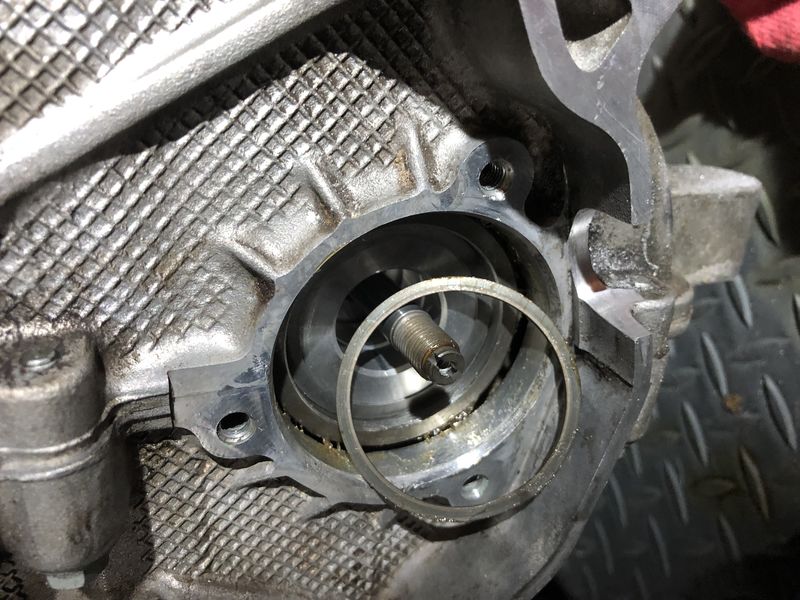

Jake Raby mentioned that variances in the inside diameter of the intermediate shaft can sometimes result in a tight fit for the bearing, and he wasn't kidding. Forget tapping — seating the bearing required many mighty blows with a heavy rubber mallet. That was a surprise, since I kept the bearing in the freezer and lubricated its outside liberally with assembly lube, as per Step 30 in the

IMS Solution Installation Manual. I managed to get it seated before my arm gave out. Next comes a shim, followed by a retainer clip that fits in a groove around the inside of the shaft to keep the bearing in place. Getting it in the groove is a challenge. After a couple of unsuccessful attempts to master the technique, I decided I needed a break. I'm on my break now!

One hour later... I can't think of a single reason why that

blankety-blank clip can't wait until tomorrow.