11-15-2013, 09:55 AM

11-15-2013, 09:55 AM

|

#1

|

|

Registered User

Join Date: Apr 2012

Location: Ontario, Canada

Posts: 598

|

Tony, I remember the cars. The Boxster is, of course, much more refined, has much better handling, creates a much better exhaust note, has a much better top, is better assembled and does not have the inevitable rattles of fiberglass on a steel chassis. Cool car though.

Brad

|

|

|

01-03-2014, 01:36 PM

01-03-2014, 01:36 PM

|

#2

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

I am liking this setup.

I may have shown too many holes, but it illustrates various routes that may be possible to collect drain-off.

__________________

It's all bad

|

|

|

01-03-2014, 08:30 PM

01-03-2014, 08:30 PM

|

#3

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

It would be nice if you could miracle those passageways into place.

I don't concur with this logic about removing oil from the area any more than delivering oil to the area and keeping a ball bearing in place.

How do you foresee testing this theory? Do you realize how long it will take to gather trend data that supports if it works or if it doesn't?

Ever taken apart an M96?

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

12-30-2013, 08:32 PM

12-30-2013, 08:32 PM

|

#4

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

I was just figuring out the minimum and maximum pressure the IM shaft would see if it were sealed with a freeze plug. Using P1/T1 = P2/T2, volume is not a variable. So that would mean that if the bearing is sealed with its own seals, it would see the same changes in pressure over temperature? Venting the shaft would not help? The grease in the sealed bearing will still see the same pressure changes I think.

__________________

It's all bad

|

|

|

12-30-2013, 10:20 PM

12-30-2013, 10:20 PM

|

#5

|

|

Registered User

Join Date: Sep 2013

Location: Montreal, QC. (currently expat to Shanghai)

Posts: 3,249

|

That is one of many other calculators that we often use for some applications we engineer.

http://www.skf.com/group/knowledge-centre/engineering-tools/skfbearingcalculator.html

Of course Porsche's R&D have designed better formulas, but it could give you a head start selecting a, perhaps?, better bearing than what Porsche initially came us with.

Bearing life, frictional moment, frequencies, viscosity, dynamic bearing load, etc etc...

__________________

______________________________

'97 Boxster base model 2.5L, Guards Red/Tan leather, with a new but old Alpine am/fm radio.

|

|

|

01-17-2014, 01:06 PM

01-17-2014, 01:06 PM

|

#6

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

Quote:

Originally Posted by Walter White

I was just figuring out the minimum and maximum pressure the IM shaft would see if it were sealed with a freeze plug. Using P1/T1 = P2/T2, volume is not a variable. So that would mean that if the bearing is sealed with its own seals, it would see the same changes in pressure over temperature? Venting the shaft would not help? The grease in the sealed bearing will still see the same pressure changes I think.

|

I have been spin-testing my bearing with the supplemental seal and it spits out a little grease each time I start spinning it after a cool down period. I have a feeling my prediction may be correct. It may be that using grease will require some type of ventilation.

__________________

It's all bad

|

|

|

11-15-2013, 01:15 PM

11-15-2013, 01:15 PM

|

#7

|

|

petrolinmyveins

Join Date: Apr 2013

Location: cumbria uk

Posts: 5

|

Help!!!!!

I replied to this thread but it hasn't shown. It is in my post history but other than that it has disappeared

|

|

|

11-16-2013, 04:47 AM

11-16-2013, 04:47 AM

|

#8

|

|

Registered User

Join Date: Aug 2005

Location: Sanford NC

Posts: 2,580

|

Another day, another proposed approach.

Based on theory. Untested in quantity.

|

|

|

11-16-2013, 06:04 AM

11-16-2013, 06:04 AM

|

#9

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

True enough there isn't a track record for this as I made it up myself, but based on "theory" is debatable. Its based on engineering experience with unintentional pressure vessels and the perfect gas law.

|

|

|

11-27-2013, 10:19 AM

11-27-2013, 10:19 AM

|

#10

|

|

Registered User

Join Date: Sep 2010

Location: Foster City CA

Posts: 1,099

|

Two thoughts...

Vibration may not be the best word. I used it to make the point that IMSB is not purely rotational. There are side forces that contribute to loading. The article you referenced hit the nail on the head - spalling is is the path to failure. The rate of spalling is inversely proportional to loading, which explains the higher OEM single row failure rates. That is, higher single row point loadings lead to increased spalling compared to dual row bearings

In some sense, the IMS Solution is the biggest roller bearing possible. It provides the largest surface area to distribute bearing load.

Last edited by thom4782; 11-28-2013 at 03:28 PM.

|

|

|

01-02-2014, 03:41 PM

01-02-2014, 03:41 PM

|

#11

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

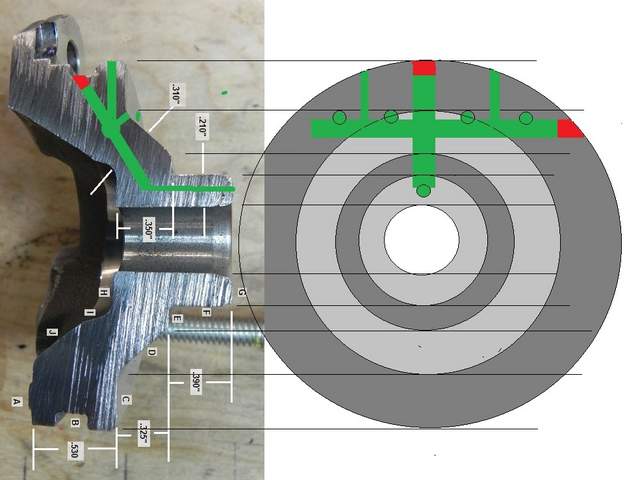

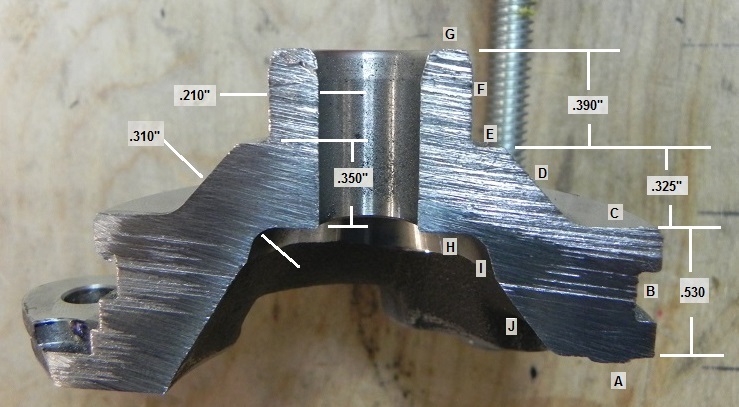

Single row IMSB flange

__________________

It's all bad

|

|

|

01-02-2014, 05:03 PM

01-02-2014, 05:03 PM

|

#12

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

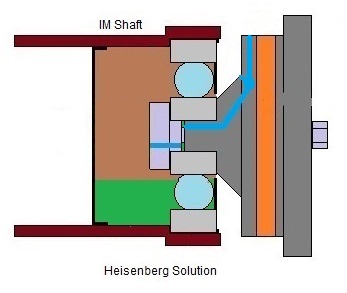

So is the thought to run a pump inside the IMS shaft using the rotation motion of the shaft and the stationary bearing retaining stud? The oil then exits through an open bearing into the crankcase? I'm not sure what type of pump would lift the oil, but this concept is intriguing. Maybe some type of modified stator vane pump? First pumps air to create a vacuum and lift the oil, and then can handle oil as well? That would eliminate any new moving parts, make the stator and vanes part of a new stud and IMS tube closeout? Neat idea. Lots of technical challenges come to mind. Keep going and have fun!

|

|

|

01-02-2014, 05:34 PM

01-02-2014, 05:34 PM

|

#13

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

I'm looking at pumping the oil. It would be nice if it could be done. As I see it, the oil only has to be lifted about an inch. There are several types of pumps that may be viable. But yes I have considered the stator type too. Plan B is to be able to pump grease into the bearing. The biggest question now is can a tube fit down into the sump from the flange. Always looking for help. That's why I post the pics.

__________________

It's all bad

Last edited by Walter White; 01-02-2014 at 05:36 PM.

|

|

|

02-08-2014, 02:57 PM

02-08-2014, 02:57 PM

|

#14

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

Is there any chance of drilling a 1/16" hole in the IM shaft from the sump?

__________________

It's all bad

|

|

|

02-08-2014, 05:05 PM

02-08-2014, 05:05 PM

|

#15

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

Not sure what you mean. I would not drill the IMS tube between the end fittings from a structural consideration standpoint. That's not to say it would certainly lead to a failure over time, but it's not a slam dunk it won't start a crack and fail the tube over time.

__________________

2003 S manual

|

|

|

01-15-2014, 05:47 PM

01-15-2014, 05:47 PM

|

#16

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

Took a little time today to cut an IMSB flange for the supplemental seal and glue a piece of sheet rubber to the existing seal on a Nachi 6204.

I have the setup soaking in oil as I type, except I went straight to the torsional load test with the vice grips.

__________________

It's all bad

|

|

|

01-18-2014, 07:23 AM

01-18-2014, 07:23 AM

|

#17

|

|

Registered User

Join Date: Nov 2013

Location: Arizona

Posts: 90

|

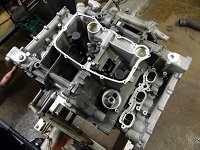

How the heck did you fit a 2 row bearing into the single row shaft? I am amazed!

Edit: Okay, I see

__________________

It's all bad

Last edited by Walter White; 01-18-2014 at 07:32 AM.

|

|

|

01-18-2014, 08:34 AM

01-18-2014, 08:34 AM

|

#18

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

Originally Posted by Walter White

How the heck did you fit a 2 row bearing into the single row shaft? I am amazed!

Edit: Okay, I see

|

It's what happens when you allow a problem and it's solutions to consume your life completely, and when you have the proper resources to carry out development with an open checkbook.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

01-18-2014, 08:38 AM

01-18-2014, 08:38 AM

|

#19

|

|

Registered User

Join Date: Oct 2008

Location: O.C. CA

Posts: 3,709

|

Well done Jake & team! Thank you for all your dedication to our hobby!

__________________

OE engine rebuilt,3.6 litre LN Engineering billet sleeves,triple row IMSB,LN rods. Deep sump oil pan with DT40 oil.

|

|

|

01-18-2014, 02:05 PM

01-18-2014, 02:05 PM

|

#20

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

My pleasure... Literally!

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 12:24 AM.

| |