Hi there 986 Forum!

I purchased a new to me 2001 Boxster S last June with just about 49k miles on the clock. The car was super clean inside and out with the exception of the engine/transmission area... it was covered in oil and grease. All the axle boots were torn, RMS was presumably leaking, IMS was original, and it had very limited service info other than oil changed once per year. The price was right so I decided to drive it home knowing full well what I got myself in to. I enjoyed the car for the rest of 2020 then parked it for the winter and started planning all the maintenance work I needed to do. Here is my story... this is not meant to be a DIY post, there are plenty of resources out there which were very helpful to me so I won't repeat them.

Put the car up on jack stands and started disassembly, this was the easy part

Here are the engine and transmission

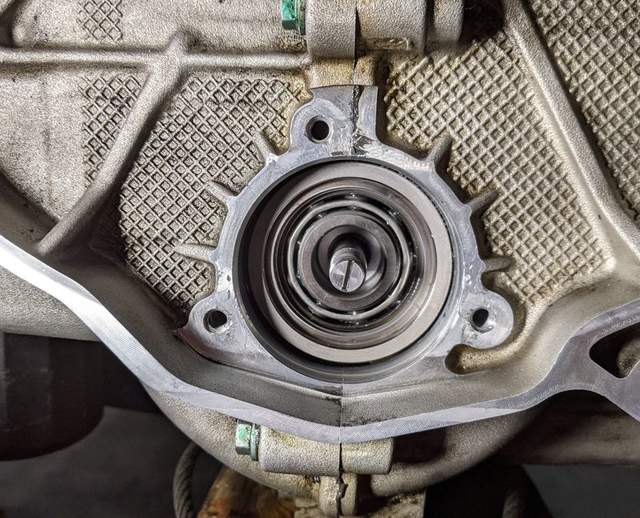

Once I got here I saw that I had a factory double row bearing so I decided to go with the LNE retrofit kit. Rented the tool kit from an online place for about $120 including shipping back and fourth. Getting the old bearing out was very easy with the extractor. (I only removed 2 chain tensioners, left the one below the AC compressor on with no major issues). At first inspection it seemed like to was fine but oh well, I'm already here:

Getting the new bearing in was a complete pain in the ass... I put it in the freezer overnight and it started to tap in nicely for the first 50%... then nothing. I used the old cover plate and screws to drive it in but that only got me to about 90%... there was still like 1-2mm of travel needed to get the circlip in. I had to really hammer it home to get it to go. I was worried to hit it in so hard but I may have let my frustration get the best of me... after 30-40 really hard smacks with a rubber mallet I got it in far enough to put the circlip in the IMS shaft groove.

With the big job done I changed out the rear main seal with the new seal design, new clutch and flywheel, throw out bearing, transmission gear oil, and lots of degreasing.

Also put in a new Air Oil Separator and coolant expansion tank while the transmission was out... both were annoying with the transmission out, must be real fun with the car assembled. Also got new transmission mounts, sway bar bushings, end links, and new axles.

While all of this was happening I noticed the old IMS bearing was sitting in a little pool of oil.... so the seal had definitely been compromised and the grease was likely washed out. I haven't torn it open yet but I imagine it was on it's way to a potential failure.

And then as all the maintenance manuals say "the assembly is simply the reverse process"... only much more frustrating. Getting the transmission back in took about 20 tries over 4 days... you need the splines to line up perfectly. Once I had it about right, I spun one output flange while holding the other still to make the input shaft spin. That got me most of the way but it took many attempts to finally get it just right so it would slide into the flywheel bearing. Very frustrating... I took the recommendation to try for 1-2 hours at a time and then leave it so as not to make a bad decision. The exhaust and transmission cover plate were also not cooperative but lots of fiddling did the job eventually.

Finally the time came to turn her over. I pulled the fuel pump fuze and cranked it a few times to build oil pressure.... and the battery was dead

One new battery the next morning and the car started up nicely. Been driving it gingerly for now to make sure it's all good... need to tighten some exhaust bolts but overall I think it was a success.

This is by far the most difficult work I've ever done on a car (I am not a mechanic) and in retrospect I don't know if it was worth it doing it myself.... it took 2 months, 20 working days, 55ish man hours and the parts alone cost me about $2000. But I hope I have a slightly more reliable boxster at the end of the day... met a guy at a PCA Auto-x event last weekend who told me his LNE dual row retrofit bearing failed after 35k miles so there's that... Hopefully I'll be able to afford a newer, non-IMS roadster before that time comes