01-02-2014, 06:56 PM

01-02-2014, 06:56 PM

|

#121

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

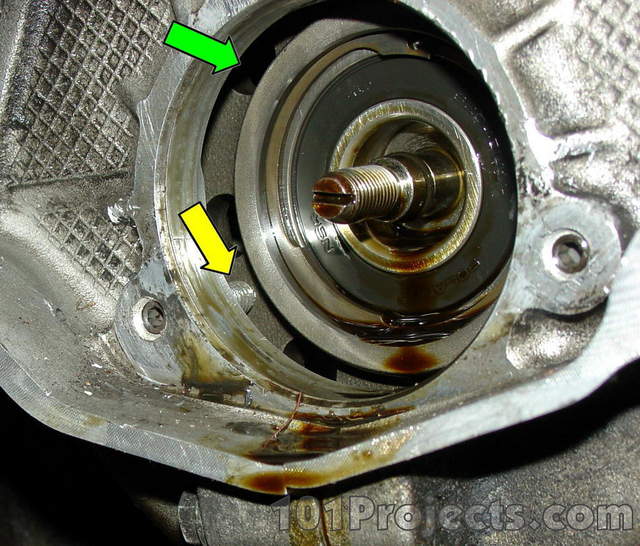

It looks like there is plenty of space between the case wall and the end of the IM shaft for a tube in this picture. But is the shaft pushed back I wonder.

Another way to get to the oil may be through one of the lower bolts.

__________________

It's all bad

|

|

|

01-02-2014, 07:10 PM

01-02-2014, 07:10 PM

|

#122

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

Quote:

Originally Posted by Jake Raby

Always consider the windage that your "fix" may create. Foamy oil has no film strength.

Nothing like solving one problem only to create another thats 10X more critical for the rest of the engine.

|

Jake, I always go to the big knobs on a system. For windage I look at the crank/ piston/rod bearings as the main movers of air in the crankcase and for splashing/foaming oil. Add timing chains for splashing/foaming oil to the preceding and that's about it. Any other items appear to be second or third order effects. What am I missing?

|

|

|

01-02-2014, 07:25 PM

01-02-2014, 07:25 PM

|

#123

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Anything that disturbs the oil, in any way will lead to added windage.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

01-03-2014, 06:04 AM

01-03-2014, 06:04 AM

|

#124

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

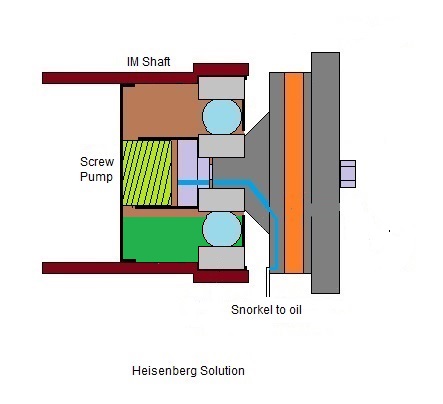

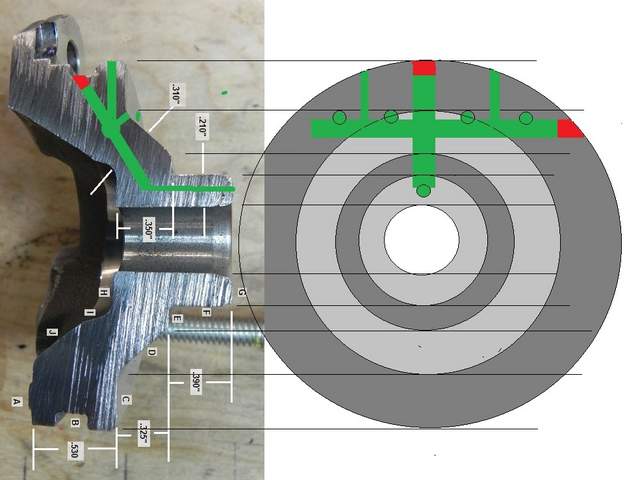

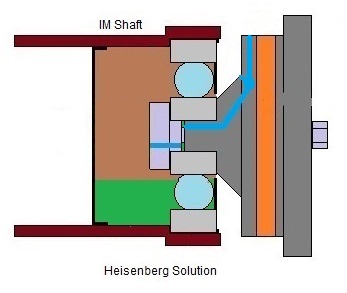

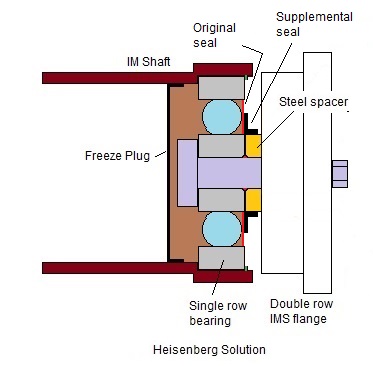

The thinking is to just try to keep a low level of oil behind the bearing, just a supplement to the oil feed the engineers already provide. This would be a very low pressure, low volume pump. I imagine much less than 1 psi and on the order of 1 liter per hour. I drew the seal a little better to show how it is trimmed near the center race to hold oil until it reaches a certain level.

I am looking at this as more of a drip system, not a fire hose.

__________________

It's all bad

Last edited by Walter White; 01-03-2014 at 07:15 AM.

|

|

|

01-03-2014, 07:49 AM

01-03-2014, 07:49 AM

|

#125

|

|

Registered User

Join Date: Sep 2010

Location: Foster City CA

Posts: 1,099

|

Spallation seems to be the primary cause for IMS failures. Installing unsealed dual row ceramic bearings reduces it to nil. Although close, the same would be true for single row bearing installations if they had greater load carrying capacity.

So Walter what problem are you trying to solve here?

Are you trying to find a lower cost alternative to the IMS Solution which fixes the IMS problem for single row cars because it distributes dynamic loads over a very large area?

|

|

|

01-03-2014, 11:53 AM

01-03-2014, 11:53 AM

|

#126

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

|

just a supplement to the oil feed the engineers already provide.

|

What oil feed is that?? You lost me.

One issue that leads to wear is longitudinal thrust loads and the ball bearing trying to control them while providing radial support as well. With bank #1 dragging the IMSB sideways and the IMS Tensioner paddle doing the same all these forces challenge both axis of the assembly.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

01-03-2014, 12:12 PM

01-03-2014, 12:12 PM

|

#127

|

|

Registered User

Join Date: Oct 2008

Location: O.C. CA

Posts: 3,709

|

Quote:

Originally Posted by Jamesp

Jake, I always go to the big knobs on a system. For windage I look at the crank/ piston/rod bearings as the main movers of air in the crankcase and for splashing/foaming oil. Add timing chains for splashing/foaming oil to the preceding and that's about it. Any other items appear to be second or third order effects. What am I missing?

|

I'm thinking the pressure relief holes in your IMS are functioning like carb jets made to atomize & aerate fluids.

__________________

OE engine rebuilt,3.6 litre LN Engineering billet sleeves,triple row IMSB,LN rods. Deep sump oil pan with DT40 oil.

|

|

|

01-03-2014, 02:15 PM

01-03-2014, 02:15 PM

|

#128

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

Quote:

Originally Posted by BYprodriver

I'm thinking the pressure relief holes in your IMS are functioning like carb jets made to atomize & aerate fluids.

|

BYprodriver, here is the logic trail I followed along with "simpler is better" when I modified my engine by drilling carefully placed holes in my IMS shaft. "How much oil is in the IMS tube at startup? (maybe 8 Oz at startup) and how long will it be there? (maybe 10 seconds after startup due to the IMS spinning and casting the oil out the holes). Can more oil get into the IMS tube while it is spinning? (no, centrifugal force makes that impossible, the spinning shaft precludes that) where does the oil get slung for ~ten seconds? (onto the timing chains). How much effect does that have compared to the oil continuously spewing from the rod bearings as the crank rotates at thousands of RPMs slinging oil everywhere? (essentially nothing, not even in the noise) The real question here is whether oil can get past the IMS bearing seals to wash out the grease destroying the bearing without the differential pressure that is relieved by the holes drilled venting the IMS shaft. The seals on the bearings I removed looked great, and still were grabbing the inner race as one might expect from good seals. Still there was no grease in that IMS bearing. I think the answer is that the seals do maintain their design integrity but have oil under pressure pumped through them which washes out the grease. To retain the grease as expected by Porsche engineers the differential pressure across the IMSB can be eliminated by venting the shaft.

|

|

|

01-03-2014, 02:36 PM

01-03-2014, 02:36 PM

|

#129

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

I am liking this setup.

I may have shown too many holes, but it illustrates various routes that may be possible to collect drain-off.

__________________

It's all bad

|

|

|

01-03-2014, 09:30 PM

01-03-2014, 09:30 PM

|

#130

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

It would be nice if you could miracle those passageways into place.

I don't concur with this logic about removing oil from the area any more than delivering oil to the area and keeping a ball bearing in place.

How do you foresee testing this theory? Do you realize how long it will take to gather trend data that supports if it works or if it doesn't?

Ever taken apart an M96?

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

01-04-2014, 09:35 AM

01-04-2014, 09:35 AM

|

#131

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

Quote:

Originally Posted by Jamesp

I used the pelican parts bolt (Thanks Wayne!) but chose a Nachi 6204 NSE s - the seal material is Viton instead of Buna-n - a little better material and it is a sealed bearing.

|

I have been doing my oil seal test on a Nachi 6204 NSE. After 24 hours it shows no sign of leaking. This is the best result I have seen so far. Some bearings fill with oil after only a few minutes, like the one below, just 3 minutes into test.

I have an NSK DDU on order.

__________________

It's all bad

|

|

|

01-04-2014, 09:56 AM

01-04-2014, 09:56 AM

|

#132

|

|

Registered User

Join Date: Sep 2013

Location: Montreal, QC. (currently expat to Shanghai)

Posts: 3,249

|

Having now seen all kind of tricks RE "the remedy of the IMSB", I take it that nobody really understand the "real" cause of failure of the IMSB? Would that be correct?

Lack of lubrification, high pressure, oil contaminations, driving style, luck/bad luck, karma, or all of these combined maybe?

I respect all those who have brilliant ideas like Walter but man, no prototyping, no testing, no data acquisitions methods, not even a simulation..... you guys have a lot of courage drilling these things

__________________

______________________________

'97 Boxster base model 2.5L, Guards Red/Tan leather, with a new but old Alpine am/fm radio.

Last edited by Nine8Six; 01-04-2014 at 10:00 AM.

|

|

|

01-04-2014, 10:31 AM

01-04-2014, 10:31 AM

|

#133

|

|

Registered User

Join Date: Oct 2009

Location: Pittsburgh, PA

Posts: 153

|

Quote:

Originally Posted by Jake Raby

The Gen 2 retrofit details have not been disclosed publicly as of yet. This will occur after the first of the year as our focus is to get the units in the hands of our distributors before releasing the details.

The 06-08 IMSB have proven to be solid. Though we have seen some failures they only occur on-track.

|

Jake - Any update on Gen 2 release? If already posted elsewhere missed it. I'm waiting to do a single row 3.2L until I can learn more.

__________________

Barkinfool

'02 Boxster S

|

|

|

01-04-2014, 11:25 AM

01-04-2014, 11:25 AM

|

#134

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

Originally Posted by Walter White

I have been doing my oil seal test on a Nachi 6204 NSE. After 24 hours it shows no sign of leaking. This is the best result I have seen so far. Some bearings fill with oil after only a few minutes, like the one below, just 3 minutes into test.

I have an NSK DDU on order. |

Add an oil to the mix thats highly concentrated with chlorinated paraffin… Then heat it to 240*, then thermal cycle it hundreds of times, then add 1.5-3% fuel intrusion, then…..

Of course, I'd hope that you know about a durometer and how to use it, and why. We were doing the tests that you are now way back in 2007 and they continue as we develop oils with Joe Gibbs Driven Racing Oils, from scratch.

Quote:

|

Jake - Any update on Gen 2 release? If already posted elsewhere missed it. I'm waiting to do a single row 3.2L until I can learn more.

|

It has been released to our distributors for some time now and their purchase orders are being filled. We are waiting until the time is right and distributors have units in stock (a few hundred per distributor) before the big release.

We are waiting as long as we can after the holidays… However I did recently spill the beans about it in a 5 page interview in a certain publication. :-)

Trust that Gen 2 is NOT "better" than the IMS Solution; nothing will be, because nothing else removes the wear components from the equation. Gen 2 is better than Gen 1, and is a mid price point thats far superior to anything else at the same price. In fact, Gen 2 is the same cost as it could cost to simply "spray oil" onto your OEM bearing and accepting all the compromises that come with that.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

Last edited by Jake Raby; 01-04-2014 at 11:43 AM.

|

|

|

01-04-2014, 02:23 PM

01-04-2014, 02:23 PM

|

#135

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

Quote:

Originally Posted by Walter White

I have been doing my oil seal test on a Nachi 6204 NSE. After 24 hours it shows no sign of leaking. This is the best result I have seen so far. Some bearings fill with oil after only a few minutes, like the one below, just 3 minutes into test.

I have an NSK DDU on order. |

That is why I chose the NSE. In some bearings the rubber seal comes close to, but does not seal the inner race. The Nachi 6204 NSE seals the inner race, and uses higher temp non metallics than the standard bearing. I specifically did not use a bearing that does not completely seal the inner race. Check out the bearing manufacturers spec sheets to tell one from the other, they look similar. The pressure differential between the inside and outside of a non vented IMS will be much higher than the centimeter or so of oil pressure you are seeing in your test. The differential pressure with a vented IMS will be ~zero.

__________________

2003 S manual

Last edited by Jamesp; 01-04-2014 at 06:04 PM.

|

|

|

01-08-2014, 09:56 AM

01-08-2014, 09:56 AM

|

#136

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

After days and days soaking in oil without a trace of the seal leaking, it appears the Nachi seal is not able to hold back the oil when a torsional load is placed on the bearing. After 24 hours of placing a load so that the inner race is not parallel to the outer race, oil is appearing inside the bearing.

__________________

It's all bad

|

|

|

01-10-2014, 11:01 AM

01-10-2014, 11:01 AM

|

#137

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

NSK 6204DU after 40 minutes in oil bath, filled with oil.

The box it came in says DDU, but the seal only says DU.

The Nachi seal appears superior to the NSK seal when viewed under a magnifying glass.

__________________

It's all bad

|

|

|

01-11-2014, 10:16 AM

01-11-2014, 10:16 AM

|

#138

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

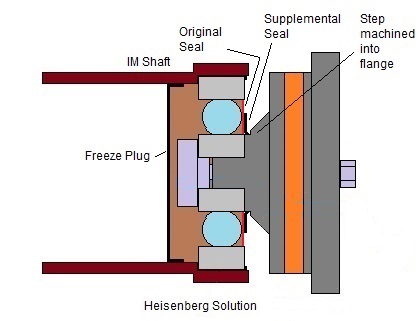

I am considering the possibility of bonding a supplemental seal to a bearings original seal.

One possibility would be to bond a trimmed-down commercially available seal to the existing seal.

Another possibility would be to bond a piece of sheet rubber to the existing seal, and machine a step on the flange which could be done on any good lathe in a few minutes.

Supplemental seals might be able to bond to original rubber seals using the same bonding agents that are used to glue O-rings together. Rubber original seals could be bonded to the outer race using a good rubber-metal bonding agent like E6000.

I have some rubber-to-rubber samples soaking in oil before I try to tear them apart. Bonding a supplemental seal to a metal original seal (Z or ZZ) would probably be the best, but a rubber-to-rubber seal would probably be the best bond.

__________________

It's all bad

Last edited by Walter White; 01-11-2014 at 10:22 AM.

|

|

|

01-11-2014, 11:28 AM

01-11-2014, 11:28 AM

|

#139

|

|

Registered User

Join Date: Sep 2013

Location: Montreal, QC. (currently expat to Shanghai)

Posts: 3,249

|

Quote:

Originally Posted by Walter White

I am considering the possibility of bonding a supplemental seal to a bearings original seal.

|

Smart a**!

I give you this, you are brilliant. Sounds like a bullet proof idea

__________________

______________________________

'97 Boxster base model 2.5L, Guards Red/Tan leather, with a new but old Alpine am/fm radio.

Last edited by Nine8Six; 01-11-2014 at 11:49 AM.

|

|

|

01-11-2014, 11:44 AM

01-11-2014, 11:44 AM

|

#140

|

|

Registered User

Join Date: Sep 2013

Location: Montreal, QC. (currently expat to Shanghai)

Posts: 3,249

|

irrelevant. .delete

__________________

______________________________

'97 Boxster base model 2.5L, Guards Red/Tan leather, with a new but old Alpine am/fm radio.

Last edited by Nine8Six; 01-11-2014 at 11:48 AM.

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 12:11 AM.

| |