Good News, I'm all done with

both sides!!!! Only took me 16 hours over last weekend. So here is how the saga played out. Although I was pretty sure the driver actuator potentially could be bad even though it was missing the spring, I found a solenoid and actuator on ebay for $300 and might be worth the chance. So once I got the part in the mail I realized it was for the passenger side. The listing had it as the left side, however, they did have the part number correct. I missed checking that one digit. But it wasn't all bad. I took it apart and realized the the spring I found on my bench was in fact not the same spring as in the actuator. Decided to keep that unit together maybe to sell and went on a hunt for a similar spring that would work. After buying three different kits, I found one that was near identical. Was picking up some rags on the floor and guess what??? Found the original spring lol. Yikes. So next I decided to check the solenoid on the used actuator because remember I thought my solenoid was dead also. Turns out the solenoid I just got was giving me weird readings like mine so I decided to put a 9V battery on each one and they both worked! So then realized that maybe my meter had a bad fuse. Checked it and yep, a bad fuse. Damn it! So both solenoids work. So these solenoids do not have a loud click to them at all so I can see why they can be mistaken as not working. So here is why I could not hear mine. The solenoid uses the pressure from the actuator spring to return back into the solenoid. So since my plunger was all the way down, I could not hear a click, because it never returned. Anyway, now it's time to decide what to do. After all this, I decide I am going to take my chances and put my old assembly back in and this time with the spring! Everything went fine getting the driver side all back together. Tore through the passenger side with very few issues. Put that side back together and checked timing and looked OK. So here is the defining moment....MY BATTERY IS NOW TOAST SO CAN'T GET THE CAR STARTED! Pumped some volts into it and manage to get it turned over and she purred like a kitten. Hooked up the durametric and let the car warm up. She has a tiny anomaly on the idle but not too bad. Check the cam deviation on the driver side and I am at around -2 which is good so check that off the list. Check passenger side and it is -13!!!! What the heck. So I decided to double check the timing again starting with the passenger side. I notice it is a hair off, but can;t believe that could be it. Anyway, spend some time getting it perfect and check again with durameteric and get a -6. I call it good. Car idles super smooth so don;t feel like there is a reason to mess around too much more. Hit the gas a couple times randomly and the cam angle go to 22-24 which was normal. BIG sigh of relief. Happy to have my buddy back after almost three months.

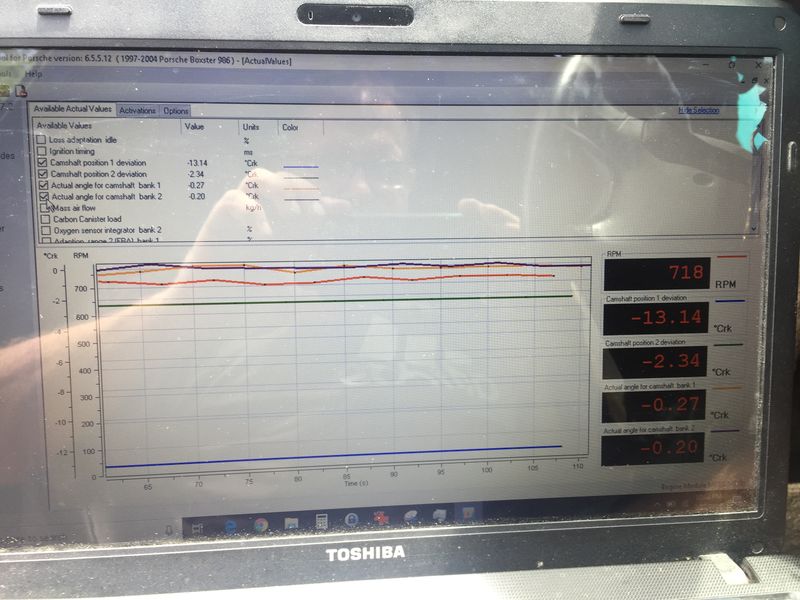

So here is a picture of the notch at -13 deviation. It is basically off half the notch.

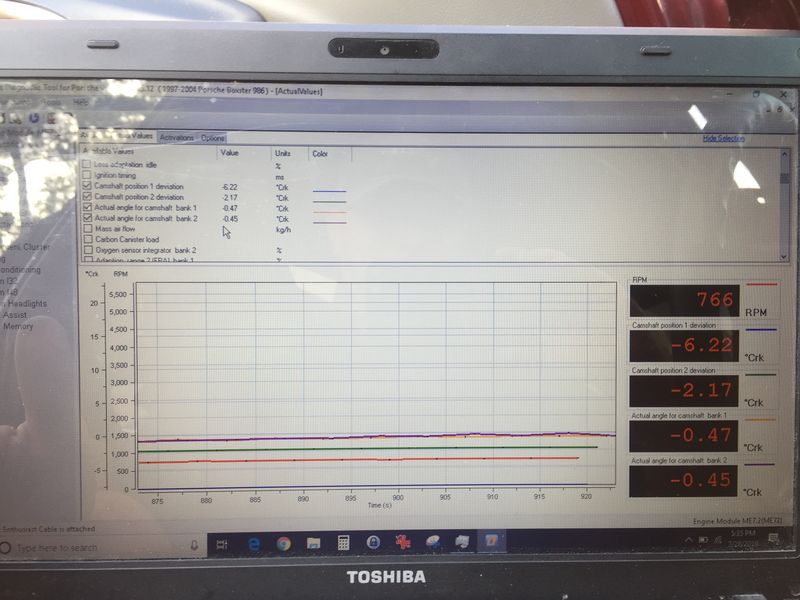

Here is the notch lined up as perfect as I can get it. You can do this without a tool.

Here is how far the crank moved for that small adjustment

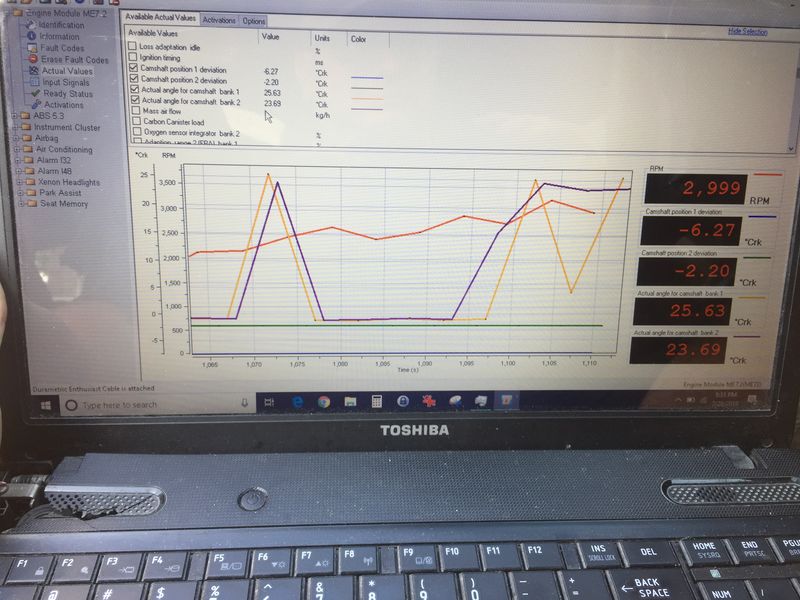

Here is a random kick of the pedal. Everything seems to be in order

So also decided to drop the oil pan and check this out. Not worms!!! They are not lying when they say to be careful how much locktight you put on. This was not from me, but what I am guessing from the original locktite from factory

Here is a picture of the guides from passenger side

Picture of the driver assembly ready to go back in (wish I would have noticed the plunger is down!!!)

Here is a picture of what it looked like when I first took it out, no guide!

I didn't find either side to be particularly easier than the other. They both had their challenges.

So in summary, what I believe probably happened was that when the guide completely disintegrated, the computer saw the deviation to be too large in the negative direction and threw it into full advance to protect the motor. I read somewhere that they fail in full advance. I wish I had checked the connector from the DME to the solenoid before I tore everything apart to see if it was forcing the solenoid on full time to keep it in advance. This is the only thing that would make sense at this point as my solenoid and actuator are fully functional.

Anyway, hope this can help someone in the future.