03-10-2013, 11:30 AM

03-10-2013, 11:30 AM

|

#1

|

|

Homeboy981

Join Date: Jan 2012

Location: Sherman, TX

Posts: 663

|

IMS Bearing Bolt Predicament

I am IMS STUCK! After removing the IMS bearing in one piece. I am not sure what do about this….

My engine is locked at TDC (at BOTH ends of crankshaft and camshafts). Chain tensioners are OUT. I removed the IMS bearing - NO PROBLEM!!

However, my IMS bolts are lining up in the crankshaft HOLES…NOT on the steel part of the crank flange. It is supposed to be a friction fit on the crank flange and MUST NOT be tightened down into the holes. HOW DO I SOLVE THIS? Will is re-seat itself when I re-install the Chain Tensioners?

I have the chain tensioners out at the moment….I am hesitant to turn the crank WITHOUT CHAIN TENSION.

So, the question is - and I have researched my tail off but cannot find an answer:

HOW do I make sure the Crankshaft holes are NOT UNDER the IMS BOLTS? How do I move them to safe ground?

__________________

2002 Porsche Boxtser S - Silver & Chrome - Died from IMS failure AFTER IMS was replaced!

|

|

|

03-10-2013, 12:10 PM

03-10-2013, 12:10 PM

|

#2

|

|

Registered User

Join Date: Sep 2010

Location: Foster City CA

Posts: 1,099

|

I'm no expert on this. And I haven't installed an IMSB myself. I will offer one thought and others will weigh in I'm sure on the technical details.

I can't believe that properly torqued IMSB flange bolts would extend through the engine case so as to interfere with the crankshaft. If such interference were possible, then it would be a terrible design. I can fully understand, however, your concern. The consequences of installing the IMSB wrong are bad.

Hope this helps. Let's see what the true experts have to say.

BTW: here is the latest set of installation instructions: http://www.lnengineering.com/imsretrofit.pdf

Last edited by thom4782; 03-10-2013 at 12:30 PM.

Reason: Added BTW

|

|

|

03-10-2013, 12:52 PM

03-10-2013, 12:52 PM

|

#3

|

|

Registered User

Join Date: Jul 2010

Location: California

Posts: 1,859

|

Quote:

Originally Posted by Homeboy981

I am IMS STUCK! After removing the IMS bearing in one piece. I am not sure what do about this….

My engine is locked at TDC (at BOTH ends of crankshaft and camshafts). Chain tensioners are OUT. I removed the IMS bearing - NO PROBLEM!!

However, my IMS bolts are lining up in the crankshaft HOLES…NOT on the steel part of the crank flange. It is supposed to be a friction fit on the crank flange and MUST NOT be tightened down into the holes. HOW DO I SOLVE THIS? Will is re-seat itself when I re-install the Chain Tensioners?

I have the chain tensioners out at the moment….I am hesitant to turn the crank WITHOUT CHAIN TENSION.

So, the question is - and I have researched my tail off but cannot find an answer:

HOW do I make sure the Crankshaft holes are NOT UNDER the IMS BOLTS? How do I move them to safe ground?

|

Did you lock your crank at TDC?

Are you trying to stabilize the IMS gear with set screws? This is not required as long as you are locked at TDC. But if you are using set screws to help stabilize the IMS do not over-tighten.

__________________

Jäger

300K Mile Club

|

|

|

03-10-2013, 02:17 PM

03-10-2013, 02:17 PM

|

#4

|

|

Homeboy981

Join Date: Jan 2012

Location: Sherman, TX

Posts: 663

|

Quote:

Originally Posted by Jager

Did you lock your crank at TDC?

|

Yes. It is at TDC, locked and double-checked. Chain tensioners are OUT.

I AM following LNE's instructions (since I am using their ceramic bearing IMS), not using Pelican's instructions. Not trying to stabilize.

I understood that, when the IMS flange is tightened down AFTER installing the bearing they are a "friction fit" against the crankshaft flange. These are the actual LNE Bearing flange nuts here, of which there are 3. Well, 2 of the 3 are lined up with the crankshaft 'cutout' holes.

I seem to remember seeing them being tightened AGAINST THE CRANK FLANGE using 7.5 Ft.Lbs. of torque.

__________________

2002 Porsche Boxtser S - Silver & Chrome - Died from IMS failure AFTER IMS was replaced!

|

|

|

03-10-2013, 02:07 PM

03-10-2013, 02:07 PM

|

#5

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

Quote:

Originally Posted by Homeboy981

I am IMS STUCK! After removing the IMS bearing in one piece. I am not sure what do about this….

My engine is locked at TDC (at BOTH ends of crankshaft and camshafts). Chain tensioners are OUT. I removed the IMS bearing - NO PROBLEM!!

However, my IMS bolts are lining up in the crankshaft HOLES…NOT on the steel part of the crank flange. It is supposed to be a friction fit on the crank flange and MUST NOT be tightened down into the holes. HOW DO I SOLVE THIS? Will is re-seat itself when I re-install the Chain Tensioners?

I have the chain tensioners out at the moment….I am hesitant to turn the crank WITHOUT CHAIN TENSION.

So, the question is - and I have researched my tail off but cannot find an answer:

HOW do I make sure the Crankshaft holes are NOT UNDER the IMS BOLTS? How do I move them to safe ground?

|

I have to ask, are you using the LN method to install the IMS, or the one Wayne espouses on Pelican with the bolts pushing on the IMS gear?

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

03-10-2013, 02:25 PM

03-10-2013, 02:25 PM

|

#6

|

|

Homeboy981

Join Date: Jan 2012

Location: Sherman, TX

Posts: 663

|

Quote:

Originally Posted by JFP in PA

I have to ask, are you using the LN method to install the IMS, or the one Wayne espouses on Pelican with the bolts pushing on the IMS gear?

|

Yes. Those bolts are pushing on the (IMS gear - you mean crankshaft flange)….they ARE NOT in THE HOLES - which is where mine are now.

I am using the LNE method. I am stuck on Item# 17.

The 3 nuts (that are 'micro coated') secure on to the solid part of the Crankshaft or AGAINST IT, don't they?

Hence, the need for such a low torque amount, it is supposed to be a 'friction fit' against the crank, isn't it?

I will grab a pic, maybe that will explain the dilemma.

Thanks.

__________________

2002 Porsche Boxtser S - Silver & Chrome - Died from IMS failure AFTER IMS was replaced!

|

|

|

03-10-2013, 03:13 PM

03-10-2013, 03:13 PM

|

#7

|

|

Registered User

Join Date: Jul 2010

Location: California

Posts: 1,859

|

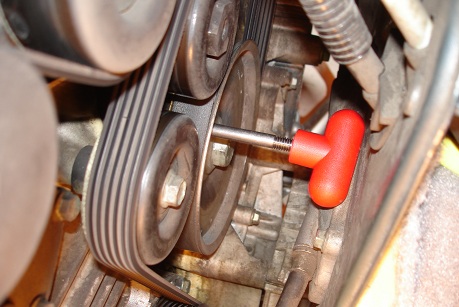

Are you talking about the IMS gear that you can see in this picture just inside the opening? The bolts should not come in contact with this gear.

__________________

Jäger

300K Mile Club

|

|

|

03-10-2013, 03:39 PM

03-10-2013, 03:39 PM

|

#8

|

|

1999 base

Join Date: Dec 2011

Location: Coral Springs FL

Posts: 1,617

|

Mark. you are mixing the two procedures.

no need for any bolts in the LN method.

you are ready to insert the bearing.

follow the instruction on the paper you got with the bearing, TO THE WORD!

the 3 25 mm bolts i sent you with the kit, are used to drive the cover into place once the bearing is installed.

|

|

|

03-10-2013, 03:55 PM

03-10-2013, 03:55 PM

|

#9

|

|

Registered User

Join Date: Sep 2010

Location: Foster City CA

Posts: 1,099

|

Following up on what Meir said, once you have used the three 25 mm bolts to seat the flange, you take them out and put the micro-encapsulated ones in their place and torque them to the proper value. See line 21 in the Jan 2013 instructions referred to in my earlier note.

Last edited by thom4782; 03-10-2013 at 03:59 PM.

|

|

|

03-10-2013, 03:07 PM

03-10-2013, 03:07 PM

|

#10

|

|

Registered User

Join Date: Feb 2005

Location: It's a kind of magic.....

Posts: 6,660

|

Now you have me completely confused; #17 in the most current LN instructions (January 2013) talks about putting the bearing and tool in the freezer before using them.

I think a picture is going to be very helpful as we have an obvious contradiction in terminology..................

__________________

“Anything really new is invented only in one’s youth. Later, one becomes more experienced, more famous – and more stupid.” - Albert Einstein

|

|

|

03-10-2013, 06:22 PM

03-10-2013, 06:22 PM

|

#11

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Unless your bolts are 3X too long they won't contact the IMS drive sprocket.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 11:04 PM.

| |