I'm still alive, still getting things set up at my new place. In the meantime, since putting the car on jack stands will be my first order of business, I've been thinking about how to make the process less frustrating. The main problem with jacking up Boxsters is the lack of jacking points at the centerline in the front and back. Without them, one must use the "approved" jacking points which, instead of at the center line, are offset a foot or so to one side. As a result, the car is not side-to-side level when elevated, which causes aggravation when trying to place jack stands under the car.

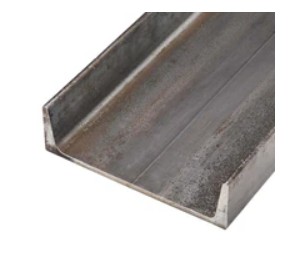

Consequently, I've come up with a Grant Hargraveish solution: a 5"-wide steel channel crossways on the floor jack, with rubber pads that correspond to left and right jacking points. The channel will be upside down on the floor jack in order to keep the profile as shallow as possible and also to prevent the floor jack's pad from slipping off the channel. I ran this plan by my friend the metal fabricator, and he gave it his blessing, although he thought steel would be preferable to aluminum, because he thought aluminum would flex too much. The issue is moot, however, since I couldn't locate aluminum channel wider than 4". Rubber jack pads, including the one on my floor jack, are close to 5" in diameter.

I would be interested to hear folks' take on this scheme.