Quote:

Originally Posted by JFP in PA

I'm sorry, but you are not correct. On shafts with this issue, if placed in fixtures outside the engine and then turned while a dial indicator tracks them at the bearing end, the run out can be substantial, to the tune of over 0.010 inches. This is in the shaft itself, with nothing else involved. Over time, the repeated wobble in an assembled engine can reek havoc on the IMS bearing.

|

Hello JFP in PA,

OK, let's go more into that. I think we're talking about the same problem, but maybe there are multiple causes why this could happen.

First of all let us compare the designs of Porsche intermediate shafts of that time. I know most of us will know the differences, so this is also for those who are new.

Fact is, the 986 2.5 engine was the first engine with an IMS tube (August 1996). Also it was the first flat six water cooled production engine in the Porsche engine line. 993 and 996 Mezgers have a different designed IMS. The 996 engine was presented with the new 996 model in 1997.

I have never heard failing a Mezger engine from a IMS failure by the IMS itself. Why is that? Because the IMS is designed completely different. It's based on a solid rod with gears and on each side it has an oil feeded plain bearing. It's a short designed construction.

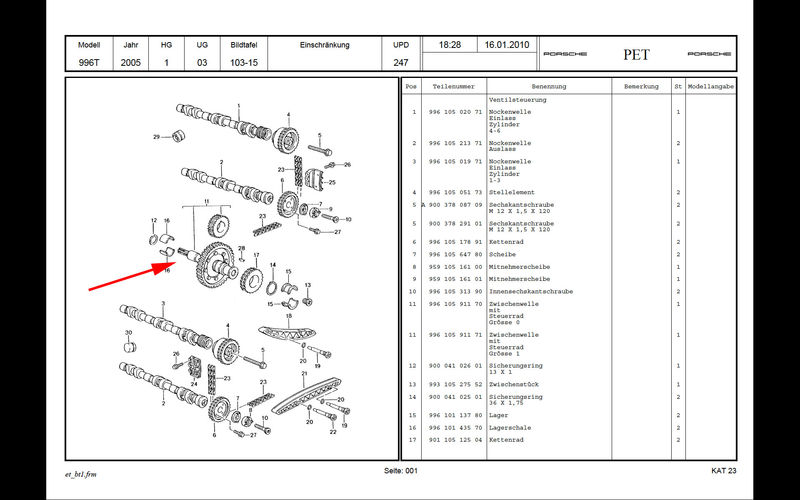

996 Mezger engine (water cooled)

993 engine (air cooled)

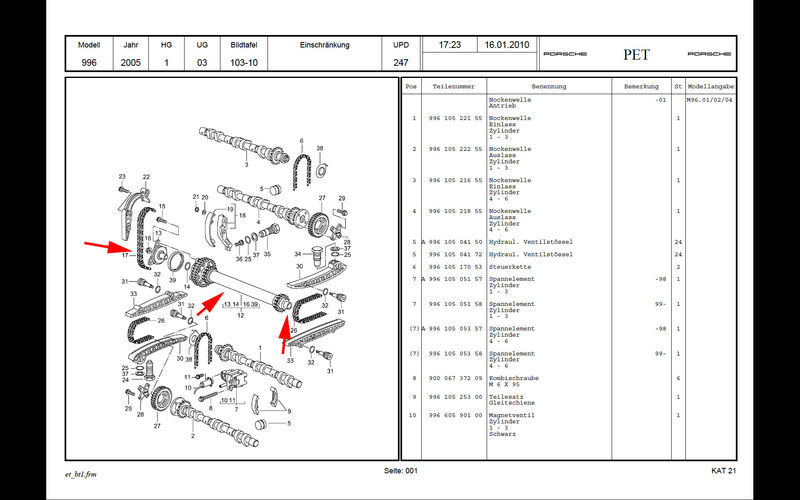

In the M96 engines this is completely different designed. The IMS is a long hollow tube, that transmits power from one end of the engine to the other to drive the camshaft drivetrain which actuates the hydraulic ilfters and the valves of this side of the cylinder head. It has gears on each side and the gears are simply pressed "on" the tube. One side of the tube has a plain bearing. The other side has a ball-bearing with a mounting mechanism. So there is a lot of torsion force on that tube.

986 engine

Personally i'm shure that every IMS was inspected before installed and get though a quality test. I don't think an engine manufacturer will build an engine that doesn't last and by that will cause an immense amount of additional costs. I also think it's well designed, means that the engineers did know what are they doing when they dimensioned parts and material quality.

Why they did use a grease filled sealed roller-bearing IMSB? I don't know. It seems to be the weak part, but there are also engine that lasts 200.000 miles without any problems - even with single row bearings. And i would say that is a very good life expectancy for a high revving sports car engine.

But the engine design was made in the start of the Wiedeking era and i think that caused a big change in the companies culture. Because from that moment every little part was cost driven and a team of pedantic financial controllers were installed to check the engineers work. And if you take a detailed look at the engine production process (casting, Lokasilů) you'll find a big amount of changes in the production process that were cost driven. The good side: it safed the company.

Thoughts why an IMS can start to wobble?

1. bad IMSB that affects the integrity of tube and gears (just remember: on one side is a plain bearing)

2. torsion overload that effects the tube of the iMS - for example by hydrolock, valve hits headů

3. torsion overload that effects the gear of the IMS - same as above

4. material fatigue

5. installation problem when exchanging an IMSB

6. problem with IMSB mount

7. problem with geometry of the 2 engine cases (or is it block?) used for the crankshaft / IMS - mostly installation fault. Cases are CNC machined.

My information from german forums is that number 7 caused most of the early engine failures and these engines where replaced completely by Porsche. Personally i would say maybe on the cause for the failure.

I'm shure i could explain that better and more detailed in german language. Hope the words make sense.

As always just my 2 cents.

Regards, Markus