01-19-2017, 05:29 PM

01-19-2017, 05:29 PM

|

#1

|

|

Registered User

Join Date: Aug 2015

Location: Brandon MB

Posts: 51

|

IMS Tool Problem

Hey all,

I'm in the middle of installing an LN Engineering dual row bearing in my 01S. I tried threading the center stud onto the installation tool and there isn't enough thread exposed for me to get the nut onto the stud. I got the tool kit from someone on the forum so it may be an older version. I guess I could either try to hammer the bearing in without securing the stud or take the tool to a machine shop to bore out 5mm or so. Am I missing something?

RD

|

|

|

01-19-2017, 05:57 PM

01-19-2017, 05:57 PM

|

#2

|

|

On the slippery slope

Join Date: Mar 2014

Location: Austin and Palm Springs

Posts: 3,803

|

Did you buy the kit or rent it?

__________________

2004 Boxster S 6 speed - DRL relay hack, Polaris AutoTop DIY

2004 996 Targa Tip

Instructor - San Diego region

2014 Porsche Performance Driving School

2020 BMW X3, 2013 Ram 1500, 2016 Cmax, 2004 F-150 "Big Red"

|

|

|

01-19-2017, 06:02 PM

01-19-2017, 06:02 PM

|

#3

|

|

Registered User

Join Date: Aug 2015

Location: Brandon MB

Posts: 51

|

I bought the kit a year or two ago. It was used and looks like the LN Engineering kit. The part of the installation tool that the stud goes through is 19.7mm thick.

Last edited by CdnRD; 01-19-2017 at 06:11 PM.

|

|

|

01-19-2017, 06:11 PM

01-19-2017, 06:11 PM

|

#4

|

|

Motorist & Coffee Drinker

Join Date: Jul 2014

Location: Oklahoma

Posts: 3,955

|

Been a while since I did my IMS. Can you post a picture or two to illustrate the issue? My guess is that you are either missing something simple, or there is a problem with the tool. Let us get a look.

This is not something to rush or improvise.

__________________

I am not an attorney, mechanic, or member of the clergy. Following any advice given in my posts is done at your own peril.

|

|

|

01-19-2017, 06:41 PM

01-19-2017, 06:41 PM

|

#5

|

|

Registered User

Join Date: Aug 2015

Location: Brandon MB

Posts: 51

|

Sure

|

|

|

01-19-2017, 06:51 PM

01-19-2017, 06:51 PM

|

#6

|

|

Motorist & Coffee Drinker

Join Date: Jul 2014

Location: Oklahoma

Posts: 3,955

|

Perfect. I'm at work tonight, but if you don't have a better answer before tomorrow, I'll measure mine so you can compare the depth. I do wonder if your installation tool was specific for a single row bearing...?

__________________

I am not an attorney, mechanic, or member of the clergy. Following any advice given in my posts is done at your own peril.

|

|

|

01-19-2017, 08:59 PM

01-19-2017, 08:59 PM

|

#7

|

|

Project Addicted

Join Date: Aug 2015

Location: Eastern Shore, MD

Posts: 623

|

Freeze the bearing overnight to install it. Don't beat on it if at all possible. With a heat gun you can heat the area of the tube and the bearing after freezing will slip in and bottom out.

__________________

______

Jon

1966 912, 1976 911

1986 944, 2000 Boxster

|

|

|

01-19-2017, 10:56 PM

01-19-2017, 10:56 PM

|

#8

|

|

Motorist & Coffee Drinker

Join Date: Jul 2014

Location: Oklahoma

Posts: 3,955

|

Quote:

Originally Posted by jcslocum

Freeze the bearing overnight to install it. Don't beat on it if at all possible. With a heat gun you can heat the area of the tube and the bearing after freezing will slip in and bottom out.

|

Yes, but I think that the issue is that he can not secure the center bolt within the installation tool. I just reviewed the instructions. It looks like the basic instructions: http://lnengineering.com/files/IMSR-Instruction-Warranty-2y.pdf do not call for the center bolt to be secured in the installation tool.

Is that correct?

The 'overview' video on this page shows the nut being removed at 6:20. IMS Retrofit & Procedure Overview IMS Retrofit

The Pelican Parts tech article (now updated to lock the cams and not use the set-screws  ) shows the nut being installed in the installation tool in Pic. 104.

So my question, and I think what the OP needs to know, is: Should the nut be put on the center bolt when you are installing?

Any chance that the center bolt will fall out into the shaft?

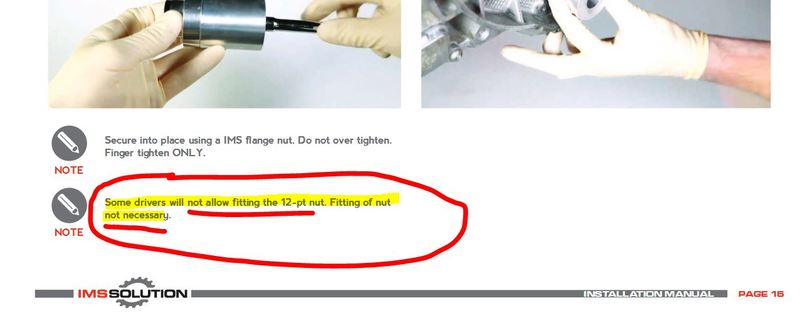

Edit: I think I found the answer in the "IMS Solution" Instructions "Some drivers will not allow fitting the 12-pt nut. Fitting of nut not necessary."

...and that's all I have to say about that. :dance:

__________________

I am not an attorney, mechanic, or member of the clergy. Following any advice given in my posts is done at your own peril.

Last edited by 78F350; 01-19-2017 at 11:15 PM.

Reason: More info found

|

|

|

01-20-2017, 04:14 AM

01-20-2017, 04:14 AM

|

#9

|

|

Registered User

Join Date: Jun 2008

Location: Illinois

Posts: 147

|

Early driver tools allowed for the bearing to be secured to the driver.

We had a shop have 6 ims retrofits fail. Turns out the same tech did each one and was using an air tool to drive the nut down on the install tool, which damaged the bearing even prior to installation, pre-disposing it to an early failure.

I figured that if one person was stupid enough to do this, there have to be others and promptly redesigned the driver tool to prevent the user from securing the bearing with a nut. Problem solved :-)

If our procedures seem to be borderline paranoid or ocd, there is a reason behind everything we do and require.

__________________

Charles Navarro

President, LN Engineering and Bilt Racing Service

http://www.LNengineering.com

Home of Nickies, IMS Retrofit, and IMS Solution

|

|

|

01-20-2017, 04:38 AM

01-20-2017, 04:38 AM

|

#10

|

|

Registered User

Join Date: Aug 2015

Location: Brandon MB

Posts: 51

|

Thanks for the info Charles! I had seen the instructions that said to use the nut. BTW the bearing kit is a beautiful bit of engineering!

|

|

|

01-20-2017, 07:19 AM

01-20-2017, 07:19 AM

|

#11

|

|

Registered User

Join Date: Sep 2016

Location: Stow, MA

Posts: 918

|

Quote:

Originally Posted by cnavarro

We had a shop have 6 ims retrofits fail. Turns out the same tech did each one and was using an air tool to drive the nut down on the install tool, which damaged the bearing even prior to installation, pre-disposing it to an early failure.

|

So did the shop purchase 6 new engines for the unfortunate owners?

__________________

2004 Boxster S Silver - FUNTOY

2002 Boxster Base Guardsy Red - FUNBOX

1987 Caterham Super 7 1700 Supersprint

2009 Mercedes Benz CLK 350 convertible

1941 Dodge Luxury Liner Coupe

|

|

|

01-20-2017, 09:01 AM

01-20-2017, 09:01 AM

|

#12

|

|

Registered User

Join Date: May 2014

Location: S.California

Posts: 2,029

|

Quote:

Originally Posted by cnavarro

Early driver tools allowed for the bearing to be secured to the driver.

We had a shop have 6 ims retrofits fail. Turns out the same tech did each one and was using an air tool to drive the nut down on the install tool, which damaged the bearing even prior to installation, pre-disposing it to an early failure.

I figured that if one person was stupid enough to do this, there have to be others and promptly redesigned the driver tool to prevent the user from securing the bearing with a nut. Problem solved :-)

If our procedures seem to be borderline paranoid or ocd, there is a reason behind everything we do and require.

|

Charles - your 17 pages of Instructions are word perfect. I wish all vendors used such Instructions.

When IMSB questions come up I often mention your 17 pages to the guys who say : "slap it in, get 'er done 'n have another beer' .

Most of us are doing an IMSB Retrofit for the first time. It is a daunting task because going back in to remedy a faulty install is awful. That assumes you get that 'opportunity'!

So thank you for taking the time to write it up. It must have been frustrating to try to imagine every conceivable way an Installer could screw up a repair job that is "just procedural" to quote our mutual friend.

|

|

|

01-20-2017, 09:38 AM

01-20-2017, 09:38 AM

|

#13

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

I'm sure that Charles would agree that you can make things "idiot resistant" but can never make them "idiot proof", as for some reason, God seems to side with the idiots..............

__________________

Anything really new is invented only in ones youth. Later, one becomes more experienced, more famous and more stupid. - Albert Einstein

|

|

|

01-20-2017, 11:15 AM

01-20-2017, 11:15 AM

|

#14

|

|

Motorist & Coffee Drinker

Join Date: Jul 2014

Location: Oklahoma

Posts: 3,955

|

Quote:

Originally Posted by Gelbster

Charles - your 17 pages of Instructions are word perfect. I wish all vendors used such Instructions.

When IMSB questions come up I often mention your 17 pages to the guys who say : "slap it in, get 'er done 'n have another beer' . ...

|

In my post further above, I linked a couple versions of the instructions directly from LN Engineering's IMS retrofit web page. The link to download the Single Row Pro and Dual Row IMS Retrofit has a single page of instructions as does the "Single Row Classic IMS Retrofit only". The IMS Solution manual is 31 pages, about 25 of which are installation instructions. I have often read your "17 pages of instructions" statement. Count me as one of JFP's idiots, because I can not find it. ...and yes, I have searched for 10 minutes for my car keys to find that I am holding them in my hand. Where is the 17 pager?

__________________

I am not an attorney, mechanic, or member of the clergy. Following any advice given in my posts is done at your own peril.

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 05:22 AM.

| |