Quote:

Originally Posted by itsnotanova

I believe the biggest flex on a boxster that isn't caged is in between the door pillars.

|

Yes. ^^^^

The mid-section of the car is essentially a plat panel and as it flexes the front and rear suspension components undergo different geometry, forces, and dynamics - all of which are not good for optimal handing. There are two ways to make a flat panel stiffer - make it thicker, make it out of stiffer material, or add some structure to it.

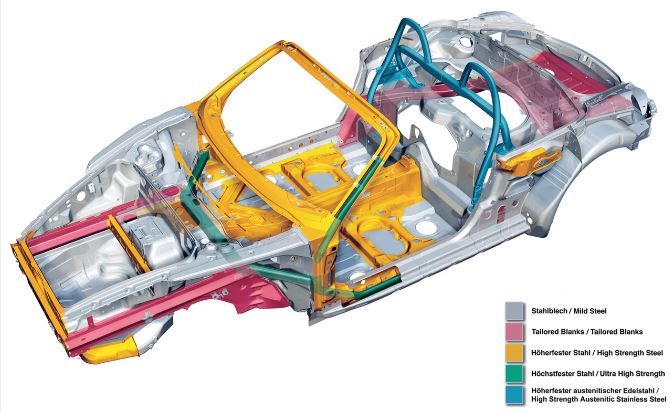

And this is what Porsche originally did. If you look at the center/passenger section, Porsche added a tall center tunnel (structure) made from high strength steel (stiffer material) with bracing that adds height to the floor pan and extends to the door sills (thicker, stiffer, and structure).

The challenge to further stiffening of the chassis is where/how to attach additional structural components. The front and rear are easy, add a front shock tower brace (or x-brace as shown in the previous link) and add something like a techno-brace to the rear.

The real challenge is how to add a bolt-on structural component to the central section of the chassis without encroaching on occupant space/ingress/egress along with aesthetic considerations. Underneath the car, it would be hard to add bracing since the car is already pretty low and its not clear exactly how to mount it.

Quote:

Originally Posted by The Radium King

... there's gotta be a way to stiffen this thing.

|

If I was so inclined, I would look into having the chassis seam welded. This could increase chassis stiffness without having to add any new components. However, there are trade offs to seam welding that need to be taken into account before going down this path (some have reported that a seam welded chassis is too stiff and they had to adjust/soften the suspension to get the car/suspension back into balance). Also, there are some safety concerns when seam welding the front crumple zone as it could affect how the chassis deforms (and absorbs energy) in an accident - not an issue for a race car but might be a concern for a street car.

Most of the experience with seam welding is for race cars so there may not be a lot of info/resources pertaining to seam welding an otherwise stock car. Let me say that I have never driven a seam welded Boxster and therefore do not know what results to expect. But as I said, if I was inclined to wanting a stiffer chassis, I might spend some time investigating this approach.

Maybe someone else has first hand (or even second hand) experience in seam welding a chassis and can add to the conversation.