As the original poster I feel the need to add a few comments.

1) I am surprised at the response… guess it was a worthwhile thread to post.

2) A couple of people suggested that one should read the Owner’s Manual…

I wasted some time looking at the owners manual that I have and, as I expected, found NOTHING on supporting the engine… which is what this thread is about.

3) Since I have my cracked oil pan sitting on a table I have spent some more time inspecting it and make the following observations.

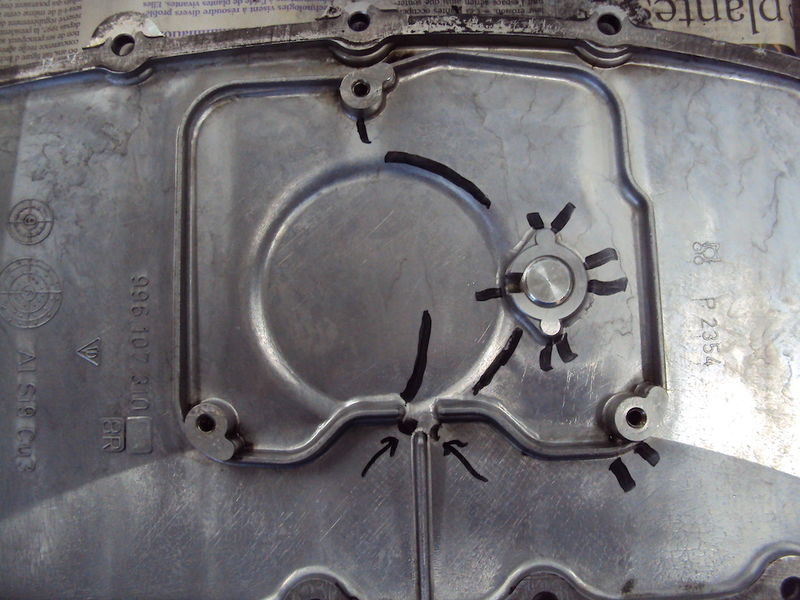

a) The the lowest points of the pan are the two front to back ribs on either side of the circular depression for the oil pickup and also the part of the casting around the drain hole.

I coloured one of the ribs red so it would stand out in the next photo.

So even if a plank is between a jack and the pan the weight will be on the ribs and the raised part around the drain hole. My pan does have cracks around the drain hole and at least one of the ribs, even if the worst ones are in the center around the oil pickup depression.

I marked the cracks in black... these are cracks that I can feel with a fingernail.

So just putting a plank or piece of plywood will not prevent the weight being concentrated in the middle of the thin casting.

My solution for future engine removal will be to make a square wooden frame that fits around periphery of the oil pan, under the bolts, which will accept the weight from the vertical walls of the sump.

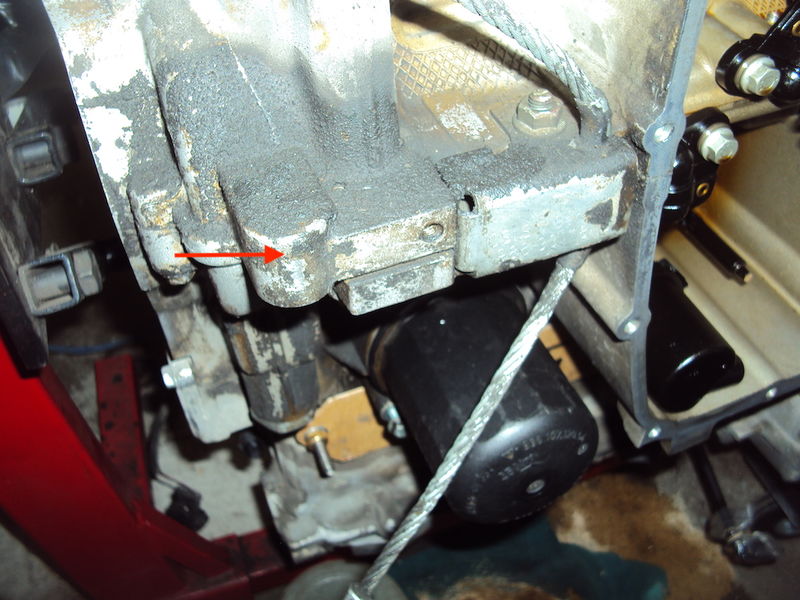

For supporting the engine for engine mount removal there are areas of the crankcase in front of and behind the sump that are about an inch thick that should do very well, of course with a piece of wood on the jack.

I could use my engine support bar but that means going to all the bother of removing the engine cover and I would not be comfortable working under the car with the engine weight on that little bracket... even if I have hung the engine on it in the past (when I wasn't under the car) and even if Porsche recommends it. But that's just me.

b) Most of us, after the removal of the engine, put it on a dolly of some sort… where the same problem will occur. A carpet or rubber layer on the dolly (or lift table) will help distribute the load but it has to be soft and deep enough to allow the central part of the pan to sink in about a quarter of an inch before the load will be distributed to the rest of the surface area of the pan. The wooden frame that I plan on making will overcome this problem also.

c) I have an engine support bar (that I made myself), but using it to lower and raise the engine would be a way too unwieldy with the equipment I have, so I will continue to use my transmission jack with the wooden frame (that has yet to be created).