10-07-2010, 06:11 AM

10-07-2010, 06:11 AM

|

#1

|

|

Registered User

Join Date: Sep 2004

Location: Atlanta

Posts: 1,820

|

DIY: Setting Cam Timing on M96

this applies to non-variocam plus M96 motors (basically, the early ones)

straightforward & easy; no need for any funky tools.

to do this right, you'll need a couple of spare parts:

(3) green camshaft plugs (996.104.215.54)

(8) microencapsulated bolts (900.385.275.01)

(2) o-rings (996.107.221.51)

(1) tube of green loctite

first, we need to explain some things. top dead center (TDC) occurs when a piston is at its uppermost position within the cylinder. it's the point at which the piston stops travelling up and begins travelling down. the tricky part is that TDC occurs TWICE during an engine's 4 cycles. the first time is on the compression stroke & the second time is on the exhaust stroke.

per the factory shop manual, we want to be at TDC compression when we time bank 1 (cylinders 1-3) and TDC exhaust when we time bank 2 (cylinders 4-6).

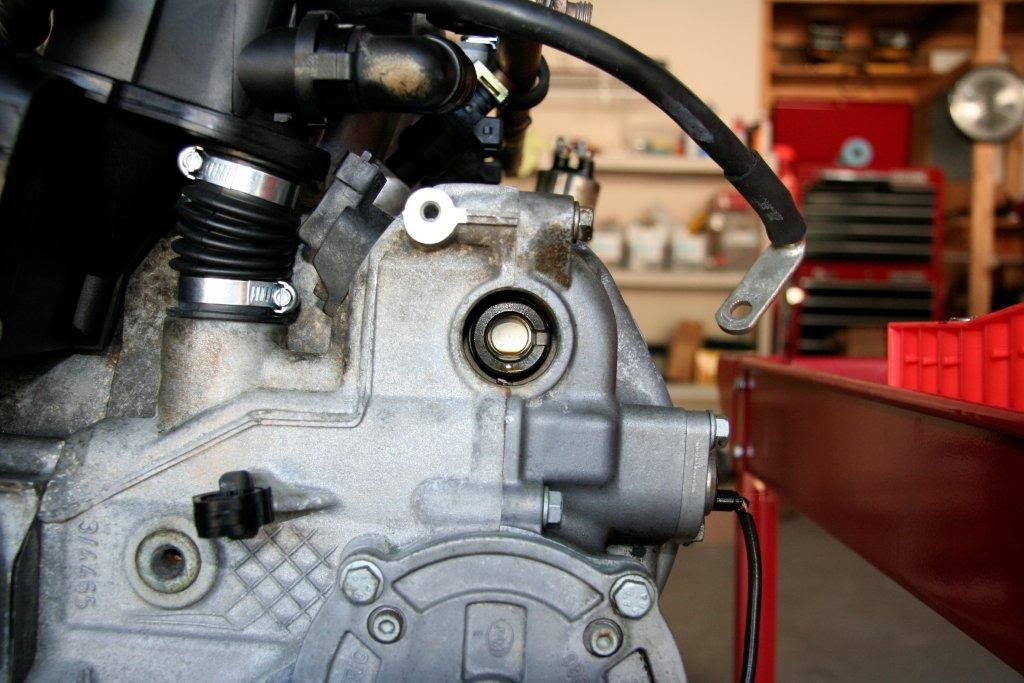

first things first. in the picture below, we're looking at the front of the engine. if the engine were in the car, we'd be looking back through the firewall toward the rear of the vehicle. bank 1 is on the left and bank 2 is on the right.

now we need to remove three of the little green camshaft plugs from the motor. there are six total cam plugs in the motor. in the photo above, you would normally see three. there would be three on the other side as well. they're already removed in this photo.

on the left side would be two plugs. remove the bottom one. on the other side of the motor on the other head, remove the bottom one. on the flywheel side of bank 1, there is only one plug. remove it.

what we've done is to remove the cover for the timing side of the exhaust cams and the index side of the intake cams. more on this in a minute.

now, put a 24mm wrench on the crank pulley and rotate the engine CLOCKWISE until you get close to TDC.

TDC is indicated by a notch on the pully matching a mark on the crankcase as shown in the photo below:

you can 'lock' TDC at the crank by inserting an 8mm bolt through the hole on the pulley marked OT. it will slide into a recepticle on the crankcase as shown in this photo:

now we should have the motor at TDC. we need to make sure we're at TDC compression before we proceed. to do this, look at the notch in the intake cam we uncovered (this will only have ONE notch in it). it should be pointing OUTWARD like this:

if it is pointing inward, rotate the motor 360 degrees to TDC again. now the notch will be pointing outward.

now we will check / set the timing on Bank 1. look at the end of the exhaust cam on bank 1. if the engine is timed properly, the notches will be straight up and down; perfectly parallel to the seam between the head & the valve cover:

if your timing is off, the notches won't line up; they'll look like this:

|

|

|

10-07-2010, 06:21 AM

10-07-2010, 06:21 AM

|

#2

|

|

Registered User

Join Date: Sep 2004

Location: Atlanta

Posts: 1,820

|

if your timing is off, now we need to set it. rotate the engine about 1.5 full rotations. as you approach TDC on the second rotation, check the timing marks. keep rotating the engine until the notches on the bank 1 camshaft are perfectly aligned with the head. once you're there, verify you're at TDC compression by looking at the single notch on the intake cam. it should be pointing OUTWARD.

once your timing marks are lined up & you've verified TDC compression, it's time to change the timing.

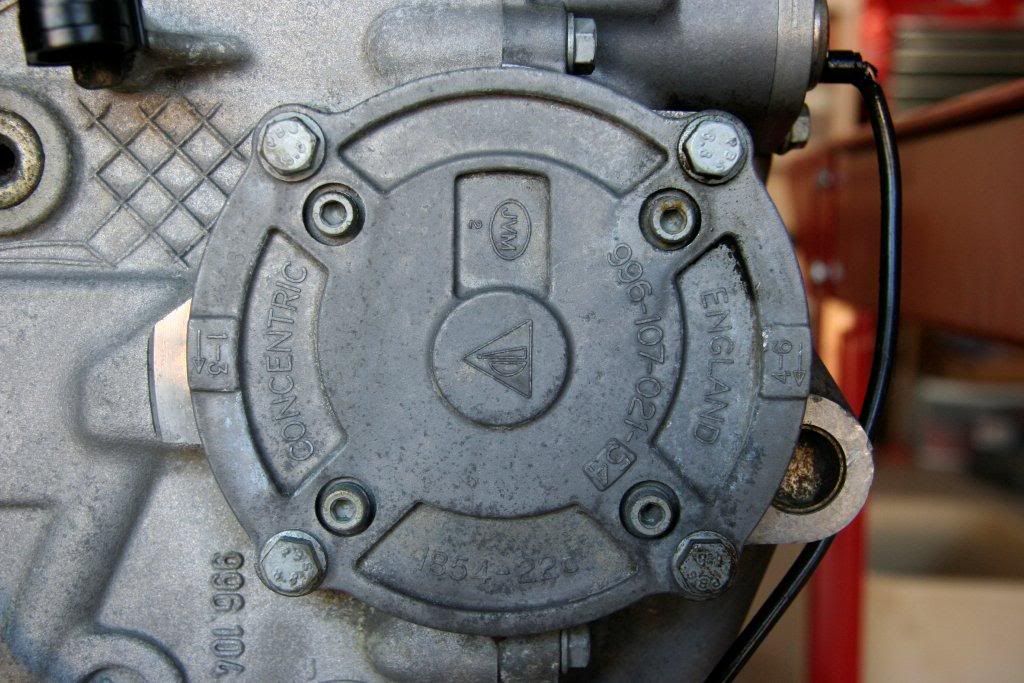

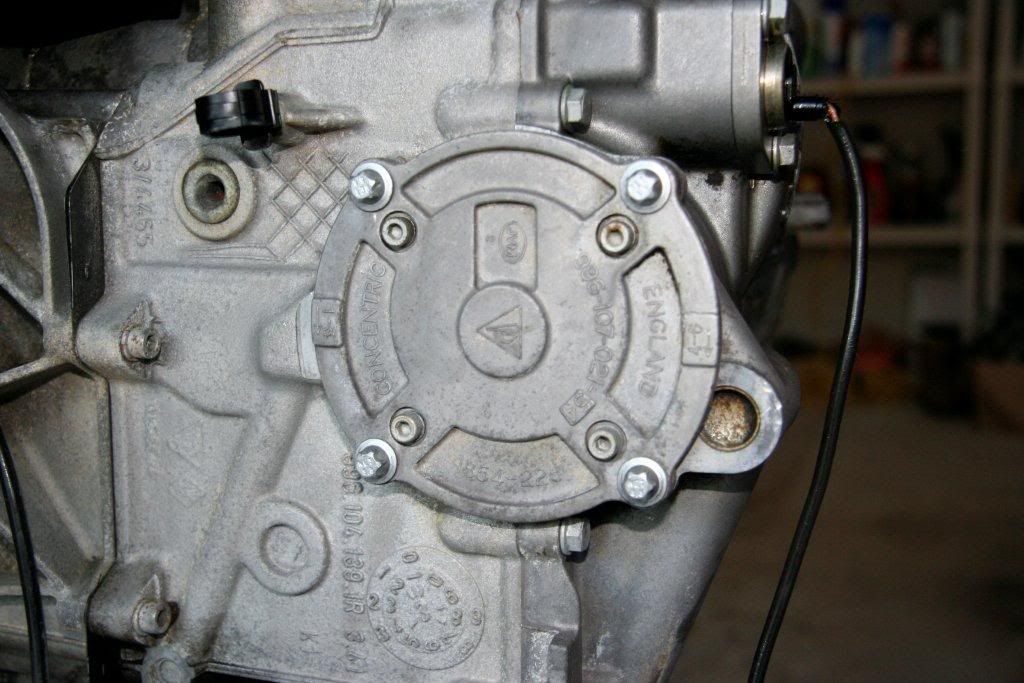

on the back of bank 1, put a match mark onto the oil scavenge pump (THIS IS IMPORTANT). remove the 10mm bolts and gently tap out the scavenge pump.

scavenge pump:

match mark:

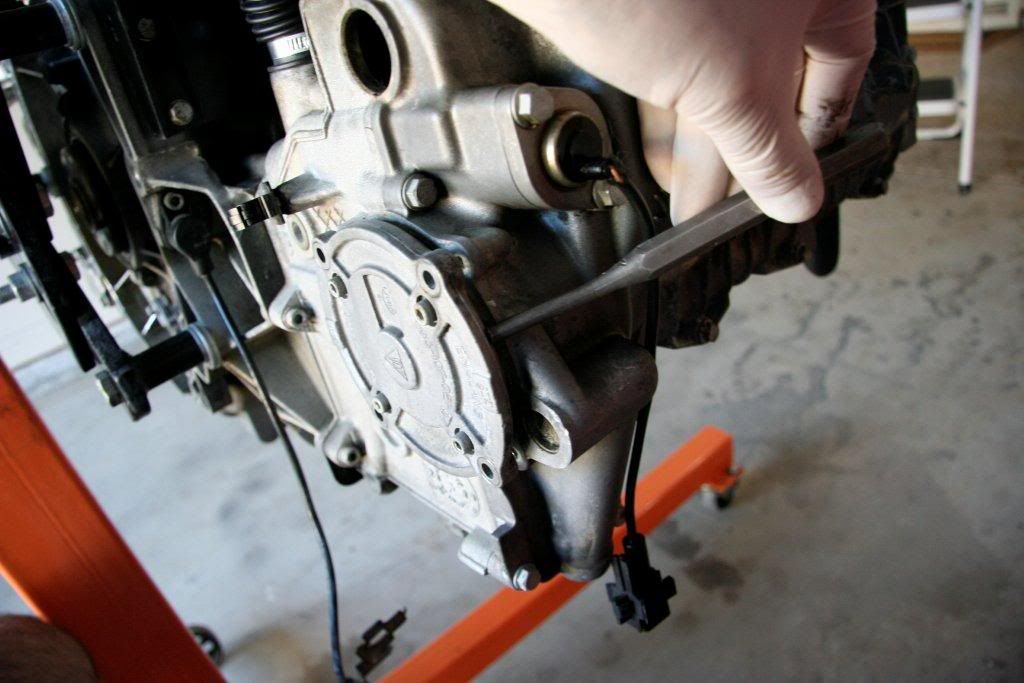

tap it out:

now what you should see is this:

this is the camshaft sprocket. it is adjustable. loosening the four bolts will decouple the camshafts from the crankshaft, allowing you to alter the timing. LOOSEN, but don't remove, the four bolts. rotate the crankshaft to TDC (it's ok if you rotate the motor a tad backward). tighten the four bolts & check the timing notches on the bank 1 camshaft. if you are:

1) at TDC compression (intake cam index notch facing OUTWARD)

2) your bank 1 timing notches are lined up with the head

you have timed bank 1. don't re-install the scavenge pump yet; we'll get there.

now we need to time bank 2. to do this, we need to be at TDC exhaust. rotate the crank ALMOST one full rotation. as you finish the rotation, check the bank 2 timing notches. we want to get them perfectly lined up.

once they're lined up, verify we're near TDC EXHAUST. look at the end of the intake cam, the notch should point INWARD like this:

once you've verified this & bank 2's camshaft is lined up properly, put TWO (this is important) match marks on the bank 2 scavenge pump. we do this because we don't want to get the scavenge pumps mixed up. it's possible to install them upside down & they won't work. by placing two match marks on bank 2's scavenge pump, we can both line it up AND identify which bank it goes into just in case we get confused.....

now, pull the bank 2 scavenge pump and LOOSEN the sprocket bolts. rotate the engine to TDC and tighten the bolts.

now rotate the engine three full rotations to TDC and verify cam timing on bank 1. rotate another 360 degrees and verify cam timing on bank 2.

if all is well, we can begin reassemlby.

first, we are going to remove the cam sprocket bolts ONE AT A TIME, apply loctite, and torque to spec (10.5 ft-lb + 10% to account for loctite = 11.5 ft-lb). BE CAREFUL, DO NOT DROP A BOLT INTO THE ENGINE.

once the cam sprockets are installed, replace the scavenge pumps with new o-rings (lube w/ engine oil first!). install new microencapsulated bolts, and torque to spec (8.5 ft-lb).

tap in new green cam covers with a hammer. no need to add sealant.

you are now done! relax & finish reassembly. drive your car.

|

|

|

10-07-2010, 07:56 AM

10-07-2010, 07:56 AM

|

#3

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

Nice write up..............

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

10-07-2010, 04:11 PM

10-07-2010, 04:11 PM

|

#4

|

|

Registered User

Join Date: Jul 2010

Location: USA

Posts: 276

|

Thanks for the nice write-up Kenvin ......... this should be the standard for DIY threads!

I do have one more question regarding the intake cam notch location.

1.) My pulley is set to top dead center

2.) my exhaust cam notches for bank 1 are lined up parallel to the seam between the head & the valve cover

My question:

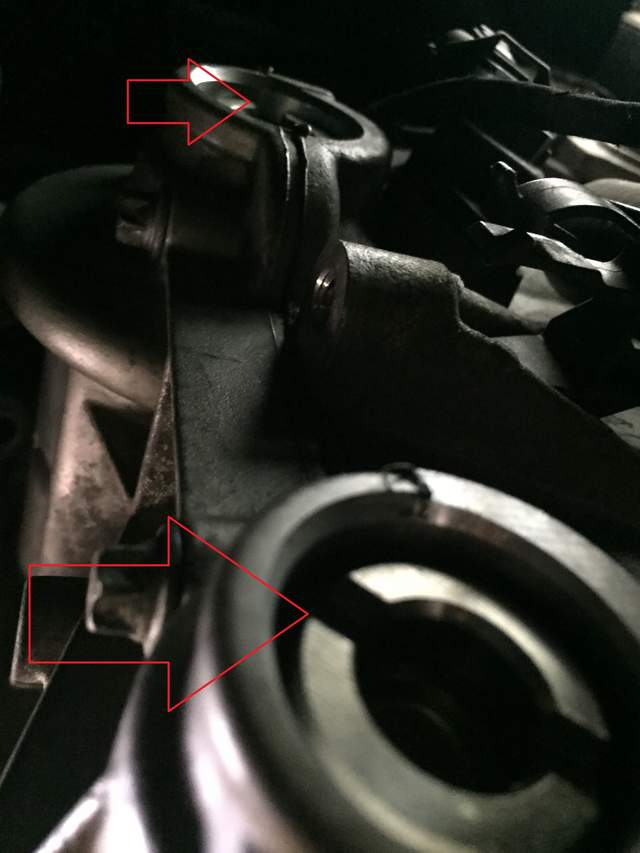

My intake cam notch(one next to air oil separator thing) is pointed too the right but its not perfectly horizontal like to ones in the pics you provided. Mine is sorta at a angle pointed upwards a little. Pic attached of how mine is situated with all other things lined up. Red arrow shows the angle.

Is this normal??

|

|

|

10-07-2010, 07:09 PM

10-07-2010, 07:09 PM

|

#5

|

|

Registered User

Join Date: Jan 2009

Location: Arvada, CO

Posts: 229

|

Quote:

|

Originally Posted by dirkdiggler

My question:

My intake cam notch(one next to air oil separator thing) is pointed too the right but its not perfectly horizontal like to ones in the pics you provided. Mine is sorta at a angle pointed upwards a little. Pic attached of how mine is situated with all other things lined up. Red arrow shows the angle.

Is this normal??

|

To answer the question as simply as possible, the answer is:

NO!!

If you re-read the write up, you will notice that the most important thing to tell that the timing is correct is to line up that one single notch so that it is perfectly pointing to the right, and then see if the cam-notches are parallel to the engine cases.

That notch is the important one, and you will adjust the other notches to line up with regards to it. When it is pointing perfectly to the right, if everything is fine, then the notches on the cams are lines up. If everything isn't set right, then the two cam notches are not lined up.

Your description means that your cams are out of time.

You need to align them, and honestly, it sounds really, really easy.

BC.

__________________

Its not how fast you go, or how expensive your toys are.

Its all about how big your smile is at the end of the day that truly matters.

'98 Silver Boxster, '08 Ducati 848, '89 Honda Hawk GT, '89 Honda Pacific Coast

Last edited by Bladecutter; 10-07-2010 at 07:12 PM.

|

|

|

10-07-2010, 07:40 PM

10-07-2010, 07:40 PM

|

#6

|

|

Registered User

Join Date: Jan 2007

Location: Depends on the day of the week....

Posts: 1,400

|

Quote:

|

Originally Posted by Bladecutter

To answer the question as simply as possible, the answer is:

NO!!

If you re-read the write up, you will notice that the most important thing to tell that the timing is correct is to line up that one single notch so that it is perfectly pointing to the right, and then see if the cam-notches are parallel to the engine cases.

That notch is the important one, and you will adjust the other notches to line up with regards to it. When it is pointing perfectly to the right, if everything is fine, then the notches on the cams are lines up. If everything isn't set right, then the two cam notches are not lined up.

Your description means that your cams are out of time.

You need to align them, and honestly, it sounds really, really easy.

BC.

|

Actually, no it's not. The "timing marks" that the factory tools hold are on the NON-driven side of the cam. I'm still not exactly sure how Insite managed to hold the cams EXACTLY parallel to the valve cover/ head seam without the tool.

These engines are actually very tolerant of small timing errors, and I'm sure that Insite is within the allowable limits, but it's not how I'd do it.

__________________

Boxster S

|

|

|

10-07-2010, 08:55 PM

10-07-2010, 08:55 PM

|

#7

|

|

Registered User

Join Date: Jul 2010

Location: USA

Posts: 276

|

Now I am confused...ugghh

sooooo with:

1.) My pulley is set to top dead center

2.) my exhaust cam notches for bank 1 are lined up parallel to the seam between the head & the valve cover

3.) My other notch is at the angle shown in the pic below

Is my Timing considered off or on?

I have heard yes and no so far......?

I can turn the motor over by hand with-out it binding up so I dont think I can blow it by starting it....right?

|

|

|

10-08-2010, 04:02 AM

10-08-2010, 04:02 AM

|

#8

|

|

Registered User

Join Date: Sep 2004

Location: Atlanta

Posts: 1,820

|

cloudsurfer is 100% correct. the cams with the single notches are the intake cams. their timing is set relative to the exhaust cams, and is done so at the factory. it is not possible to alter the baseline timing between intake & exhaust cams without physically removing the camshafts from the head.

variocam, of course, DOES alter the timing between the two ('overlap'). we are only using the single notch to determine whether we are on the compression stroke or the exhaust stroke when we set TDC. we are checking that it's pointing ROUGLY outward (compression) or ROUGHLY inward (exhaust).

in fact, even the factory shop manual shows it pointing a bit upward as you describe:

|

|

|

10-08-2010, 04:12 AM

10-08-2010, 04:12 AM

|

#9

|

|

Registered User

Join Date: Sep 2004

Location: Atlanta

Posts: 1,820

|

Quote:

|

Originally Posted by Cloudsurfer

These engines are actually very tolerant of small timing errors, and I'm sure that Insite is within the allowable limits, but it's not how I'd do it.

|

cloudsurfer: i initially planned only to CHECK if i could set timing without the tools. i actually used metrology shots to index the cams to the heads. after rotating the crank, i shot them again to make sure the cam hadn't turned. they didn't move even a sliver. setting TDC compression on bank 1 & TDC exhaust for bank 2 ensures that the cams are 'off lobe' and no valve springs are creating a polar moment. in this position, the cams actually 'WANT' to center on the timing marks. in fact, if you rotate the cams like 20deg one direction or the other, they will rotate back!

that having been said, it's pretty easy to eyeball the groove in the cams & the seam between the head & valve cover. the only concern for me at that point was whether the cams would move at all when i rotated the crank. they don't.

this is the only car i've worked on where the factory tries to get you to use all these holding fixtures. every other car involves us simply eyeballing the crank to a matchmark & doing the same thing w/ the camshaft. i find it hard to believe that only the porsche would be affected by thousandths of a degree here.

in fact, before i timed my motor, both banks were visibly off. jake says he sees them this way ALL THE TIME and that many are set improperly from the factory. IMO, the chains stretch over the engine life cycle, too.

it's not important to be PERFECT here, merely very good.

|

|

|

10-08-2010, 08:01 AM

10-08-2010, 08:01 AM

|

#10

|

|

Registered User

Join Date: Jan 2007

Location: Depends on the day of the week....

Posts: 1,400

|

Quote:

|

Originally Posted by insite

cloudsurfer: i initially planned only to CHECK if i could set timing without the tools. i actually used metrology shots to index the cams to the heads. after rotating the crank, i shot them again to make sure the cam hadn't turned. they didn't move even a sliver. setting TDC compression on bank 1 & TDC exhaust for bank 2 ensures that the cams are 'off lobe' and no valve springs are creating a polar moment. in this position, the cams actually 'WANT' to center on the timing marks. in fact, if you rotate the cams like 20deg one direction or the other, they will rotate back!

that having been said, it's pretty easy to eyeball the groove in the cams & the seam between the head & valve cover. the only concern for me at that point was whether the cams would move at all when i rotated the crank. they don't.

this is the only car i've worked on where the factory tries to get you to use all these holding fixtures. every other car involves us simply eyeballing the crank to a matchmark & doing the same thing w/ the camshaft. i find it hard to believe that only the porsche would be affected by thousandths of a degree here.

in fact, before i timed my motor, both banks were visibly off. jake says he sees them this way ALL THE TIME and that many are set improperly from the factory. IMO, the chains stretch over the engine life cycle, too.

it's not important to be PERFECT here, merely very good.

|

All very good points. As I mentioned in another thread, I think the way the procedure works is less than ideal when you really think about it anyway. How much variation is there from pulley to pulley, as far as where that mark is machined and/or where the hole is to insert the locking pin? How much variations is there from cam to cam in terms of those slots being machined? There are several places where these potential errors can add up.

While it's absolutely true that the bulk of production car engines simply have visual marks to line up, and that's just what it is. However, on air cooled engines, you actually (or rather, the guys who really know what they're doing do so) time them by true TDC (dial indicator on cylinder 1 or 4) and split overlap method, which is DEAD on if you do it right.

No matter how careful you are timing an engine the M96 way, or visually (for most other engines), the best you're going to get is within a degree or two, which on a street car, admittedly, just doesn't matter. However, watch the race team guys and the cool looking tools they use....ya....their engines are DEAD on.

I'm still interested in solid lifters and "race" cams (no VarioCam BS) for my 3.8 and if/ when I find them or get them made, will time those via split overlap method with a dial indicator to determine TDC.

__________________

Boxster S

|

|

|

10-08-2010, 09:36 AM

10-08-2010, 09:36 AM

|

#11

|

|

Registered User

Join Date: Oct 2008

Location: O.C. CA

Posts: 3,709

|

+ cam timing off 1 way increases low rpm torque & the other way increases high rpm power.

|

|

|

09-30-2011, 04:01 AM

09-30-2011, 04:01 AM

|

#12

|

|

Registered User

Join Date: Mar 2010

Location: Australia

Posts: 11

|

This is a great write up, thanks insite!!

Just want to confirm, probably stating the obvious but when checking the intake cam guide pointing in or out, you are referring to the intake guide on the SAME bank (1-3 or 4-6) as the exhaust cam, i.e. on opposite ends of the engine.

You talk about the exhaust cams being perfectly vertical (as fitted to car) with the camshaft cover seam on the appropriate TDC. How do the exhaust cams look at the other TDC? Do they almost line up?

Why is bank 1 timed for TDC intake & bank 2 timed for TDC exhaust?

I've started to play around with it with engine fitted in car & it sure hard to get to the relevant parts!

Cheers,

Matt

|

|

|

09-30-2011, 12:03 PM

09-30-2011, 12:03 PM

|

#13

|

|

Registered User

Join Date: Dec 2009

Location: Orange County, CA

Posts: 2,015

|

Quote:

Originally Posted by mattatk

This is a great write up, thanks insite!!

Cheers, Matt

|

++ 1,

Yes great write up, thank you!

BTW, when are you going to write the procedure for the variocam engines

Regards, Gilles

|

|

|

09-11-2012, 08:25 AM

09-11-2012, 08:25 AM

|

#14

|

|

Registered User

Join Date: Feb 2009

Location: SF BayArea

Posts: 7

|

Thanks for this wonderful post insite. I especially liked your prelude mentioning some super basic things like TDC etc..

I have question regarding that:

As mentioned, TDC-compression for bank-1 timing and then a 360 rotation to TDC-exhaust for bank-2 timing - does that mean the timing marks on bank-2 IS NOT/MAY NOT BE exactly vertical at TDC-compression (while bank-1 is) and then vice-versa for TDC-exhaust?

|

|

|

06-21-2013, 11:27 AM

06-21-2013, 11:27 AM

|

#15

|

|

Registered User

Join Date: Apr 2013

Location: Saratoga, NY

Posts: 172

|

Will the index marks on the intake cams be opposite of each other? Or will they be the same as each other? For example if bank 1-3 exhaust marks are lined up perfectly with the cam cover seam, and the index mark is facing outward will the index mark for bank 4-6 be facing inward, or outward?

__________________

2001 Boxster S 6speed- weekend warrior

2015 Explorer Sport- New DD

2011 Taurus SHO- Sold

2010 CBR1000RR- Sold

|

|

|

06-25-2013, 01:10 PM

06-25-2013, 01:10 PM

|

#16

|

|

Registered User

Join Date: Sep 2004

Location: Atlanta

Posts: 1,820

|

they will both face outward

|

|

|

06-25-2013, 01:35 PM

06-25-2013, 01:35 PM

|

#17

|

|

Registered User

Join Date: Apr 2013

Location: Saratoga, NY

Posts: 172

|

Quote:

Originally Posted by insite

they will both face outward

|

Confirming you mean both outward at the same time, not check bank 1-3 its outward, spin 360 check bank 4-6 now its outward correct?

__________________

2001 Boxster S 6speed- weekend warrior

2015 Explorer Sport- New DD

2011 Taurus SHO- Sold

2010 CBR1000RR- Sold

|

|

|

05-03-2015, 12:12 AM

05-03-2015, 12:12 AM

|

#18

|

|

Registered User

Join Date: Jan 2015

Location: Bulgaria

Posts: 6

|

Hello,

I have problem with the Bank 1

when i turn the Crank to TDC the Bank 1 is not align that means i need to re-timing it . Any advice ,

|

|

|

05-04-2015, 06:38 AM

05-04-2015, 06:38 AM

|

#19

|

|

Registered User

Join Date: May 2011

Location: weehawken nj

Posts: 240

|

What year is that engine? Also, it doesnt look like youre anywhere near TDC.

|

|

|

11-12-2016, 05:43 AM

11-12-2016, 05:43 AM

|

#20

|

|

Registered User

Join Date: Mar 2016

Location: Quebec

Posts: 5

|

Insite timing procedure

Hi

When timing is completed on bank 1 1 understand I have to follow same procedure on bank 2. Question..will moving the crank for bank 2 also have bank 1 cams move a bit since they are connected to the crank themselves. Will timing on bank still be good..?

Thank you

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 02:33 AM.

| |