02-06-2011, 07:33 AM

02-06-2011, 07:33 AM

|

#1

|

|

Registered User

Join Date: Jun 2007

Location: Colchester, CT

Posts: 489

|

Flywheel bolt torque?

Having done so many other jobs on the car now I want to do my first ever clutch job and have been reading up on the procedure. I've got the 101 projects book but he mentions two different tightening procedures. One was a 90deg final turn and the other was 120deg. What is the actual correct procedure for these bolts?

Thanks

Chris

__________________

1999 986 2.5L, Stock Exhaust (S muffler), EVO Intake, 18" Stock rims (17" during winter), IMS Upgrade, 150k+ miles and counting!

87 944S brought back to life

|

|

|

02-06-2011, 10:15 AM

02-06-2011, 10:15 AM

|

#2

|

|

Registered User

Join Date: Jan 2007

Location: BC

Posts: 1,355

|

Have you posted this question on the Pelican tech forum? I'm sure Wayne would be more than happy to address it.

http://forums.pelicanparts.com/boxster-cayman-forum/

__________________

2001 Boxster, 5 spd, Seal Grey

Last edited by clickman; 02-06-2011 at 10:17 AM.

|

|

|

02-06-2011, 10:25 AM

02-06-2011, 10:25 AM

|

#3

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

There are not two procedures, there are two stages; for the flywheel bolts (new only, do not reuse), torque to 19 ft lb, then tighten another 120 degrees of rotation to gain the correct bolt stretch. For the pressure plate, torque to 17 ft lb.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

02-06-2011, 11:36 AM

02-06-2011, 11:36 AM

|

#4

|

|

Registered User

Join Date: Dec 2006

Location: shoreham, ny

Posts: 1,619

|

It is an easy job. I'm not too far away if you get stuck and want help.

__________________

996 3.4 engine with 2.7 986 5speed transmission

Ebay Headers, Fabspeed high flow cats, JIC Cross, IPD Plenum, H&R Coilovers, B&M Short Shifter, AEM Uego Gauge Type Analog, Apexi S-AFC Select, 987 air box, Litronics, 2000 Tails and side markers, painted center console, 18" 987 S-Wheels, GT3 Front bumper with splitter.

|

|

|

02-06-2011, 01:00 PM

02-06-2011, 01:00 PM

|

#5

|

|

Registered User

Join Date: Jun 2007

Location: Colchester, CT

Posts: 489

|

Thanks guys, and JAAY that's very kind of you. I thought the 120 was the proper one but in one photo he wrote tighten to 50%, then final torque, then 90deg further. The 2nd just mentioned the 120 degrees. I'll post the the Pelican tech too.

Thanks,

Chris

__________________

1999 986 2.5L, Stock Exhaust (S muffler), EVO Intake, 18" Stock rims (17" during winter), IMS Upgrade, 150k+ miles and counting!

87 944S brought back to life

|

|

|

02-06-2011, 08:08 PM

02-06-2011, 08:08 PM

|

#6

|

|

Crazy Austrian

Join Date: Dec 2008

Location: Florida

Posts: 269

|

Quote:

|

Originally Posted by JFP in PA

There are not two procedures, there are two stages; for the flywheel bolts (new only, do not reuse), torque to 19 ft lb, then tighten another 120 degrees of rotation to gain the correct bolt stretch. For the pressure plate, torque to 17 ft lb.

|

Hi JFP, just a quick question, I know the bentley book says 120 but in my Porsche manual it says 18 and 90 - why the difference and which is right?

__________________

Crazy Austrian 007

http://www.ws-ab.com

|

|

|

02-07-2011, 11:20 AM

02-07-2011, 11:20 AM

|

#7

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

I just took a moment to look it up in my OEM manual set, and in Group 3, 30-1, page five under torque specs for dual mass flywheel, it says “25 Nm (19 Ft. Lb) plus 120 degree tightening angle”. As we kept this set current with all updates, I believe this is the most current info; yours may be from an earlier text.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

02-07-2011, 11:59 AM

02-07-2011, 11:59 AM

|

#8

|

|

Registered User

Join Date: Dec 2009

Location: Orange County, CA

Posts: 2,015

|

JFP,

Out of curiosity, if you use Locktite red on these bolts (4 insurance) before applying torque, would the real torque values be too different? Since you are supposed to oil the threads..

Quote:

|

Originally Posted by JFP in PA

I just took a moment to look it up in my OEM manual set, and in Group 3, 30-1, page five under torque specs for dual mass flywheel, it says “25 Nm (19 Ft. Lb) plus 120 degree tightening angle”. As we kept this set current with all updates, I believe this is the most current info; yours may be from an earlier text.

|

|

|

|

02-07-2011, 12:14 PM

02-07-2011, 12:14 PM

|

#9

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

You should be using some type of lubricant on any torqued fastener, be it anti seize, oil, or thread locker. I’m sure there are small differences between each, but that there would also be a larger variance if the fasteners were assembled dry. I think ARP did a “white paper” on this subject several years ago, so you may want to check their site for more info.

In any case, by far the most accurate way to assemble with fasteners is to measure bolt stretch rather than torque. This is one of the reasons why Porsche uses “micro encapsulated” single use fasteners in several locations (like the flywheel), and uses torque specs followed by “tightening angles”, which are attempting to take into account the stretch factor………

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

02-07-2011, 04:53 PM

02-07-2011, 04:53 PM

|

#10

|

|

Crazy Austrian

Join Date: Dec 2008

Location: Florida

Posts: 269

|

Quote:

|

Originally Posted by JFP in PA

I just took a moment to look it up in my OEM manual set, and in Group 3, 30-1, page five under torque specs for dual mass flywheel, it says “25 Nm (19 Ft. Lb) plus 120 degree tightening angle”. As we kept this set current with all updates, I believe this is the most current info; yours may be from an earlier text.

|

Thanks JFP , I must not have the updates, do you know where I can get those?

__________________

Crazy Austrian 007

http://www.ws-ab.com

|

|

|

02-07-2011, 07:14 PM

02-07-2011, 07:14 PM

|

#11

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

Quote:

|

Originally Posted by harryrcb

Thanks JFP , I must not have the updates, do you know where I can get those?

|

You can no longer get them; they went out of print when Porsche stopped printing the manual sets and switched to an electronic subscription system at the time of the advent of the PIWIS system. You may be able to find someone selling a print copy of the last updates somewhere on the web…….

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

Last edited by JFP in PA; 02-07-2011 at 07:21 PM.

|

|

|

02-07-2011, 08:48 PM

02-07-2011, 08:48 PM

|

#12

|

|

Crazy Austrian

Join Date: Dec 2008

Location: Florida

Posts: 269

|

Quote:

|

Originally Posted by JFP in PA

You can no longer get them; they went out of print when Porsche stopped printing the manual sets and switched to an electronic subscription system at the time of the advent of the PIWIS system. You may be able to find someone selling a print copy of the last updates somewhere on the web…….

|

Thanks. BTW what do you think of either Mitchell or Alldata ? Do they have enough data to make it worthwhile. I believe Mitchell has an electronic manual for single car for around $29/yr and alldata has a similar offer for around $23/yre or 44 for 5 yrs

__________________

Crazy Austrian 007

http://www.ws-ab.com

|

|

|

02-08-2011, 11:07 AM

02-08-2011, 11:07 AM

|

#13

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

Both are OK in general, but all these services have weak spots with any particular make, and Porsche is anything but an exception to that rule. While often hard to decipher, and totally dependant on hard to find and expensive specialty tools, the OEM manuals are still the best.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

02-08-2011, 12:05 PM

02-08-2011, 12:05 PM

|

#14

|

|

Crazy Austrian

Join Date: Dec 2008

Location: Florida

Posts: 269

|

Quote:

|

Originally Posted by JFP in PA

Both are OK in general, but all these services have weak spots with any particular make, and Porsche is anything but an exception to that rule. While often hard to decipher, and totally dependant on hard to find and expensive specialty tools, the OEM manuals are still the best.

|

I agree about the OEM manuals but it does not apply to the new cars I have a project that I'm working on and need the 09 Manual but cannot afford the $5k per year to access the electronic one.

__________________

Crazy Austrian 007

http://www.ws-ab.com

|

|

|

02-08-2011, 01:50 PM

02-08-2011, 01:50 PM

|

#15

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

Well, they were offering a deal on subscription pricing, if you lease a PIWIS system, for $18,000 a year, they give you access to the manuals for $1,000.............

Seriously, this subscription nonsense is just another “intellectual property” doge designed to keep independents away from the cars, pure and simple. And I used to think that the 986 and 996 printed manual sets were overpriced at $2,300 (each) for the set….

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

Last edited by JFP in PA; 02-08-2011 at 02:03 PM.

|

|

|

02-08-2011, 06:50 PM

02-08-2011, 06:50 PM

|

#16

|

|

Crazy Austrian

Join Date: Dec 2008

Location: Florida

Posts: 269

|

Quote:

|

Originally Posted by JFP in PA

Well, they were offering a deal on subscription pricing, if you lease a PIWIS system, for $18,000 a year, they give you access to the manuals for $1,000.............

Seriously, this subscription nonsense is just another “intellectual property” doge designed to keep independents away from the cars, pure and simple. And I used to think that the 986 and 996 printed manual sets were overpriced at $2,300 (each) for the set….

|

Gee what a deal, where do I sign up? You are dead on about keeping independents at bay.

__________________

Crazy Austrian 007

http://www.ws-ab.com

|

|

|

07-08-2015, 01:27 PM

07-08-2015, 01:27 PM

|

#17

|

|

Registered User

Join Date: Dec 2014

Location: California

Posts: 246

|

JFP and Team,

I finally have my adapter plate in my Boxster EV conversion and am going to be assembling the drive train - DC Motor + DMFW (stock) + Clutch Plate (stock) + 5 spd Tx (Stck).

Researched and found the below post and details from JFP on torque specs: FW - 19ftlbs+120deg, Clutch plate - 17ftlbs. Thanks!

What about balancing? I have no tools for balancing...  Should I be worried about it given I will be using my Warp 9 DC motor and not the engine?

Please advise. Thanks!

|

|

|

07-08-2015, 03:23 PM

07-08-2015, 03:23 PM

|

#18

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

Quote:

Originally Posted by PorscheFan5

JFP and Team,

I finally have my adapter plate in my Boxster EV conversion and am going to be assembling the drive train - DC Motor + DMFW (stock) + Clutch Plate (stock) + 5 spd Tx (Stck).

Researched and found the below post and details from JFP on torque specs: FW - 19ftlbs+120deg, Clutch plate - 17ftlbs. Thanks!

What about balancing? I have no tools for balancing...  Should I be worried about it given I will be using my Warp 9 DC motor and not the engine?

Please advise. Thanks! |

Porsche factory components are "somewhat" balanced, but probably not to the RPM levels the electric motor can turn. You might want to consider having an engine balancing shop true yours up.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

07-09-2015, 02:09 PM

07-09-2015, 02:09 PM

|

#19

|

|

1999 base

Join Date: Dec 2011

Location: Coral Springs FL

Posts: 1,617

|

just for future reference.

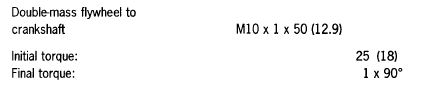

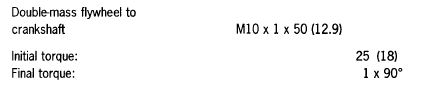

final torque on DMFW should be 90 degrees and not 120.

in the 101 book there is a mistake that was copied from the Bentley book.

in the Bentley book it say 90 in one project and 120 in another.

this is from the shop manual.

|

|

|

07-09-2015, 03:17 PM

07-09-2015, 03:17 PM

|

#20

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

Quote:

Originally Posted by Meir

just for future reference.

final torque on DMFW should be 90 degrees and not 120.

in the 101 book there is a mistake that was copied from the Bentley book.

in the Bentley book it say 90 in one project and 120 in another.

this is from the shop manual.

|

And for your reference, the was a later supplement to the Porsche service manual (a3050371, dated 2002) which reads:

"25 Nm(19 ft. lb.) plus 120 degrees."

That later data remains current according to Porsches electronic information system, PIWIS TSI.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

Last edited by JFP in PA; 07-09-2015 at 03:51 PM.

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 08:54 PM.

| |