12-25-2013, 04:03 AM

12-25-2013, 04:03 AM

|

#81

|

|

Registered User

Join Date: Apr 2011

Location: DFW

Posts: 713

|

I'm really interested on the thoughts of driving habits. Its been mentioned numerous times on drive it like you stole it but what particular driving habit causes the most load on the bearing?

|

|

|

12-26-2013, 07:45 AM

12-26-2013, 07:45 AM

|

#82

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

As my attempts to provide a better seal for the IMS bearing seem to be harder than I was hoping at this point, I have been thinking of ways to improve the flow of engine oil to the bearing. At times I have considered that if the pressure inside the IM shaft, or just behind the bearing, was lower than outside the shaft, oil mist and vapor might flow through the bearing at a higher rate than normal. Then I realized that if holes were drilled into the shaft, those holes may produce a low pressure inside the shaft when the shaft was turning.

I drilled a 1/16" hole in 2" pipe with a manometer connected to the pipe end and spun it on a lathe.

At 1K rpm, I got peaks of -.15 inches of water, and at 2.5K rpm I got peaks of -.3 inches of water pressure differential.

Drilling the hole bigger produced less pressure differential.

Drilling additional 1/16" holes had no affect on the initial pressure differential of the original 1/16" hole. But I would think that additional holes would provide high volumes of flow.

Not a lot of pressure differential. I wonder if it would even help any in increasing oil flow through the bearing.

__________________

It's all bad

|

|

|

12-26-2013, 09:54 AM

12-26-2013, 09:54 AM

|

#83

|

|

Registered User

Join Date: Feb 2007

Location: malta

Posts: 210

|

This issue is driving me crazy. Today I started the car and stayed trying to listed for any noises. I couldnt hear anything from inside the car. then I went near the rear wheels and also couldnt hear anything. then I crawled under the car, and could hear some light ticking sounds, (tick tick tick tick.....) but I have no idea where its coming from exactly, or if it has anything to do with the IMS bearing. the noise is hardly noticeable. but if you crawl under the car and try to block out the exhaust sound, you can hear it. Any ideas what it could be? does it have to be the bearing? or is it normal for a boxer engine perhaps?

|

|

|

12-26-2013, 10:11 AM

12-26-2013, 10:11 AM

|

#84

|

|

Registered User

Join Date: May 2011

Location: Miami florida

Posts: 1,591

|

My motor has a bit of a tick, which I think is probably an injector, they can be fairly loud, or possibly something in the valve train, but it goes away, or at least I can't hear it, as soon as I accelerate past idle. I'm not worried.

If you want trace the sound, you need a stethoscope. Put the probe right against the IMSB housing and on both tensioners and listen for anything abnormal.

__________________

Current car

2000 Boxster 2.7l red/black

Previous cars

1973 Opel Manta

1969(?) Fiat 850 Convertible

1979 Lancia Beta Coupe

1981 Alfa Romeo GTV 6

1985 Alfa Romeo Graduate

1985 Porsche 944

1989 Porsche 944

1981 Triumph TR7

1989 (?) Alfa Romeo Milano

1993 Saab 9000

|

|

|

12-26-2013, 10:24 AM

12-26-2013, 10:24 AM

|

#85

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

|

As my attempts to provide a better seal for the IMS bearing seem to be harder than I was hoping at this point,

|

You thought any of this would be easy?

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

12-26-2013, 11:17 AM

12-26-2013, 11:17 AM

|

#86

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

I have the ticking too. I am not too worried about it. I think it could be injectors, lifters, maybe exhaust leaks or loose spark plugs. Comes and goes. Sometimes left side, sometimes right. Sometime when cold, sometimes when hot.

__________________

It's all bad

Last edited by Walter White; 12-26-2013 at 11:25 AM.

|

|

|

12-26-2013, 10:25 PM

12-26-2013, 10:25 PM

|

#87

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

I hit the "Submit" button before I could post pictures.

|

|

|

12-26-2013, 10:27 PM

12-26-2013, 10:27 PM

|

#88

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

Dag nabbit! I did it again. If there is a way to delete these post please let me know.

__________________

It's all bad

|

|

|

12-26-2013, 10:31 PM

12-26-2013, 10:31 PM

|

#89

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

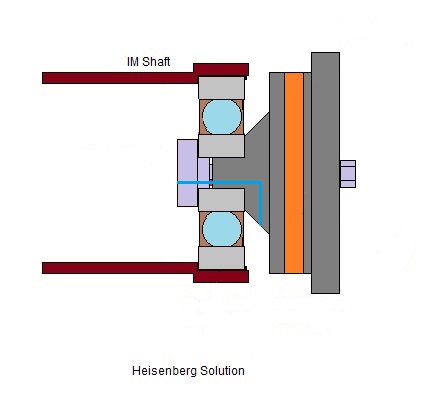

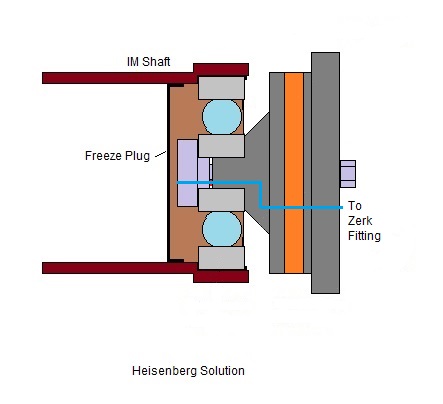

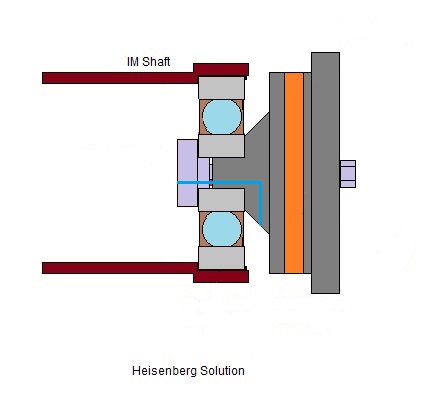

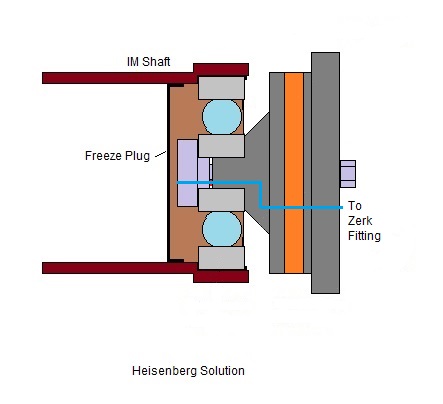

Third try is a charm.

An idea for venting IM shaft.

An idea to get grease into bearing

You can't see it too well but I have an O-ring between the flange and bolt to connect the conduit.

__________________

It's all bad

|

|

|

12-26-2013, 10:43 PM

12-26-2013, 10:43 PM

|

#90

|

|

Registered User

Join Date: Feb 2007

Location: malta

Posts: 210

|

San rensho. Thanks for the tip. You think ill be able to identify where the noise is coming from with a stethoscope? Ive never used one, so i have no idea what to hear with it. I will buy one from a drug store. I will take it with me to my mechanic and try to find where the noise is coming from whilst on the lift. As i said, i can hear nothing from inside the car or from near the wheels,the noise is that faint. When i crawled under the car i heard a slight ticking noise which seemed to be constant but couldn't tell if it quickens with the revs, there was nobody with me to press the accelerator whilst i was under the car.

|

|

|

12-27-2013, 07:21 AM

12-27-2013, 07:21 AM

|

#91

|

|

Registered User

Join Date: May 2011

Location: Miami florida

Posts: 1,591

|

Quote:

Originally Posted by boxster

San rensho. Thanks for the tip. You think ill be able to identify where the noise is coming from with a stethoscope? Ive never used one, so i have no idea what to hear with it. I will buy one from a drug store. I will take it with me to my mechanic and try to find where the noise is coming from whilst on the lift. As i said, i can hear nothing from inside the car or from near the wheels,the noise is that faint. When i crawled under the car i heard a slight ticking noise which seemed to be constant but couldn't tell if it quickens with the revs, there was nobody with me to press the accelerator whilst i was under the car.

|

You don't need a medical scope. Auto Parts stores sell them for about $10. Your mechanic should probably have one. Of he is experienced with it, he will find the culprit fairly quickly and can also listen to the IMSB to determine if anything is wrong.

__________________

Current car

2000 Boxster 2.7l red/black

Previous cars

1973 Opel Manta

1969(?) Fiat 850 Convertible

1979 Lancia Beta Coupe

1981 Alfa Romeo GTV 6

1985 Alfa Romeo Graduate

1985 Porsche 944

1989 Porsche 944

1981 Triumph TR7

1989 (?) Alfa Romeo Milano

1993 Saab 9000

|

|

|

12-27-2013, 07:23 AM

12-27-2013, 07:23 AM

|

#92

|

|

Registered User

Join Date: May 2011

Location: Miami florida

Posts: 1,591

|

Quote:

Originally Posted by Walter White

Third try is a charm.

An idea for venting IM shaft.

An idea to get grease into bearing

You can't see it too well but I have an O-ring between the flange and bolt to connect the conduit. |

Just remember, according to the Heisenberg principle, just the act of observing the IMSB will cause it to change!

__________________

Current car

2000 Boxster 2.7l red/black

Previous cars

1973 Opel Manta

1969(?) Fiat 850 Convertible

1979 Lancia Beta Coupe

1981 Alfa Romeo GTV 6

1985 Alfa Romeo Graduate

1985 Porsche 944

1989 Porsche 944

1981 Triumph TR7

1989 (?) Alfa Romeo Milano

1993 Saab 9000

|

|

|

12-27-2013, 07:46 AM

12-27-2013, 07:46 AM

|

#93

|

|

Registered User

Join Date: Oct 2012

Location: Wake Forest, NC

Posts: 867

|

Quote:

Originally Posted by Walter White

Dag nabbit! I did it again. If there is a way to delete these post please let me know.

|

Why not just edit the post to include the pictures?

__________________

2000 Boxster S, 6 speed, Sport Package, Litronics, LED tail lights, LNE IMS-B, OBC, Skybreaker wind deflector, Arctic Silver/Graphite Grey

Last edited by kjc2050; 12-27-2013 at 10:18 AM.

|

|

|

12-27-2013, 08:09 AM

12-27-2013, 08:09 AM

|

#94

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

"Why not just edit the post to include the pictures??"

If you know how please let me know. I can't find any way to either delete or add photos to a post once it has been posted.

"Just remember, according to the Heisenberg principle, just the act of observing the IMSB will cause it to change!?"

Was that Heisenberg? I thought it was some ancient Greek philosopher.

There's a Breaking Bad marathon coming up on AMC soon. But I live for Gold Rush now. Change.

"You think ill be able to identify where the noise is coming from with a stethoscope?"

You can use a length of garden hose. That works pretty good too.

On the vented picture, the vent should go up, and maybe a short section of tubing pressed into the vent hole, going up then bent down like an upside down J to help keep oil from building up in the vent.

Also, realized that the improved bolt has an O-ring that may interfere with my idea. Hopefully it is not too big to interfere.

__________________

It's all bad

Last edited by Walter White; 12-27-2013 at 08:30 AM.

|

|

|

12-27-2013, 08:26 AM

12-27-2013, 08:26 AM

|

#95

|

|

Registered User

Join Date: Sep 2013

Location: Montreal, QC. (currently expat to Shanghai)

Posts: 3,249

|

Would it be common sense to implant the bearing located inside your lathe's headstock into your boxster then?!

I have a few 5,000~25,000RPM spindles that runs nsk's. We've machined over 10,000 hours on each of them. Same bloody bearing and still looking good (of course)

What are you doing exactly there?

__________________

______________________________

'97 Boxster base model 2.5L, Guards Red/Tan leather, with a new but old Alpine am/fm radio.

|

|

|

12-27-2013, 10:14 AM

12-27-2013, 10:14 AM

|

#96

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

I would assume your bearings are properly lubricated. I am testing with no lubrication. So far I have found that the J type cage appears susceptible to vibration, causing metal fatigue resulting in the cage breaking apart. But I also theorize that a good grease or gear oil will suppress the vibration and the J cage will be fine under those conditions.

I have also found that the W type cage appears impervious to vibration. Is it the best all-around choice? Maybe, maybe not. But so far I am putting my money on the W type cage for my next bearing.

__________________

It's all bad

Last edited by Walter White; 12-27-2013 at 10:30 AM.

|

|

|

12-27-2013, 10:19 AM

12-27-2013, 10:19 AM

|

#97

|

|

Registered User

Join Date: Oct 2012

Location: Wake Forest, NC

Posts: 867

|

Quote:

Originally Posted by Walter White

"Why not just edit the post to include the pictures??"

If you know how please let me know. I can't find any way to either delete or add photos to a post once it has been posted.

|

Click "Edit;" click "Go Advanced;" edit post and add pictures as needed.

__________________

2000 Boxster S, 6 speed, Sport Package, Litronics, LED tail lights, LNE IMS-B, OBC, Skybreaker wind deflector, Arctic Silver/Graphite Grey

|

|

|

12-27-2013, 10:27 AM

12-27-2013, 10:27 AM

|

#98

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Carry out these experiments within an engine and you'll see that your observations change.

Over time we have found that not just the strength of the cage matters, but also the weight of the balls and the cage. This is because the inner race is parked and the outer race is rotating, among other things.

Of course, the only real solution to the issue is removing the balls and the cage completely from the equation.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

12-27-2013, 10:55 AM

12-27-2013, 10:55 AM

|

#99

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

Quote:

Originally Posted by Jake Raby

Over time we have found that not just the strength of the cage matters, but also the weight of the balls and the cage.

|

That is why I haven't tried PEEK or PTFE cages with steel balls. On the other hand, the J and W type cages both have a track record with the OEM steel ball IMS bearing.

__________________

It's all bad

Last edited by Walter White; 12-27-2013 at 11:05 AM.

|

|

|

12-27-2013, 11:17 AM

12-27-2013, 11:17 AM

|

#100

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Don't limit your possibilities by what you **think** will work. All too often I find the things that prove themselves are either the opposite of what I thought would work or they were never intended to work as explained by others.

Spinning that bearing unloaded really isn't proving much, because the dynamics change with vibrations imposed by the engine and the timing chains as well as the rapid acceleration and deceleration of the engine. There's a reason why lots of IMSBs fail on the track just after someone zings an engine from a missed shift.

Really figuring this out requires sacrificing engines.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 05:41 PM.

| |