01-19-2014, 01:20 AM

01-19-2014, 01:20 AM

|

#181

|

|

Registered User

Join Date: Dec 2008

Location: Queensland, Australia

Posts: 1,522

|

Now lets see the "opposition" jump on the bandwagon & start the diatribe scramble to poo-poo this great idea.....

__________________

2001 Boxster S (triple black). Sleeping easier with LN Engineering/Flat 6 IMS upgrade, low temp thermostat & underspeed pulley.

2001 MV Agusta F4.

|

|

|

01-19-2014, 05:08 AM

01-19-2014, 05:08 AM

|

#182

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

Originally Posted by Steve Tinker

Now lets see the "opposition" jump on the bandwagon & start the diatribe scramble to poo-poo this great idea.....

|

It would have been so much better for them if they would have chosen to work with us, rather than against us. Best friend or worst enemy; there's only two choices when dealing with my breed. We never quit, we never give up and we live for resistance.

Quote:

|

Thanks Jake. I am amazed - again

|

Just wait till you see what I have saved for last.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

01-19-2014, 05:48 AM

01-19-2014, 05:48 AM

|

#183

|

|

Registered User

Join Date: Oct 2012

Location: Cincinnati, Ohio

Posts: 373

|

Jake,

Nice selfe!

|

|

|

01-19-2014, 06:18 AM

01-19-2014, 06:18 AM

|

#184

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

Originally Posted by Van914

Jake,

Nice selfe!

|

I didn't even have to photoshop it! Although I think I have gotten too much sun lately...

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

01-19-2014, 08:55 PM

01-19-2014, 08:55 PM

|

#185

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

After I exhaled I am not so high on grease anymore.

While testing the seals on the Nachi bearing, I was surprised to feel and hear any clunking from the bearing even with grease in it. I get a lot of that when spinning the bearings dry, but didn't expect any when greased, but there is still some of that going on even with grease. I assume it is bits of debris getting caught between the balls and race, or the cage getting in a jam.

After a couple hours, what started out as a golden honey-like grease has turned to black goo. I am now thinking the grease may not be as good a lubricant as a continuous flow of oil. So I think I will go back to the oil route.

One thing I do know, before my new bearing goes into my Box, it is going to be run in grease for 3 minutes, cleaned and re-greased, run for 20 minutes, clean and re-grease, then run for 3 hours on the test stand before being oiled and installed.

__________________

It's all bad

|

|

|

01-19-2014, 09:10 PM

01-19-2014, 09:10 PM

|

#186

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

|

So I think I will go back to the oil route.

|

If feeding directly into the bearing you might want to do a Patent search first.

Thats the case for anyone wanting to develop an IMS fix, don't assume that its not in existence just because you haven't heard that it is.

And no longer is something a quality product just because its patented, there are instances where the bad ideas are protected simply as flanking maneuvers.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

Last edited by Jake Raby; 01-19-2014 at 09:13 PM.

|

|

|

01-20-2014, 05:42 PM

01-20-2014, 05:42 PM

|

#187

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

[QUOTE=Walter White;381890]So I think I will go back to the oil route.QUOTE]

Grease is used successfully in many bearings. Ask just about any electric motor or wheel you know.

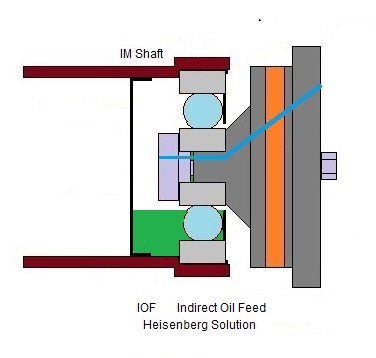

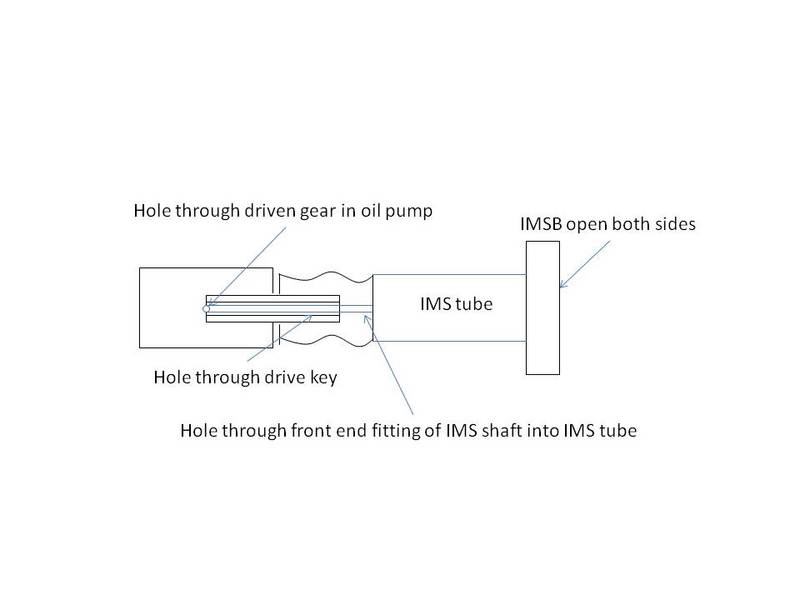

But if you want to go oil, try to skip the hoses and fittings and go straight to the source. You should be able to introduce oil directly through the oil pump drive key into the IMS shaft, and I have the start of an idea of how to do it with a very minimum of structural compensation to the drive key. Another item, I keep seeing things about sealing the IMS, a "lightly pressed" assembly. I do a lot of crazy things but making a pressure vessel that undergoes frequent thermal / pressure cycles (while bathed in oil and undergoing structural cyclical stress and strain no less) out of a lightly pressed assembly is not one of them. My sense is those forces are likely to take that assembly apart over time.

__________________

2003 S manual

Last edited by Jamesp; 01-20-2014 at 06:40 PM.

|

|

|

01-20-2014, 08:35 PM

01-20-2014, 08:35 PM

|

#188

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

Yeah, I don't really want to run pipe or tubing anywhere.

But I am pretty sure I want to feed my bearing indirectly with oil. The cooler and cleaner the oil the better.

I have been testing the partially open seal design and so far, measuring the oil that comes out, I calculate that 10cc/min or less may be enough. I may see if some design changes to the seal will reduce consumption. But the most important thing is to keep the oil moving through to keep the bearing clean.

I can't remember my exact calculations on the pressure of sealing the IM shaft but I think it was a difference of 30 psi from 0 to 300*F. So if the shaft were sealed with an air temperature of 70*F, the maximum pressure it would see is about +23 psi, and a minimum of about -7 psi. Since the plug would be near the end of the shaft, I think the sprocket assembly outside the shaft will provide plenty of support. I don't think it would be as stressed as if it were near the middle of the shaft. I think a plastic cam plug with some Loctite or similar adhesive would probably work. Maybe install two plugs, back-to-back.

__________________

It's all bad

Last edited by Walter White; 01-20-2014 at 08:38 PM.

|

|

|

01-21-2014, 03:59 AM

01-21-2014, 03:59 AM

|

#189

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

If a hole is drilled through a loaded shaft, the most load efficient way to do it is along the axis of the shaft. Drilling a hole through the IMS bearing bolt would require a larger bolt diameter than normal to maintain load carrying capacity.

__________________

2003 S manual

|

|

|

01-21-2014, 08:02 AM

01-21-2014, 08:02 AM

|

#190

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

Actually, the hole does not go through the bolt shank, only the shoulder.

I think .032" should do.

But I was considering making a larger bolt and going through the cener of the shank. It would actually be easier and stronger. It would only require drilling the flange shoulder bigger. Much like the later model flange.

I PM'd you yesterday.

__________________

It's all bad

|

|

|

01-21-2014, 02:49 PM

01-21-2014, 02:49 PM

|

#191

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

got the pm - What graphics program do you use?

__________________

2003 S manual

|

|

|

01-21-2014, 03:44 PM

01-21-2014, 03:44 PM

|

#192

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

Here was the thought, sizing the oil hole to allow only a tiny bit of oil (very small hole) would be critical. Additionally the small hole would have a small effect on key strength. Key material could be upgraded if that were found to be a problem.

__________________

2003 S manual

|

|

|

01-21-2014, 06:39 PM

01-21-2014, 06:39 PM

|

#193

|

|

Registered User

Join Date: Jul 2010

Location: California

Posts: 1,859

|

Quote:

Originally Posted by Jake Raby

Just wait till you see what I have saved for last.

|

DVD's on how to rebuild a M96?? I have been patiently waiting.

__________________

Jäger

300K Mile Club

|

|

|

01-21-2014, 06:46 PM

01-21-2014, 06:46 PM

|

#194

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

James, I use a very sophisticated graphics program that takes a very powerful computer and extensive training. MS Paint. I am Paint certified.

Can this be done with the engine in the car?

I have another question for you. Is it possible to get a wrench on the IMSB bolt nut when the flywheel, clutch and tranny is installed if there were an access port in the bell housing. Or is the flywheel just too close. Is there any recess in the back of the flywheel that might allow access to that nut with a wrench when the flywheel is in a certain position.

__________________

It's all bad

Last edited by Walter White; 01-21-2014 at 06:57 PM.

|

|

|

01-21-2014, 07:06 PM

01-21-2014, 07:06 PM

|

#195

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

Quote:

Originally Posted by Walter White

James, I use a very sophisticated graphics program that takes a very powerful computer and extensive training. MS Paint. I am Paint certified.

Can this be done with the engine in the car?

I have another question for you. Is it possible to get a wrench on the IMSB bolt nut when the flywheel, clutch and tranny is installed if there were an access port in the bell housing. Or is the flywheel just too close. Is there any recess in the back of the flywheel that might allow access to that nut with a wrench when the flywheel is in a certain position.

|

Should be able to be done with the engine in the car.

No way I can see of getting the the IMSB with tranny and flywheel installed. No place for an access port - its all load bearing/ primary structure

__________________

2003 S manual

|

|

|

01-21-2014, 07:18 PM

01-21-2014, 07:18 PM

|

#196

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

|

I have another question for you. Is it possible to get a wrench on the IMSB bolt nut when the flywheel, clutch and tranny is installed if there were an access port in the bell housing. Or is the flywheel just too close. Is there any recess in the back of the flywheel that might allow access to that nut with a wrench when the flywheel is in a certain position.

|

You might want to lay your hands on one of these engines before attempting to save the world. Having a passionate understanding of every part is the key to solving these problems.

BTW- Their won't be any M96 DVDs, only my assembly manuals. DVDs can't be updated as we develop and understand more.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

01-21-2014, 07:26 PM

01-21-2014, 07:26 PM

|

#197

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

Quote:

Originally Posted by Jamesp

Should be able to be done with the engine in the car.

|

So the oil pump can be removed through the access panel in the car interior?

Incoming PM

__________________

It's all bad

|

|

|

01-22-2014, 04:41 PM

01-22-2014, 04:41 PM

|

#198

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

I never really looked at taking the oil pump out throught the access panel. I've been more of a "just drop the engine and go to town" kind of a mechanic, so I'm very limited in my knowledge of working on the engine while it's actually in the car. Dropping the engine the first time was a hassle, the second time, not so much. I'm sure as I learn, it will become second nature. From what little I've done, there is a world of difference between trying to work on it in the car, and out on a stand. My sense is that to leave the engine in the car and remove the oil pump getting the front engine mount out of the way would be a benefit. At that point dropping the front down for more clearance seems logical. Someone else who has actually done that can chime in if they have a mind to.

__________________

2003 S manual

|

|

|

01-22-2014, 05:52 PM

01-22-2014, 05:52 PM

|

#199

|

|

Registered User

Join Date: Dec 2006

Location: shoreham, ny

Posts: 1,619

|

if you guys are really going to dive into this, the engine is easier to drop than working with it in there. Don't be scared. Just take it out.

__________________

996 3.4 engine with 2.7 986 5speed transmission

Ebay Headers, Fabspeed high flow cats, JIC Cross, IPD Plenum, H&R Coilovers, B&M Short Shifter, AEM Uego Gauge Type Analog, Apexi S-AFC Select, 987 air box, Litronics, 2000 Tails and side markers, painted center console, 18" 987 S-Wheels, GT3 Front bumper with splitter.

|

|

|

01-22-2014, 06:03 PM

01-22-2014, 06:03 PM

|

#200

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

Originally Posted by Walter White

So the oil pump can be removed through the access panel in the car interior?

Incoming PM

|

No way, its way too low in the chassis and the oil pump body is part of the front console. To remove the console in the car is a royal ********************, I have done it once and will never do it again.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 08:42 AM.

| |