07-25-2011, 01:01 PM

07-25-2011, 01:01 PM

|

#1

|

|

Registered User

Join Date: Mar 2007

Location: Ohio

Posts: 2,031

|

Motor mount re-assembly question

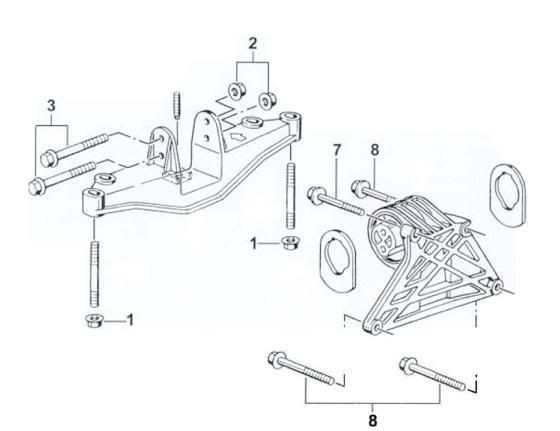

Putting my motor mount back together, using an aftermarket mount. When assembled, it looked like this:

When I took everything apart, I don't recall there being that much of a gap between the engine mount and the yoke. In other words, the rubber stops on either side of the rubberized mount (one is just to the right of the pencil) just kind of dangle loosely. In fact, on the one side (where the pencil is) I'm pretty sure I could fit a second one in there. Both bolts are torqued to the required 48 ft-lbs.

Does this look right?

|

|

|

07-25-2011, 02:15 PM

07-25-2011, 02:15 PM

|

#2

|

|

Registered User

Join Date: Aug 2010

Location: Germany

Posts: 97

|

That looks ok

I just did mine this weekend, and had the same gap.

My guess is that the rubber pieces are just to prevent metal-to-metal contact if the engine flexes sideways.

|

|

|

07-25-2011, 02:29 PM

07-25-2011, 02:29 PM

|

#3

|

|

Registered User

Join Date: Jun 2007

Location: Littleton, CO

Posts: 456

|

Aren't those thin black plastic pieces supposed to be mounted differently? I think the part number should be opposite of where they are. I think they should be down in the yoke. In other words, the shorter end of the plastic should be on the pencil side. Fitment of these thin pieces over the metal part of the mount should work better one way than the other. Can someone please confirm this for me?

__________________

"Of all the extreme sports I've ever participated in- windsurfing, kite boarding, wake boarding, tow-in surfing and snowboarding- skiing, for me, made everything else easy."

-Chuck Patterson

|

|

|

07-25-2011, 02:30 PM

07-25-2011, 02:30 PM

|

#4

|

|

Registered User

Join Date: Mar 2007

Location: Ohio

Posts: 2,031

|

Thanks. Got an email response from Pedro (where I got the mount re-done)--in 3 minutes! He basically said what you said.

|

|

|

07-25-2011, 03:19 PM

07-25-2011, 03:19 PM

|

#5

|

|

Registered User

Join Date: Mar 2007

Location: Ohio

Posts: 2,031

|

Follow-up question:

Has to do with replacing the bolts attaching the yoke to the body (these being the ones that sometimes come out nut + stud and sometimes nut followed by stud):

Bentley says to torque it to 48 ft-lb, but I assume that's just for the nut itself. The studs (with the 7 mm head on them) I would think you would just tighten until they're snug, then crank the nuts to 48. Right?

|

|

|

07-25-2011, 03:51 PM

07-25-2011, 03:51 PM

|

#6

|

|

Registered User

Join Date: May 2011

Location: Miami florida

Posts: 1,591

|

Quote:

|

Originally Posted by Frodo

Follow-up question:

Has to do with replacing the bolts attaching the yoke to the body (these being the ones that sometimes come out nut + stud and sometimes nut followed by stud):

Bentley says to torque it to 48 ft-lb, but I assume that's just for the nut itself. The studs (with the 7 mm head on them) I would think you would just tighten until they're snug, then crank the nuts to 48. Right? |

NO! You have to torque the studs into the frame at 48 ft-lbs. Then torque the nuts onto the studs at 34 ft-lbs. If the studs aren't torqued, thay can pull out of the frame, goobering the threads in the frame. Then you will be in a world of ********************.

__________________

Current car

2000 Boxster 2.7l red/black

Previous cars

1973 Opel Manta

1969(?) Fiat 850 Convertible

1979 Lancia Beta Coupe

1981 Alfa Romeo GTV 6

1985 Alfa Romeo Graduate

1985 Porsche 944

1989 Porsche 944

1981 Triumph TR7

1989 (?) Alfa Romeo Milano

1993 Saab 9000

|

|

|

07-25-2011, 04:19 PM

07-25-2011, 04:19 PM

|

#7

|

|

Registered User

Join Date: Mar 2007

Location: Ohio

Posts: 2,031

|

So you can put 48 ft-lbs of torque on those little 7 mm heads without chewin' them up?? And, regarding torque values, Bentley says

Engine yoke to body 48 ft-lb They don't distinguish between the nuts and the studs.

|

|

|

07-25-2011, 06:24 PM

07-25-2011, 06:24 PM

|

#8

|

|

Registered User

Join Date: Jun 2007

Location: Littleton, CO

Posts: 456

|

Yoke to body = 48

Nut to stud = 34

__________________

"Of all the extreme sports I've ever participated in- windsurfing, kite boarding, wake boarding, tow-in surfing and snowboarding- skiing, for me, made everything else easy."

-Chuck Patterson

|

|

|

07-25-2011, 08:30 PM

07-25-2011, 08:30 PM

|

#9

|

|

Registered User

Join Date: Mar 2007

Location: Ohio

Posts: 2,031

|

You guys are confusing me...

Regarding torque values, this is what Bentley recommends, in full:

Engine mount to engine 34 ft-lb

Engine yoke to body 48 ft-lb

Engine yoke to engine mount 48 fl-lb Now, what I've been talking about is the second in the list..my only question is whether they're recommending 48 ft-lb to the stud, or 48 ft-lb to the nut that threads onto the stud. Both are involved in fastening the yoke to the body.

The only 34 ft-lb recommendation is for the bolts that actually go into the engine. That seemed crystal clear, and I've already followed that advice.

Back to the studs mentioned above. With the heads on them at 7 mm, the only wrench I have that's that small is about 4" long. If I'm supposed to crank that to 48 ft-lb, I need to get a longer wrench...I'm not sure I can put almost 150 lb of force on that little wrench, which is what I'd need to accomplish 48 ft-lb. In any case, it just seems to be asking for trouble--I think with that much torque you'd be likely to tear up the wimpy little 7 mm heads. I put 'em in basically pretty much as tight as I could with the little wrench I mentioned and am going from there. (When the nuts are threaded on and torqued to 48 ft-lb, that's gonna put a lot of outward force on the stud threads in the body, which should make the fit pretty secure---I just don't see them coming undone.)

|

|

|

07-25-2011, 10:53 PM

07-25-2011, 10:53 PM

|

#10

|

|

Registered User

Join Date: May 2011

Location: Miami florida

Posts: 1,591

|

Its 48 for the studs that go into the frame. Then, its 34 for the NUTS that go onto the studs. Very straightforward.

I used a cheap 7mm socket on my torque wrench and I had absolutely no problem getting the torque to 48 on the studs.

__________________

Current car

2000 Boxster 2.7l red/black

Previous cars

1973 Opel Manta

1969(?) Fiat 850 Convertible

1979 Lancia Beta Coupe

1981 Alfa Romeo GTV 6

1985 Alfa Romeo Graduate

1985 Porsche 944

1989 Porsche 944

1981 Triumph TR7

1989 (?) Alfa Romeo Milano

1993 Saab 9000

|

|

|

07-26-2011, 05:35 AM

07-26-2011, 05:35 AM

|

#11

|

|

Registered User

Join Date: Mar 2007

Location: Ohio

Posts: 2,031

|

This has largely become a mental exercise for me---I've cranked on enough variously sized nuts & bolts (stripped a few!) to have a pretty good "feel" for what's about right, torque-wise. (With the total inaccessibility of so many of them on Boxster repairs, I've considered tossing the torque wrench into the trash can.) But, I'm sorta having fun with the discussion...here's the diagram:

Now, back to my list from Bentley:

A) Engine mount to engine 34 ft-lb

B) Engine yoke to body 48 ft-lb

C) Engine yoke to engine mount 48 fl-lb Is it just me, or isn't it clear that "A" refers to Bolts 7 & 8 in the diagram? That's the only torque value in this section of Bentley that specifies 34 ft-lbs.

And "B", to me, seems just as clearly to refer to the fasteners numbered 1 (of which there are actually four total). Inconveniently, Bentley didn't specifically provide separate torque values for the stud and nuts in their description.

Likewise, "C" corresponds to nuts/bolts 2 & 3. Right?

Where do you guys get "34 ft-lb" for the torque setting for the nuts (numbered 1, in the diagram) to the studs??

|

|

|

07-26-2011, 05:43 AM

07-26-2011, 05:43 AM

|

#12

|

|

Registered User

Join Date: May 2011

Location: Miami florida

Posts: 1,591

|

From the porsche factory manual and Pedro's write up.

__________________

Current car

2000 Boxster 2.7l red/black

Previous cars

1973 Opel Manta

1969(?) Fiat 850 Convertible

1979 Lancia Beta Coupe

1981 Alfa Romeo GTV 6

1985 Alfa Romeo Graduate

1985 Porsche 944

1989 Porsche 944

1981 Triumph TR7

1989 (?) Alfa Romeo Milano

1993 Saab 9000

|

|

|

07-26-2011, 06:25 AM

07-26-2011, 06:25 AM

|

#13

|

|

Registered User

Join Date: Mar 2007

Location: Ohio

Posts: 2,031

|

Quote:

|

Originally Posted by san rensho

From the porsche factory manual and Pedro's write up.

|

Regarding the factory manual---unfortunately I can't comment, I don't have it.

Regarding Pedro's write up---read it again. He ( quite possibly being smarter than all of us) simplified to the extreme: He just recommends 34 ft-lb for ALL of them ( http://www.pedrosgarage.com/Site_3/Install_Front_Engine_Mount.html).

|

|

|

07-26-2011, 06:38 AM

07-26-2011, 06:38 AM

|

#14

|

|

Registered User

Join Date: Nov 2010

Location: Philly

Posts: 594

|

I don't know much about tools, but when you guys say 48 lb-ft. How do you know you tightened it that much?

Is there a tool that tells you? What is it called?

__________________

00 2.7 5SPD MT

|

|

|

07-26-2011, 07:48 AM

07-26-2011, 07:48 AM

|

#15

|

|

Registered User

Join Date: Nov 2005

Location: Florida

Posts: 529

|

People tend to ...

... get all bent out of shape about tightening torques and trying to be perfect about it.

Most of the torque-wrenches sold on the market don't get calibrated regularly and the values have to be all over the place.

Most of the time a more-or-less tightening is what's done.

I am extremely conscious of torque values in only selected places such as internal engine components, etc. where I use a digital and calibrated torque wrench to follow the specified values. Also in these cases the pattern used in tightening can be as important as the torque applied.

For most jobs I just do a "manual" tightening.

After you've tightened a few fasteners in your life you get a "feel" for it.

It's like golf. You should always have the same swing, the difference in each shot (long game or approach) is the club.

In our case the difference is the wrench. You should tighten basically with the same hand strength, but using a 5 in wrench vs a 12 in wrench will offer vastly different torques on the fastener. That's why each wrench is a bit longer, depending on it's aperture size.

Most people also tend to over-tighten fasteners.

I constantly get cars where the owner has completely sheared off a fastener due to over tightening.

Use a torque wrench, but don't despair if you can't find a particular torque value to apply. Use common sense and your feel for the fastener's size.

Happy Boxstering,

Pedro

__________________

Racecar spelled backwards is: Racecar!

|

|

|

07-26-2011, 03:15 PM

07-26-2011, 03:15 PM

|

#16

|

|

Registered User

Join Date: Oct 2008

Location: Canyon Lake, Texas

Posts: 801

|

Quote:

|

Originally Posted by ProjectM96

I don't know much about tools, but when you guys say 48 lb-ft. How do you know you tightened it that much?

Is there a tool that tells you? What is it called?

|

Torque Wrench.

I'm a stickler for torquing things to spec. My dad is the "Mr. GoodAndTight" type though.. it's annoying...

As was stated though, there's a lot of places on the Boxster that call for torque values, but it's hard to get a torque wrench in the space (a lot of torque wrenches are a bit large). They range from $20 up to several hundred. I've had good luck with the Harbor Freight torques, but use a Craftsman for most jobs.

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 10:31 AM.

| |