Quote:

Originally Posted by piper6909

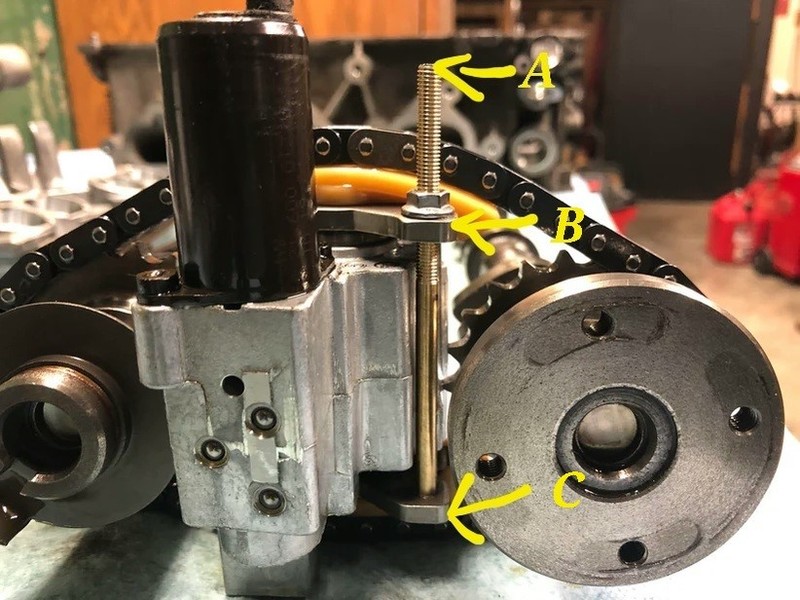

First, correct me if I'm wrong, because I've never done these. But it seems you need to compress B and C together. And B itself, is not threaded at all, otherwise how would you get the unthreaded part of the tool through there? So, you screw the tool into C, run the nut down on B which either pushes B down towards C or pulls C up towards B, or both. Right? Why can't you find out the the thread size of C is (probably M6 or M8, can't tell by the pics) measure the distance between B and C and get either a piece of allthread a few inches longer (like the tool) or even a bolt and a nut?

|

I'm looking forward to JFP's or another guru's reply to Al's question, because I wondered the same thing. By the way, I've read that some folks have used a heavy-duty pull tie to compress the solenoid, but I also read a scare story about the pull tie failing and the solenoid snapping back with tremendous force.