06-25-2015, 05:34 PM

06-25-2015, 05:34 PM

|

#1

|

|

Registered User

Join Date: Nov 2009

Location: San Jose , CA

Posts: 579

|

about ready to start the IMS project

I'm about ready to start the IMS replacement project. I'm doing all of these things at the same time:

RMS

Luc Clutch kit

dual mass Flywheel

Manzo Exhaust/TopSpeed test pipes

AOS

serpentine belt

spark plugs

I think I have all the parts and tools to finish everything.

Tony

Wish me luck.

Tony

__________________

Lapis Blue 03 Boxster S

Seal Grey 04 Boxster S (RIP 9-21-14)

|

|

|

06-25-2015, 07:30 PM

06-25-2015, 07:30 PM

|

#2

|

|

Registered User

Join Date: Mar 2014

Location: Eastern NC

Posts: 701

|

Good Luc.

|

|

|

06-25-2015, 08:08 PM

06-25-2015, 08:08 PM

|

#3

|

|

On the slippery slope

Join Date: Mar 2014

Location: Austin and Palm Springs

Posts: 3,800

|

Go for it Tony

__________________

2004 Boxster S 6 speed - DRL relay hack, Polaris AutoTop DIY

2004 996 Targa Tip

Instructor - San Diego region

2014 Porsche Performance Driving School

2020 BMW X3, 2013 Ram 1500, 2016 Cmax, 2004 F-150 "Big Red"

|

|

|

06-25-2015, 08:32 PM

06-25-2015, 08:32 PM

|

#4

|

|

Registered User

Join Date: Oct 2014

Location: Santa Rosa, CA

Posts: 520

|

Crossing my fingers!

__________________

2003 2.7 Boxster - Tiptronic - Carrera wheels - OBC - Red calipers - Cat pipes - Modified muffler - Rear speakers - K&N - Litronics

2006 V6 Mustang

2008 ML 350

|

|

|

06-27-2015, 11:57 PM

06-27-2015, 11:57 PM

|

#5

|

|

Registered User

Join Date: Nov 2009

Location: San Jose , CA

Posts: 579

|

OK. I need advice. I'm at the point where I have the transmission out and I need to put the cam lock (LN engineering) for a 2003, 3 chain engine. I'm putting the cam lock into the cams on bank one behind the passenger seat (right side of vehicle for the RHD folks), but I can't seem to get it to go in. It fits in the bank to cams but not in bank one. This tells me that one of the cams on bank one is out of timing. It's only out by lest than one degree. is there ant way to fix this without having to put the whole thing back together?

Please help.

Tony

__________________

Lapis Blue 03 Boxster S

Seal Grey 04 Boxster S (RIP 9-21-14)

|

|

|

06-28-2015, 08:53 AM

06-28-2015, 08:53 AM

|

#6

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,653

|

Quote:

Originally Posted by amagalla

OK. I need advice. I'm at the point where I have the transmission out and I need to put the cam lock (LN engineering) for a 2003, 3 chain engine. I'm putting the cam lock into the cams on bank one behind the passenger seat (right side of vehicle for the RHD folks), but I can't seem to get it to go in. It fits in the bank to cams but not in bank one. This tells me that one of the cams on bank one is out of timing. It's only out by lest than one degree. is there ant way to fix this without having to put the whole thing back together?

Please help.

Tony

|

Try rotating the engine (by hand, clockwise direction only) another lap or two and see if the cam lines up then. What ever you do, do not attempt to rotate the engine counter clockwise.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

06-28-2015, 12:40 PM

06-28-2015, 12:40 PM

|

#7

|

|

Registered User

Join Date: Nov 2009

Location: San Jose , CA

Posts: 579

|

OK. Thanks Jeff. I got the cam lock in, but now the special tool TDC lock won't slip into the hole. Is it OK to do the bearing change if I lock the engine from the flywheel (without the special locking tool)?

Tony

__________________

Lapis Blue 03 Boxster S

Seal Grey 04 Boxster S (RIP 9-21-14)

|

|

|

06-28-2015, 01:18 PM

06-28-2015, 01:18 PM

|

#8

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,653

|

Quote:

Originally Posted by amagalla

OK. Thanks Jeff. I got the cam lock in, but now the special tool TDC lock won't slip into the hole. Is it OK to do the bearing change if I lock the engine from the flywheel (without the special locking tool)?

Tony

|

No, because you will need to remove the flywheel to do either the IMS or RMS. You need to find out why the cam tool will not go in with the crank pin in place.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

06-28-2015, 03:39 PM

06-28-2015, 03:39 PM

|

#9

|

|

Registered User

Join Date: Nov 2009

Location: San Jose , CA

Posts: 579

|

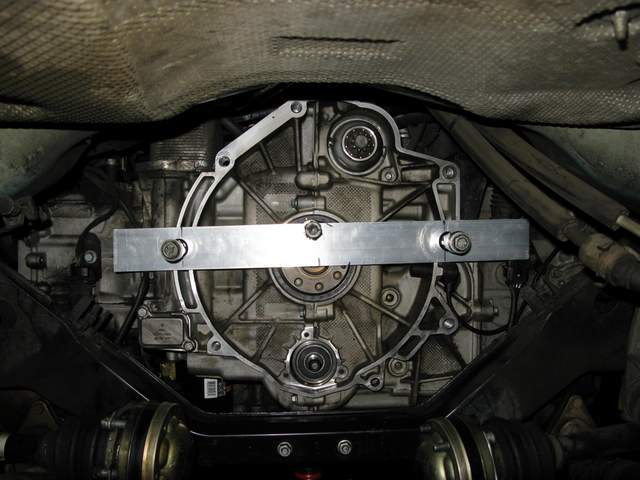

My bad. I meant the rear crank (after the the flywheel has been removed). The reason the tool won't go in is that with the cam lock in, it's ever so slightly out of TDC. Here is what I was thinking:

__________________

Lapis Blue 03 Boxster S

Seal Grey 04 Boxster S (RIP 9-21-14)

|

|

|

06-28-2015, 07:28 PM

06-28-2015, 07:28 PM

|

#10

|

|

02 box s

Join Date: Sep 2011

Location: alabama

Posts: 226

|

My Indy just did my 996 last week and we went through this. Everything at tdc. Cams have to be locked on bank 1-3. Crank lock tool needs to be inserted. 1-3 chain tensioner removed and ims chain tensioner removed. On 3 chain motors you also have to lock bank 4-6 cam (intake iirc) to keep it from moving with the slackness of the chain. You can then remove the ims but you have to note if there is any side movement if the ims shaft. If there is then you have to also take out the bank 4-6 tensioner (hence the locking of the cams on that bank as well). I will,try to have my Indy post tomorrow for you. I am sure that jfp can guide you better, but thought I would try to help as the 3chain motors are a bit more involved than the five chain motors.

__________________

Gone- 02 boxter s

02 911 carrera2, full leather, tubi exhaust, colored gauge faces, agency power short shift, DOF IMS fix, litronics, tech art shifter, spin on filter adapter

|

|

|

06-28-2015, 08:38 PM

06-28-2015, 08:38 PM

|

#11

|

|

Registered User

Join Date: Nov 2009

Location: San Jose , CA

Posts: 579

|

My thought is that the locking tool is to lock the motor by locking the crank shaft. The tool locks the crank shaft in front. The picture above locks the crank from the rear. The cam lock is to keep the spring load in the head from moving the cams when there is slack in the chain (tensioner removed for that bank). Is that not correct? Or, is there another reason for having the engine at TDC?

Tony

__________________

Lapis Blue 03 Boxster S

Seal Grey 04 Boxster S (RIP 9-21-14)

|

|

|

06-29-2015, 03:30 AM

06-29-2015, 03:30 AM

|

#12

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,653

|

Quote:

Originally Posted by amagalla

My thought is that the locking tool is to lock the motor by locking the crank shaft. The tool locks the crank shaft in front. The picture above locks the crank from the rear. The cam lock is to keep the spring load in the head from moving the cams when there is slack in the chain (tensioner removed for that bank). Is that not correct? Or, is there another reason for having the engine at TDC?

Tony

|

The engine has to be a TDC, as that is the only rotational position where all of the valves are close and the cams are unloaded (spring pressure is what causes these engines to jump time). Any other position and at least one or more valves are partially open and under spring loads.

If the cams do not sit in the correct position at TDC, something is wrong and needs to be corrected before moving forward. Did you check the cam deviation values before you started this project?

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

Last edited by JFP in PA; 06-29-2015 at 03:38 AM.

|

|

|

06-29-2015, 09:40 AM

06-29-2015, 09:40 AM

|

#13

|

|

Registered User

Join Date: Nov 2009

Location: San Jose , CA

Posts: 579

|

Yes. Using Durametric. I wrote the numbers down, but I can't find the sheet right now. It was only a few degrees. Neither bank went passed -3. When I say not at TDC, it's REALLY REALLY close. It's off just enough to not let the locking tool slip into the boss. Using a mirror I can see the hole in the boss through the hole in the main pulley, but it's slightly off.

__________________

Lapis Blue 03 Boxster S

Seal Grey 04 Boxster S (RIP 9-21-14)

|

|

|

06-29-2015, 09:45 AM

06-29-2015, 09:45 AM

|

#14

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Quote:

Originally Posted by amagalla

Yes. Using Durametric. I wrote the numbers down, but I can't find the sheet right now. It was only a few degrees. Neither bank went passed -3. When I say not at TDC, it's REALLY REALLY close. It's off just enough to not let the locking tool slip into the boss. Using a mirror I can see the hole in the boss through the hole in the main pulley, but it's slightly off.

|

3 degrees isn't close, its a mile...

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

07-03-2015, 05:48 AM

07-03-2015, 05:48 AM

|

#15

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

If you're not already done, locking the crank at zero degrees is what is important because that unloads all of the valve springs so the cannot physically push the cams to change the valve timing. Locking the cams with the cam locking tool is not necessary for an IMSB replacement. The durametric is giving you valve deviation while running, which is all about the chain ramps, chain tensioners, and timing chain stretch. There are quite a few threads on adjusting the cams to try to compensate for the deviation due to wear.

__________________

2003 S manual

|

|

|

07-03-2015, 07:12 AM

07-03-2015, 07:12 AM

|

#16

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,653

|

Quote:

Originally Posted by Jamesp

Locking the cams with the cam locking tool is not necessary for an IMSB replacement.

|

You have got to be kidding...............

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

07-03-2015, 07:20 AM

07-03-2015, 07:20 AM

|

#17

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

Quote:

Originally Posted by JFP in PA

You have got to be kidding...............

|

And you work on these cars? Not mine if you don't even know that at TDC the lifters are sitting on the Cam circles and it is physically impossible for the valve springs to move the cams. I suppose you use two cam locking tools and the crankshaft zero lock along with bolting the flywheel end of the crankshaft to the block before changing an IMS?

__________________

2003 S manual

|

|

|

07-03-2015, 08:41 AM

07-03-2015, 08:41 AM

|

#18

|

|

Registered User

Join Date: Nov 2014

Location: Ocean Springs, Ms.

Posts: 30

|

I just had the IMS bearing replaced in my '99 986 base. the clutch was getting a little spongy and some ever so slight slip (I really took it to my indie because of a really bad clatter that started quite suddenly). any way, clatter was from the water pump deciding to retire.

so anyway, clutch need changing so might as well do IMS too.

I wish I had taken pix of the operation to change the IMS. my mech didn't lock down the crank, just the cam shafts. He has done a bunch of boxsters and made the job look easy.

my indie mech is a little ocd. I don't know if it's because he's a retired navy fighter jock and a top gun grad, but the guy is better than most dealer mechs.

everything went fine and the old IHS was starting to stick instead of spinning freely. good call on his part. he said there was no deviation in the cams which surprised him as the car has 94K on the clock...

tim

|

|

|

07-03-2015, 08:48 AM

07-03-2015, 08:48 AM

|

#19

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,653

|

Quote:

Originally Posted by Jamesp

And you work on these cars? Not mine if you don't even know that at TDC the lifters are sitting on the Cam circles and it is physically impossible for the valve springs to move the cams. I suppose you use two cam locking tools and the crankshaft zero lock along with bolting the flywheel end of the crankshaft to the block before changing an IMS?  |

Yes, I do work on these cars, and have been called upon to reset the cam timing on more than one three chain motor that jumped time when the owner removed the tensioners without locking the cams while the engine was at TDC. You should never pull the tensioners on the three chain motors unless the engine is locked at TDC, and the cam lock is in place. To do so is inviting a disaster.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

Last edited by JFP in PA; 07-03-2015 at 08:52 AM.

|

|

|

07-03-2015, 10:48 AM

07-03-2015, 10:48 AM

|

#20

|

|

Beginner

Join Date: Mar 2013

Location: Houston

Posts: 1,659

|

Quote:

Originally Posted by JFP in PA

Yes, I do work on these cars, and have been called upon to reset the cam timing on more than one three chain motor that jumped time when the owner removed the tensioners without locking the cams while the engine was at TDC. You should never pull the tensioners on the three chain motors unless the engine is locked at TDC, and the cam lock is in place. To do so is inviting a disaster.

|

Well then you should be using 2 cam locks, not a cam lock. It would be interesting to understand what would you think could drive the cams to move independent of the chains as there is no driving force to rotate them at TDC to lose timing. I've had my 3 chain apart and set the timing without the cams locked, all that was needed was TDC as there is nothing to cause the cams to rotate independent of the chains. Tearing the engine down for the first time after an IMSB failure, I made the choice not to be at TDC because I thought I might have valve to piston interference if I rotated it. A poor choice as I can confirm through personal experience the valve springs will rotate the cam independent of the chain if not at TDC, and they will not, and indeed can not if the engine is at TDC. I prefer to complete jobs without unnecessary parts (cam plugs) and time (messing with the cam locking tool).

__________________

2003 S manual

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 06:58 PM.

| |