02-09-2014, 06:40 PM

02-09-2014, 06:40 PM

|

#1

|

|

Registered User

Join Date: Apr 2011

Location: DFW

Posts: 713

|

Quote:

Originally Posted by Jake Raby

Someone else has used this configuration to develop a component and made a critical mistake, actually more than one.

|

James, if I'm not mistaken, there is a fixt that sells a oil feed using something similar to what you describe.

Jake, tell us why wouldn't this work?

Last edited by rp17; 02-09-2014 at 06:50 PM.

|

|

|

02-09-2014, 09:08 PM

02-09-2014, 09:08 PM

|

#2

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

|

Jake, tell us why wouldn't this work?

|

Much like the factory cam timing procedure, this configuration of the oil system is missing some critical points.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

02-10-2014, 10:55 AM

02-10-2014, 10:55 AM

|

#3

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

Having an oil flow from the pump would be nice. If I were to use engine oil for lubrication, I figure 10cc/min would be enough to keep the bearing in oil, under certain conditions.

I am looking at vacuum powered pumps now.

__________________

It's all bad

|

|

|

02-10-2014, 03:14 PM

02-10-2014, 03:14 PM

|

#4

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

Walter,

What are you doing to that poor engine? It looks a little... experimental.

__________________

2003 S manual

|

|

|

02-15-2014, 09:05 AM

02-15-2014, 09:05 AM

|

#5

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

Thanks James. This IMS bearing thing has been fun.

Quote:

Originally Posted by rp17

James, if I'm not mistaken, there is a fixt that sells a oil feed using something similar to what you describe.

|

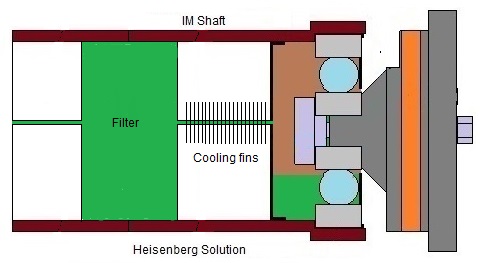

If I were to go this route, this is the way I would want to do it

As I have mentioned, I think 10 cc/min would keep oil flowing out the bearing.

__________________

It's all bad

Last edited by Walter White; 02-15-2014 at 10:08 AM.

|

|

|

11-13-2014, 09:00 AM

11-13-2014, 09:00 AM

|

#6

|

|

Registered User

Join Date: May 2010

Location: uk

Posts: 4

|

Can a blanking plate be fitted before inserting the new IMS bearing. this would stop oil getting into IMS shaft and stop air pressure into bearing from inside shaft, just a thought.

|

|

|

12-17-2016, 08:51 AM

12-17-2016, 08:51 AM

|

#7

|

|

Registered User

Join Date: May 2014

Location: S.California

Posts: 2,029

|

Quote:

Originally Posted by bobclive

Can a blanking plate be fitted before inserting the new IMS bearing. this would stop oil getting into IMS shaft and stop air pressure into bearing from inside shaft, just a thought.

|

Yes, a good idea -"The Solution" uses one. IIRC it is the only IMSB to do so.

|

|

|

01-24-2014, 08:59 AM

01-24-2014, 08:59 AM

|

#8

|

|

Registered User

Join Date: Oct 2013

Location: Atlanta, GA

Posts: 419

|

Quote:

Originally Posted by Jake Raby

Thats up to the publisher.

Its a step by step assembly manual.

|

Really looking forward to getting a copy when it's available...

__________________

2001 Boxster S - Speed Yellow, Black Leather, Tiptronic, Jake Raby rebuilt 3.2 with IMS Solution

|

|

|

02-14-2014, 08:02 AM

02-14-2014, 08:02 AM

|

#9

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

I decided to spend my time omitting the ball bearing, rather than applying a band aid :-)

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

02-14-2014, 04:01 PM

02-14-2014, 04:01 PM

|

#10

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

What I like about you Walter, is that you work in that kingdom where great ideas come from. I think many may look at your ideas and think , "what the heck?". I know I do, some are downright scary to me, but that's the land where really inventive and great ideas come from. Keep it up!

__________________

2003 S manual

|

|

|

11-13-2014, 09:04 AM

11-13-2014, 09:04 AM

|

#11

|

|

Registered User

Join Date: May 2010

Location: uk

Posts: 4

|

Jamesp,

Can you fit a blanking plate into end of IMS before fitting bearing.

|

|

|

11-14-2014, 02:21 PM

11-14-2014, 02:21 PM

|

#12

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

Wow - a blast from the past! A couple of thoughts on the blanking plate:

The IMS shaft is a pressed assembly and a sealed blanking plate would turn it into a pressure vessel. one that gets temperature and pressure cycled every time the engine runs. That would likely disassemble the IMS tube over time with disastrous results.

The plate would be hard to seal, and would take up real estate on the IMS bearing bore the bearing needs, so the bearing would not fit without additional machining of the IMS shaft which would be complicated.

The IMS threads sure have legs!

I sprung for a Durametric (BUY ONE OF THESE!) and my valve timing is still rock solid after a couple thousand miles with my unique IMS bearing fix which is at least a start. Now I have cam sensor problem I'm chasing and it looks like something electronic crapped out. The engine harness buzzes out clean so I'm looking at the driver for the sensor. My thought is the sensor is not getting energized, just like my thought was the engine harness had a broken wire. Oh well, time will tell and it's a hobby. With luck I wont smoke my ECU searching for voltage. I'm thinking about documenting troubleshooting the camshaft sensor and posting it here as there is almost no information on it on this forum or the rest of the internet. Anybody interested?

__________________

2003 S manual

|

|

|

12-27-2014, 06:31 PM

12-27-2014, 06:31 PM

|

#13

|

|

Registered User

Join Date: Dec 2013

Location: Muncie, In

Posts: 1

|

IMS replacement - Indianapolis

Sorry guys but I'm really needing some help on this one. My 2002 986-S is about to send me to the poorer farm  Anyone know of a good non-Dealer in Indianapolis or close who could handle my IMS replacement. 35,000 miles but I'm paranoid, it had been garaged for most of its life prior to my purchase at 29,000. I guess I should also take this opportunity to replace the clutch?

thanks in advance for any advice..

|

|

|

01-09-2015, 11:06 PM

01-09-2015, 11:06 PM

|

#15

|

|

Registered User

Join Date: Jan 2015

Location: Bulgaria

Posts: 6

|

Hello i made a big mess on my Boxster S 987 3.4 L

I remove the flange to change the rubber seal of IMS without locking the Crankshaft

and now the shaft is on a side.

What should i do now !

Please check the attached photos

Thank you in advance

|

|

|

01-10-2015, 08:32 AM

01-10-2015, 08:32 AM

|

#16

|

|

Registered User

Join Date: Jul 2014

Location: Tacoma

Posts: 429

|

The problem isn't that you didn't lock the crankshaft, it's that you didn't undo the chain tensioner.

There are plenty of good detailed write ups on doing this job correctly. If you look at one you'll see you caused yourself a ton of extra work. You are now facing a complete cam timing job.

|

|

|

01-11-2015, 05:52 AM

01-11-2015, 05:52 AM

|

#17

|

|

Registered User

Join Date: Jan 2015

Location: Bulgaria

Posts: 6

|

Quote:

Originally Posted by flaps10

The problem isn't that you didn't lock the crankshaft, it's that you didn't undo the chain tensioner.

There are plenty of good detailed write ups on doing this job correctly. If you look at one you'll see you caused yourself a ton of extra work. You are now facing a complete cam timing job.

|

So i face a big problem now ,

Any other advice ?

|

|

|

01-11-2015, 06:51 AM

01-11-2015, 06:51 AM

|

#18

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

Quote:

Originally Posted by Boxe1

So i face a big problem now ,

Any other advice ?

|

If it were me, first thing I would do is slowly and carefully turn the engine clockwise to zero timing and lock it. Now you've unloaded the valve spring tension from trying to rotate the cams. Chances are good you won't lose valve timing, and you need the engine at TDC in any case. I would not remove a tensioner before rotating the engine, you want chain tension to keep from losing timing. The pickle you are in now is losing timing by rotating the engine (my engine ran at low RPM for two blocks with a failed IMSB before it was turned off and did not lose timing) or loosening the chain tension to try and center the IMSB bolt, which might allow the valve springs to rotate the cams. I have first hand knowledge that the cams can rotate in spectacular fashion due to valve spring tension (one of many mistakes I've personally made during engine re-assembly). The other thing that is going on is the IMS shaft is supported by a journal bearing at the other end, and the geometry of that bearing is none too happy with the loads currently being imparted on it. That's my 2 cents, with luck others will chime in with their respective experiences.

__________________

2003 S manual

|

|

|

01-12-2015, 01:20 AM

01-12-2015, 01:20 AM

|

#19

|

|

Registered User

Join Date: Jan 2015

Location: Bulgaria

Posts: 6

|

Quote:

Originally Posted by Jamesp

If it were me, first thing I would do is slowly and carefully turn the engine clockwise to zero timing and lock it. Now you've unloaded the valve spring tension from trying to rotate the cams. Chances are good you won't lose valve timing, and you need the engine at TDC in any case. I would not remove a tensioner before rotating the engine, you want chain tension to keep from losing timing. The pickle you are in now is losing timing by rotating the engine (my engine ran at low RPM for two blocks with a failed IMSB before it was turned off and did not lose timing) or loosening the chain tension to try and center the IMSB bolt, which might allow the valve springs to rotate the cams. I have first hand knowledge that the cams can rotate in spectacular fashion due to valve spring tension (one of many mistakes I've personally made during engine re-assembly). The other thing that is going on is the IMS shaft is supported by a journal bearing at the other end, and the geometry of that bearing is none too happy with the loads currently being imparted on it. That's my 2 cents, with luck others will chime in with their respective experiences.

|

Thanks for your detailed help,

i did remove both tensioners at the back first,something made a click noise inside the engine,i think it is the cam moved because of the valve springs,still i am afraid to turn the crank to lock the engine at TDC,i removed the rubber covers of the valves and it looks like the timing is lost now

|

|

|

09-26-2024, 10:01 AM

09-26-2024, 10:01 AM

|

#20

|

|

Registered User

Join Date: May 2014

Location: S.California

Posts: 2,029

|

Did you mean this ?

https://lnengineering.com/pel-ims-1-pelican-parts-intermediate-shaft-bearing-update-kit.html

The budget IMS (LN) bearing is now the RND bearing..Suggest you forget the Pelican bearing .The cost increase for using a much better bearing is insignificant in the overall cost of thIMS replacement job + all the wise "while you are in there" work.

https://rndengines.com/roller-bearing-ims-retrofit-kit/

My Pelican bearing fitted by P.O. worked O.K. but he failed to remove all the circulated debris from the original IMS failure. Result was the need to rebuild the entire engine.

So whatever bearing you use, the results can be compromised by lack of due diligence .This is often dismissed as excessive. For example the "Solution" fitting Instructions are 33 pages long and the pre-qualification Instructions are 11 pages.

So skill.,specific specialized tools,diligence and strict observance of Instructions is probably more important than just bearing design ?

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 09:04 AM.

| |