07-30-2012, 02:47 PM

07-30-2012, 02:47 PM

|

#1

|

|

DIY extremist

Join Date: Jul 2011

Location: Brooklyn

Posts: 348

|

Pelican IMS bearing stud has separated inside shaft

I have a 2000 Boxster S 3.2 w/ factory single row bearing and am currently stalled in my install of the Pelican IMS replacement kit using LN toolkit (my order id #1339174643-508). I followed the current web installation guide instructions for project #14 ( Pelican Technical Article: Boxster Intermediate Shaft Bearing Replacement and Upgrade (IMS) - 986 Boxster (1997-04) - 987 Boxster (2005-06)) to the letter and had no issues until the step illustrated in fig. 109. We assembled the install tool, bearing w/ prepressed stud and the 12mm nut, with the nut lubed and hand-tightened with a deep socket and froze it overnight. We tapped it into the motor and then hit our snag: the nut WOULD NOT come off by any ordinary means (slotted screwdriver inserted through 12mm deep socket held by vise grips), meaning that the installation tool was stuck in the engine. I fabricated a long slotted bit for my hand impact driver that could reach thru the socket, and was finally able this afternoon to remove the nut after much despair and gnashing of teeth. When the tool was pulled off, it appears that the center stud had been pushed through and was not longer pressed into the bearing (see attached photo).

As you can see in my photo, the center stud is now just floating in the tube and is no longer attached to the inner race of the bearing. I may be able to use the installation tools to pull the stud back through and get it snug again in place, or I can remove the entire assembly and press it back together with a vise and repeat the entire process with the un- and re-installed bearing/stud assembly. I am not sure if that route is safe though, because of degradation of the bearing due to pulling it. If it is possible to get another one of the bearings by itself, that seems like safest course, although I'd like to get my car back on the road ASAP.

Additionally, the entire IMS shaft appears to be off-centered, cocked up and to the right at about 1 o'clock (see pics again). As I followed the Pelican instructions exactly, I removed the two rear tensioners and used set screws to secure the IMS sprocket, but did not lock out the motor at TDC, as the LN instructions dictate. I have since learned that this allowed some cam chain tension to remain and that the front side tensioner paddle must have pushed the IMS shaft off at an angle. I don't know if installing the cover will push the tube back to the center.

I've already given myself the deserved 40 lashes for not locking out at TDC, but will say that I would've done this had I known to -- my kit's instructions did not mention it at all.

So, do you think it's safe to leave the bearing in place and try to get the stud back in, or do I need to go back to square one? And what about the IMS tube being off-center? I know that this has happened to other guys before me and it seemed to work out, but I am feeling pretty nervous about the whole thing.

Thanks for your feedback!

__________________

"Betty" -- 2000 Boxster S, Triple Black, loaded except PSM (sold to a good home)

"Veronica" -- 2008 Boxster S, Arctic Silver on Blue

"Maleficent" -- 2007 Cayman S, Red and Black, TPC Turbo 3.6L 460 RWHP, H&R RSS Coilover / TPC stage 2 suspension

|

|

|

07-31-2012, 07:18 AM

07-31-2012, 07:18 AM

|

#2

|

|

Registered User

Join Date: Jul 2011

Location: Richmond, VA (The Fan)

Posts: 978

|

These IMS jobs really can get nasty! Mine certainly did. I would increase the bevel in your removal tool to help guide the offcenter bearing into the sleeve(I did this and it worked great). Once it is half way in the sleeve I would adjust your allen bolts so that when its time to put the bearing back in it will be centered. I would then completely remove the IMS and make sure that the stud is properly seated.

__________________

1997 Boxster 4.2L Audi V8 Bi-Turbo

2003 911 C2

NASA HPDE Instructor

|

|

|

07-31-2012, 09:35 AM

07-31-2012, 09:35 AM

|

#3

|

|

DIY extremist

Join Date: Jul 2011

Location: Brooklyn

Posts: 348

|

Am I correct in saying that you installed the pelican bearing, and then removed it and reinstalled a new one? I don't want to do that, but will if it means my motor will be safe.

Over at Pelican, Wayne suggested that I use a washer and a nut to pull the stud back into the bearing, then use wrangle the IMS tube back into place using the IMS cover. Was that an option for you too?

__________________

"Betty" -- 2000 Boxster S, Triple Black, loaded except PSM (sold to a good home)

"Veronica" -- 2008 Boxster S, Arctic Silver on Blue

"Maleficent" -- 2007 Cayman S, Red and Black, TPC Turbo 3.6L 460 RWHP, H&R RSS Coilover / TPC stage 2 suspension

|

|

|

07-31-2012, 07:12 PM

07-31-2012, 07:12 PM

|

#4

|

|

Crazy Austrian

Join Date: Dec 2008

Location: Florida

Posts: 269

|

Hi got a couple of questions for you. I might have missed it but did you take the tensioners all the way out? if not do that. As far as the center bolt, that should be relatively easy. Line the bolt up and get a thick washer or space and tighten the nut, holding the stud with a screw driver, once seated you should be able to get the nut back off.

After you tensioners are completely out start the cover on and wrangle it back in place, you may have to pry on the case but be very careful that you only pry on a reinforced section of the case. I have a couple that did this.

For others who are going to do this job please!!! do yourself a favor and set #1 piston on top dead center and lock the crank. Also lock the cams on bank 1-3 no need to even use the set screws if you do this and if you get in trouble this is where the crank and cams need to be to get out of trouble.

Good luck and if you need more help pm me, I have done several dozens of the IMS bearing changes using both LN engineering and Pelicans bearings.

__________________

Crazy Austrian 007

http://www.ws-ab.com

|

|

|

07-31-2012, 07:29 PM

07-31-2012, 07:29 PM

|

#5

|

|

Registered User

Join Date: May 2009

Location: Frederick, MD

Posts: 1,396

|

i believe this is the PP bearing, which is "similar" the porsche bearing, not the LN bearing. i would think calling PP might generate a little interest in getting it back for analysis, but maybe not. i've read a lot of posts lately from people using the PP instructions which do not indicate locking at TDC. jfp and jake have even mentioned in a previous post that this keeps tension on the shaft and can cause it to go off center.

http://986forum.com/forums/performance-technical-chat/35618-ims-install-help-ims-bearing-not-centered.html

maybe the above thread can help.

__________________

"Speed has never killed anyone, suddenly becoming stationary... that's what gets you."

|

|

|

07-31-2012, 08:22 PM

07-31-2012, 08:22 PM

|

#6

|

|

Engine Surgeon

Join Date: Aug 2008

Location: Cleveland GA USA

Posts: 2,425

|

Dude, that stud is FUBAR.. Why did you mangle it like that? Good luck getting the nut to install onto that stud without cross threading. I'd pull the whole thing out and replace that stud, then start over. You don't want to know the nightmares a cross threaded stud can cause when it gets 1/2 way installed then decides not to tighten any further.

__________________

Jake Raby/www.flat6innovations.com

IMS Solution/ Faultless Tool Inventor

US Patent 8,992,089 &

US Patent 9,416,697

Developer of The IMS Retrofit Procedure- M96/ M97 Specialist

|

|

|

07-31-2012, 08:54 PM

07-31-2012, 08:54 PM

|

#7

|

|

Autobahn Glanz

Join Date: Dec 2010

Location: Charlotte, NC

Posts: 1,282

|

I'm not the expert, I've only done one of these, but I would do what Wayne said to seat the center stud then pre-test the threads with the nut to make sure it won't do what Jake is indicating could happen, if the threads f'd then start over. Make sure the tensioners are completely out and the cams are locked. I think you'll have to take those set screws out to recenter the shaft. My shaft floated around a little too but caused no issue, put thousands of miles on the car with no issues.

I think you are going to be fine, if everything goes back together as planned close her back up and drive the hell out of it. After changing mine I never think about it for a second anymore.

|

|

|

08-01-2012, 07:53 AM

08-01-2012, 07:53 AM

|

#8

|

|

DIY extremist

Join Date: Jul 2011

Location: Brooklyn

Posts: 348

|

I will go ahead and try to cinch up the stud back into the bearing. the thing that got chewed up was the head of the stud, from slipping several times with a slotted screwdriver in it trying to get the nut off. Took impact driver to sort it out. I'll use my dental mirror to inspect the threads before trying to do anything, and if it gets stuck I'm pulling the whole thing out again. I have the set screws in, both rear tensioners out and camshaft ends marked, but would like to lock them all the same - is there a tool available to do this that's not a specialty porsche piece?

__________________

"Betty" -- 2000 Boxster S, Triple Black, loaded except PSM (sold to a good home)

"Veronica" -- 2008 Boxster S, Arctic Silver on Blue

"Maleficent" -- 2007 Cayman S, Red and Black, TPC Turbo 3.6L 460 RWHP, H&R RSS Coilover / TPC stage 2 suspension

|

|

|

08-01-2012, 10:14 AM

08-01-2012, 10:14 AM

|

#9

|

|

Registered User

Join Date: Oct 2010

Location: US, Calif

Posts: 72

|

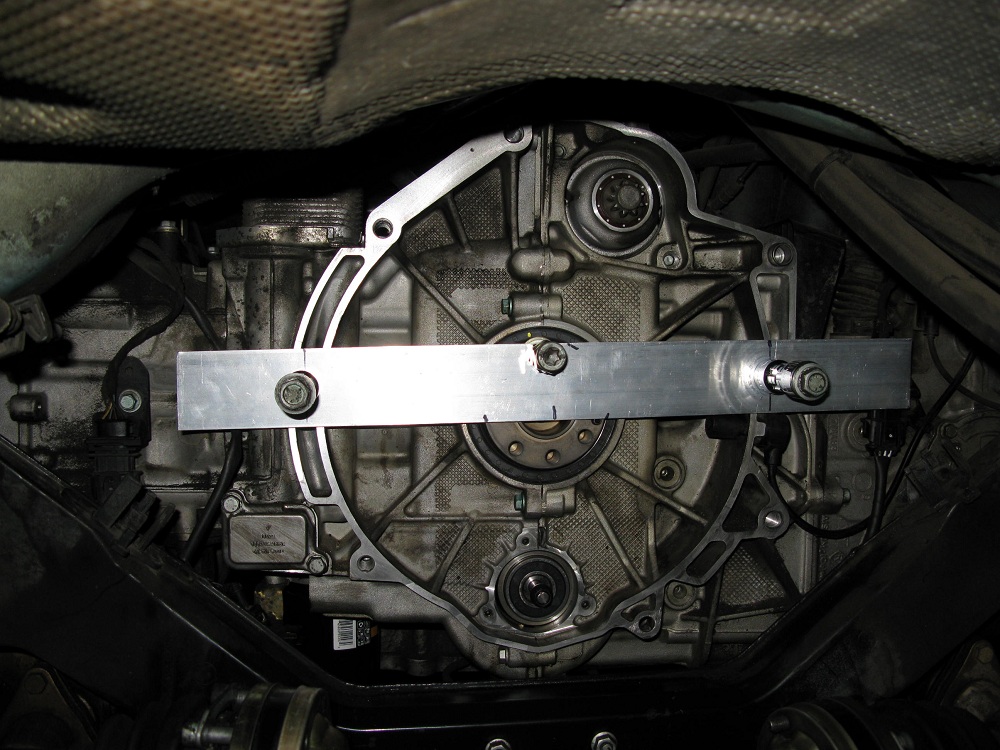

Brace

Probably at this point you should at least brace the main shaft... just a measure of assuring things don't move. I used a piece of aluminum as shown. As far as the IMS shifted in the hole. In my case it went back to center pretty easily once the cover was put on. I did use a screwdriver to help it along. Gently press it against the thick part of the engine case.

It will go on.

|

|

|

08-01-2012, 11:25 AM

08-01-2012, 11:25 AM

|

#10

|

|

Autobahn Glanz

Join Date: Dec 2010

Location: Charlotte, NC

Posts: 1,282

|

Quote:

Originally Posted by black_box

I will go ahead and try to cinch up the stud back into the bearing. the thing that got chewed up was the head of the stud, from slipping several times with a slotted screwdriver in it trying to get the nut off. Took impact driver to sort it out. I'll use my dental mirror to inspect the threads before trying to do anything, and if it gets stuck I'm pulling the whole thing out again. I have the set screws in, both rear tensioners out and camshaft ends marked, but would like to lock them all the same - is there a tool available to do this that's not a specialty porsche piece?

|

Sorry thought you said you had the LNS kit...it has the cam locks. Or do what 2000 said

|

|

|

08-05-2012, 02:11 AM

08-05-2012, 02:11 AM

|

#11

|

|

Registered User

Join Date: Nov 2010

Location: France

Posts: 32

|

Hello from France

After having read you post, I was smilling ( not because you have a problem) but because the same thing happened to me when I changed mine.

Don't worry and above all do not rotate anything

First completely realease the chain tensioners and after, unscrew a little the srews used to immobilize the IMS sprocket in order to be able to center it .

Use the tool to put back the center piece in the bearing from behind ( use the cover like you have finished the job to pull it throught).

I wouldn't change the bearing as It didn't get hammered or damaged.

After this rotate manually the engine to check that the marks are back in line (720°).

Good luck

|

|

|

08-06-2012, 06:24 AM

08-06-2012, 06:24 AM

|

#12

|

|

DIY extremist

Join Date: Jul 2011

Location: Brooklyn

Posts: 348

|

Going to go do it today (I run my own biz, so I can get greasy on Monday mornings

Wish me luck, hopefully I won't kill my engine!

__________________

"Betty" -- 2000 Boxster S, Triple Black, loaded except PSM (sold to a good home)

"Veronica" -- 2008 Boxster S, Arctic Silver on Blue

"Maleficent" -- 2007 Cayman S, Red and Black, TPC Turbo 3.6L 460 RWHP, H&R RSS Coilover / TPC stage 2 suspension

|

|

|

08-06-2012, 07:29 PM

08-06-2012, 07:29 PM

|

#13

|

|

DIY extremist

Join Date: Jul 2011

Location: Brooklyn

Posts: 348

|

it did not go well at all today.

Try as I might, I couldn't get the stud to press back into bearing evenly. I tried putting the cover on to pull the whole thing into place, but every time I did so, the stud would pop back out. I pulled the bearing again and tried to get the pelican stud into the factory cover and realized that it was never going to work in the motor -- the fit was just too tight and it was always going to overcome the pressfit of the stud into the bearing.

I reverted to the OEM stud, which the cover fits onto just fine... only problem is that I think I must've inadvertently tossed the M8 1.0mm thread nut that fits onto the smaller OEM stud.

Anyone know where I can get another one of these nuts? The hardware stores don't have anything with that fine of thread. Anyone think it's not worth it to reuse the OEM bearing retainer stud? Mine seems fine.

__________________

"Betty" -- 2000 Boxster S, Triple Black, loaded except PSM (sold to a good home)

"Veronica" -- 2008 Boxster S, Arctic Silver on Blue

"Maleficent" -- 2007 Cayman S, Red and Black, TPC Turbo 3.6L 460 RWHP, H&R RSS Coilover / TPC stage 2 suspension

|

|

|

08-06-2012, 11:36 PM

08-06-2012, 11:36 PM

|

#14

|

|

Registered User

Join Date: Nov 2010

Location: France

Posts: 32

|

Sorry about your failled attempt but nothing is lost..

I thing that you cannot put back the stud in place because you don't pull it in the axis of the bearing

so to achieve that you should build a little tool (basically a piece of steel with a hole in the middle) which is going to cover the bearing without touching the engine case( because your bearing is not well alligned yet).. The stud should enter the outer part of the bearing without a big effort unless it has been damaged.

I thought that the retrofit set had a bigger axis to prevent faillure ( The one I bought is bigger).

Keep in mind that so far you didn't dammage your engine and you can still fix the situation you are in, no rush, a lot of thinking, and worst case scenario would be to buy a new set and to not damage it learning from the présent situation.

can you still put a nut on you stud ?

ph.

Last edited by philou320; 08-07-2012 at 09:05 AM.

|

|

|

08-07-2012, 09:33 AM

08-07-2012, 09:33 AM

|

#15

|

|

Registered User

Join Date: Oct 2010

Location: US, Calif

Posts: 72

|

I have one...

Hi Blackbox,

Part of the upgrade bearing is the stronger shaft. I'm not sure how many failures (if any) of the OEM shaft have occurred but someone felt it was better to have the stronger shaft. It almost sounds like the Pelican stud is damaged because it should fit without too much pressure. Given that, if you are going to use the old stud then I believe I still have the nut that came off of mine. I can send it to you. It might be better however at this point to research with Pelican on why the shaft didn't fit. Maybe... they can arrange to send you a new one. It's worth a query to them. If you get that worked out and since the bearing is out you might put the stud in the freezer for a while and then press it into the bearing with a socket that matches the inner race of the bearing and your shop vise. It should just press right in. Send me a private note with your address and I'll send you the nut if you wish to go that route. Cheers,

|

|

|

08-07-2012, 05:20 PM

08-07-2012, 05:20 PM

|

#16

|

|

DIY extremist

Join Date: Jul 2011

Location: Brooklyn

Posts: 348

|

My Boxster is turning into a black pearl!

I noticed a little friction in the bearing from Pelican, so I cross-referenced it with NAPA and got another identical bearing from them, tapped it into the engine (this time without freezing the bolt onto the stud, and thus not getting it stuck) and used the provided bolts to cinch the cover up. Everything went together perfectly, and according to plan.

After tightening down the cover, I removed the bolts and inserted the final, sealant coated bolts with the tamper proof heads into the factory IMSB cover and tightened them by hand until snug. I set my torque wrench to 8 ft-lbs and took turns tightening each bolt a turn or two and then.... DISASTER! One of the bolt heads snapped off, leaving the shaft embedded in the engine case.

The bolt had to have been defective -- I can't see any other way it could fail with that little torque being applied. Tomorrow I will try using a reverse drill bit to extract it, but am not hopeful. I am rueing the day that I thought it was a good idea to try to do the IMS -- this has been nothing but trouble. I am also really unhappy with the Pelican kit and instructions I've been using -- every single part of it has failed in some way and it looks like I will wind up not having used any of it, having reverted back to the factory stud and getting a new bearing from NAPA, even the damn bolt they included has broken. No idea how long it will take to sort this out, giving up on planned weekend trip with the girlfriend.

__________________

"Betty" -- 2000 Boxster S, Triple Black, loaded except PSM (sold to a good home)

"Veronica" -- 2008 Boxster S, Arctic Silver on Blue

"Maleficent" -- 2007 Cayman S, Red and Black, TPC Turbo 3.6L 460 RWHP, H&R RSS Coilover / TPC stage 2 suspension

|

|

|

08-08-2012, 03:36 AM

08-08-2012, 03:36 AM

|

#17

|

|

Registered User

Join Date: Nov 2010

Location: France

Posts: 32

|

Bummer

Be carreful not to put some drilling chips into the engine case ( do not go through entirely).

use the old bolts to finish the job, after all, they have proved themselves OK.

|

|

|

08-08-2012, 04:17 AM

08-08-2012, 04:17 AM

|

#18

|

|

Registered User

Join Date: Apr 2008

Location: Southern New jersey

Posts: 1,054

|

Another possibility is that your torque wrench is not reading correctly.

|

|

|

08-08-2012, 05:59 AM

08-08-2012, 05:59 AM

|

#19

|

|

Registered User

Join Date: Nov 2010

Location: France

Posts: 32

|

Quote:

Originally Posted by stephen wilson

Another possibility is that your torque wrench is not reading correctly.

|

I thought about this too, or the conversion if you don't use thoses units ft/lbs is wrong

|

|

|

08-08-2012, 06:44 AM

08-08-2012, 06:44 AM

|

#20

|

|

Registered User

Join Date: Oct 2010

Location: US, Calif

Posts: 72

|

:(

How far into the case did the bolt snap? I know you probably don't want to pull the bearing cover back off but can you tell if there is any bolt stud sticking out? Better to try and grab it with vice grips then attempt a drill out. Just a thought.

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 12:16 PM.

| |