Yeah, I don't really want to run pipe or tubing anywhere.

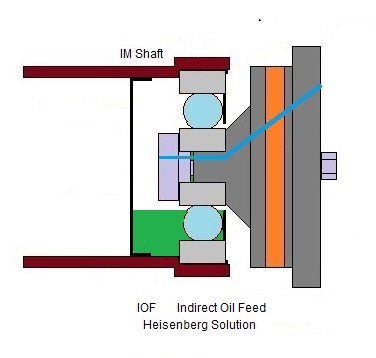

But I am pretty sure I want to feed my bearing indirectly with oil. The cooler and cleaner the oil the better.

I have been testing the partially open seal design and so far, measuring the oil that comes out, I calculate that 10cc/min or less may be enough. I may see if some design changes to the seal will reduce consumption. But the most important thing is to keep the oil moving through to keep the bearing clean.

I can't remember my exact calculations on the pressure of sealing the IM shaft but I think it was a difference of 30 psi from 0 to 300*F. So if the shaft were sealed with an air temperature of 70*F, the maximum pressure it would see is about +23 psi, and a minimum of about -7 psi. Since the plug would be near the end of the shaft, I think the sprocket assembly outside the shaft will provide plenty of support. I don't think it would be as stressed as if it were near the middle of the shaft. I think a plastic cam plug with some Loctite or similar adhesive would probably work. Maybe install two plugs, back-to-back.