Quote:

Originally Posted by Jamesp

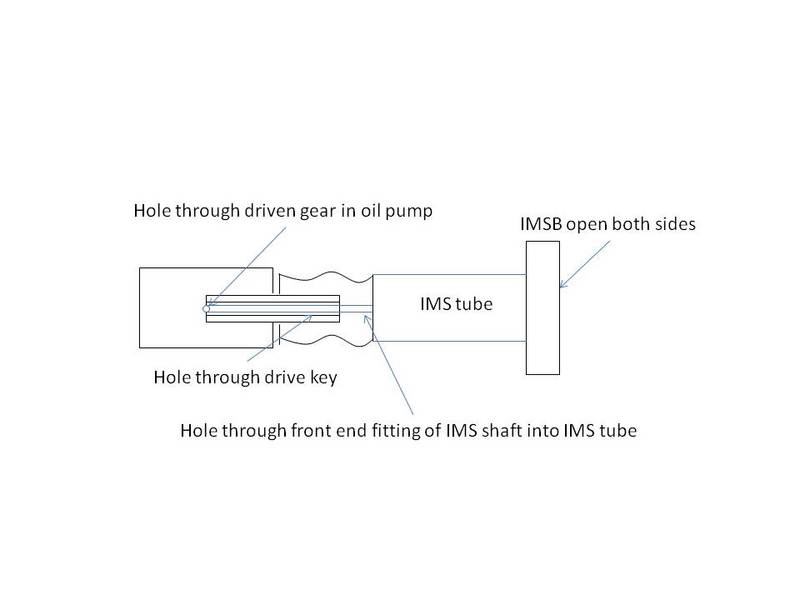

Here was the thought, sizing the oil hole to allow only a tiny bit of oil (very small hole) would be critical. Additionally the small hole would have a small effect on key strength. Key material could be upgraded if that were found to be a problem.

|

Your engine is out. Are you going to do it?