01-05-2013, 03:31 PM

01-05-2013, 03:31 PM

|

#1

|

|

The Legend

Join Date: Oct 2012

Location: NJ

Posts: 41

|

Removal of Torque Converter?

'98 Tip. Both the engine and transmission are separated and on the floor. I've been looking for how to remove the TQ from the engine half of the assembly, and could not figure it out. I read somewhere that in order to do this, they must be removed from the car as a unit. If so, do I need to re-mate them? What would be the next step?

|

|

|

01-05-2013, 03:52 PM

01-05-2013, 03:52 PM

|

#2

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,659

|

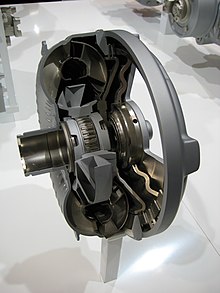

The bolts go thru the converter and into the flex plate; they are removed thru the starter's opening in the transmission case. You can see where they are in this photo:

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

Last edited by JFP in PA; 01-05-2013 at 03:54 PM.

|

|

|

01-05-2013, 07:31 PM

01-05-2013, 07:31 PM

|

#3

|

|

The Legend

Join Date: Oct 2012

Location: NJ

Posts: 41

|

Thank you JFP. I followed the Bentley manual, which had us lock down the crank and remove those 6 bolts with both the engine and transmission in the vehicle. The TC is now mated to the engine and I can't figure out how to remove it.

|

|

|

01-06-2013, 09:30 AM

01-06-2013, 09:30 AM

|

#4

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,659

|

First of all, without beating a dead horse, you should not remove the transmission and leave the torque converter attached to the engine; the snout of the converter engages the trans pressure pump, and the trans front spline engages into the stator assembly.

In the process of pulling the heavy trans back, it is very easy to bend or damage either of these, making the unit useless. The torque converter should remain on the trans when it is separated from the engine.

That said, if you have all six bolts removed, and the converter is still "attached" to the flex plate after the trans is removed, it is probably just stuck to the flex plate. Notice the two longer bolts in the photo above? If you insert these from the snout side of the converter, you should be able to rock the converter back and forth slightly until it releases. When it does, just remember that it still contains a lot of fluid, so watch how you handle it.

When you put the car back together, you can used those long bolts to get the converter fully engaged with the Tip before mating it to the engine. Once attached to the engine, use a 5/16 rod (see the photo) to hold the converter while you put the converter to flex plate bolts back in thru the starter opening, pulling the rod and rotating the engine (clockwise only) until the next set of bolt holes show up in the starter opening. One very large caution: Be very careful not to drop any of the bolts into the bell housing during this process, otherwise you will have to separate the trans and engine again to recover them.

Good luck............

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

10-23-2014, 07:13 AM

10-23-2014, 07:13 AM

|

#5

|

|

Registered User

Join Date: Oct 2014

Location: Chattanooga, TN, USA

Posts: 2

|

Tool advice

What is the best tool to remove the six bolts that attach the torque converter to the flywheel? Thanks

|

|

|

10-23-2014, 09:18 AM

10-23-2014, 09:18 AM

|

#6

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,659

|

Quote:

Originally Posted by ThaKid

What is the best tool to remove the six bolts that attach the torque converter to the flywheel? Thanks

|

They are metric Allen bolts, so an appropriated sized Allen socket (6MM) on the end of a long 3/8 drive extension is the best approach.

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

Last edited by JFP in PA; 10-23-2014 at 09:21 AM.

|

|

|

08-02-2016, 01:25 PM

08-02-2016, 01:25 PM

|

#7

|

|

Registered User

Join Date: May 2013

Location: Central Illinois

Posts: 403

|

Flex plate orientation?

With TC pinned in place and tranny bolted up except last 1/8 to 1/4", was planning to bolt flex plate to converter then finish bolting tranny to engine. Problem is, there are no holes in portion of flex plate accessible through starter hole.

Tried rotating engine, thus flex plate, but converter wants to move with it when attempting to rotate. Pins stops rotation. Pulling pin will allow flex plate to rotate, but converter is moving too, so while I can get flex plate holes to appear inside starter hole, when I do, they do not match up with converter, since I had to unpin it to rotate flex plate.

Obviously I've gone wrong somewhere. Trying to understand where. Was there a mark on the flex plate for correct orientation to line up?

Thanks, Joe

|

|

|

08-02-2016, 02:52 PM

08-02-2016, 02:52 PM

|

#8

|

|

Registered User

Join Date: May 2013

Location: Central Illinois

Posts: 403

|

Update: of course the flex plate can only go onto the crank one way with the pin. So maybe the better question should have been, with the pinned crank at TDC, should two bolts be accessible through the starter hole?

|

|

|

08-02-2016, 02:55 PM

08-02-2016, 02:55 PM

|

#9

|

|

Registered User

Join Date: May 2013

Location: Central Illinois

Posts: 403

|

Update two, was finally able to rotate crank without spinning TC too by pulling back tranny just a little more. Have now matched up pinned TC and pinned crank. Whew, what a day.

|

|

|

08-02-2016, 02:57 PM

08-02-2016, 02:57 PM

|

#10

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,659

|

Quote:

Originally Posted by Xcellr8

Flex plate orientation?

With TC pinned in place and tranny bolted up except last 1/8 to 1/4", was planning to bolt flex plate to converter then finish bolting tranny to engine. Problem is, there are no holes in portion of flex plate accessible through starter hole.

Tried rotating engine, thus flex plate, but converter wants to move with it when attempting to rotate. Pins stops rotation. Pulling pin will allow flex plate to rotate, but converter is moving too, so while I can get flex plate holes to appear inside starter hole, when I do, they do not match up with converter, since I had to unpin it to rotate flex plate.

Obviously I've gone wrong somewhere. Trying to understand where. Was there a mark on the flex plate for correct orientation to line up?

Thanks, Joe

|

The object of the long pin thru the bell housing and into the converter is two fold: It hold the system in position while inserting and tightening the converter to flex plate fasteners, and hold the converter to the trans while removing it. You insert the long pin once you have the flex plate and converter bolt holes lined up, insert and tighten the two Allen head bolts, and then remove the pin to allow the converter and flex plate to rotate to the next set of bolt holes, re insert the pin and do the nest set of fasteners. There is no "alignment mark" on either the converter or flex plate, just three sets of two bolt holes. Once you get the pinned converter lined up with the first set of holes in the converter, the rest should already be aligned as well. Did you insert the pin into the converter while the trans was still out of the car?

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

Last edited by JFP in PA; 08-02-2016 at 03:01 PM.

|

|

|

08-02-2016, 04:40 PM

08-02-2016, 04:40 PM

|

#11

|

|

Registered User

Join Date: May 2013

Location: Central Illinois

Posts: 403

|

Yes, I pinned the TC before pulling the tranny, but once it was out I did remove the TC to change the TC shaft seal. Then reinstalled the TC and pinned it again before reinstalling the tranny. Meanwhile, removed flex plate to do RMS and IMSB. After that work went on vacation and when I came back thought I put engine back to TDC, but since cam plugs were already back in place, guess it was 180 off which I'm guessing is why the flex plate didn't match up with the TC.

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 05:30 AM.

| |