09-28-2016, 04:26 PM

09-28-2016, 04:26 PM

|

#21

|

|

Registered User

Join Date: May 2014

Location: S.California

Posts: 2,029

|

I followed the "runout" threads elsewhere with interest.

Interesting to see the runout is 10 thou" (0.254mm). That is new info for me.Seems like it should be part of a thorough rebuild check. Too late for me and Flaps - next time perhaps !

Interesting how the discussion eventually comes back to the same remedy despite flirtations with alternatives.

|

|

|

09-29-2016, 05:42 AM

09-29-2016, 05:42 AM

|

#22

|

|

Registered User

Join Date: Jul 2014

Location: Canada

Posts: 487

|

Replacing the IMS is like getting a Flu shot. Get the shot one less worry. Or don`t get one and hopefully you won`t get sick.

I had mine done around 133 kms. Dual row.

__________________

99 Boxster sold

88 944S sold

Xpit Formula Four sold

95 Integra Solo I sold

71 Opel GT sold

|

|

|

09-29-2016, 09:44 AM

09-29-2016, 09:44 AM

|

#23

|

|

Registered User

Join Date: Jun 2014

Location: LB, Germany

Posts: 1,526

|

Quote:

Originally Posted by JFP in PA

I'm sorry, but you are not correct. On shafts with this issue, if placed in fixtures outside the engine and then turned while a dial indicator tracks them at the bearing end, the run out can be substantial, to the tune of over 0.010 inches. This is in the shaft itself, with nothing else involved. Over time, the repeated wobble in an assembled engine can reek havoc on the IMS bearing.

|

Hello JFP in PA,

OK, let's go more into that. I think we're talking about the same problem, but maybe there are multiple causes why this could happen.

First of all let us compare the designs of Porsche intermediate shafts of that time. I know most of us will know the differences, so this is also for those who are new.

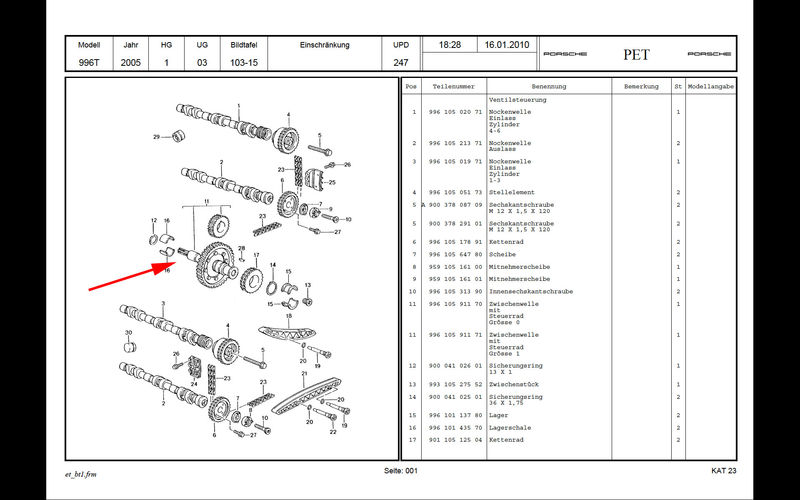

Fact is, the 986 2.5 engine was the first engine with an IMS tube (August 1996). Also it was the first flat six water cooled production engine in the Porsche engine line. 993 and 996 Mezgers have a different designed IMS. The 996 engine was presented with the new 996 model in 1997.

I have never heard failing a Mezger engine from a IMS failure by the IMS itself. Why is that? Because the IMS is designed completely different. It's based on a solid rod with gears and on each side it has an oil feeded plain bearing. It's a short designed construction.

996 Mezger engine (water cooled)

993 engine (air cooled)

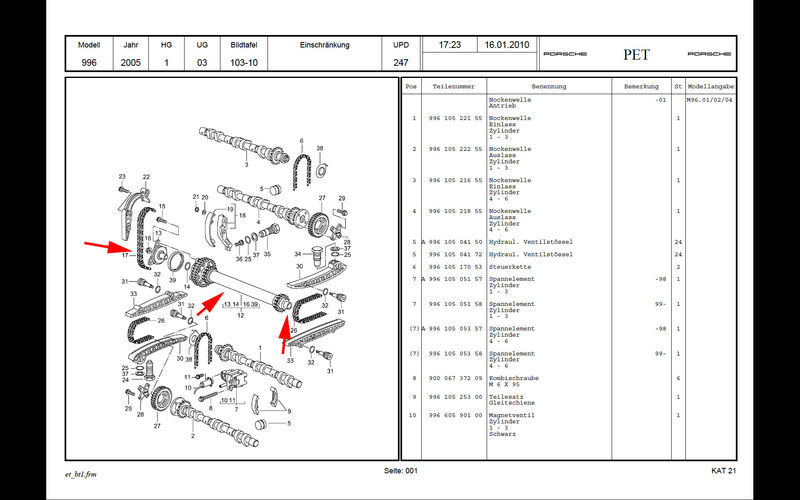

In the M96 engines this is completely different designed. The IMS is a long hollow tube, that transmits power from one end of the engine to the other to drive the camshaft drivetrain which actuates the hydraulic ilfters and the valves of this side of the cylinder head. It has gears on each side and the gears are simply pressed "on" the tube. One side of the tube has a plain bearing. The other side has a ball-bearing with a mounting mechanism. So there is a lot of torsion force on that tube.

986 engine

Personally i'm shure that every IMS was inspected before installed and get though a quality test. I don't think an engine manufacturer will build an engine that doesn't last and by that will cause an immense amount of additional costs. I also think it's well designed, means that the engineers did know what are they doing when they dimensioned parts and material quality.

Why they did use a grease filled sealed roller-bearing IMSB? I don't know. It seems to be the weak part, but there are also engine that lasts 200.000 miles without any problems - even with single row bearings. And i would say that is a very good life expectancy for a high revving sports car engine.

But the engine design was made in the start of the Wiedeking era and i think that caused a big change in the companies culture. Because from that moment every little part was cost driven and a team of pedantic financial controllers were installed to check the engineers work. And if you take a detailed look at the engine production process (casting, Lokasil…) you'll find a big amount of changes in the production process that were cost driven. The good side: it safed the company.

Thoughts why an IMS can start to wobble?

1. bad IMSB that affects the integrity of tube and gears (just remember: on one side is a plain bearing)

2. torsion overload that effects the tube of the iMS - for example by hydrolock, valve hits head…

3. torsion overload that effects the gear of the IMS - same as above

4. material fatigue

5. installation problem when exchanging an IMSB

6. problem with IMSB mount

7. problem with geometry of the 2 engine cases (or is it block?) used for the crankshaft / IMS - mostly installation fault. Cases are CNC machined.

My information from german forums is that number 7 caused most of the early engine failures and these engines where replaced completely by Porsche. Personally i would say maybe on the cause for the failure.

I'm shure i could explain that better and more detailed in german language. Hope the words make sense.

As always just my 2 cents.

Regards, Markus

|

|

|

09-29-2016, 10:14 AM

09-29-2016, 10:14 AM

|

#24

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

You are missing the point. Brand new, unused M96 shafts, right out of the box can demonstrate this run out. Shafts removed from running engines with perfectly good IMS bearings show run out to varying degrees, while many well used M96 shafts show no or very little run out at all. On top of this, the shafts from used M97 engine's do not show this tendency.

So basically, if you got an M96 with a shaft with run out, and it happened to be a single row engine, the odds were stacked against you being a happy camper.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

09-29-2016, 10:16 AM

09-29-2016, 10:16 AM

|

#25

|

|

Registered User

Join Date: May 2014

Location: S.California

Posts: 2,029

|

Markus,

You have a welcome & different perspective than the rest of us because you have access(via language) to different information - the German-speaking Porsche Forums. I try but stumble at Lagerdeckel !

This is important because I notice a difference even between U.K. and USA forums.Because our ideas here are developed in isolation we are vulnerable to 'drinking our own Cool-Aid'

Your list of 7 IMSB problems/causes is interesting.I have never seen such a list before. The pragmatic question is - what can we do about it?

Any of the 7 issues ,if severe enough will eventually cause IMSB failure. Let's suppose I have a still-running engine with one or more of these issues(but have no way of measuring it). I remove my original OEM IMSB at 90K miles and find the seals 'blown, the tube with oil in it, the bearing a little wobbly, no ferrous debris in the filter or pan. I have 'caught; it just in time.

So what do I replace the IMSB with - suspecting I have one or more of the 7 deadly problems with the tube?

The answer is - the most fault-tolerant bearing available - The Solution.But will it pass "Pre-Qualification" for Pro installation+warranty??

If not ,what to do ? The second best choice is debatable - as are the tolerances for all the 7 deadly IMSB sins in your list and the way they do/do not interact to cause premature failure of the IMSB.

I guess the second best choice is DIY install of "The Solution" in this scenario or a cylindrical roller bearing if on a budget?

Thank you for your interesting perspective that may clarify this mystery a bit more.

|

|

|

09-29-2016, 10:21 AM

09-29-2016, 10:21 AM

|

#26

|

|

Registered User

Join Date: May 2014

Location: S.California

Posts: 2,029

|

Quote:

Originally Posted by JFP in PA

You are missing the point. Brand new, unused M96 shafts, right out of the box can demonstrate this run out. Shafts removed from running engines with perfectly good IMS bearings show run out to varying degrees, while many well used M96 shafts show no or very little run out at all. On top of this, the shafts from used M97 engine's do not show this tendency.

So basically, if you got an M96 with a shaft with run out, and it happened to be a single row engine, the odds were stacked against you being a happy camper.

|

Here is a hint of how to qualify a would-be M96 engine rebuilder: "Would you let me see the IMS runout test on my shaft?

And what about the other 6 items on the list of 7 supplied by Smallblock

My guess is that only well equipped and trained machinists would be able to do this test.The average engine rebuilder would not have the correct equipment ,nor even know what to look for.

The pragmatic suggestion is to use a new M97 shaft when rebuilding an old M96 ?How else do you buy an M96 shaft that is straight? Then you do not need such a fault-tolerant/expensive bearing ?Dang - I did not know this when I rebuilt mine - next time.....:-)

Last edited by Gelbster; 09-29-2016 at 12:49 PM.

|

|

|

09-29-2016, 03:46 PM

09-29-2016, 03:46 PM

|

#27

|

|

Registered User

Join Date: Jul 2014

Location: Tacoma

Posts: 429

|

Sorry Markus, I don't mean to pick on you. This is a great, healthy discussion and I just want to make sure that some assumptions die where they should, so thanks for contributing to the discussion.

CNC machinery (which I've spent my entire working career around) only make it possible to make the same exact mistake a shocking number of times. People like to assume that CNC means perfect when compared to an old man on a 100 year old conventional mill or lathe. Accuracy and repeatabilty are functions of machine rigidity (stiffness) and not the black box hanging on the side of the machine giving orders.

The case halves are cast (and rather poorly if you examine them), which are then machined in several operations before they are assembled into an engine. Each time you remove the casting from one machining operation a human puts the casting into the next machine. There is room for error and variation every time you touch the part, and depending on how the part is "registered" (that is, how they pick up previously machined features to index the next operation from) it can have a huge effect on the consistency of the finished product.

A loose chip in the fixture will cause variation, a cutter that is getting dull or has runout, how tight one operator clamps the part in the fixture compared to another guy, etc. I've seen marks in a part after a train went by the shop I worked in at the time and older machines could just take a left through the middle of a part on a hot day for no reason.

IMS runout doesn't surprise me since the thing is pressed together, and having a sprocket slip isn't uncommon.

|

|

|

09-29-2016, 05:43 PM

09-29-2016, 05:43 PM

|

#28

|

|

Registered User

Join Date: Apr 2016

Location: Rangiora NZ

Posts: 64

|

Gelbster, If you have removed your ims bearing at 90 K , found it a little worn ( to be expected ) but still ok , and no ferrous metal in the filter or sump , then the engine with regard to the IMSB is running just fine . So then for peace of mind , why not just treat the bearing as a replaceable maintenance item and install a new bearing of the same type ,[ without seals ] after all the original has done 90k without failure. The original bearing is a $10 bearing , the "Solution " is in excess of $2000 .The critical point to note is that it should be replaced as early as possible in the life cycle of the engine . It seems to me to be a situation of a very expensive sledge hammer to crack a very small nut.

JFP, When you talk of IMS run out I guess you are meaning that the shaft ( tube ) is either bent or not round or both to a max of .010"?

__________________

2000 Triple Black Boxster S

2017 Subaru Outback Grey

|

|

|

09-29-2016, 06:00 PM

09-29-2016, 06:00 PM

|

#29

|

|

Registered User

Join Date: May 2014

Location: S.California

Posts: 2,029

|

"The critical point to note is that it should be replaced as early as possible in the life cycle of the engine "

And in a perfect (Porsche) world we would love to know how to time that so perfectly !

Pray tell us !

This is a reality thread. It is about mitigating risk. And as far as cost is concerned a good total rebuild from IMSB failure is $7000+. And that is just parts and equipment-assuming the engine can be saved.That is the number that matters ,not the $10 for the bearing.

So discussing any cheaper option = be it The Solution or a cylindrical roller bearing like NUP204 is obviously valid. Replacing with the same failure prone part when we are still discovering causal factors does nothing to mitigate risk.

And it is runout not out of round. The 2 are obviously different. The IMS is bent not squished.

Last edited by Gelbster; 09-29-2016 at 06:02 PM.

|

|

|

09-29-2016, 06:34 PM

09-29-2016, 06:34 PM

|

#30

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

Quote:

Originally Posted by Froggo

The original bearing is a $10 bearing , the "Solution " is in excess of $2000 .The critical point to note is that it should be replaced as early as possible in the life cycle of the engine . It seems to me to be a situation of a very expensive sledge hammer to crack a very small nut.

JFP, When you talk of IMS run out I guess you are meaning that the shaft ( tube ) is either bent or not round or both to a max of .010"?

|

The cost benefit calculation for the IMS Solution is multi faceted. First, and perhaps most importantly, it is a permanent fix that never needs replacement. So if you plan on keeping the car for a longer period, you need to consider the cost of multiple IMS retrofits vs. the one time cost of around $1700 for the Solution. Secondly, the IMS Solution is tolerant of conditions that no other retrofit would tolerate, such as high run out shafts. As I keep my cars for a long time (my daily driver, purchased new, will turn 20 next year), when I retrofitted both my and my better half's M96 cars (both purchased new), I did not even consider another choice, they both got IMS Solutions (one dual row, one single row), and I could not be happier with the outcome. And as we do PPI's for customers, I can also tell you that buyer's are aware of the value of the IMS Solution as well. People tend to forget that even a quality IMS retrofit that has 60K miles on it looses some of its value at resale, as the buyer has to factor in doing it again in the foreseeable future. The IMS Solution does not.

When I refer to run out, I am looking at how true the surface that hold the IMS bearing stays as the shaft rotates. Exactly where the movement comes from is a more complex issue than just bending. Because the bearing mount surface is machined into the shaft, its center line may not be on the shaft's center line, which could give you a straight shaft that turns true, but that is not what the bearing sees. Some shafts may also not be true themselves (perhaps from the process of pressing the chain gears on), causing the same issue even if both centerlines coincide. And while I have obviously not personally seen the numbers of these units that Jakes has, he has shown photos of shafts where the run out was well beyond 0.010 " and mentioned how he has had to develop screening procedure's to test shafts going into the engines he builds. Just another one of the joys of the M96 engine.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

Last edited by JFP in PA; 09-29-2016 at 06:50 PM.

|

|

|

09-30-2016, 02:54 AM

09-30-2016, 02:54 AM

|

#31

|

|

Registered User

Join Date: Jun 2014

Location: LB, Germany

Posts: 1,526

|

Hello,

Quote:

Originally Posted by Gelbster

Markus,

…Your list of 7 IMSB problems/causes is interesting. I have never seen such a list before. The pragmatic question is - what can we do about it?

Any of the 7 issues, if severe enough will eventually cause IMSB failure. Let's suppose I have a still-running engine with one or more of these issues(but have no way of measuring it). I remove my original OEM IMSB at 90K miles and find the seals 'blown, the tube with oil in it, the bearing a little wobbly, no ferrous debris in the filter or pan. I have 'caught; it just in time.

So what do I replace the IMSB with - suspecting I have one or more of the 7 deadly problems with the tube?

The answer is - the most fault-tolerant bearing available - The Solution. But will it pass "Pre-Qualification" for Pro installation+warranty?

If not, what to do? The second best choice is debatable - as are the tolerances for all the 7 deadly IMSB sins in your list and the way they do/do not interact to cause premature failure of the IMSB.

I guess the second best choice is DIY install of "The Solution" in this scenario or a cylindrical roller bearing if on a budget?

Thank you for your interesting perspective that may clarify this mystery a bit more.

|

Hi Gelbster,

well first of all there is a myth that the IMSB never was designed to be replaced while the engine is in the car. Because there is no official Porsche special tool offered? Simple question: would some shurely not too dumb engineers would have designed the mount and bearing this way?

Best solution:

There are different aspects. I think everybody has to decide himself what he or she wants to do and what amount of investment and risk to take.

Pre qualification: i completely understand why there is that process. If you have hard metal debree in a soft full aluminium engine with Lokasil coated cylinders you have a major problem. Some of these engines will still run for some time (maybe if you're lucky and the metal debree amount wasn't high forever), but sooner or later you can run into problems. A new IMSB will not solve the problem. And as said there are a lot more causes why the engines can fail.

Cost:

Does it make sense to put a 2K-3K solution in a 10K car? Would you think one minute if it would be a 100K car?

On the other side:

A 986 engine rebuilt in Germany starts at about 12K Euros and grows up to about 15-20K Euros for a more optimized engine.

An used 986 engine is available at about. 3-4K Euros. But you'll never know what you get. And to make it a good one you also have to put some additional money into it precautionary.

Installation:

From my personal POV an installation can definitely go wrong if not done properly.

Perfection / perfect world:

If you want to make 100% shure that there is no problem you have to rebuilt the engine every 50K miles.  But as always - also a rebuilt engine can fail sometimes.

Conclusion:

I don't have a solution for that.

My personal opinion:

A proper installed high quality roller ISMB with every clutch replacement. And if your DMF is worn even if the clutch isn't, replace the DMF, clutch and IMSB all together. And: if the engine fails, it fails - there are a lot of causes why the engine can fail. IMSB is only one.

Quote:

Originally Posted by Gelbster

Here is a hint of how to qualify a would-be M96 engine rebuilder: "Would you let me see the IMS runout test on my shaft?

And what about the other 6 items on the list of 7 supplied by Smallblock.

My guess is that only well equipped and trained machinists would be able to do this test. The average engine rebuilder would not have the correct equipment, nor even know what to look for.

The pragmatic suggestion is to use a new M97 shaft when rebuilding an old M96? How else do you buy an M96 shaft that is straight? Then you do not need such a fault-tolerant/expensive bearing? Dang - I did not know this when I rebuilt mine - next time... :-)

|

As for installation and quality tests.

@ JFP in PA: If you have got new parts from Porsche that are out of tolerance, sent them back, tell them what you found and ask them to sent you a new part.

I see a lot of causes why a new part can be out of tolerance. Example: i lately ordered some Brembo brake pads in Italy (around 600 miles to my home). I asked kindly to package everything very safely before shipping. What did the idiots do. They throwed the OEM packaged brake pads (just put in a card box) in another card box and shipped them this way. The result is expensive garbage you can throw into a trashcan.

Also there are tolerances. These engine parts are mass production. Pistons and rods are not equally weighted before installation. Crankshafts are not finely balanced… If you want a 100% perfect spec engine you'll need to bring it to the 100% perfection yourself or by somebody else. Not to mention you'll need the machinery and know how to do it – in your case i have no doubts that you can do it.

@****Gelbster: For the DIY man who is doing a repair or engine rebuild in you own garage (like you did) i don't think there is a simple way to get everything perfect. Shure with time, know how and patience you can build a really good engine. But you need very expensive machinery and also know how to do and test some things. One solution could be to bring the parts to a local machinery shop and let them do the tests and optimization for you.

Quote:

Originally Posted by flaps10

Sorry Markus, I don't mean to pick on you. This is a great, healthy discussion and I just want to make sure that some assumptions die where they should, so thanks for contributing to the discussion.

CNC machinery (which I've spent my entire working career around) only make it possible to make the same exact mistake a shocking number of times. People like to assume that CNC means perfect when compared to an old man on a 100 year old conventional mill or lathe. Accuracy and repeatabilty are functions of machine rigidity (stiffness) and not the black box hanging on the side of the machine giving orders.

The case halves are cast (and rather poorly if you examine them), which are then machined in several operations before they are assembled into an engine. Each time you remove the casting from one machining operation a human puts the casting into the next machine. There is room for error and variation every time you touch the part, and depending on how the part is "registered" (that is, how they pick up previously machined features to index the next operation from) it can have a huge effect on the consistency of the finished product.

A loose chip in the fixture will cause variation, a cutter that is getting dull or has runout, how tight one operator clamps the part in the fixture compared to another guy, etc. I've seen marks in a part after a train went by the shop I worked in at the time and older machines could just take a left through the middle of a part on a hot day for no reason.

IMS runout doesn't surprise me since the thing is pressed together, and having a sprocket slip isn't uncommon.

|

@ flaps10. That is what i've wrote / meant. The aluminium engine case is made by an aluminium cast. Then it was CNC machined. Then it was Lokasil coated. Think i've wrote that, no problem at all. If there is something misleading or not understandable just ask. My english skills are just the way they are. Always a problem to be exact and precise for me.

I agree that CNC machining doesn't mean there can be faults and errors. But if you take a look at modern engine production plants you'll find the processes everywhere. Also every 986/996 engine at Porsche were assembled by skilled and educated mechanics. So there was a quality control by eye and also by machines that controlled the results - shurely not at todays standards.

I could go more further in that production process, but i think that would be much to much for that post and honestly it would take me a long time to translate the terms and processes precisely.

Quote:

Originally Posted by JFP in PA

The cost benefit calculation for the IMS Solution is multi faceted. First, and perhaps most importantly, it is a permanent fix that never needs replacement. So if you plan on keeping the car for a longer period, you need to consider the cost of multiple IMS retrofits vs. the one time cost of around $1700 for the Solution. Secondly, the IMS Solution is tolerant of conditions that no other retrofit would tolerate, such as high run out shafts. As I keep my cars for a long time (my daily driver, purchased new, will turn 20 next year), when I retrofitted both my and my better half's M96 cars (both purchased new), I did not even consider another choice, they both got IMS Solutions (one dual row, one single row), and I could not be happier with the outcome. And as we do PPI's for customers, I can also tell you that buyer's are aware of the value of the IMS Solution as well. People tend to forget that even a quality IMS retrofit that has 60K miles on it looses some of its value at resale, as the buyer has to factor in doing it again in the foreseeable future. The IMS Solution does not.

When I refer to run out, I am looking at how true the surface that hold the IMS bearing stays as the shaft rotates. Exactly where the movement comes from is a more complex issue than just bending. Because the bearing mount surface is machined into the shaft, its center line may not be on the shaft's center line, which could give you a straight shaft that turns true, but that is not what the bearing sees. Some shafts may also not be true themselves (perhaps from the process of pressing the chain gears on), causing the same issue even if both centerlines coincide. And while I have obviously not personally seen the numbers of these units that Jakes has, he has shown photos of shafts where the run out was well beyond 0.010 " and mentioned how he has had to develop screening procedure's to test shafts going into the engines he builds. Just another one of the joys of the M96 engine.

|

@ JFP in PA: These are interesting aspects.

Let's calculate some things:

LN premium solution: $1700 plus professional installation or premium tool $600 and plus cam locking… tools plus DIY. I would estimate 2.5K plus.

Conventional high quality ball bearing plus new updated mount: $200 plus materials for tools made yourself $50. I would estimate $ 250 plus.

Clutch needed around every 60-70K miles. AT-car - other calculation.

IMS run out:

I'm not an engine engineer, but i think it's an interesting aspect. Is a ball bearing capable to handle more IMS tolerances than a plain bearing? I did a research and from what i understood i would say yes.

@ all / for those who are interest in bearing technologies and want to get more into it:

Some infos about bearings in general (english language)

Schaeffler Germany | Products & Services | Rolling and Plain Bearings

Some infos about roller bearings (sorry, only german language)

Technische Grundlagen

Regards, Markus

PS: If you have access to a spare engine and a 3D scanner and a 3D construction program you can do funny things.

Last edited by Smallblock454; 09-30-2016 at 03:05 AM.

|

|

|

09-30-2016, 07:46 AM

09-30-2016, 07:46 AM

|

#32

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

Quote:

Originally Posted by Smallblock454

Hello,

Hi Gelbster,

well first of all there is a myth that the IMSB never was designed to be replaced while the engine is in the car. Because there is no official Porsche special tool offered? Simple question: would some shurely not too dumb engineers would have designed the mount and bearing this way?

Best solution:

There are different aspects. I think everybody has to decide himself what he or she wants to do and what amount of investment and risk to take.

Pre qualification: i completely understand why there is that process. If you have hard metal debree in a soft full aluminium engine with Lokasil coated cylinders you have a major problem. Some of these engines will still run for some time (maybe if you're lucky and the metal debree amount wasn't high forever), but sooner or later you can run into problems. A new IMSB will not solve the problem. And as said there are a lot more causes why the engines can fail.

Cost:

Does it make sense to put a 2K-3K solution in a 10K car? Would you think one minute if it would be a 100K car?

On the other side:

A 986 engine rebuilt in Germany starts at about 12K Euros and grows up to about 15-20K Euros for a more optimized engine.

An used 986 engine is available at about. 3-4K Euros. But you'll never know what you get. And to make it a good one you also have to put some additional money into it precautionary.

Installation:

From my personal POV an installation can definitely go wrong if not done properly.

Perfection / perfect world:

If you want to make 100% shure that there is no problem you have to rebuilt the engine every 50K miles.  But as always - also a rebuilt engine can fail sometimes.

Conclusion:

I don't have a solution for that.

My personal opinion:

A proper installed high quality roller ISMB with every clutch replacement. And if your DMF is worn even if the clutch isn't, replace the DMF, clutch and IMSB all together. And: if the engine fails, it fails - there are a lot of causes why the engine can fail. IMSB is only one.

As for installation and quality tests.

@ JFP in PA: If you have got new parts from Porsche that are out of tolerance, sent them back, tell them what you found and ask them to sent you a new part.

I see a lot of causes why a new part can be out of tolerance. Example: i lately ordered some Brembo brake pads in Italy (around 600 miles to my home). I asked kindly to package everything very safely before shipping. What did the idiots do. They throwed the OEM packaged brake pads (just put in a card box) in another card box and shipped them this way. The result is expensive garbage you can throw into a trashcan.

Also there are tolerances. These engine parts are mass production. Pistons and rods are not equally weighted before installation. Crankshafts are not finely balanced… If you want a 100% perfect spec engine you'll need to bring it to the 100% perfection yourself or by somebody else. Not to mention you'll need the machinery and know how to do it – in your case i have no doubts that you can do it.

@****Gelbster: For the DIY man who is doing a repair or engine rebuild in you own garage (like you did) i don't think there is a simple way to get everything perfect. Shure with time, know how and patience you can build a really good engine. But you need very expensive machinery and also know how to do and test some things. One solution could be to bring the parts to a local machinery shop and let them do the tests and optimization for you.

@ flaps10. That is what i've wrote / meant. The aluminium engine case is made by an aluminium cast. Then it was CNC machined. Then it was Lokasil coated. Think i've wrote that, no problem at all. If there is something misleading or not understandable just ask. My english skills are just the way they are. Always a problem to be exact and precise for me.

I agree that CNC machining doesn't mean there can be faults and errors. But if you take a look at modern engine production plants you'll find the processes everywhere. Also every 986/996 engine at Porsche were assembled by skilled and educated mechanics. So there was a quality control by eye and also by machines that controlled the results - shurely not at todays standards.

I could go more further in that production process, but i think that would be much to much for that post and honestly it would take me a long time to translate the terms and processes precisely.

@ JFP in PA: These are interesting aspects.

Let's calculate some things:

LN premium solution: $1700 plus professional installation or premium tool $600 and plus cam locking… tools plus DIY. I would estimate 2.5K plus.

Conventional high quality ball bearing plus new updated mount: $200 plus materials for tools made yourself $50. I would estimate $ 250 plus.

Clutch needed around every 60-70K miles. AT-car - other calculation.

IMS run out:

I'm not an engine engineer, but i think it's an interesting aspect. Is a ball bearing capable to handle more IMS tolerances than a plain bearing? I did a research and from what i understood i would say yes.

@ all / for those who are interest in bearing technologies and want to get more into it:

Some infos about bearings in general (english language)

Schaeffler Germany | Products & Services | Rolling and Plain Bearings

Some infos about roller bearings (sorry, only german language)

Technische Grundlagen

Regards, Markus

PS: If you have access to a spare engine and a 3D scanner and a 3D construction program you can do funny things. |

OK, let’s look at your comments, point by point:

The “myth”: The reason for the “myth” that the IMS bearing cannot be changed without disassembling the engine happened because Porsche notified US dealers in writing that this was the factory’s official position on the subject. US dealers had been pleading with the factory for a fix for what was rapidly becoming a major issue influencing North American sales, with many pointing to Jake Raby and LN Engineering’s then newly announced retrofit system. The factory said no, it simply would not work, and the rest as they say is history. So the “myth” is indeed a fact that many dealers here still adhere to even today.

Prequalification procedures: What you are looking for is one of two conditions, the presence of quantities of ferrous particulates, or large amounts of alloy flakes. Ferrous materials are serious and probably an already dying IMS. Alloy flakes are always present in these engines, but usually is small amounts. When you start see them is large amounts, something is wrong, and installing an expensive IMS bearing that is open to oil lubrication is asking for a premature bearing failure due to debris ingestion.

Replacing the IMS with a low cost off the shelf all steel bearing every time you do the clutch: This idea sounds fine until you look at expected clutch life. We have customers that are still on their factory clutch at 200K miles, and a few at or over 300K. Like the Tiptronic cars, these would have never been retrofitted using your approach. But all of them were, and the original clutch was reinstalled either because it still looked fine, or the customer insisted on it.

Roller bearings: We do not install them for a multitude of reasons. They do not offer any significantly higher load carrying capacity than ceramic hybrid bearings, and some of the kits installation techniques are questionable at best. They also have a very limited performance history. As my shop’s reputation is on the line with every retrofit, we go with what we know has a proven record of over 25K installs with no issues. And quite plainly, they are not that much cheaper than the ceramic hybrids, and in any case the parts costs are only a small fraction of the total installed cost to the customer.

Returning defective parts: A nice idea, but what do you do when you send one back because its run out is too high, and the replacement you get is even worse? And you can only buy an assembled shaft with an oversized IMS bearing in it from the factory, at over $1K my cost, and to fully test the shaft you have to remove the factory bearing, which kills it. Jake has the luxury of having a pile of shafts to go through and select the good ones to put on the shelf for future engine builds. I do not have that luxury, we are always under time constraints to get the car back on the road ASAP.

CNC variations: How do you explain the issue if you can take one shaft out and put in one with little or no run out and the problem goes away? It may be the cases in some situations, but the shafts in the M96 engines decidedly have a problem all their own that is quickly solved by using a different shaft in the same cases.

IMS Solution costs: One Solution cost about as much as two ceramic hybrids, just for the parts. And with the exception of a small amount of additional labor to notch the bell housing to accept the oil line, the costs to do the Solution are exactly the same as the hybrid bearings. But the Solution is also a permanent life of the engine retrofit. So if an owner expects to keep the car for a bit, or sell it 60K miles down the road they would actually be ahead of the game when the first retrofit would have come up for subsequent replacement, and history has already shown that the Solution being permanent holds its value at resale while the hybrid is discounted for mileage since install. And to put an incorrect idea away, once and for all, you can install the Solution using the original tool kit, but will need the supplemental tool kit to install the IMS shaft plug behind the bearing on a Solution install. Most shops have the supplemental kit as it contains additional parts needed to do the later designed bearing, like the Single Row Pro. And many shops went to the Faultless tool as soon as it became available, simply because it makes any extraction or installation a quicker turn around, plus it eliminates any chance of a cocked single row installation, and is an absolute requirement for the Single Row Pro bearing. Using the Faultless tool, you shorten the time and reduce issues, which is every shops dream.

Sales of Solution installs also speak volumes; the demand for them has exceeded the supply nearly all of this year. Early this year, the wait time from order to delivery was exceeding 90 days. And we have more inquiries for the Solution than any other style retrofit bearing.

Ball bearings are more tolerant to run out than solid bearings: Jake’s experience is just the opposite. People seem to forget that, being an innovator, he relishes testing things to destruction to learn more. He has taken shafts with considerable run out that had factory steel bearings showing the telltale signs of shaft wobble and put a Solution in them and put them back in the engine. Then he ran the Hell out them and pulled them out for examination. While the solid bearing showed some polishing on the run out side, it was otherwise fine. If you have ever had the chance to hold an IMS Solution in your hand, and in particular the dual row version, the total contact area of continuously oiled surface is utterly immense when compared with the available contact patch of any type of ball or roller bearing. And because the solid bearing surface is both lubricated and cooled by twin oil ports and an annular oil channel, the Solution is a happy camper in situations that would be fatal to other types of bearings.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

Last edited by JFP in PA; 09-30-2016 at 08:00 AM.

|

|

|

09-30-2016, 08:20 AM

09-30-2016, 08:20 AM

|

#33

|

|

07 Carrera S Cab

Join Date: Nov 2005

Location: New Jersey

Posts: 2,273

|

I have kept my Boxster what I consider long term (have had it for 15 yrs now), and have never bought into this need to preemptively change out the IMS or install an oil feed system. I don't drive it that much either (only put about 3-4K miles a year), and only change the oil every 2 yrs with Mobil 1 0w-40 (oil that most people here don't recommend). Whatever, the car runs awesome and has never failed me (have only had to replace a water pump, coolant tank, engine mount, a MAF, and brakes). It's still running. Amazing, huh?  Just drive it and enjoy it.

__________________

Current: 07 Carrera S Cab in Midnight Blue

Previous: 01 Boxster in Arctic Silver, 86 944 in Guards Red

|

|

|

09-30-2016, 08:38 AM

09-30-2016, 08:38 AM

|

#34

|

|

WALDMEISTER

Join Date: Sep 2013

Location: Germany

Posts: 1,381

|

Quote:

Originally Posted by Boxtaboy

I have kept my Boxster what I consider long term (have had it for 15 yrs now), and have never bought into this need to preemptively change out the IMS or install an oil feed system. I don't drive it that much either (only put about 3-4K miles a year), and only change the oil every 2 yrs with Mobil 1 0w-40 (oil that most people here don't recommend). Whatever, the car runs awesome and has never failed me (have only had to replace a water pump, coolant tank, engine mount, a MAF, and brakes). It's still running. Amazing, huh?  Just drive it and enjoy it. |

/sign

could have been my post almost

Basically the same here...16 years old and max 5k km per year (obviously not my DD), service @ dealership every other year...nothing...nada...no repairs...nothing failed...it runs and runs and runs.

If the engine fails, it fails, there are other things to worry about in life

ENJOY PORSCHE. Don't worry!

__________________

Original Owner | PORSCHE Boxster 2.7L (MY01) | Seal Gray

|

|

|

09-30-2016, 08:44 AM

09-30-2016, 08:44 AM

|

#35

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

Guys, that is just fine; it is your car and your money, and you are entitled to your opinion. None of what I posted here is designed to get anyone to change their behavior; it is just to clear up misunderstandings or misconstrued facts, nothing more.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

09-30-2016, 08:57 AM

09-30-2016, 08:57 AM

|

#36

|

|

Registered User

Join Date: May 2014

Location: S.California

Posts: 2,029

|

Obviouly JFP has way more experience of these issues than any single owner. These are technical issues and wishing them away or denying them doesn't affect the defects.

The value of this thread and similar ones is to accumulate a list of actions to mitigate the risk, know the symptoms and causes and how to effectively fix them. Recommending the 'head in the sand' approach based on one personal anecdote is not technically adequate.

|

|

|

09-30-2016, 08:58 AM

09-30-2016, 08:58 AM

|

#37

|

|

WALDMEISTER

Join Date: Sep 2013

Location: Germany

Posts: 1,381

|

Quote:

Originally Posted by JFP in PA

Guys, that is just fine; it is your car and your money, and you are entitled to your opinion. None of what I posted here is designed to get anyone to change their behavior; it is just to clear up misunderstandings or misconstrued facts, nothing more.

|

always welcome...

I gave up reading this thread as my technical understanding/background/experience is (sadly) limited for being a sales/marketing person by profession

I guess it is sometimes, somehow beneficial not knowing everything

__________________

Original Owner | PORSCHE Boxster 2.7L (MY01) | Seal Gray

|

|

|

09-30-2016, 09:14 AM

09-30-2016, 09:14 AM

|

#38

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

Quote:

Originally Posted by BRAN

I gave up reading this thread as my technical understanding/background/experience is (sadly) limited for being a sales/marketing person by profession  |

Which is exactly what I did for a living before abandoning corporate life. It never hurts to learn.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

09-30-2016, 09:31 AM

09-30-2016, 09:31 AM

|

#39

|

|

07 Carrera S Cab

Join Date: Nov 2005

Location: New Jersey

Posts: 2,273

|

I have no issues with the extra knowledge put out here either, but I kinda treat it like I do health info on the Internet... The more I read about things/ailments, the more I worry, so instead just try to enjoy and live my life as healthy as I can without obsessing about the little things that'll drive me crazy, and it works for me. So far, no IMS failure of my health.

__________________

Current: 07 Carrera S Cab in Midnight Blue

Previous: 01 Boxster in Arctic Silver, 86 944 in Guards Red

|

|

|

09-30-2016, 09:40 AM

09-30-2016, 09:40 AM

|

#40

|

|

WALDMEISTER

Join Date: Sep 2013

Location: Germany

Posts: 1,381

|

Quote:

Originally Posted by JFP in PA

Which is exactly what I did for a living before abandoning corporate life. It never hurts to learn.

|

Sure thing, that is exactly my credo, especially when getting older.

Sorry for not being able to contribute in this clash of paradigms, guys.

I just know my limits and know when to put my head in the sand

...and happy birthday to me, 400 posts

__________________

Original Owner | PORSCHE Boxster 2.7L (MY01) | Seal Gray

Last edited by BRAN; 09-30-2016 at 09:43 AM.

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 08:18 PM.

| |