06-14-2012, 02:36 PM

06-14-2012, 02:36 PM

|

#41

|

|

Registered User

Join Date: Oct 2010

Location: US, Calif

Posts: 72

|

Hi Truegearhead, Yes you are so correct. There are definitely some sensitive areas on these cars and lot's of things that break. I'm thankful Wayne has written the 101 projects book as it has really opened my eyes to what we can do with these cars on a hobbyist basis and some of the pitfalls to watch for. It's an excellent resource. It's the book that gave me the confidence to go ahead and tackle a clutch and IMS change. It would be cool if LNE and Wayne's article were showing the same methods but it is what it is and both methods do apparently work. Hey, we're leaning here  That's why we tinker. Just scares me when things don't go as planned.  Thanks for your help here. I'll let you guys know what happens.

|

|

|

06-14-2012, 04:12 PM

06-14-2012, 04:12 PM

|

#42

|

|

Registered User

Join Date: Oct 2010

Location: US, Calif

Posts: 72

|

Tensioner spring force

Was just out cleaning up some parts and noticed something that I haven't seen in any documentation as yet. At least on my car the drivers side rear tensioner I pulled has less spring force then the one on the pass side rear. I assume noted by 1 spiral band on the case vs 2 bands on the other. So in case you didn't notice this it might not be a good idea to mix them up.

Just a little info to end Thursday.

|

|

|

06-14-2012, 06:26 PM

06-14-2012, 06:26 PM

|

#43

|

|

Registered User

Join Date: Jul 2010

Location: California

Posts: 1,859

|

Look at the head of the tensioner, you will notice a different ring count identifying it.

__________________

Jäger

300K Mile Club

|

|

|

06-14-2012, 06:46 PM

06-14-2012, 06:46 PM

|

#44

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

The tensioners are side specific.. They are different because the 4-6 bank has lower effective oil pressure than the 1-3, abut 7PSI in my research.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

06-14-2012, 08:00 PM

06-14-2012, 08:00 PM

|

#45

|

|

Registered User

Join Date: Oct 2010

Location: US, Calif

Posts: 72

|

Thanks Jake Raby and Jager.

|

|

|

06-15-2012, 10:11 AM

06-15-2012, 10:11 AM

|

#46

|

|

Registered User

Join Date: Jul 2011

Location: Richmond, VA (The Fan)

Posts: 978

|

Quote:

Originally Posted by Jake Raby

The tensioners are side specific.. They are different because the 4-6 bank has lower effective oil pressure than the 1-3, abut 7PSI in my research.

|

Good to know, it really bothered that they were just a little different when I took them out.

__________________

1997 Boxster 4.2L Audi V8 Bi-Turbo

2003 911 C2

NASA HPDE Instructor

|

|

|

06-16-2012, 10:07 AM

06-16-2012, 10:07 AM

|

#47

|

|

Registered User

Join Date: Oct 2011

Location: sac. ca

Posts: 156

|

Any update John? Did you get your bearing out?

__________________

98 boxster

82 280sl parts for sale

|

|

|

06-16-2012, 02:52 PM

06-16-2012, 02:52 PM

|

#48

|

|

Registered User

Join Date: Oct 2010

Location: US, Calif

Posts: 72

|

Hi Tim,

Yes, thanks for checking on me. The tool from LNE arrived and I pulled the bearing late last night. It looked fine and turned smooth. I Put it in the freezer overnight and was really careful putting it in the IMS this morning. It went in fine. The secret for me at least was starting it with the plastic hammer and then I used a short 2x4 between the aluminum installer and plastic hammer so I wouldn't hit the cross member. I think that's what happened last time. I hit the cross member and missed the center of the install tool and cocked it in the IMS. But, it's in, YAY! The little spiral lock was a pain but finally got it in. I put the cam tensioners back in and checked for cam slippage (none), then rotated 360 and checked the cam slots. All good. Then rotated to TDC and checked cam slots again. All good. I put the sparkplugs and coils back in and cleaned up my mess. Now just need to order a flywheel since mine appears to be shot. Thank you and thanks to all who responded to my panic. Guess it wasn't that bad but I hate to mess things up. Thanks guys. If it would be helpful to post a 'what went right and wrong' with this job I'll happy to write one up... might help someone in the future.

|

|

|

06-16-2012, 03:07 PM

06-16-2012, 03:07 PM

|

#49

|

|

Registered User

Join Date: Oct 2011

Location: sac. ca

Posts: 156

|

Glad to hear everything went ok, John...... I would of dreaded the drive in this heat.

105F here today.

__________________

98 boxster

82 280sl parts for sale

|

|

|

06-16-2012, 07:08 PM

06-16-2012, 07:08 PM

|

#50

|

|

Registered User

Join Date: Oct 2010

Location: US, Calif

Posts: 72

|

Thanks Tim, Yes it would have been a long hot one for sure. I'll get you plane ticket next time.  Cheers

|

|

|

06-17-2012, 08:16 AM

06-17-2012, 08:16 AM

|

#51

|

|

Registered User

Join Date: Jul 2011

Location: Richmond, VA (The Fan)

Posts: 978

|

The Box is back on the road, what a nightmare! The headers sound amazing, I can't really tell if there is more power or not

Cheers,

__________________

1997 Boxster 4.2L Audi V8 Bi-Turbo

2003 911 C2

NASA HPDE Instructor

|

|

|

06-17-2012, 07:34 PM

06-17-2012, 07:34 PM

|

#52

|

|

Registered User

Join Date: Oct 2010

Location: US, Calif

Posts: 72

|

Excellent! what type of muffler are you running? I picked up a second hand stebo (sp?) can't wait to try it.

|

|

|

11-10-2014, 03:34 PM

11-10-2014, 03:34 PM

|

#53

|

|

Registered User

Join Date: Nov 2014

Location: Palo Alto, CA

Posts: 18

|

I am in a similar situation as others in this thread except that I have not yet extracted the original bearing. I have set screws in place but the bearing is off-center. Only 2 of the 3 tensioners are out. Some ideas for getting the job done from here:

1) Remove 3rd tensioner in attempt to center the bearing in the case hole. Is there significant risk of a timing slip from removing the third tensioner? I have an '01, 5-chain engine.

2) Try to get the engine to TDC, then use cam lock (which came with the ln retrofit kit) and follow ln engineering instructions from the top. To do this, the idea is to reinstall the tensioners and then rotate the engine manually to TDC. JFP stated this is unlikely to work because the flange from the ims bearing is no longer being held in place by the cover. In my case, the old ims bearing is still installed, so I think I have two options to keep it centered while I move to TDC:

a) reinstall the cover. Since the flange is now off-center I'm not sure if this will work. Plus, the flange is broken and would not be able to be secured from the outside of the engine case.

b) use the LN easy-out tool in combination with the removal tool to keep the IMS centered while reinstalling the tensioners and rotating the engine to TDC.

Any feedback on these approaches? I am especially curious about what the risks are when removing the third tensioner--I don't want to mess up the timing.

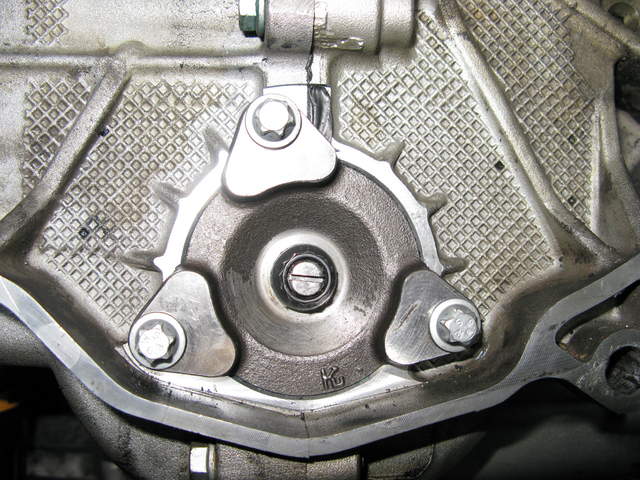

Image below. FYI, the set screws are just m6 bolts with their heads chopped off:

|

|

|

11-10-2014, 04:30 PM

11-10-2014, 04:30 PM

|

#54

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

Originally Posted by gonzojive

I am in a similar situation as others in this thread except that I have not yet extracted the original bearing. I have set screws in place but the bearing is off-center. Only 2 of the 3 tensioners are out. Some ideas for getting the job done from here:

1) Remove 3rd tensioner in attempt to center the bearing in the case hole. Is there significant risk of a timing slip from removing the third tensioner? I have an '01, 5-chain engine.

2) Try to get the engine to TDC, then use cam lock (which came with the ln retrofit kit) and follow ln engineering instructions from the top. To do this, the idea is to reinstall the tensioners and then rotate the engine manually to TDC. JFP stated this is unlikely to work because the flange from the ims bearing is no longer being held in place by the cover. In my case, the old ims bearing is still installed, so I think I have two options to keep it centered while I move to TDC:

a) reinstall the cover. Since the flange is now off-center I'm not sure if this will work. Plus, the flange is broken and would not be able to be secured from the outside of the engine case.

b) use the LN easy-out tool in combination with the removal tool to keep the IMS centered while reinstalling the tensioners and rotating the engine to TDC.

Any feedback on these approaches? I am especially curious about what the risks are when removing the third tensioner--I don't want to mess up the timing.

Image below. FYI, the set screws are just m6 bolts with their heads chopped off:

|

This is a very poor method of securing the IMS during the procedures.

Have you pulled the other two tensioners completely from the engine? Were you on TDC when you began the procedure?

How did you break the flange?

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

11-10-2014, 04:50 PM

11-10-2014, 04:50 PM

|

#55

|

|

Registered User

Join Date: Nov 2014

Location: Palo Alto, CA

Posts: 18

|

Quote:

Originally Posted by Jake Raby

This is a very poor method of securing the IMS during the procedures.

Have you pulled the other two tensioners completely from the engine? Were you on TDC when you began the procedure?

|

I am certainly not disagreeing with you there - should have at least ordered proper set screws. I followed the Pelican Parts guide that uses set screws and doesn't call for starting from TDC.

I was not on TDC when I began the procedure. I initially removed both tensioners completely, though they are now partly screwed in.

Quote:

Originally Posted by Jake Raby

How did you break the flange?

|

Flange is partly broken because I cut off the nut that was attached to it outside of the engine case. I was not able to rotate the nut with respect to the flange and eventually cut it off because the flathead end of the flange was stripped.

|

|

|

11-10-2014, 05:39 PM

11-10-2014, 05:39 PM

|

#56

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

Originally Posted by gonzojive

I am certainly not disagreeing with you there - should have at least ordered proper set screws. I followed the Pelican Parts guide that uses set screws and doesn't call for starting from TDC.

I was not on TDC when I began the procedure. I initially removed both tensioners completely, though they are now partly screwed in.

Flange is partly broken because I cut off the nut that was attached to it outside of the engine case. I was not able to rotate the nut with respect to the flange and eventually cut it off because the flathead end of the flange was stripped.

|

Wow... You couldn't hold the center stud while breaking torque on the center nut? Why?

Not starting at TDC is a recipe for disaster. The load from the cams is way too much and overcomes those measley little screws in a heartbeat.

There's one crank position where ALL the cams are unloaded, and that's at TDC.

You will not return the IMS to center withoutbremovingvthe loads from it, so you can't get the flange back on to rotate back to TDC; because you can't center it for re installation.

You now have to re- time the engine from scratch, just like everyone else who pulls the flange at any crank position other than TDC.

I developed the simplest procedure for this, it's been adopted by around 30,000 installers and you never see this post from folks that follow it.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

11-10-2014, 06:11 PM

11-10-2014, 06:11 PM

|

#57

|

|

Motorist & Coffee Drinker

Join Date: Jul 2014

Location: Oklahoma

Posts: 3,955

|

I tried using the set screws and directions in the Pelican Parts DIY too. Bad. bad....

Then there was this Video which is referenced by LN: Porsche 911 Carrera (996) 1999-2005 - Intermediate shaft (IMS) bearing DIY, how to replace - YouTube

After doing the job on two engines I really think that this is the BEST DIY for this job: PORSCHE BOXSTER IMS INSTALLATION

Mr. Raby is most certainly correct, and being a skilled professional would not endorse how I would attempt to complete the installation using the failed procedure. But I had a bad engine already and nothing to lose:

You marked your cam positions IAW the Pelican directions didn't you? If so, you can try following through on that troubled path....

No need to review my troubles, but at this point, I'd suggest that you put a broom handle size dowel or pipe in the bearing hole and guide it as close as you can back into position with all three tensioners released. Then reset the set-screws (best with 2 people). From there try the 'easy out tool' and follow through the directions of that DIY. Be sure to FREEZE THE NEW BEARING AND TOOL. The next critical point is getting the shaft centered enough to get the cover back in position. Mine was only slightly out at this point and I was able to align the screws enough to pull it into place.

If you think that in the process, you stressed the new bearing enough to damage it, you probably did. Get a new one and start again. This time use the TDC method.

Good luck

|

|

|

11-10-2014, 06:48 PM

11-10-2014, 06:48 PM

|

#58

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Don't force anything back to center... That's an easy way to stretch a section of timing chain on bank one.. It'll put all the load between the exhaust cam sprocket and the IMS drive section of chain.

The first rule of mechanical manipulation is never to force anything... If it doesn't want to go, you must address the root of the issue to correct the secondary aspects.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

11-10-2014, 07:07 PM

11-10-2014, 07:07 PM

|

#59

|

|

Registered User

Join Date: Nov 2014

Location: Palo Alto, CA

Posts: 18

|

Thanks a ton for your help.

Quote:

Originally Posted by Jake Raby

Wow... You couldn't hold the center stud while breaking torque on the center nut? Why?

|

Your understanding is correct. The nut was stuck to the stud. I'm not sure why it was stuck on so tight.

In part I damaged the stud head because I initially used a screwdriver that was too small and stripped the slot. I tried larger screwdrivers and holding the stud head with vice-grips but could not break torque that way. I was stuck on this step for a few days.

One data point, not sure how relevant: The inside of the transmission is very dirty, and it's an '01... perhaps this contributed to the tightness.

Quote:

Originally Posted by Jake Raby

Not starting at TDC is a recipe for disaster. The load from the cams is way too much and overcomes those measley little screws in a heartbeat.

There's one crank position where ALL the cams are unloaded, and that's at TDC.

|

Thanks for this warning to future readers. Had I read this advice before the install I would have done it the way you describe.

Quote:

Originally Posted by Jake Raby

You will not return the IMS to center without removing the loads from it, so you can't get the flange back on to rotate back to TDC; because you can't center it for re installation.

|

There are a few things I don't understand here:

1) What is the nature of the load being put on the IMS? Is it bad for any engine component to apply a force opposite to this force?

2) Why is it important that the bearing is centered when rotating back to TDC?

3) In my first post I proposed using the removal tool to center the bearing by overcoming the force from the cams. The large cylinder part of the removal tool could be used to keep the bearing centered while moving the engine back to TDC. What are the issues with this approach?

Quote:

Originally Posted by Jake Raby

You now have to re- time the engine from scratch, just like everyone else who pulls the flange at any crank position other than TDC.

|

Can you help me understand what exactly has gone wrong that requires retiming from scratch? Have I likely already let the chains slip (even with my 5-chain engine)?

Also, to "re-time from scratch," is it necessary to drop out the engine and take it apart?

Last edited by gonzojive; 11-10-2014 at 07:22 PM.

Reason: I was using "flange" incorrectly. The IMS flange is the plate bolted to the case.

|

|

|

11-10-2014, 09:04 PM

11-10-2014, 09:04 PM

|

#60

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

There are a few things I don't understand here:

1) What is the nature of the load being put on the IMS? Is it bad for any engine component to apply a force opposite to this force?

|

Whats holding the IMS sideways in the bore is the timing chain for bank 1. That chain has load because at least one pair of cam lobes on that bank are opening valves. If you force the IMS sideways, you are stretching a chain thats already known to stretch and break. I have the only matter linked chains in the world, but they are far from cheap, if you ever need one. Also, never force anything within an engine, if it doesn't want to budge, you must find whats necessary and relieve the tension. If not, you'll be sorry.

Quote:

|

2) Why is it important that the bearing is centered when rotating back to TDC?

|

Because rotating the engine ANY from the point you are at now will make the cam timing even worse, and you can crash valves into pistons. You can't get the flange back on to support the IMS, because its no longer centered in the bore, so rotating an unsupported IMS is a recipe for bigger disaster.

Quote:

|

3) In my first post I proposed using the removal tool to center the bearing by overcoming the force from the cams. The large cylinder part of the removal tool could be used to keep the bearing centered while moving the engine back to TDC. What are the issues with this approach?

|

I invented and developed that tool, this was never its intended purpose. That said, you do not know how far out the cams are at the present, and you won't know if things will crash until you move the engine. Not saying this won't work, but I am saying that its not a smart approach.

Quote:

|

Can you help me understand what exactly has gone wrong that requires retiming from scratch? Have I likely already let the chains slip (even with my 5-chain engine)?

|

The entire valve drive system has shifted when the flange was removed without the engine being at TDC and having the CAMS locked. Something had to move when the flange was removed, and its likely retarding bank 1. This means that the exhaust valves on that bank can crash into the pistons fairly easily, and you don't want to risk that.

Quote:

|

Also, to "re-time from scratch," is it necessary to drop out the engine and take it apart?

|

No, it can be done in the chassis, engine assembled. Pull both cam covers, and have fun.

Now, do you guys see why we only sell our IMSR products through distributors supplying them to professionals? This sort of thing should be avoided at all costs, and this is not a job for the faint of heart. The learning curve is 90 degrees, and using a procedure that looks good on paper, is a lot different than one that was developed in the real world from trial and error.

I've made lots of errors, but thats what happens when you blaze the trail that leads to the super highway that everyone else decides to travel.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 10:42 PM.

| |