02-19-2020, 10:30 PM

02-19-2020, 10:30 PM

|

#1

|

|

Registered User

Join Date: Oct 2018

Location: North Cali

Posts: 857

|

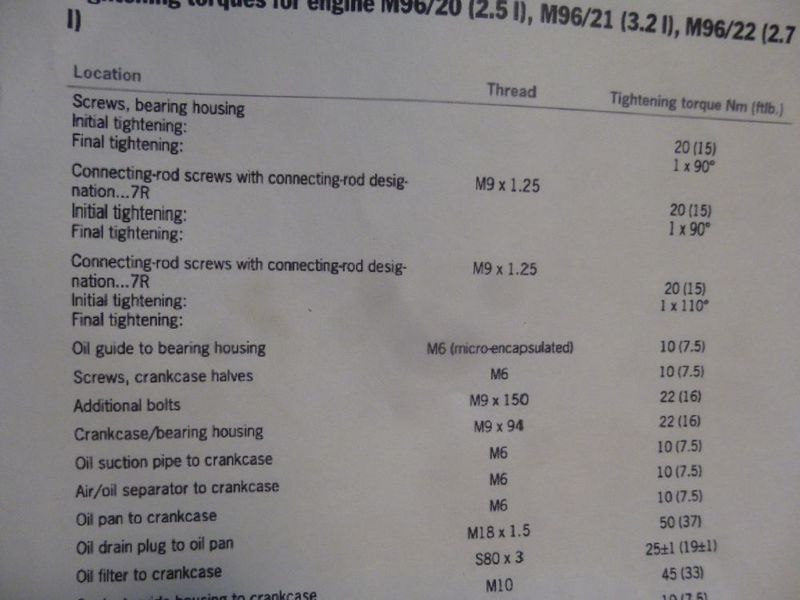

Connecting rod bolt torque

Hey Folks, I`m a bit confused with this chart on torque settings. There are two different angle values (90 vs 110) listed for the conrod bolts, but I can`t see the difference, the text is the same for both.. Could someone enlighten me please? See below.

|

|

|

02-20-2020, 11:27 AM

02-20-2020, 11:27 AM

|

#2

|

|

Registered User

Join Date: Oct 2008

Location: O.C. CA

Posts: 3,709

|

Quote:

Originally Posted by Homeoboxter

Hey Folks, I`m a bit confused with this chart on torque settings. There are two different angle values (90 vs 110) listed for the conrod bolts, but I can`t see the difference, the text is the same for both.. Could someone enlighten me please? See below.

|

It's a 2 step process, 1st torque to the 1st spec for both bolts on the same rod, then tighten the stated degree. So if it calls for 90 degree, tighten a additional 1/4 rotation. I'm not sure about the 7r designations because I always chunk the stock bolts & install ARP bolts that have a torque spec only, and they are much better than oe.

I have a set of ARP's in stock I'll sell if you want to upgrade.

__________________

OE engine rebuilt,3.6 litre LN Engineering billet sleeves,triple row IMSB,LN rods. Deep sump oil pan with DT40 oil.

Last edited by BYprodriver; 02-20-2020 at 11:29 AM.

|

|

|

02-20-2020, 02:29 PM

02-20-2020, 02:29 PM

|

#3

|

|

Registered User

Join Date: Oct 2018

Location: North Cali

Posts: 857

|

Quote:

Originally Posted by BYprodriver

It's a 2 step process, 1st torque to the 1st spec for both bolts on the same rod, then tighten the stated degree. So if it calls for 90 degree, tighten a additional 1/4 rotation. I'm not sure about the 7r designations because I always chunk the stock bolts & install ARP bolts that have a torque spec only, and they are much better than oe.

I have a set of ARP's in stock I'll sell if you want to upgrade.

|

Yeah, I got that, what I don`t understand is when you need to use the 90 degreee turn and when the 100 degree. The text is identical for both. Thanks for the ARP offer but I already have a new set of the original bolts. Would you share the torquing specs for the ARPs just for comparison? Thanks!

|

|

|

02-20-2020, 12:38 PM

02-20-2020, 12:38 PM

|

#4

|

|

Who's askin'?

Join Date: Mar 2018

Location: Utah

Posts: 2,448

|

Quote:

Originally Posted by Homeoboxter

Hey Folks, I`m a bit confused with this chart on torque settings. There are two different angle values (90 vs 110) listed for the conrod bolts, but I can`t see the difference, the text is the same for both.. Could someone enlighten me please? See below.

|

It's odd, for sure. I suspect an editing issue, like a typo, and here's why;

googling, there are some obvious references to some M96 engines which had a M10x1.25 connecting rod screw. I can't find anything defining when / where they were used, but in each case I've found them in use it's been on a 3.2L engine. I wonder if this was in the early M96 motors destined for GT3 cars, or some other performance-spec? It's very vague and incomplete information, yet it's out there.

So I wonder if they meant to list the M10x1.25 on one of those lines, but typo'd it, or auto-correct "fixed it" for them? OR - when they compiled the values for whatever your source is, the M10 was determined to be unnecessary in that context so it was expressly changed to M9, but left the line there so as not to interrupt the page-breaks in an otherwise-ready-to-print document.

These are "guesses" based on the information available.

|

|

|

02-20-2020, 02:26 PM

02-20-2020, 02:26 PM

|

#5

|

|

Registered User

Join Date: Oct 2018

Location: North Cali

Posts: 857

|

Quote:

Originally Posted by maytag

It's odd, for sure. I suspect an editing issue, like a typo, and here's why;

googling, there are some obvious references to some M96 engines which had a M10x1.25 connecting rod screw. I can't find anything defining when / where they were used, but in each case I've found them in use it's been on a 3.2L engine. I wonder if this was in the early M96 motors destined for GT3 cars, or some other performance-spec? It's very vague and incomplete information, yet it's out there.

So I wonder if they meant to list the M10x1.25 on one of those lines, but typo'd it, or auto-correct "fixed it" for them? OR - when they compiled the values for whatever your source is, the M10 was determined to be unnecessary in that context so it was expressly changed to M9, but left the line there so as not to interrupt the page-breaks in an otherwise-ready-to-print document.

These are "guesses" based on the information available.

|

My source is the forum, I found this chart somewhere here in one of the threads. It`s entirely possible what you are saying, if I understand correctly. I didn`t know about M10 bolts, but I assume the 110 degree turn belongs to those ones and it`s a typo.

|

|

|

Posting Rules

Posting Rules

|

You may not post new threads

You may not post replies

You may not post attachments

You may not edit your posts

HTML code is On

|

|

|

All times are GMT -8. The time now is 09:41 PM.

| |