04-25-2019, 10:55 PM

04-25-2019, 10:55 PM

|

#1

|

|

Registered User

Join Date: Dec 2018

Location: Australia

Posts: 5

|

986 driveshaft spline hopelessly stuck

Hi all,

First time poster, I've had my 1998 Boxster 986 for about 4 months and I've loved every minute of it up to now.

I noticed a few weeks ago that I had a torn outer CV boot, so I've set about replacing it while also replacing the rear shocks.

I've finally managed to disconnect enough suspension and exhaust bits that the driveshaft has room to drop down and be pulled out. The problem I've got now is that the spline very much doesn't want to be pulled out.

I've tried spraying penetrating oil around the teeth, I've also tried hitting the end of the shaft with a mallet about as hard as I can without knocking the car off the stands.

Does anyone have any good tips/techniques for getting the stuck driveshaft spline out of the hub?

Thanks in advance.

|

|

|

04-26-2019, 03:54 AM

04-26-2019, 03:54 AM

|

#2

|

|

Registered User

Join Date: Jan 2019

Location: PA

Posts: 1,726

|

I haven't tried it on my 986 yet, but I imagine it's not much different than other cars.

If you have a compressor, I've had good luck with a Harbor Frieght air hammer and pointed bit right into center hole of the axle.

I hope you didn't flare the end of the axle when you beat on it with a mallet. If so, you may want to grind it down, before you try to push it back.

Here's an extreme case, but I doubt yours is this bad.

https://www.youtube.com/watch?v=SFScIV92ODE

Good luck!

|

|

|

04-26-2019, 05:19 AM

04-26-2019, 05:19 AM

|

#3

|

|

Need For Speed

Join Date: Feb 2013

Location: Funville

Posts: 2,114

|

__________________

2003 Boxster S

| 987 Air Box | K&N Air Filter | 76mm Intake Pipe| 996 76mm TB | 997 Distribution T | Secondary Cat Delete Pipes | Borla Muffler | NHP 200 Cell Exhaust Headers |

|

|

|

04-26-2019, 05:42 AM

04-26-2019, 05:42 AM

|

#4

|

|

Registered User

Join Date: Dec 2018

Location: Australia

Posts: 5

|

Thanks very much for the suggestions.

Hadn't thought of using an air hammer. I don't have one but I have a compressor, could easily pick one up and give it a go.

Using a puller seems like a decent approach too. Was hoping to not have to take the brake caliper off, but I think the pads need replacing anyway so could do that while I'm here.

Will try one of these and post results.

|

|

|

04-26-2019, 05:51 AM

04-26-2019, 05:51 AM

|

#5

|

|

Registered User

Join Date: Dec 2018

Location: Australia

Posts: 5

|

Thanks very much for the suggestions.

Hadn't thought of using an air hammer. I don't have one but I have a compressor, could easily pick one up and give it a go.

Using a puller seems like a decent approach too. Was hoping to not have to take the brake caliper off, but I think the pads need replacing anyway so could do that while I'm here.

Will try one of these and post results.

|

|

|

04-26-2019, 06:42 AM

04-26-2019, 06:42 AM

|

#6

|

|

Registered User

Join Date: Dec 2012

Location: FL

Posts: 4,145

|

I used a 3 jaw puller with the legs on the hub and the nose on the axle and pushed it out that way, the two times I've had my axles off. Got it as a loaner tool from O'Reilly auto parts.

|

|

|

04-26-2019, 07:48 AM

04-26-2019, 07:48 AM

|

#7

|

|

Registered User

Join Date: Aug 2015

Location: Brandon MB

Posts: 51

|

Just watched the 996 episode of Wheeler Dealers and Ant used a brass drift and a hammer to knock it out.

|

|

|

04-26-2019, 07:56 AM

04-26-2019, 07:56 AM

|

#8

|

|

Registered User

Join Date: Dec 2016

Location: Clifton, NJ

Posts: 1,135

|

if its just the boot, then you can handle that without pulling the whole axle out.

Just remove the inner CV joint, slide both boots off, clean best you can, add grease, new boots, and you're off.

|

|

|

04-26-2019, 12:43 PM

04-26-2019, 12:43 PM

|

#9

|

|

Registered User

Join Date: Aug 2009

Posts: 1,466

|

I've been using a puller plate from a slide hammer with the center bolt from a normal 3/2 arm puller I bought a kit from OTC years ago.

This has worked really well for me. The other tool is what I use to pop the links out of the suspension. But you can bolt the puller plate with 3 of the wheel bolts to the hub.

__________________

2003 Black 986. modified for Advanced level HPDE and open track days.

* 3.6L LN block, 06 heads, Carrillo H rods, IDP with 987 intake, Oil mods, LN IMS. * Spec II Clutch, 3.2L S Spec P-P FW. * D2 shocks, GT3 arms & and links, Spacers front and rear * Weight reduced, No carpet, AC deleted, Remote PS pump, PS pump deleted. Recaro Pole position seats, Brey crouse ext. 5 point harness, NHP sport exhaust

Last edited by jsceash; 04-26-2019 at 12:47 PM.

|

|

|

05-03-2019, 12:42 AM

05-03-2019, 12:42 AM

|

#10

|

|

Registered User

Join Date: Dec 2018

Location: Australia

Posts: 5

|

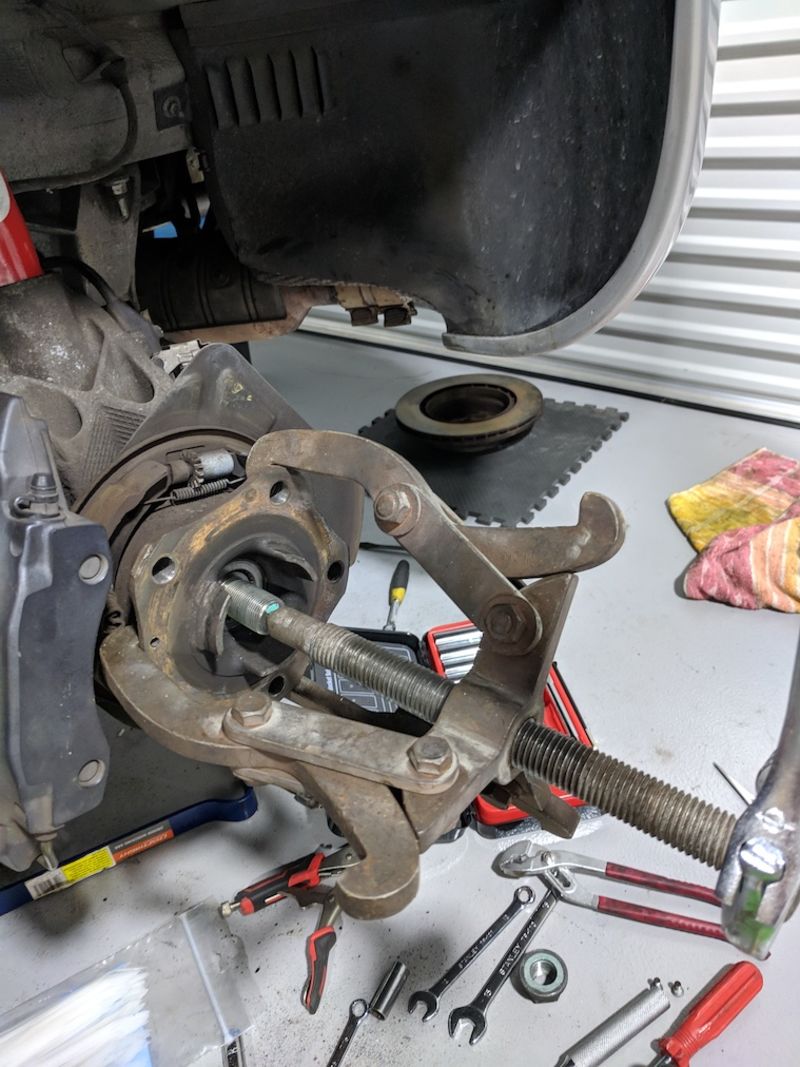

I ended up using this giant 3 jaw puller. It quite easily did the job.

I had to stop the hub from turning by attaching a set of multi grips to the puller, but once I did that and tightened it up the spline came straight out.

Reason for it being so stuck was a bit of rust. What do you guys recommend I use for cleaning up the parts and getting the rust off? And what type of grease should I apply to the shaft before I put it back in?

Thanks in advance.

|

|

|

05-03-2019, 04:00 AM

05-03-2019, 04:00 AM

|

#11

|

|

Registered User

Join Date: Dec 2013

Location: Dahlonega , Georgia

Posts: 1,364

|

Clean up the rust with a combination of wire brushes and sandpaper . A wire brush chucked into a drill motor will speed things up . I would lightly coat with anti-seize and install .

__________________

2002 Boxster S Arctic Silver with black top with glass window and black leather interior. Jake Raby 3.6 SS ( the beast ) with IMS Solution. 996 GT3 front bumper , GT3 rocker covers and GT3TEK rear diffuser and Joe Toth composites rear ducktail spoiler .

|

|

|

05-03-2019, 04:01 AM

05-03-2019, 04:01 AM

|

#12

|

|

Registered User

Join Date: Jan 2019

Location: PA

Posts: 1,726

|

Congrats on getting it out! You can use a wire brush on the splines to clean out the rust and then put on some Permatex anti-seize.

|

|

|

05-03-2019, 04:54 AM

05-03-2019, 04:54 AM

|

#13

|

|

Registered User

Join Date: Jul 2013

Location: Bastrop, Tx

Posts: 2,644

|

I've removed well over 100 axles. I hit the socket used to loosen the nut with. Back the nut off a little bit and one or two good hits from a big hammer usually knocks it loose. The early boxsters came with a flared nut but later ones came with a nut/attached washer. The washer will become detached using this method but can be reattached with a quick strike of a hammer or pressed together in a vice.

__________________

Woody

|

|

|

05-03-2019, 05:18 AM

05-03-2019, 05:18 AM

|

#14

|

|

Registered User

Join Date: Dec 2018

Location: Australia

Posts: 5

|

Great, thanks guys.

That Permatex anti-seize certainly looks like it'll do the job. It's cheap and easy to find too, even better.

|

|

|

05-03-2019, 09:24 AM

05-03-2019, 09:24 AM

|

#15

|

|

Registered User

Join Date: Oct 2008

Location: O.C. CA

Posts: 3,709

|

Quote:

Originally Posted by itsnotanova

I've removed well over 100 axles. I hit the socket used to loosen the nut with. Back the nut off a little bit and one or two good hits from a big hammer usually knocks it loose. The early boxsters came with a flared nut but later ones came with a nut/attached washer. The washer will become detached using this method but can be reattached with a quick strike of a hammer or pressed together in a vice.

|

Service Manual says to replace the axle nut everytime. I replace mine every other time with no problems, and that's in rust free So,CA.

__________________

OE engine rebuilt,3.6 litre LN Engineering billet sleeves,triple row IMSB,LN rods. Deep sump oil pan with DT40 oil.

|

|

|

05-03-2019, 11:07 AM

05-03-2019, 11:07 AM

|

#16

|

|

Registered User

Join Date: Jul 2017

Location: Tucson AZ

Posts: 536

|

Quote:

Originally Posted by BYprodriver

Service Manual says to replace the axle nut everytime. I replace mine every other time with no problems, and that's in rust free So,CA.

|

+1 And they aren't expensive. I use sylglide (napa silicone grease) which doesn't wash away or break down. I live in rust free So AZ. We are so freaking spoiled by our rust free vehicles!

__________________

2001 Boxster

2007 Toyota Highlander

2003 New Beetle Convertible, Turbo, Tip 6 speed

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 05:40 AM.

| |