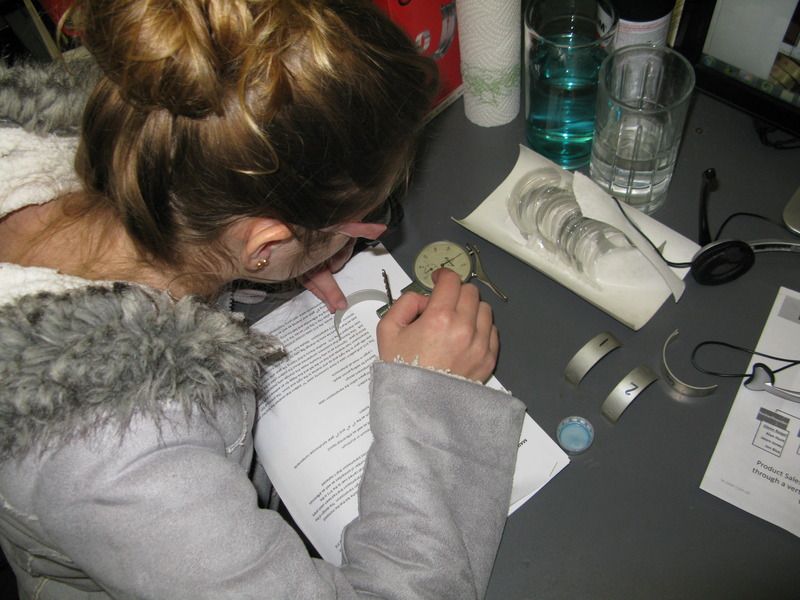

I'm the lucky dad!! She's a great gal and has been my garage buddy since a baby. We have 4 girls and they can all change a tire but Allie is a real gearhead. She has an instagram account @theporschegirl where she updates some of the work she does. She's a little bit famous on Pelican for building her own 3.4 engine for her hot rod '76 911.

She is also an excellent welder with TIG, MIG and Gas. She does all of her own maintenance on her 944 too and helps me with my projects by doing all of the welding.

If the car was in better shape and in DC she would be doing all of the work. But I have the time and she has the small budget, so the work gets done here for now.

The car was parked on the street in Brooklyn so the kids are just local kids with an easy target that didn't move and the owner didn't care about. Sad but true and it worked in our favor. There are not many cars that can be bought this cheap, have so much potential and intrinsic value. She will keep it for a few years, sell it on and try to move up to a Cayman or 911 as DD and keep her 911 as a play car.

The downside to this is that it makes dating quite hard!! She meets guys that want to talk cars and they tell her about the new LED washer nozzles, Soup Can muffler and huge stereo amps and she has to bite her tongue and not talk about building engines and welding on cars. It's a bit intimidating for guys her age.....