07-25-2021, 08:12 PM

07-25-2021, 08:12 PM

|

#81

|

|

Registered User

Join Date: Aug 2018

Location: Woodland Wa

Posts: 1,319

|

In the snap throttle video I notice that your vacuum is down to about 13 in.hg at idle.

which is low vacuum

The needle acts sort of correct on snap throttle.

But vacuum is low

I also notice your spoiler light is on.

In the next video your gauge is now (around 1:15- 1:30) in the green at around 19 in.hg

I notice a needle tick several times when holding steady RPM those are probably due to misfires.

Toward the end of the vid I see the needle tick and a light flash on the dash.

But I can't tell if it is a CEL or an oil light.

And the spoiler light is still on

You may have some restriction in you exhaust. that can cause low vacuum at idle.

Also causes needle to slowly drop at idle or steady RPM

It can cause misfires because the cylinder cannot fill with fuel/air mixture correctly.

what do your post cat O-2sensor signals look like at idle???

Can you graph them with Durametric for a few minutes and post them???

put all 4 O2 signals up on one graph if you can with RPM

|

|

|

07-25-2021, 08:20 PM

07-25-2021, 08:20 PM

|

#82

|

|

Registered User

Join Date: May 2017

Posts: 1,180

|

It's the oil light. It comes on, but only sometimes when coming off the throttle such as coming to a stop light. Oil level is correct (just changed the oil last weekend, 8.5qt) and even has a brand new level/temp sender. Only happens when coming off the throttle though.

Other thing...watch the lights dim when coming off throttle.

Yes, spoiler light on this car stays on until the car moves a few feet and then goes off. Always been that way. My 03 doesn't do that.

I'll get the o2 stuff in the morning. Do you know which values they are?

clogged cat could be the issue. Going to see if I can make adapters this week to fit the pressure gauge/vac gauge. If I can will see what pressure is before & after the 1st cat that is part of the header. I would just loosen the bolts between the header & muffler but those are ones I can't get off unless I'm going to cut them off.

__________________

2000 Boxster Tiptronic

2003 Boxster

2003 996 C2 Cab

2002 996 (SOLD)

1986 944 (gone but missed)

|

|

|

07-25-2021, 08:21 PM

07-25-2021, 08:21 PM

|

#83

|

|

Registered User

Join Date: May 2017

Posts: 1,180

|

I get vacuum not building until the rpms increase, makes sense. What doesn't make sense to me is the vacuum dropping so much and so fast after though. It should hold or drop very very slowly right?

__________________

2000 Boxster Tiptronic

2003 Boxster

2003 996 C2 Cab

2002 996 (SOLD)

1986 944 (gone but missed)

|

|

|

07-25-2021, 08:25 PM

07-25-2021, 08:25 PM

|

#84

|

|

Registered User

Join Date: Aug 2018

Location: Woodland Wa

Posts: 1,319

|

Quote:

Originally Posted by Stl-986

It's the oil light. It comes on, but only sometimes when coming off the throttle such as coming to a stop light. Oil level is correct (just changed the oil last weekend, 8.5qt) and even has a brand new level/temp sender. Only happens when coming off the throttle though.

Other thing...watch the lights dim when coming off throttle.

Yes, spoiler light on this car stays on until the car moves a few feet and then goes off. Always been that way. My 03 doesn't do that.

I'll get the o2 stuff in the morning. Do you know which values they are?

clogged cat could be the issue. Going to see if I can make adapters this week to fit the pressure gauge/vac gauge. If I can will see what pressure is before & after the 1st cat that is part of the header. I would just loosen the bolts between the header & muffler but those are ones I can't get off unless I'm going to cut them off.

|

How about I hook up my Durametric to my 2000S in the morning and then I let you know which values to graph.

It's cocktail time here

|

|

|

07-25-2021, 08:31 PM

07-25-2021, 08:31 PM

|

#85

|

|

Registered User

Join Date: Oct 2014

Location: California Central Coast

Posts: 1,476

|

Jake Raby has a post somewhere that states there are different modes of failure of the AOS. One is the vacuuming of oil from the crankcase but there is also a mode that causes massive vacuum to the crankcase which can suck the shaft seals in and can cause oil starvation to the oil pump. With the oil pressure dropping low when coming off idle you might want to get a manometer and see what is happening there.

|

|

|

07-25-2021, 09:49 PM

07-25-2021, 09:49 PM

|

#86

|

|

Registered User

Join Date: Oct 2020

Location: KY

Posts: 1,213

|

Quote:

Originally Posted by blue62

that formula for compression does not work

My 1969 Jaguar E-type XK engine has a 9:1 CR factory spec.for compression is 175 PSI

My 1960 Austin healey BT7 engine has 9:1 CR factory spec. for compression is also 175 PSI  |

How is that possible? Not questioning your experience, but the math there doesnt add (or multiply) up lol.

Sent from my SM-G970U1 using Tapatalk

__________________

2000 Box Base, Renegade Stage 1 performance mods complete, more to come

When the owners manual says that the laws of physics can't be broken by this car, I took it as a challenge...

Last edited by ike84; 07-25-2021 at 10:08 PM.

|

|

|

07-25-2021, 10:08 PM

07-25-2021, 10:08 PM

|

#87

|

|

Registered User

Join Date: Oct 2020

Location: KY

Posts: 1,213

|

Quote:

Originally Posted by Stl-986

It's the oil light. It comes on, but only sometimes when coming off the throttle such as coming to a stop light. Oil level is correct (just changed the oil last weekend, 8.5qt) and even has a brand new level/temp sender. Only happens when coming off the throttle though.

Other thing...watch the lights dim when coming off throttle.

Yes, spoiler light on this car stays on until the car moves a few feet and then goes off. Always been that way. My 03 doesn't do that.

I'll get the o2 stuff in the morning. Do you know which values they are?

clogged cat could be the issue. Going to see if I can make adapters this week to fit the pressure gauge/vac gauge. If I can will see what pressure is before & after the 1st cat that is part of the header. I would just loosen the bolts between the header & muffler but those are ones I can't get off unless I'm going to cut them off.

|

Sorry, i misread the post earlier, I thought it was 18 at idle I haven't gotten to watch any videos (everyone else asleep in the house) but the voltage and light dimming that youre describing is no bueno. Have you checked your alternator and battery? Im not sure how that would play in here but it's hard to tell with electronically controlled fuel injectors.

To measure the exhaust pressure, don't try to separate the joints. There are 18mm bung adapters to hook a pressure gauge to. The cheap way to do it would actually be just remove a sensor and leave them bung open - if that changes performance then you know you have a backpressure issue.

I didn't see if you responded earlier but what's the deal with your aos? Monty is right, the aos can actually kill your oil pressure if the failure is complete. All this could go together - bad aos, poor idle vacuum, intake flooded with oil, intake gasket degraded, fouled injectors causing lean running (? Maybe?), fouled spark plugs, clogged cats.

Sent from my SM-G970U1 using Tapatalk

__________________

2000 Box Base, Renegade Stage 1 performance mods complete, more to come

When the owners manual says that the laws of physics can't be broken by this car, I took it as a challenge...

Last edited by ike84; 07-25-2021 at 10:16 PM.

|

|

|

07-25-2021, 10:39 PM

07-25-2021, 10:39 PM

|

#88

|

|

Registered User

Join Date: May 2017

Posts: 1,180

|

AOS is good, it's actually new oem one. dont get any smoke on startup

__________________

2000 Boxster Tiptronic

2003 Boxster

2003 996 C2 Cab

2002 996 (SOLD)

1986 944 (gone but missed)

|

|

|

07-25-2021, 10:46 PM

07-25-2021, 10:46 PM

|

#89

|

|

Registered User

Join Date: May 2017

Posts: 1,180

|

Quote:

Originally Posted by ike84

How is that possible? Not questioning your experience, but the math there doesnt add (or multiply) up lol.

Sent from my SM-G970U1 using Tapatalk

|

off topic, but, I know what you are saying here, but.....his numbers are right. I thought the same about the multiplication you mentioned. Even our cars the math doesn't work cause these are 11.1 compression rate which means they should top out at 163.17. Not the case though. This isn't my video but one I found while going through the process today: https://www.youtube.com/watch?v=cznw9idwpkU & this: http://986forum.com/forums/boxster-general-discussions/35231-compression-test-results.html

in my own words....no clue how it's all calculated. Too much work to figure it out.

__________________

2000 Boxster Tiptronic

2003 Boxster

2003 996 C2 Cab

2002 996 (SOLD)

1986 944 (gone but missed)

|

|

|

07-25-2021, 10:49 PM

07-25-2021, 10:49 PM

|

#90

|

|

Registered User

Join Date: May 2017

Posts: 1,180

|

Quote:

Originally Posted by ike84

The cheap way to do it would actually be just remove a sensor and leave them bung open - if that changes performance then you know you have a backpressure issue.

|

I actually had this same thought about an hour ago. IF it doesn't throw any codes in the morning I am going to try and get it inspected. If that happens and it passes I will have some breathing room and can start to do things like this. Dont want an O2 code to come up if I can prevent it for the moment.

__________________

2000 Boxster Tiptronic

2003 Boxster

2003 996 C2 Cab

2002 996 (SOLD)

1986 944 (gone but missed)

|

|

|

07-26-2021, 04:51 AM

07-26-2021, 04:51 AM

|

#91

|

|

Registered User

Join Date: Oct 2020

Location: KY

Posts: 1,213

|

I was just thinkingore about your alternator...

A year ago the alternator on my wife's escalade went bad. The primary symptom was rough running at low rpm and then stall at idle. At higher rpms, everything was fine

It still doesn't explain the low vac at idle but just something (even more) to think about. Good luck with the emissions test!

Sent from my SM-G970U1 using Tapatalk

__________________

2000 Box Base, Renegade Stage 1 performance mods complete, more to come

When the owners manual says that the laws of physics can't be broken by this car, I took it as a challenge...

|

|

|

07-26-2021, 04:57 AM

07-26-2021, 04:57 AM

|

#92

|

|

Registered User

Join Date: Aug 2018

Location: Woodland Wa

Posts: 1,319

|

Quote:

Originally Posted by ike84

How is that possible? Not questioning your experience, but the math there doesnt add (or multiply) up lol.

Sent from my SM-G970U1 using Tapatalk

|

Well you can start with things like valve overlap.

Valve timing. air temp.

The simple math formula of multiplying atmospheric air pressure by CR assumes things like.

Intake valve wide open exactly at BDC and closed at exactly TDC with no exhaust valve overlap.

Piston cranking speed is another example. Watch the needle on the vacuum gauge in the video's in this thread.

As RPM increases vacuum increases. = increased cylinder fill.

So the simple math formula of multiplying atmospheric air pressure by CR will not work to give you cranking PSI.

Look up any engine specs. you can find that show CR and cranking compression PSI

That simple math formula will not give you stated cranking PSI

As for leak down tests being more helpful than compression tests:

A leak down test is a "static test" of the cylinders ability to seal. (hold pressure)

A compression test is more of an operational test of volumetric efficiency (cylinder air filling ability) which is directly related to vacuum

and the ability to "build pressure"

Very closely related but you can get a little different info from each test.

So it depends on what info your after on how helpful a given test method is.

Last edited by blue62; 07-26-2021 at 07:01 AM.

|

|

|

07-26-2021, 06:44 AM

07-26-2021, 06:44 AM

|

#93

|

|

Registered User

Join Date: Aug 2018

Location: Woodland Wa

Posts: 1,319

|

STL-986

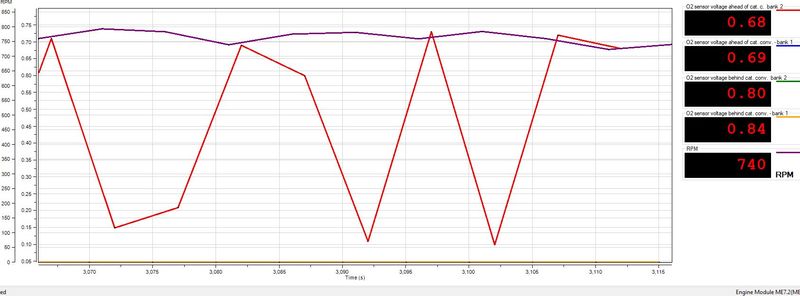

When you get time graph your O2 sensor "voltage signals" for all 4 O2 sensors at idle.

and RPM. Then post the graph so I can have a look see.

They are in actual values under the engine module.

Before you do the graphing go in and click on each O2 sensor "voltage signal" with key on but engine off.

That should show you the "BIAS" voltage on the signal wire.

It should be 0.45V That will test the signal wiring between the DME/ECU and the O2sensor.

Then click on the O2 sensor heater signal again with key on but engine off. This will test the wiring and voltage to the O2 sensor heater circuit. I think the spec. is 4.5V or close to that.

Then get the car up to operating temp. and graph the 4 O2 sensor voltage signals and the RPM.

Just let it idle during the graphing

|

|

|

07-26-2021, 07:39 AM

07-26-2021, 07:39 AM

|

#94

|

|

Registered User

Join Date: May 2017

Posts: 1,180

|

Here you go. Couple charts from a cold engine:

Without rpm - Easier to see just the voltages

__________________

2000 Boxster Tiptronic

2003 Boxster

2003 996 C2 Cab

2002 996 (SOLD)

1986 944 (gone but missed)

|

|

|

07-26-2021, 07:47 AM

07-26-2021, 07:47 AM

|

#95

|

|

Registered User

Join Date: May 2017

Posts: 1,180

|

__________________

2000 Boxster Tiptronic

2003 Boxster

2003 996 C2 Cab

2002 996 (SOLD)

1986 944 (gone but missed)

|

|

|

07-26-2021, 08:35 AM

07-26-2021, 08:35 AM

|

#96

|

|

Registered User

Join Date: Aug 2018

Location: Woodland Wa

Posts: 1,319

|

Everything looks good to me with one possible exception.

In the third chart the post cat O2 sensor (green line) should be more like the yellow line.

More steady and above .450mv around .650-.750mv

"BUT" you did the test with a cold engine. The dips could also be from misfires or rise and fall of RPM.

So it could be fine.

When you get time you could test that post cat O2 sensor on bank 2 again as a follow up check or proof.

Do it after a good drive and at idle. you want a graph line more like the other post cat O2 sensor (yellow line)

You may also want to think about the alternator situation you brought up.

I had not thought about that.

Could very well be a factor in the misfire situation.

|

|

|

07-26-2021, 09:20 AM

07-26-2021, 09:20 AM

|

#97

|

|

Registered User

Join Date: May 2017

Posts: 1,180

|

The alternator thing is just something that has stuck in my mind. It does make some sense. Electrical issues can be so weird at times, especially with noise. But it's also like trying to find a bad ground. Such a rabbit hole you could go down and still come to no conclusion.

I am going to pull bank 1 front o2 to see if it runs any better to see if cat is an issue.

It's back to running as bad as it did before. The only thing I have done is just let it run. Didn't touch anything else.

__________________

2000 Boxster Tiptronic

2003 Boxster

2003 996 C2 Cab

2002 996 (SOLD)

1986 944 (gone but missed)

|

|

|

07-26-2021, 10:09 AM

07-26-2021, 10:09 AM

|

#98

|

|

Registered User

Join Date: May 2017

Posts: 1,180

|

Video from this morning. Car warmed up. Not sure how the audio will be from the gopro. I'm not even sitting in the car when I did this.

It is back to do exactly the same thing as before. Constant misfire on cyl 1-3 but I haven't touched a single thing since last evening when it was doing so much better & idling higher.

Cat test up next as soon as it cools enough some for me to get under it.

__________________

2000 Boxster Tiptronic

2003 Boxster

2003 996 C2 Cab

2002 996 (SOLD)

1986 944 (gone but missed)

|

|

|

07-26-2021, 11:58 AM

07-26-2021, 11:58 AM

|

#99

|

|

Registered User

Join Date: Aug 2018

Location: Woodland Wa

Posts: 1,319

|

Quote:

Originally Posted by Stl-986

The alternator thing is just something that has stuck in my mind. It does make some sense. Electrical issues can be so weird at times, especially with noise. But it's also like trying to find a bad ground. Such a rabbit hole you could go down and still come to no conclusion.

I am going to pull bank 1 front o2 to see if it runs any better to see if cat is an issue.

It's back to running as bad as it did before. The only thing I have done is just let it run. Didn't touch anything else.

|

At the least you could have the alternator tested.

Either remove it and take it in.

Or find a shop that will test it on the car.

Or find all the specs. and test it yourself with a mutimeter

|

|

|

07-26-2021, 12:06 PM

07-26-2021, 12:06 PM

|

#100

|

|

Registered User

Join Date: Aug 2018

Location: Woodland Wa

Posts: 1,319

|

Quote:

Originally Posted by Stl-986

Video from this morning. Car warmed up. Not sure how the audio will be from the gopro. I'm not even sitting in the car when I did this.

It is back to do exactly the same thing as before. Constant misfire on cyl 1-3 but I haven't touched a single thing since last evening when it was doing so much better & idling higher.

Cat test up next as soon as it cools enough some for me to get under it.

|

Interesting.

May be time to disconnect and block off the SAI which I think is just one vacuum hose connected to the intake plenum. easy to get to.

Also disconnect the EVAP system more of a PITA.

Just to see if doing that changes anything???

couple of question????

Have you recalibrated your E-gas pedal lately????

Also have you checked for exhaust leaks???

Exhaust leaks is where a smoke machine could be handy.

plug the tail pipes and the intake.

Insert the smoke into the tailpipe

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 10:27 AM.

| |