. Case in point, we have seen several dual row bearings that were installed in engines where the original bearing had failed. Even with extensive cleanup of the sump and many oil changes, contamination from the original failure damaged the replacement bearing, but they keep running and don't fail, whereas, when the same was done with a single row, they almost immediately fail.

So if all these other ceramic hybrid bearings have been working flawlessly with zero failures only with lubrication from the sump, what conclusions would you draw.

The single row bearing by itself has the lowest load capacity. The bearing's lack of load capacity is the only variable here.

Granted, many single row bearings last well over 10 years/100,000 miles with no problems where others fail much sooner. There are lots of variables affecting bearing life, all of which have been discussed at length over the years. Although the IMS Retrofit with the single row 6204 ceramic hybrid bearing addresses many of the issues of a conventional ball bearing in this application, the issue of load capacity is one that could not be addressed with a direct replacement until we released the IMS Solution and which will be addressed next year with the next generation of IMS Retrofit.

I for one won't won't be happy until we achieve a 100% success rate.

__________________

Charles Navarro

President, LN Engineering and Bilt Racing Service

http://www.LNengineering.com

Home of Nickies, IMS Retrofit, and IMS Solution

|

|

|

10-21-2013, 08:14 AM

10-21-2013, 08:14 AM

|

#69

|

|

Registered User

Join Date: Jun 2008

Location: Illinois

Posts: 147

|

Quote:

Originally Posted by Kirk

I am with you. Okay, I think I will do some calculations this next week too. We know the load ratings for the NSK stock bearing. I posted on Pelican Parts a link to the SKF bearing calculator that makes it easy to get an L10 calc. This assumes that the inner race is moving though. I suspect you can just multiply the results by 0.8 to get an answer for the outer race rotating.

SKF Bearing Calculator

You can use the numbers from the stock bearing to compare to other options. I believe I have seen LN post their ceramic bearing load figures in a forum post. You will have to "assume" a certain level of radial and axial loads. Thus you won't get a definitive answer, but you will get calculations that you can use to compare the options available. |

L10 life of the 6204 bearing is 90,000 miles assuming an average speed of 60 mph in top gear (the speed mph isn't really what is important - it's the engine RPM that is as engine rpm is directly related to IMS rpm to ball bearing life). Driving habits play directly to this.

Quote:

|

The one variable I don't know is what TuneRS is using for their ceramic bearing. What is the load capacity of that option? Does it use a nylon cage? I plan to call Mike at TuneRS next week to ask these questions and add it to the mix for comparison. I want to include them because, although I am still investigating, my gut feel right now is that the TuneRS DOF with ceramic bearing is the best "bang for buck" option that I can install myself in my own shop. If the radial load rating of their bearing is good and you've got consistent oil feed, then it seems that this solution would address the major failings of the stock bearing.

|

How does adding more oil to a bearing that is already submerged address the major failing of the stock bearing and furthermore constitute being the best bang for the buck?

__________________

Charles Navarro

President, LN Engineering and Bilt Racing Service

http://www.LNengineering.com

Home of Nickies, IMS Retrofit, and IMS Solution

|

|

|

10-21-2013, 08:22 AM

10-21-2013, 08:22 AM

|

#70

|

|

Registered User

Join Date: Jun 2008

Location: Illinois

Posts: 147

|

Quote:

Originally Posted by Jamesp

Jake,

Any idea of the typical run out on the IMS driven gear? I had the failed IMS from my engine measured at 0.015. Quite a bit for a gear, but as it is a chain drive if may be ok. In any event that was a major driver in replacing the damaged shaft with an undamaged one. My thought at the time was if the IMS gear run out was poorly controlled in the design, additional side loads could shorten bearing life in high run out cases even with a deep groove ball bearing.

|

This is one of our tests to qualify an IMS for our upgrade procedure. If the shaft has more than .005" of runout on the main sprocket, we fail it. Most shafts however don't have any. Only when the shaft has been subjected to an IMS failure or some other kind of trauma (broken chain), is it that we see runouts starting at .015" and only getting worse from there.

The other issue we check for is concentricity of the bearing housing bore as well as runout and taper. Most usually have a few tenths, but we've seen some that have several thousands when the sprocket has zero runout and in those cases, we will junk those shafts too. Unfortunately, this is all stuff you can't easily check for when the intermediate shaft is still in the car and specifically why carrying out a retrofit procedure on a bearing that has failed or is close to failure is not advised (excluding the foreign object debris that has already compromised the engine and will compromise the replacement bearing).

__________________

Charles Navarro

President, LN Engineering and Bilt Racing Service

http://www.LNengineering.com

Home of Nickies, IMS Retrofit, and IMS Solution

|

|

|

10-21-2013, 08:49 AM

10-21-2013, 08:49 AM

|

#71

|

|

Registered User

Join Date: Aug 2005

Location: Sanford NC

Posts: 2,605

|

Is the IMS bearing submerged? I thought I had been told it was mist lubricated.

|

|

|

10-21-2013, 09:12 AM

10-21-2013, 09:12 AM

|

#72

|

|

Registered User

Join Date: Jun 2008

Location: Illinois

Posts: 147

|

Quote:

Originally Posted by mikefocke

Is the IMS bearing submerged? I thought I had been told it was mist lubricated.

|

The only time the IMS would be lubricated by mist would be if the engine is suffering from oil starvation. The IMS is located well below the where the oil level sits during normal operation in the integrated dry sump (i.e. wet sump).

__________________

Charles Navarro

President, LN Engineering and Bilt Racing Service

http://www.LNengineering.com

Home of Nickies, IMS Retrofit, and IMS Solution

|

|

|

10-21-2013, 10:45 AM

10-21-2013, 10:45 AM

|

#73

|

|

Registered User

Join Date: Apr 2012

Location: Ontario, Canada

Posts: 598

|

Charles, the successful history of your ceramic bearing upgrade is precisely why I recommend the same for all except: 1. those with unlimited budgets, for whom I suspect that the LN Solution would be the way to go (in spite of the relative lack of vehicles on road to prove the technology); 2. those with the large single bearing who cannot upgrade the bearing without an engine tear-down. For those I would suggest that DOF lubrication of the original bearing, even if there are minor risks of aeration and oil pressure loss, would be better than leaving in the original bearing and hoping that it lasts now with just the removal of a seal.

I wonder, however, if a dual standard is not at play here. When LN introduced the ceramic bearing upgrade, customers installed the same even though they had not yet been proven in large numbers over a long period of time. They were convinced by the initial testing and the inherent logic of the design - something which you and others are now suggesting would be inappropriate for prospective customers of DOF technology. What is more, your new 'solution' is also not supported by a large number of installations over long periods of time. To remain logically consistent, doesn't that mean that the upgrade should also be preferrred to the solution because of its proven track record?

Brad

Last edited by southernstar; 10-21-2013 at 10:46 AM.

Reason: sp

|

|

|

10-21-2013, 02:17 PM

10-21-2013, 02:17 PM

|

#74

|

|

Registered User

Join Date: Jul 2007

Location: Texarkana, Texas

Posts: 959

|

Quote:

Originally Posted by cnavarro

The IMS is located well below the where the oil level sits during normal operation in the integrated dry sump (i.e. wet sump).

|

In this discussion we've tried to focus on facts and what has been proven through testing. I believe this view though that the IMS bearing is well lubricated without the seal through oil bath or splash lubrication is an assumption not based on actual testing. It would be pretty hard to measure, but I don't think the actual sump level has been measured through the dynamic loads that a car would see during normal driving. I would like to see any data that has been collected, if this has been done.

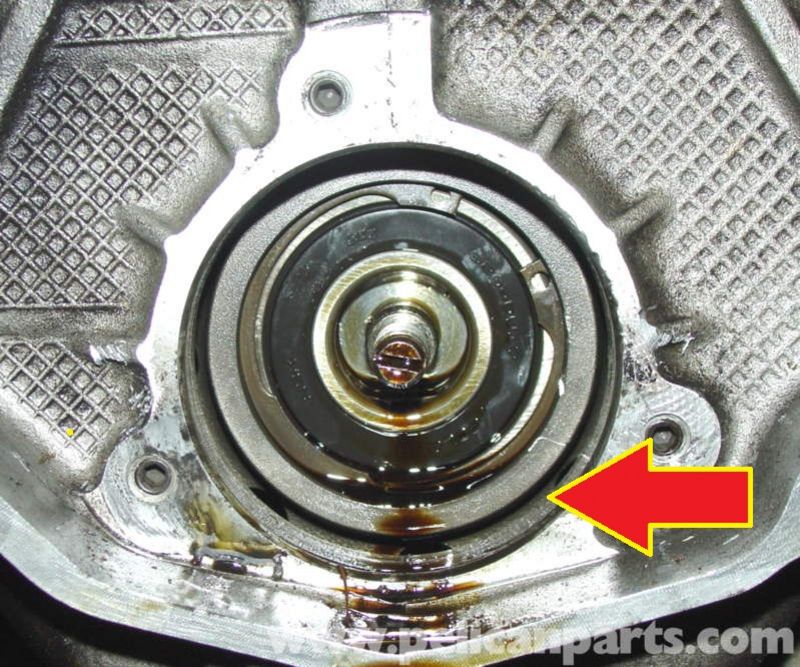

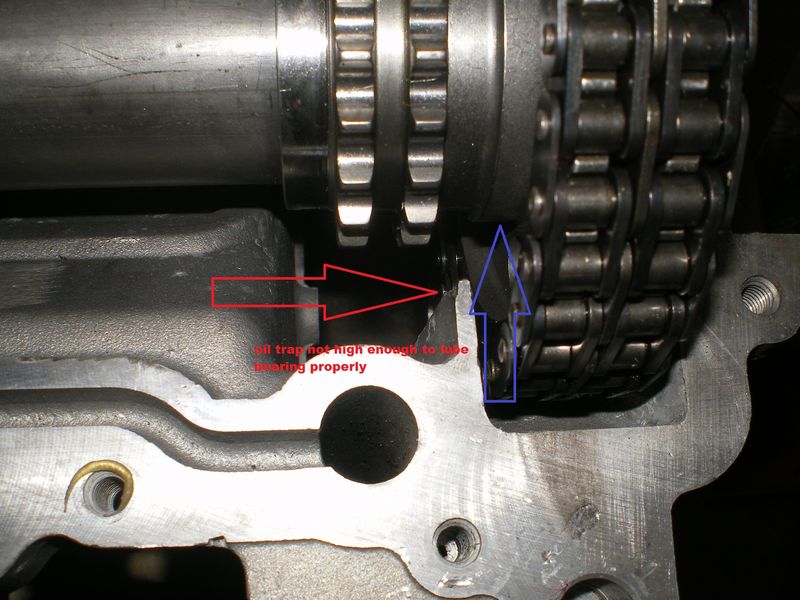

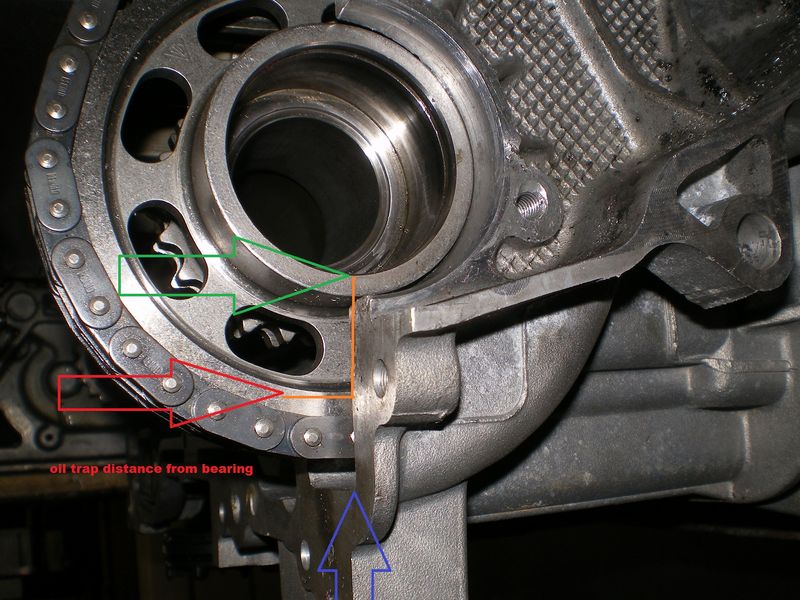

As such, I personally do not hold to this assumption that the bearing will see adequate lubrication with simply the seal removed. What I have seen, on the contrary, points to mediocre lubrication at best. Seeing is believing though and this is what I have seen, stolen from Feelyx on Pelican Parts:

The intermediate shaft sits up relatively tight against the engine case, allowing just a small slit for oil to get through to lubricate it from the sump below. Some oil will fall off the chain from above, but will still need to get through this small slit. This picture does not show the cover that would further block flow of oil through splash lubrication to the bearing.

Some more pictures of different views further illustrating this point.

So, would I depend on splash lubrication for this critical bearing? Absolutely not!

But what about oil bath lubrication? Maybe the bearing is partially submerged...

These photos from Feelyx again show where the oil bath is located. Obviously the chain was designed by Porsche to be lubricated by an oil bath. The IMS bearing was not.

So how much oil does the bearing get then if you just remove the seal? The truth is that we don't really know. LN Engineering "assumes" that it is enough. I personally look at the location of the bearing and I do not come to that same conclusion. Instead, what I am willing to bet on is having a good, consistent flow of oil directly to the bearing - direct oil feed. With DOF there is no guessing, no assumptions, you KNOW the bearing is going to get enough oil regardless of how much oil is in the sump and regardless of vehicle dynamics (hard braking, hard cornering, etc.). With a very expensive engine on the line and a car that I love, I am going to trust something that is a lot more certain and consistent - direct oil feed. This is why I've been such a big proponent of the DOF system - it just makes sense to me!

Kirk Bristol

__________________

2000 Boxster S - Gemballa body kit, GT3 front bumper, JRZ coilovers, lower stress bars

2003 911 Carrera 4S - TechArt body kit, TechArt coilovers, HRE wheels

1986 911 Carrera Targa - 3.2L, Euro pistons, 964 cams, steel slant nose widebody

1975 911S Targa - undergoing a full restoration and engine rebuild

Also In The Garage - '66 912, '69 912, '72 914 Chalon wide body, '73 914

|

|

|

10-21-2013, 02:27 PM

10-21-2013, 02:27 PM

|

#75

|

|

Registered User

Join Date: Jul 2007

Location: Texarkana, Texas

Posts: 959

|

Quote:

Originally Posted by Kirk

But ceramic bearings in general are designed for all forms of oil lubrication. Since you are providing some technical detail regarding your ceramic bearing would you mind providing some better detail on why the LN Retrofit does not work with direct oil feed?

|

Given my last post with the photos I will pose this question again... if I don't feel comfortable relying just on oil bath and oil splash lubrication, what is wrong with direct oil feed to a ceramic ball bearing - specifically the LN Engineering bearing??? Wouldn't the DOF allow the bearing to run with less wear and cooler? Wouldn't it remove variable lubrication and make it more consistent? These all seem like good things to me, and I really can't see aeration and system pressure losses as being significant down sides. So what exactly is the problem with DOF on a ceramic bearing?

Kirk Bristol

__________________

2000 Boxster S - Gemballa body kit, GT3 front bumper, JRZ coilovers, lower stress bars

2003 911 Carrera 4S - TechArt body kit, TechArt coilovers, HRE wheels

1986 911 Carrera Targa - 3.2L, Euro pistons, 964 cams, steel slant nose widebody

1975 911S Targa - undergoing a full restoration and engine rebuild

Also In The Garage - '66 912, '69 912, '72 914 Chalon wide body, '73 914

|

|

|

10-21-2013, 04:04 PM

10-21-2013, 04:04 PM

|

#76

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

|

I really can't see aeration and system pressure losses as being significant down sides.

|

Time and studies will tell.

Kirk, It sounds like you've made your mind up. I believe that decisiveness is a key to anything, so it looks like stage 1 is complete for you.

Charles and I had our version of the DOF in 2007, the studies that we did then, and the data that we collected are the reasons why we do not support a DOF when being utilized with the LN Ceramic hybrid bearing. We did this when having a difficult time extracting OEM dual row bearings, hoping that it would be an alternative to a retrofit, which at the time seemed was not an easy process.

The mistake we made then was not patenting the procedure. We've learned from our mistakes, and trust that from this point forward we'll not only protect the things that we plan to bring to market, but also competing technologies, even if we don't prefer them, or have any plan to bring them to market.

Let us know how the DOF install goes.

Quote:

|

What is more, your new 'solution' is also not supported by a large number of installations over long periods of time.

|

Been there and done that before... Remember, we were the guys getting chastised here on the forums for "a retrofit" back in the day. Back then any retrofit wasn't accepted and people basically made these same statements about anything that we did. Thats what happens when you pioneer something.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

Last edited by Jake Raby; 10-21-2013 at 04:26 PM.

|

|

|

10-21-2013, 04:33 PM

10-21-2013, 04:33 PM

|

#77

|

|

Registered User

Join Date: Jun 2012

Location: Ontario,Canada

Posts: 84

|

Does anyone believe that Porsche even remotely looked into any other solution when they updated once again the 06 and up IMS bearing design.Simply installing a larger bearing seems pretty limited outlook for thease world famous engineers it seems.If they had already dropped near 20 million in warranty claims before the law suit even surfaced i would have thought that they would have put there best tech on that one. Apparently not !! I love my car (06 boxster s) but if i had to do it all over again,i wouldent touch an IMSB Porsche auto.Worth noting is i contacted my Porsche private shop that are very well established in ontario,Canada to ask if he could install one off thease systems and cost,he told me not to waste my money and the whole IMS issue is blown out off proportion.Strange! I am sure those that have suffered the financial loss don,t feel that way.By the way Porsche lawyers did contact his shop for a customer list for which he declined.

|

|

|

10-21-2013, 04:40 PM

10-21-2013, 04:40 PM

|

#78

|

|

Registered User

Join Date: Aug 2005

Location: Sanford NC

Posts: 2,605

|

What do we know about what happens if you remove the seal?

With product H we have a use the OEM part but remove the seal process. Done in the UK and done for several years. Unknown quantity and unknown miles and unknown analysis of long used bearings. UK forums not full of failure reports.

With product N we have a ceramic part and remove the seal. Lots out there and comparatively lots of years and miles. The forums aren't full of failure reports so we know at least something. Not the ultimate shape of the failure curves but something out to 50k.

With product C we have something similar to the N but small quantities.

And then there are two pressurized oil lubed bearings that are both different in their lubrication method but how many have been used and under what conditions? We have no data. Not even the sketchiest.

Since someone are doing an IMS to reduce risk, how much added risk is there to using one of the lesser known-about products even if their logic appeals to you?

Isn't the one common thing about the two approaches that have been in the wild for the longest that they use the "remove the seal" approach? Doesn't that tell us something about them getting enough lubrication? Maybe not enough to last forever but for a long time?

|

|

|

10-21-2013, 05:00 PM

10-21-2013, 05:00 PM

|

#79

|

|

Registered User

Join Date: Jun 2012

Location: Ontario,Canada

Posts: 84

|

Good feedback Mike but that brings me back to same question then why did Porsche not use that same procedure and remove one seal off the bearing,whay through another sealed bearing in,they have to have a good reason not to.

|

|

|

10-21-2013, 05:01 PM

10-21-2013, 05:01 PM

|

#80

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

|

Simply installing a larger bearing seems pretty limited outlook for thease world famous engineers it seems.

|

By that time the 9a1 was already a reality. They knew that the crankcase would go away in 2008, and the easiest way to address the issues that were occurring at low engine speeds was to increase bearing diameter, increase surface speeds and reduce load the bearing sees.

Reinventing the wheel for only 2-3 years didn't make any sense. They didn't even alter the crankcase, if they did we'd be able to retrofit M97 bearings, too.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 01:40 AM.

| |