12-10-2014, 01:55 PM

12-10-2014, 01:55 PM

|

#21

|

|

Certified Boxster Addict

Join Date: Nov 2010

Location: Los Angeles

Posts: 7,669

|

Quote:

Originally Posted by Brad Roberts

I have a chassis stiff kit we are testing  and TomS? The cage is good.. but stress analysis told me to "add a tube". The first time I pitched a SPB into T1 with our extra tube? HUGE difference and 20+ deg. tire temp increase on the right front (at WSIR where the right side of the car is mostly on vacation) I won't share any pics.. but feel free to stop in and look at the cars  |

I sent you a text. Let's get together.

__________________

1999 996 C2 - sold - bought back - sold for more

1997 Spec Boxster BSR #254

1979 911 SC

POC Licensed DE/TT Instructor

|

|

|

12-10-2014, 03:16 PM

12-10-2014, 03:16 PM

|

#22

|

|

Registered User

Join Date: Feb 2013

Location: Land of naught

Posts: 1,302

|

Quote:

Originally Posted by The Radium King

|

Thanks for that but I'm looking for a fix for the areas of the greatest flex and I'm pretty sure they're not them.

__________________

Death is certain, life is not.

|

|

|

12-10-2014, 03:20 PM

12-10-2014, 03:20 PM

|

#23

|

|

Registered User

Join Date: Feb 2013

Location: Land of naught

Posts: 1,302

|

Quote:

Originally Posted by Brad Roberts

I have a kit we are testing. It welds in under the stock carpet/pad/thing. It's multiple pieces and helps tie the center tunnel to the side rails and engine mount bulkhead.

It's very similar to what I developed with Engman for the 914 inner frame rails, but a lot more elaborate.

(Engman/Mark is no longer with us)B |

How about structural adhesive???

__________________

Death is certain, life is not.

|

|

|

12-10-2014, 03:42 PM

12-10-2014, 03:42 PM

|

#24

|

|

Registered User

Join Date: Apr 2010

Location: Canada

Posts: 3,153

|

Quote:

Originally Posted by woodsman

Thanks for that but I'm looking for a fix for the areas of the greatest flex and I'm pretty sure they're not them.

|

actually the post wasn't directed to you but rather the op.

if you look closer you'll see this:

Porsche Boxster (986) Middle Lower Bar / Middle Member Brace - Ultra Racing Product Catalog

which appears to strengthen the centre tunnel - a source of the flex.

|

|

|

12-14-2014, 07:22 AM

12-14-2014, 07:22 AM

|

#25

|

|

Registered User

Join Date: Oct 2014

Location: Fort Collins, Co.

Posts: 74

|

Quote:

Originally Posted by The Radium King

|

I've seen all of those products. I thought you mentioned something new that is essentially an X brace that goes under the carpet and strengthens the mid section?

|

|

|

12-14-2014, 12:02 PM

12-14-2014, 12:02 PM

|

#26

|

|

Registered User

Join Date: Feb 2013

Location: Land of naught

Posts: 1,302

|

Since my car's on jackstands as I type I'm going to use some flat 2* .25" wide aluminum to make a strap utilizing the 2 bolts already there to tie the center of the 'transmission' tunnel together. My main concern is the point at either end of the floor pan. I think the majority of forces push through the suspension in an upwardly direction and the lack of a roof creates flex. An 8 point cage counteracts these by directing them to the other end through the cage. Without that we have hinge- like flex points - no?

So, strut tower to floor, floor to strut tower. Or, next best thing- cowl to floor, floor to rr bulkhead? I want to trianglate these right angles.

Last edited by woodsman; 12-14-2014 at 12:08 PM.

|

|

|

07-07-2018, 09:11 AM

07-07-2018, 09:11 AM

|

#27

|

|

Registered User

Join Date: Apr 2010

Location: Canada

Posts: 3,153

|

bumping this thread. linking to this thread as well:

ultracing

any progress on stiffening the boxster chassis without a cage? or with the ultraracing product? tanks, trk.

|

|

|

07-09-2018, 04:31 PM

07-09-2018, 04:31 PM

|

#28

|

|

Registered User

Join Date: Apr 2010

Location: Canada

Posts: 3,153

|

i've got an inquiry in to ultraracing to see if they have any actual photos of their product that aren't photoshopped, and when back at home next week i'll get under my car and see if their proposed mounting points are actually viable. otherwise, sorta interested in this:

https://www.elephantracing.com/porsche/boxster-cayman/quickchange-strut-brace-chassis-brace/

buy waaaaay pricey, hey?

|

|

|

07-09-2018, 09:38 PM

07-09-2018, 09:38 PM

|

#29

|

|

Registered User

Join Date: Mar 2016

Location: Spain

Posts: 996

|

Quote:

Originally Posted by The Radium King

|

Now that looks like it would do some real frame stiffing.

__________________

2000 Boxster S Ocean Blue Metalic

|

|

|

07-20-2018, 07:03 PM

07-20-2018, 07:03 PM

|

#30

|

|

Registered User

Join Date: Sep 2009

Location: toronto

Posts: 2,668

|

Quote:

Originally Posted by The Radium King

|

Nice find....didnít know that this existed. Yeah......once coil overs with higher spring rates go in, compliance finds its way into the unibody you can really see it feel it with the top up. Maybe this thing will have some effect over and above strut braces.......but really this looks to be a dead zone for tortional rigidity resistance as opposed to the space between the axles....ie the cabin...but you never know

__________________

986 00S

|

|

|

07-20-2018, 07:37 PM

07-20-2018, 07:37 PM

|

#31

|

|

Registered User

Join Date: Apr 2010

Location: Canada

Posts: 3,153

|

well, the front strut brace keeps the strut tops from spreading under hard cornering, but the front subrame is just bolted to the front tub. i think the erp product would keep that front area from distorting when subject to torque forces. same could be accomplished by seam welding the front fenders i think.

whenever people say you just have to live with it because it is a convertible, i think of all the hypercars, most of which have targa roofs; if being a convertible was such a limiting factor with respect to frame rigidity, why are the fastest cars open-topped? there's gotta be a way to stiffen this thing.

|

|

|

07-21-2018, 08:31 AM

07-21-2018, 08:31 AM

|

#32

|

|

Registered User

Join Date: Jul 2013

Location: Bastrop, Tx

Posts: 2,644

|

I would think that if there was any real flexing going on in the front tub, stress cracks would have shown up on race cars by now. IMHO, it's a waste of money as the racing community would have figured that out by now. I cant think of any race cars I've seen where the cage is incorporated into the front or rear trunk. I believe the biggest flex on a boxster that isn't caged is in between the door pillars. I've seen lots of wrecked street and caged boxsters. A street boxster will almost fold in half in a very bad head-on collision. I think the question is how you stiffen that area without installing a cage. I would think some kind of brace that attaches to top of the window frame and the roll bar? The only problem I see with that would be the twisting might break the windshield. So if attaching to the window frame is a no go, then where could it attach to?

__________________

Woody

|

|

|

07-21-2018, 09:36 AM

07-21-2018, 09:36 AM

|

#33

|

|

Registered User

Join Date: Apr 2010

Location: Canada

Posts: 3,153

|

i think the racing community is hard to judge by, as most boxster race cars are spec, and addnl reinforcement is not allowed? regardless, i agree that the focus should be between the wheels. the doors are structural members in this car - perhaps a way to get more positive engagement between door and frame? sounds like a lot of work. tunnel reinforcement? the brackets that hold the coolant lines in the tunnel are already quite beefy and, i presume, intended for reinforcement as well. ultraracing did get back to me and weren't able to provide any pictures of their product, let alone of it installed. just photoshop i guess. really, i can't see a way to improve on the brackets already there without getting in the way of the underbody panels.

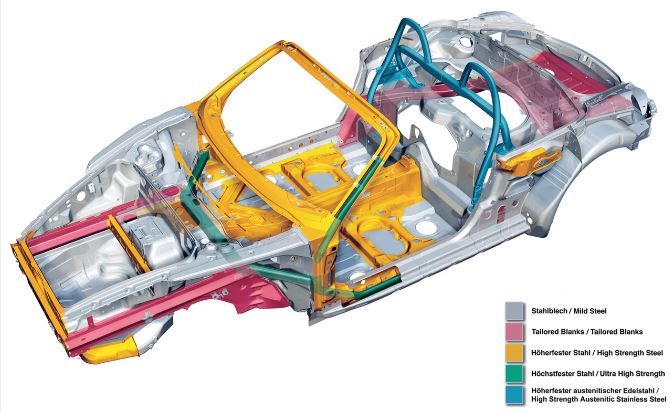

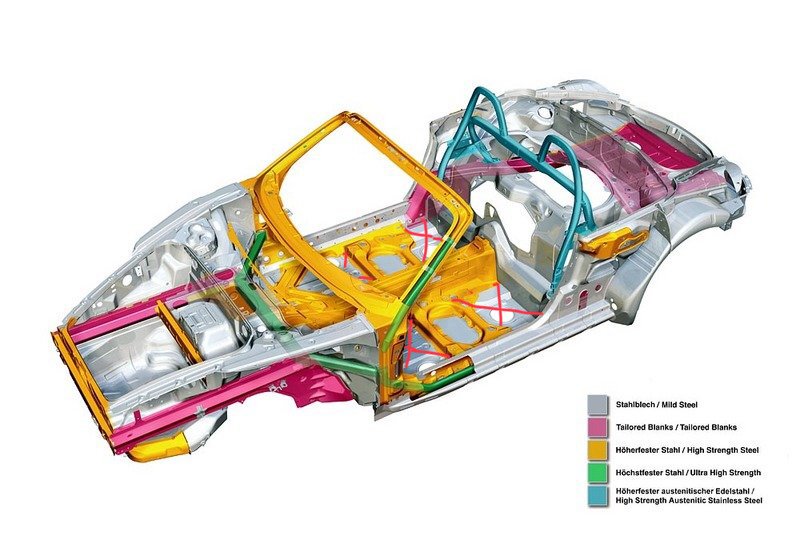

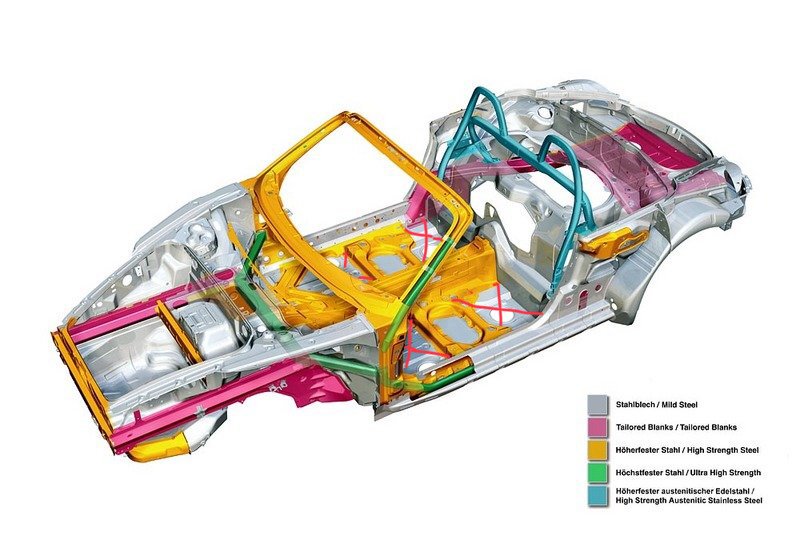

i think brad had it right - additional cross-bracing in the pssgr footwell area is the ticket - tie-in to some of that super strong green and yellow steel in the previous image.

|

|

|

07-21-2018, 09:57 AM

07-21-2018, 09:57 AM

|

#34

|

|

Certified Boxster Addict

Join Date: Nov 2010

Location: Los Angeles

Posts: 7,669

|

Quote:

Originally Posted by itsnotanova

I believe the biggest flex on a boxster that isn't caged is in between the door pillars.

|

Yes. ^^^^

The mid-section of the car is essentially a plat panel and as it flexes the front and rear suspension components undergo different geometry, forces, and dynamics - all of which are not good for optimal handing. There are two ways to make a flat panel stiffer - make it thicker, make it out of stiffer material, or add some structure to it.

And this is what Porsche originally did. If you look at the center/passenger section, Porsche added a tall center tunnel (structure) made from high strength steel (stiffer material) with bracing that adds height to the floor pan and extends to the door sills (thicker, stiffer, and structure).

The challenge to further stiffening of the chassis is where/how to attach additional structural components. The front and rear are easy, add a front shock tower brace (or x-brace as shown in the previous link) and add something like a techno-brace to the rear.

The real challenge is how to add a bolt-on structural component to the central section of the chassis without encroaching on occupant space/ingress/egress along with aesthetic considerations. Underneath the car, it would be hard to add bracing since the car is already pretty low and its not clear exactly how to mount it.

Quote:

Originally Posted by The Radium King

... there's gotta be a way to stiffen this thing.

|

If I was so inclined, I would look into having the chassis seam welded. This could increase chassis stiffness without having to add any new components. However, there are trade offs to seam welding that need to be taken into account before going down this path (some have reported that a seam welded chassis is too stiff and they had to adjust/soften the suspension to get the car/suspension back into balance). Also, there are some safety concerns when seam welding the front crumple zone as it could affect how the chassis deforms (and absorbs energy) in an accident - not an issue for a race car but might be a concern for a street car.

Most of the experience with seam welding is for race cars so there may not be a lot of info/resources pertaining to seam welding an otherwise stock car. Let me say that I have never driven a seam welded Boxster and therefore do not know what results to expect. But as I said, if I was inclined to wanting a stiffer chassis, I might spend some time investigating this approach.

Maybe someone else has first hand (or even second hand) experience in seam welding a chassis and can add to the conversation.

__________________

1999 996 C2 - sold - bought back - sold for more

1997 Spec Boxster BSR #254

1979 911 SC

POC Licensed DE/TT Instructor

Last edited by thstone; 07-21-2018 at 11:29 AM.

|

|

|

07-21-2018, 11:27 AM

07-21-2018, 11:27 AM

|

#35

|

|

Registered User

Join Date: Jul 2013

Location: Bastrop, Tx

Posts: 2,644

|

The more I think about it the more I think my original idea might work. There really isn't a great place to attach a brace to on the front of the cabin. The screw holes where the sunvisor attaches look to be the easiest place to fabricate an attachment point to. I'm starting to think the window frame might be able to handle that added stress. The A pillar is very strong. I'm bringing a boxster to scrap this week and to make it smaller I tried pushing down on the windshield with my tractor. The A pillar didn't budge with the front weight of my tractor on it. The front wheels of the tractor came a good foot or two off the ground. I had to push in the very middle of the windshield to get it to collapse and even then the A pillars were standing tall. That's maybe 1500-2500lbs pushing down on it. It's not like the brace would be forcing that much pressure on the frame? At least under normal track usage. I have a few boxster shells I could test on.

__________________

Woody

|

|

|

07-21-2018, 11:29 AM

07-21-2018, 11:29 AM

|

#36

|

|

Registered User

Join Date: Apr 2010

Location: Canada

Posts: 3,153

|

perhaps some cross-bracing as per the red markup below; under the carpet and trim the insulation ...

|

|

|

07-21-2018, 11:36 AM

07-21-2018, 11:36 AM

|

#37

|

|

Registered User

Join Date: Jul 2013

Location: Bastrop, Tx

Posts: 2,644

|

I'm just throwing ideas out there but what about a bar down the middle? Something that attaches to the middle of the roll bar and then comes down and attaches somewhere by the lower console. That lower console comes out very easily and there's some strong mounting points down there

__________________

Woody

|

|

|

07-21-2018, 11:38 AM

07-21-2018, 11:38 AM

|

#38

|

|

Registered User

Join Date: Jul 2013

Location: Bastrop, Tx

Posts: 2,644

|

Quote:

Originally Posted by The Radium King

perhaps some cross-bracing as per the red markup below; under the carpet and trim the insulation ...

|

That area has lots of room to work with. It's just 2-3 inches of foam taking up that space

__________________

Woody

|

|

|

07-21-2018, 11:59 AM

07-21-2018, 11:59 AM

|

#39

|

|

Registered User

Join Date: Dec 2012

Location: FL

Posts: 4,145

|

Woody - you should film the stripping and destruction of a Boxster and make a sped up movie, that would be cool

|

|

|

07-21-2018, 12:17 PM

07-21-2018, 12:17 PM

|

#40

|

|

Registered User

Join Date: Jul 2013

Location: Bastrop, Tx

Posts: 2,644

|

Quote:

Originally Posted by steved0x

Woody - you should film the stripping and destruction of a Boxster and make a sped up movie, that would be cool  |

I normally don't completely strip a boxster at one time. They usually get taken apart piece by piece over a few months to years. They usually have three stages of dismantling. First stage has the motor/transmission still in. This is where the high desirable parts usually sell quickly and parts that need to be sheltered get stored. Second has the motor and trans out but the suspension attached. The last stage is out in the field where they get picked at like the last buzzard on a stripped carcass. This past one was an exception because I was trying to show my nephew the ins and outs of one as I'm giving him one in a few weeks.

__________________

Woody

Last edited by itsnotanova; 07-21-2018 at 12:21 PM.

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 02:47 PM.

| |